In summary, NEX Padel guarantees top quality by combining advanced production techniques, rigorous quality control protocols1, and custom manufacturing capabilities to consistently deliver high-performance padel rackets that meet strict industry standards.

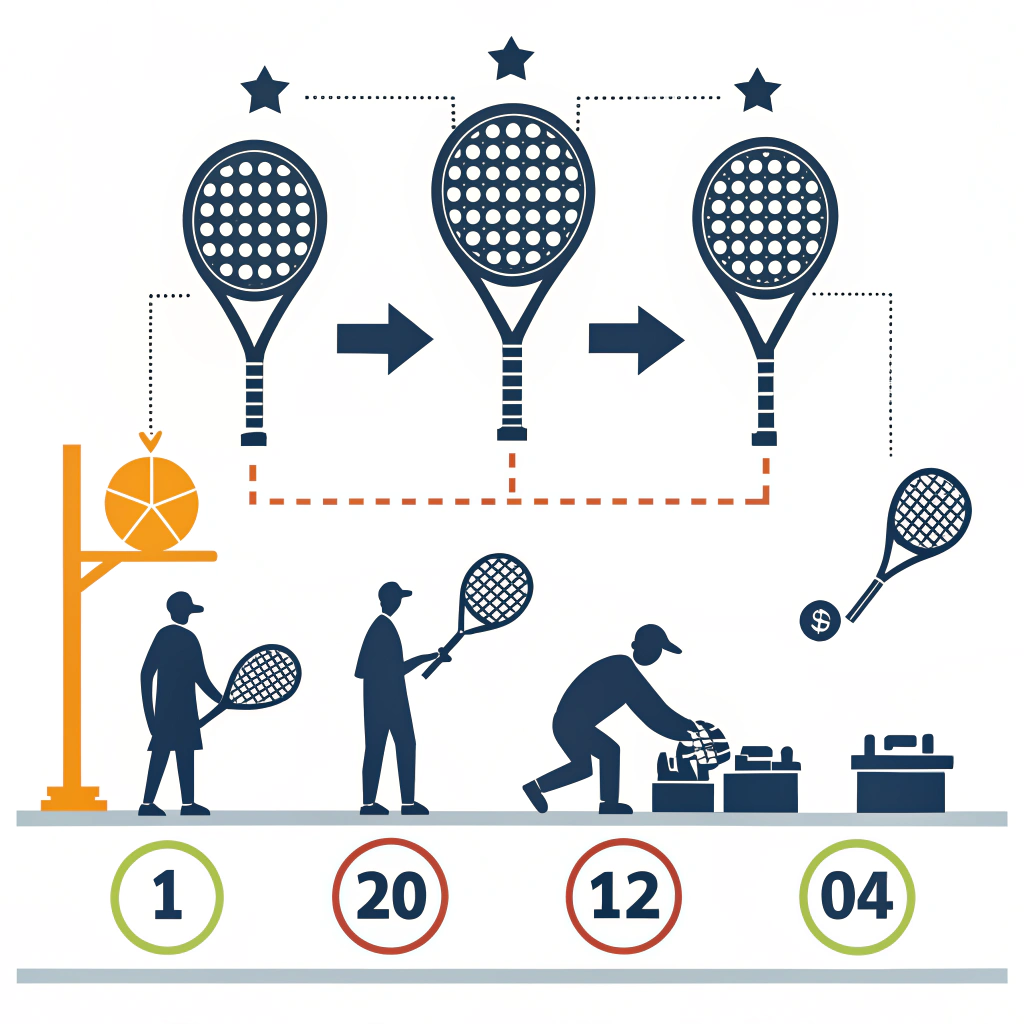

Our padel racket manufacturing process faces several challenges, from selecting premium raw materials like carbon fiber2 and glass fiber3 to ensuring each racket is produced with precision techniques such as 3k, 12k, or 18k carbon fiber layups4. In an industry where minute variations can lead to noticeable performance differences, procurement managers and quality assurance specialists must rely on production processes that minimize risks and guarantee consistency. Today, we delve into the key aspects of our production and quality control protocols, explaining why our approach helps partners make confident decisions.

