Fast delivery is not just about speed—it is a strategic advantage that combines efficient production turnaround, enhanced inventory management, and superior supply chain coordination1 to provide a competitive edge in the padel racket industry.

In today’s competitive market, fast delivery2 is not only a promise for speed but also a key factor in supporting efficient production and inventory systems. Supply chain managers and procurement professionals are increasingly challenged to balance quality, cost efficiency, and delivery speed. Especially in the padel racket sector, where seasonal demand fluctuations and rapid inventory movements are common, reducing lead times is crucial for maintaining competitive advantage. Our focus at NEX Padel is to ensure that our production turnaround and fast delivery not only meet but exceed industry standards, ensuring minimal downtime and optimized logistics.

Many sports equipment retailers and distributors face challenges that ripple throughout the supply chain:

- Extended Lead Times3: Delays in production and shipment can disrupt inventory management, forcing businesses to either stock excess inventory or face stockouts.

- Supply Chain Disruptions: Inefficient production processes and logistic delays create bottlenecks, directly impacting customer satisfaction and operational costs.

- Quality and Customization Trade-Offs: Balancing the need for rapid delivery with high-performance product manufacturing often leads to compromised quality or reduced customization options if not managed properly.

At NEX Padel, we have precisely identified these issues and tackled them head-on. Using advanced production techniques combined with a flexible logistics network, our solutions are designed to streamline the entire manufacturing process, thereby reducing unnecessary delays.

Understanding the root causes of slow delivery can help in implementing effective solutions. Here are the main factors:

- Inefficient Production Processes: Older manufacturing setups or under-optimized workflows lead to increased cycle times.

- Supply Chain Fragmentation: Working with multiple disconnected suppliers can result in coordination challenges and delayed responses.

- Customization Bottlenecks: Orders with extensive customization require additional steps like design finalization and sample approvals, extending lead time.

- Logistics and Distribution Constraints: Inadequate alignment between manufacturing and logistics can create delays in shipping products to end destinations.

At NEX Padel, our integrated approach reduces these delays by synchronizing production steps and employing state-of-the-art quality controls.

To address these issues, we introduce a step-by-step solution strategy that combines operational excellence with technological innovation. This strategy is built around the following key areas:

