The manufacturing of high-performance padel rackets combines advanced composite materials1, precise production techniques, and customizable design elements to ensure durability, consistent performance, and brand differentiation. In this article, we detail the step-by-step manufacturing process, explain the role of materials like carbon fiber2 and glass fiber3, and offer actionable recommendations for procurement managers seeking a reliable supplier partnership.

In today’s competitive sports equipment market, precision manufacturing and product customization are essential for distinguishing high-performance padel rackets from standard models. For procurement managers evaluating potential suppliers, understanding the production process is crucial to determine if a manufacturer can meet the demands of innovation and quality that modern sports distributors require.

At NEX Padel, our manufacturing approach combines industry-leading techniques with comprehensive quality control. We utilize materials ranging from basic glass fiber to advanced 3K, 12K, or even 18K carbon fiber, adapting our processes to deliver premium Diamond, Round, and Teardrop racket designs. This article explores these methods in detail, equipping you with the technical insights needed to make informed supplier decisions.

The manufacturing process for padel rackets is both art and science. Key challenges include:

- Ensuring durability and resilience while retaining a lightweight design.

- Balancing production speed with precision to meet demanding timelines.

- Integrating advanced materials that require careful handling and curing.

- Customizing designs to meet varying customer specifications, from shape to color and logo placements.

Manufacturers must overcome these challenges by combining robust engineering with flexible production lines. The following analysis shows how advanced fabrication techniques address these industry-specific hurdles.