In the competitive market of high-performance sports equipment, ensuring consistent quality is not an option—it is a necessity. Companies often struggle with:

- Inconsistent product performance due to varied manufacturing techniques.

- Lack of transparency in quality control and inspection standards.

- Challenges in accommodating custom production requirements while maintaining stringent quality checks.

These issues not only impact player performance but can also damage brand reputation if a product fails to meet consumer expectations.

Understanding the root causes of quality variation is critical. Here are some factors that can contribute to discrepancies in padel racket performance:

- Material Variability: Differences in material quality (from glass fiber to various grades of carbon fiber) can affect the overall strength and consistency of the racket.

- Production Techniques: Inconsistent techniques or outdated production methods lead to variable structural integrity. Our advanced production methods minimize such discrepancies.

- Quality Control Protocols: Inadequate quality control measures, such as sporadic factory inspections or insufficient testing protocols, can result in undetected defects.

- Customization Demands: Balancing custom production—like tailored shapes, custom prints, and personalized color schemes—with standard quality requirements is a complex challenge that requires precise methodologies.

At NEX Padel, we address these challenges through a multi-step approach that integrates advanced production techniques with rigorous quality control measures. Below is an overview of our solution strategy:

- Material Selection: We use a wide range of quality materials ranging from glass fiber to 3k, 12k, and 18k carbon fiber. Each material selection is based on strict performance specifications.

- Precision Engineering: Our manufacturing process utilizes high-tech equipment and automated processes to ensure uniformity and precision. This includes computer-controlled molding and computerized layup techniques.

- Custom Production Capability: Whether it is a Diamond, Round, or Teardrop shape, every design is meticulously produced according to custom specifications, including personalized prints and color schemes. Additionally, options for custom hand grips and handle covers enable brand-specific differentiation.

We implement multiple layers of quality control throughout the production process. This includes:

- Incoming Material Inspection: Every batch of raw materials is tested to ensure it meets our stringent quality requirements.

- In-Process Quality Checks: During production, key metrics such as material stress, vibration damping, and structural integrity are regularly monitored.

- Post-Production Testing: Finished products undergo comprehensive testing procedures including simulated performance tests and durability assessments.

- Standardized Inspection Protocols: Our quality management team follows internationally recognized standards, ensuring that each racket is inspected with identical procedures.

Below is a table summarizing our quality control checkpoints:

| Production Stage | Quality Control Measure | Tools/Methods Used |

|---|---|---|

| Material Inspection | Batch testing, chemical composition analysis | Spectrometers, material analyzers |

| In-Process Quality Checks | Dimensional accuracy, stress testing | Automated sensors, laser measurement |

| Final Product Testing | Performance simulation, impact and durability tests | High-speed cameras, impact sensors |

| Customization Verification | Visual inspection, brand-specific quality standards | Manual checks, digital imaging systems |

We believe that data is essential for managing quality. Our approach includes:

- Continuous Monitoring: Sensors and real-time monitoring systems track every production lot, ensuring that quality deviations are flagged immediately.

- Feedback Loop: Data from product tests is fed back into the production process. This continuous improvement loop helps us refine our techniques and address any potential areas of concern.

- **Traceability5: Each padel racket is traceable back to its production batch, allowing for targeted quality investigations if performance issues arise post-distribution.

Customization presents unique challenges. In meeting special client requirements—such as custom shapes, personalized printing, or even unique grip designs—we maintain a strict quality control process without compromising performance consistency. Here’s how we manage these complexities:

- Early-Stage Collaboration: Customers are involved at the design stage, allowing us to integrate custom specifications into the production blueprint.

- Dedicated Quality Checks: Extra layers of testing are applied to customized components, ensuring that even bespoke elements meet or exceed industry standards.

- Scalability: Our production systems are designed to handle both standard and custom orders, ensuring that scaling production does not diminish quality compliance.

- Post-Production Validation: For custom orders, a specialized team reviews the final output. This includes both visual and performance-related assessments to ensure every detail aligns with the client’s expectations.