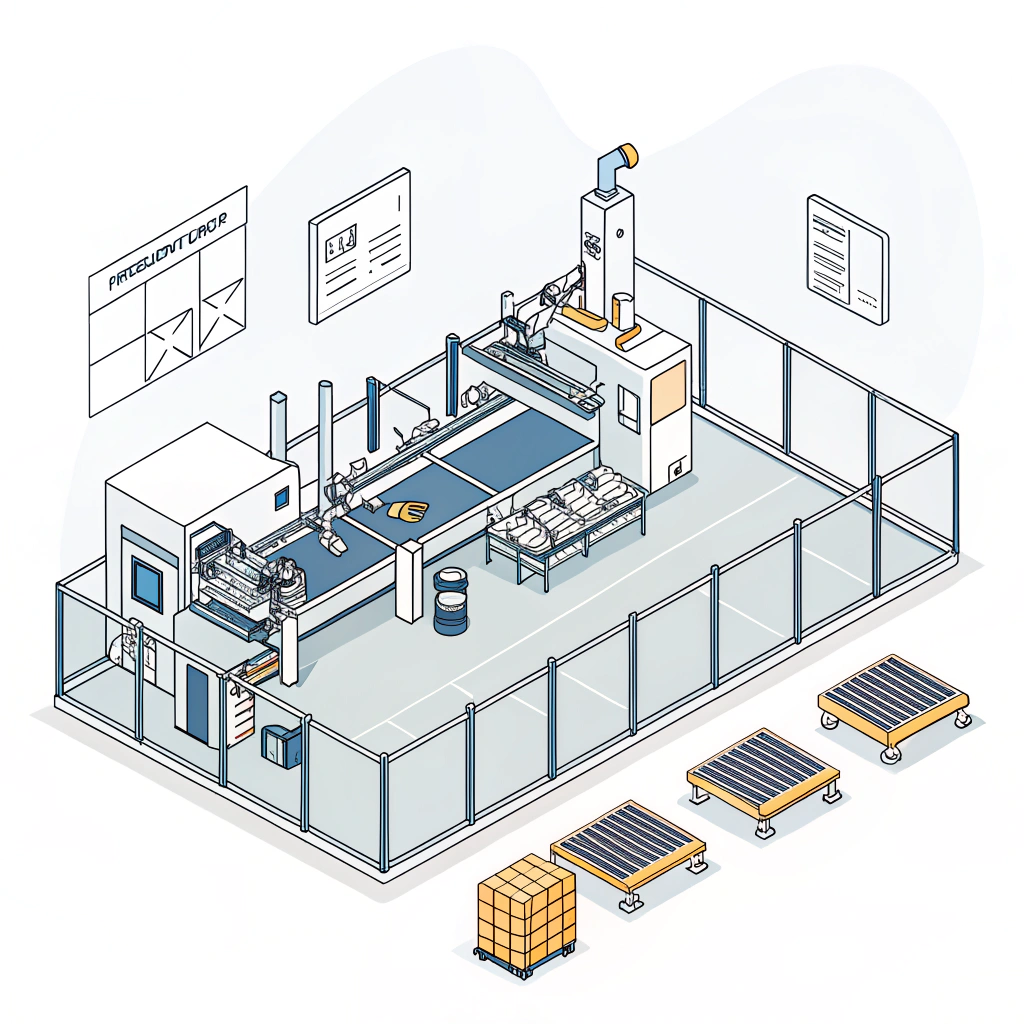

Utilizing materials ranging from fiberglass to 3k, 12k, and 18k carbon fiber4, our modern production facility in Jiaxing, Zhejiang, employs the latest in manufacturing technology. This not only ensures precision and durability but also speeds up the process, allowing for customization5 without compromising turnaround times.

Our approach streamlines interaction between suppliers, manufacturers, and logistics partners. This integrated supply chain model minimizes communication gaps and improves the synchronization of production schedules. The benefits include:

- Reduced lead times

- Timely quality control checks

- Consistent product performance

Understanding that B2B buyers often require tailored solutions, NEX Padel offers full customization for rackets, including various shapes (Diamond, Round, and Teardrop), print designs, and even custom logo placement on hand grips and handle covers. We have developed a robust customization process that is both efficient and flexible.

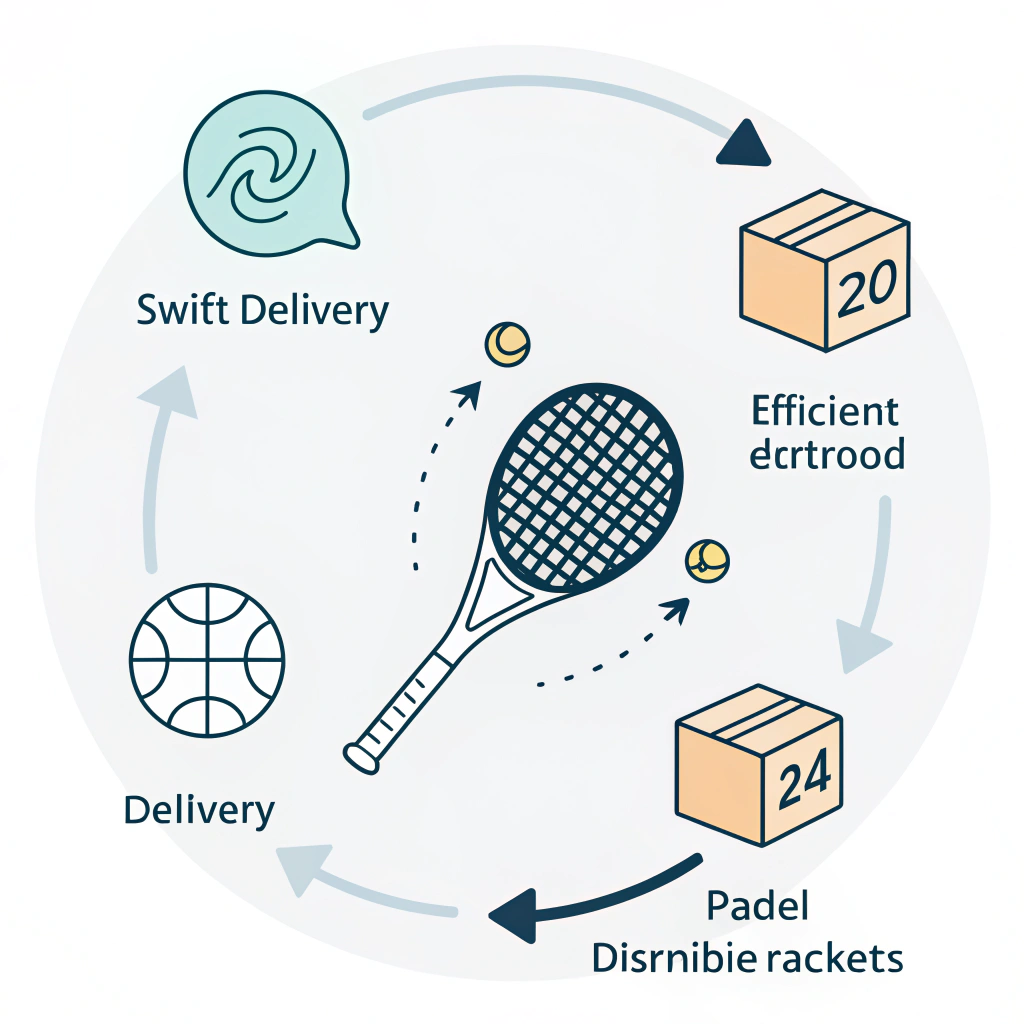

By partnering with strategic logistics providers, we are able to reduce transit times and ensure that products reach our customers reliably. This results in a reliable fast delivery promise that is vital for businesses managing tight stocks and fluctuating demand.