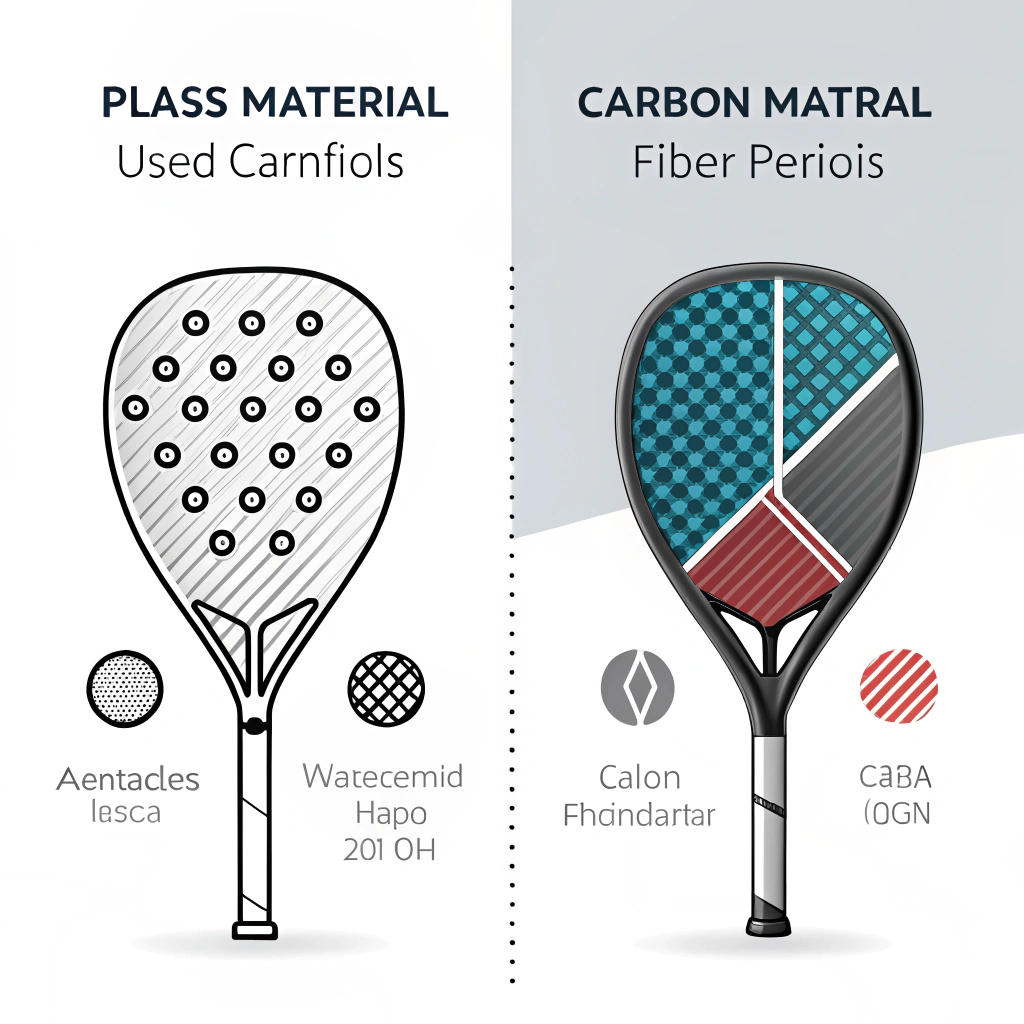

Material selection significantly influences product performance and cost. Padel rackets are generally made from either carbon fiber or glass fiber, each offering distinct advantages.

-

Glass Fiber:

- More cost-effective.

- Suitable for beginner and lower-end models.

- Provides adequate durability at a reduced price point.

-

Carbon Fiber:

- Preferred for intermediate to advanced models.

- Offers higher strength-to-weight ratio.

- Enhances racket responsiveness and fatigue resistance.

Because our ball rackets are developed using these materials, we ensure that each product is built to suit both performance requirements and budget constraints. Manufacturers must manage the curing process carefully to preserve the integrity of these fibers, ensuring long-term performance and safety.

To better outline the production choices, consider the table below:

| Material | Applications | Key Benefits | Considerations |

|---|---|---|---|

| Glass Fiber | Beginner, entry-level rackets | Cost-effective, robust enough for casual play | Limited performance for high-intensity play |

| Carbon Fiber | Intermediate to advanced rackets | Superior strength, lightweight, high performance | Higher production costs, requires precise curing process |

This table helps procurement teams quickly assess which material aligns with their market and pricing strategies.