Consider the example of one of our industry partners who required a customized Diamond-shaped padel racket. Their challenge was to maintain the performance consistency of standard models while integrating unique design and structural modifications. Our approach involved:

- Initial Consultation: We discussed the partner’s quality benchmarks and custom design specifications.

- Process Customization: Tailored production steps were introduced to accommodate the Diamond shape without affecting the racket's overall balance and durability.

- Enhanced Testing: From stress tests to dynamic performance simulations, the customized design went through enhanced quality verification procedures.

- Feedback Integration: Following initial test results, adjustments were made to the layup technique, further enhancing performance reliability.

This case study illustrates how our investment in advanced production techniques and quality control protocols enables us to meet the dual demands of customization and performance, ensuring that our padel rackets not only perform well but also comply with the highest quality standards.

For procurement managers and quality assurance specialists evaluating potential manufacturing partners, here are several action steps to ensure a sustainable partnership:

- Conduct a Thorough Audit: Evaluate the manufacturer’s production techniques and quality control protocols. Ask for detailed documentation and traceability measures.

- Request Case Studies: Look for examples of customized production projects that demonstrate the manufacturer’s ability to integrate bespoke requirements without sacrificing quality.

- Verify Data Integration Systems: Ensure that the manufacturer uses data-driven approaches, such as real-time monitoring and feedback loops, to consistently improve product quality.

- Support Certification: Confirm that the manufacturer adheres to international standards and quality certifications that are relevant to your market.

- Engage in Pilot Testing: Before full-scale production, engage in a pilot phase to verify that the manufacturer’s processes meet your stringent performance criteria.

Through these focused measures, procurement managers can confidently forge partnerships with manufacturers like NEX Padel that exhibit both high performance and robust quality management.

NEX Padel stands out in the sports equipment manufacturing industry by leveraging cutting-edge production techniques and implementing strict quality control protocols. Our process—from raw material selection to final product testing—ensures that each padel racket meets the rigorous standards required for high-performance play. For quality assurance specialists and procurement managers, our systematic approach means reliable, data-driven production outcomes and the flexibility to incorporate custom design requirements without compromising on product integrity.

As the market for high-performance padel rackets continues to evolve, our commitment to quality remains unwavering. With advanced production techniques, continuous monitoring, and robust traceability measures, we provide partners with both the technical excellence and the assurance needed for successful B2B procurement decisions. If you are in search of a partner who understands the importance of consistent quality and cutting-edge engineering, NEX Padel is well-equipped to deliver.

People Also Ask

Q: How does advanced production technology improve padel racket quality?

A: Advanced production technology improves padel racket quality by ensuring precision in material placement, consistent layering of fibers, and automated processes that reduce human error. This results in a racket that delivers predictable performance and durability.

Q: What quality control protocols are in place during the manufacturing process?

A: Our manufacturing process includes multiple quality control protocols, such as incoming material inspection, in-process quality checks using high-tech sensors, and rigorous post-production testing that verifies structural integrity and performance standards.

Q: How does NEX Padel manage custom production while maintaining high quality?

A: NEX Padel manages custom production by engaging customers early in the design phase, integrating tailored production steps, applying extra layers of quality checks on custom components, and using data-driven feedback loops to ensure that every custom order meets stringent performance criteria.

-

quality control protocols: Click to explore the rigorous quality control procedures that ensure each product meets strict industry standards, reducing risks and ensuring consistent performance. ↩ ↩

-

carbon fiber: Click to learn more about how carbon fiber materials are engineered to provide high strength-to-weight ratios and improved performance in sports equipment manufacturing. ↩ ↩

-

glass fiber: Click to understand the properties of glass fiber, its role in reinforcing composite materials, and its application in enhancing durability in high-performance products. ↩ ↩

-

3k, 12k, or 18k carbon fiber layups: Click to learn about the different carbon fiber layup configurations, how they affect the structural integrity of composite materials, and their relevance to achieving optimal performance in padel rackets. ↩ ↩

-

Traceability: Click to discover the importance of traceability in manufacturing, including how tracking production batches can help in identifying and rectifying quality issues efficiently. ↩ ↩