The following table summarizes our solution components and their benefits:

| Component | Key Feature | Benefit |

|---|---|---|

| Advanced Production | High-performance materials and precision tech | Shorter production cycles; high-quality output |

| Integrated Supply Chain | Centralized supplier management | Synchronized operations; reduced delays |

| Customization Process | Custom designs without extended wait times | Enhanced product uniqueness; satisfied client needs |

| Optimized Delivery Logistics | Strategic logistics partnerships | Reliable fast delivery; efficient inventory management |

Despite significant improvements, it is important to keep certain considerations in mind when evaluating delivery performance:

- Production Peaks and Troughs: Seasonal demand spikes might temporarily affect turnaround times. Planning and early order placement help mitigate this.

- Customization Complexity: While our process is optimized, extreme customization requests may slightly extend the overall lead time.

- International Logistics Issues: Regulations, customs clearance, and unforeseen transit delays on international shipments might impact expected delivery times, though our logistics team works relentlessly to minimize these risks.

- Continuous Improvement: The market is dynamic. We invest continuously in R&D and process optimization to stay ahead of emerging challenges.

It is these nuanced details that differentiate a reliable supplier from a merely adequate one. By understanding these limitations, procurement managers can plan more effectively and set realistic expectations with their teams.

Consider a recent collaboration with a well-known sports retail chain. Facing critical inventory shortages during a peak season, the retailer needed a rapid turnaround on a large batch of highly customized padel rackets. Our integrated workflow allowed us to deliver the product with an impressively short lead time, even while meeting the rigorous quality standards expected. As a result:

- Inventory turnaround improved by 20%.

- The retailer reduced backorder incidence significantly.

- Product quality feedback was overwhelmingly positive, leading to repeat contracts for the next season.

This case study underlines how fast delivery combined with customization does not compromise product quality and can greatly enhance your supply chain’s overall efficiency.

In summary, reducing delivery times by using efficient production and logistics coordination provides several strategic advantages:

- Enhanced Inventory Management: With shorter lead times, businesses can lower their inventory costs while meeting consumer demands in real-time.

- Improved Competitive Positioning: Fast delivery supports better market responsiveness, a critical factor in retaining customer trust and gaining market share.

- Reliability and Quality Assurance: Our approach ensures that enhanced speed does not compromise the exceptional performance of our padel rackets.

- Customization Flexibility: B2B buyers get the best of both worlds—customized products with minimal delays.

Procurement and supply chain managers should consider partnering with manufacturers who emphasize rapid and reliable delivery, along with the capacity for extensive customization. By choosing a partner like NEX Padel, you ensure that your supply chain remains agile, responsive, and competitively positioned in a fast-evolving market.

To gain further insights and boost your operational efficiency, we recommend conducting an internal review of your current supplier performance against these key factors. Ultimately, aligning with a manufacturer that prioritizes both quality and speed can lead to significant long-term cost savings and improved customer satisfaction.

People Also Ask

Q1: Which company makes the best padel rackets?

A1: While several top brands including Adidas, Bullpadel, Nox, HEAD, and Babolat are well recognized, NEX Padel stands out for its advanced production techniques, customizable options, and a strategic focus on fast delivery which provides a competitive advantage in B2B transactions.

Q2: Do expensive padel rackets make a difference?

A2: Price does not always correlate with performance, especially for beginner to intermediate players. Expensive rackets may offer specific benefits for experienced users, but for many players, the right balance of affordability and high performance—as seen in our quality-focused products—is key to optimal gameplay and value.

Q3: What is the shelf life of a padel racket?

A3: Generally, a padel racket can last just over a year at an amateur level. However, with proper maintenance and usage, it is possible to extend the racket's longevity while maintaining performance levels similar to when it was first acquired.

-

supply chain coordination: Read the article to learn how integrated management of suppliers, manufacturers, and logistics partners leads to efficient and resilient operations. ↩ ↩

-

fast delivery: Read the article to understand how expedited shipping strategies combine with optimized production processes to give businesses a competitive edge. ↩ ↩

-

Extended Lead Times: Read the article to explore the impact of production and shipping delays on inventory strategies and overall business efficiency. ↩ ↩

-

3k, 12k, and 18k carbon fiber: Read the article to gain insights into how varying grades of carbon fiber affect product strength, durability, and production efficiency. ↩ ↩

-

customization: Read the article to understand the importance of tailoring products to meet specific client needs while maintaining production speed and efficiency. ↩ ↩