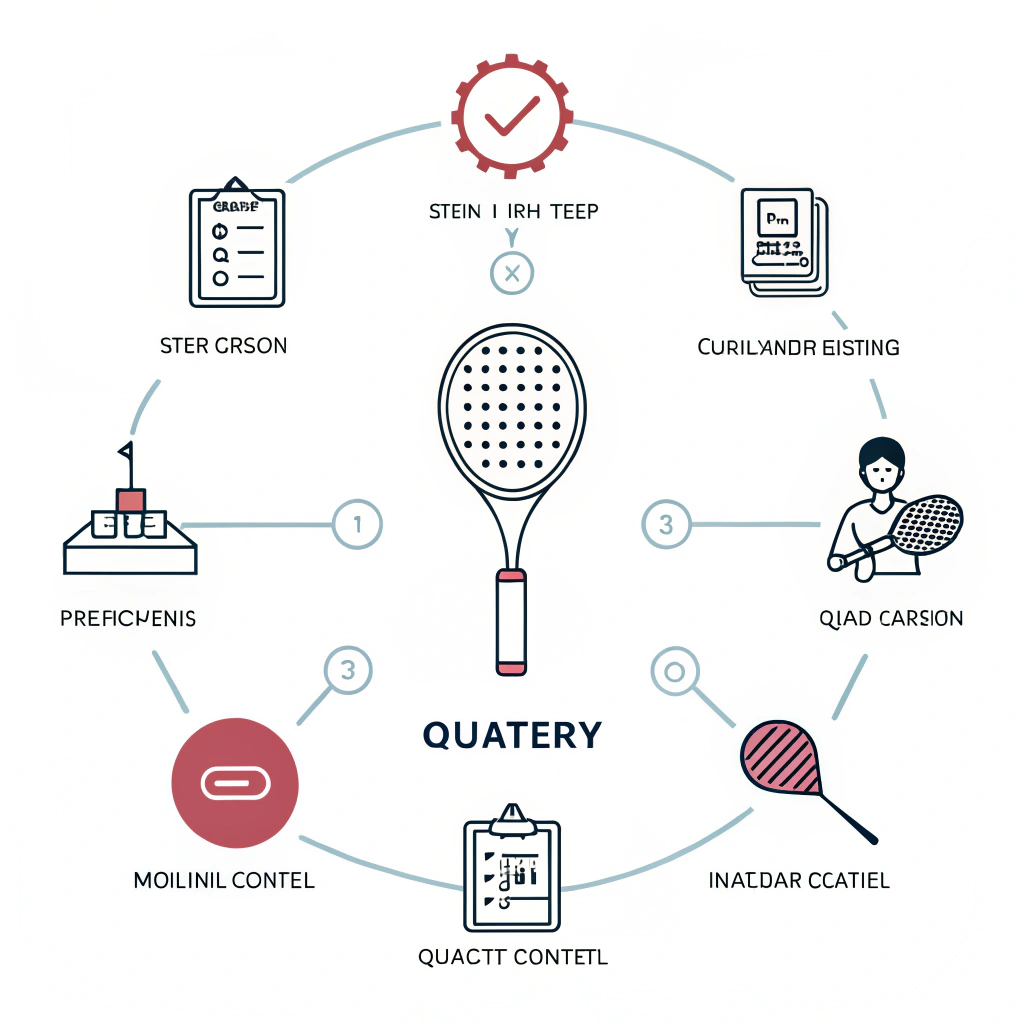

The manufacturing of high-performance padel rackets consists of several key phases. Below is a detailed guide to each step:

-

Design and Prototyping:

Using CAD software and rapid prototyping4 techniques, our engineering team creates initial design models. This phase includes assessments of weight distribution, aerodynamics, and ergonomics. Fast prototyping plays a vital role since it allows us to make adjustments quickly, ensuring that the final design meets performance expectations. -

Material Preparation:

Depending on the final product specifications, technicians prepare either glass fiber or various grades of carbon fiber. The fibers are treated and layered meticulously to create the composite structure. This step requires strict quality control to ensure consistency across all production batches. -

Molding and Curing:

The composite material is placed in a high-precision mold that represents the final racket design. Using advanced production techniques, the mold is then subjected to controlled curing5. The curing process is critical; if not managed properly, it can lead to imperfections that negatively impact performance and durability. -

Customization:

This step differentiates our production capabilities. We offer custom designs, including the iconic Diamond, Round, and Teardrop shapes, along with personalized printing and color options. Customization is extended even to accessories like hand grips and handle covers. This flexibility is essential for retailers aiming to offer unique products in a competitive market. -

Quality Control:

Every racket undergoes rigorous inspection. Our quality control tests include stress testing, impact resistance analysis, and performance simulations. This ensures that every racket leaving our factory meets the highest standards of durability and precision. -

Packaging and Delivery:

Once approved, the rackets are packaged securely. We also provide additional products like padel balls, which are produced under strict quality monitoring at our partner factories. Packaging methods, such as using a Pressurized tube for padel balls, ensure the product maintains its performance characteristics until delivery. -

Feedback Loop:

Our manufacturing system incorporates feedback from field data and performance reviews. This continuous improvement loop allows for updates in the manufacturing process to adapt to emerging market needs and technologies.

This comprehensive process is designed to maximize supply chain efficiency and set a benchmark for high-performance manufacturing in the sports equipment industry.

Customization is a key factor in meeting client-specific needs. At NEX Padel, our production system is built to allow rapid adjustments without compromising quality. Some of the core customization options include:

-

Racket Shape:

Offering three main designs—Diamond, Round, and Teardrop—each tailored for different playing styles. -

Material Options:

From basic glass fiber rackets for beginner markets to advanced carbon fiber rackets for elite performance. -

Branding:

Custom printing is available on the racket frame, hand grip, and handle cover. This ensures brands can maintain consistent identity across their product lines. -

Rapid Prototyping:

Our process allows for quick sampling and iteration. This gives procurement managers the agility to introduce new product variants rapidly.

Quality assurance is integrated into each manufacturing stage. Our detailed quality checks and certifications ensure that every product meets strict regulatory and performance standards. This commitment to quality not only improves the product’s lifespan but also helps build consumer confidence in the brand.

For procurement managers, these quality and customization measures highlight the ease and reliability of working with NEX Padel as a strategic supplier.

To illustrate the effectiveness of our advanced manufacturing techniques, consider the following case study:

A prominent sports equipment distributor was looking to upgrade their product line with state-of-the-art padel rackets. After evaluating several suppliers, they partnered with NEX Padel due to our ability to offer rapid prototyping, customized designs, and rigorous quality controls.

Key Performance Indicators Achieved:

- 30% reduction in prototype development time.

- 20% improvement in product durability based on stress testing.

- Enhanced customer satisfaction scores due to customized design options.

This case study demonstrates that by combining technical innovation with flexible manufacturing processes, suppliers can significantly enhance product performance and market competitiveness. Such data-backed insights can empower procurement teams to make informed decisions when selecting suppliers.

Manufacturing high-performance padel rackets requires a seamless integration of advanced materials, innovative production techniques, and stringent quality control measures. For procurement managers and operations executives, these insights provide a comprehensive understanding of what to look for in a strategic supplier partnership.

Key takeaways include:

- The choice of materials (glass fiber vs. carbon fiber) directly influences product performance and market segmentation.

- Advanced production techniques, including precise molding, controlled curing, and rapid prototyping, are essential for achieving superior performance and customization ability.

- Rigorous quality control at every stage minimizes production defects and maximizes product durability.

- Flexibility in customization not only meets the diverse needs of different markets but also strengthens a brand’s identity.

By partnering with a supplier capable of these advanced production techniques, such as NEX Padel, procurement managers can secure high-quality, durable, and customizable padel rackets that will meet market demands and drive competitive advantage. We advise procurement teams to conduct thorough supplier evaluations focusing on these technical parameters and to engage directly with manufacturers for detailed process insights.

For further details or to schedule a consultation with our manufacturing specialists, please feel free to contact us. We are committed to providing bespoke manufacturing solutions that align with your business objectives.

People Also Ask

Q: What is the manufacturing process of badminton rackets?

A: The process involves molding a composite material, like carbon fiber or fiberglass, in a precision mold and curing it to form the final frame. Similar methods are employed in padel racket manufacturing, where quality control and material properties play a fundamental role.

Q: Which company makes the best padel rackets?

A: While several companies are known for high-quality padel rackets, industry mentions include Adidas, Bullpadel, Nox, HEAD, and Babolat. At NEX Padel, we focus on advanced manufacturing techniques and strict quality control to provide high-performance products.

Q: What material are padel rackets made of?

A: Padel rackets are typically made of either carbon fiber or fiberglass. Glass fiber is often used in lower-end models, whereas carbon fiber is chosen for intermediate to advanced rackets due to its superior performance and durability.

-

advanced composite materials: Click here to learn how composite materials integrate diverse fibers and resins to provide enhanced strength and design flexibility in modern manufacturing. ↩ ↩

-

carbon fiber: Click here to explore the benefits of carbon fiber, including its superior strength-to-weight ratio and applications in high-performance sporting goods. ↩ ↩

-

glass fiber: Click here to understand how glass fiber is used as a cost-effective alternative in manufacturing, offering durability while maintaining affordability. ↩ ↩

-

rapid prototyping: Click here to see how rapid prototyping accelerates product development cycles and enables quick design iterations in manufacturing processes. ↩ ↩

-

controlled curing: Click here to discover the importance of controlled curing in ensuring material integrity and performance consistency in composite manufacturing. ↩ ↩