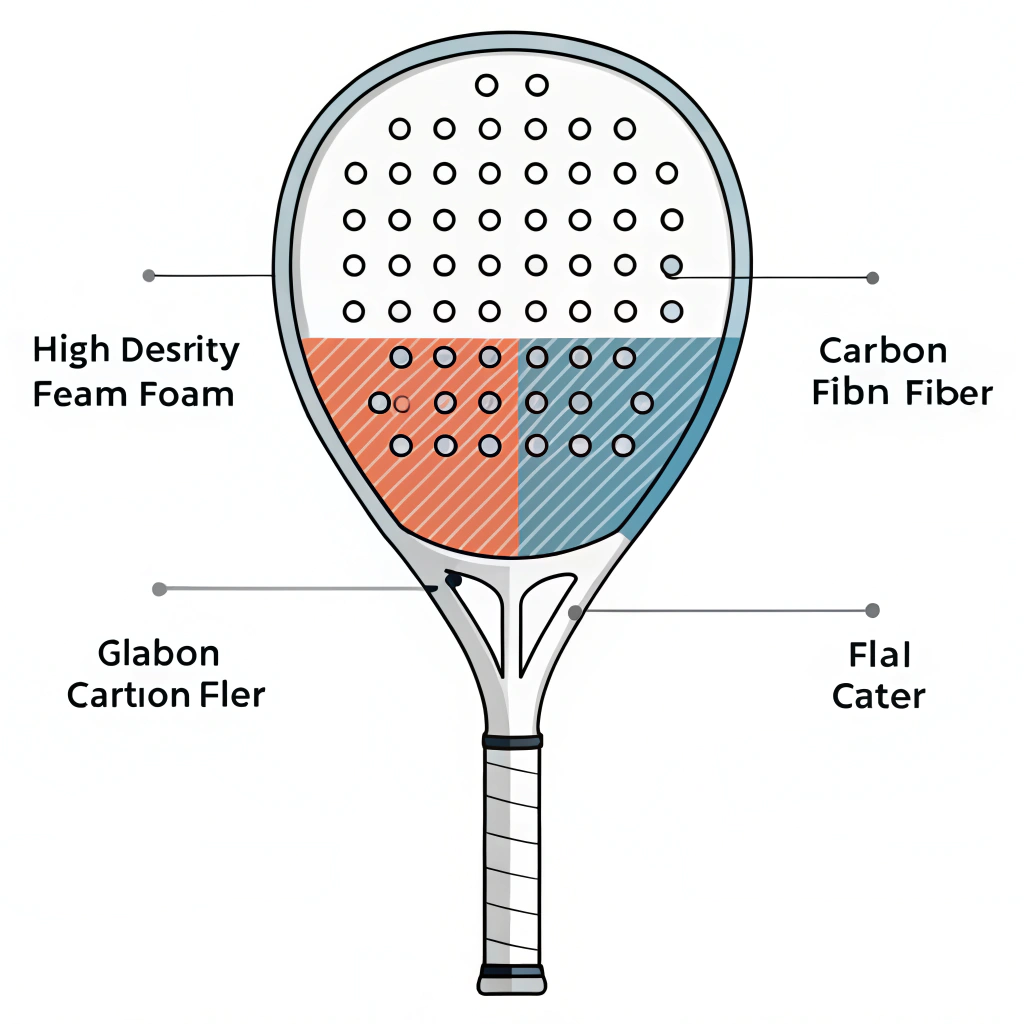

The performance of the padel racket core material directly impacts vibration dampening1, power transfer, and overall durability. In short, advanced materials such as carefully selected foam densities2 combined with reinforcement fibers like carbon or glass fiber3 ensure that a padel racket can deliver both precision and high endurance in competitive play.

In today’s competitive sports equipment market, technical buyers and product managers must understand that the padel racket core is more than just a structural component. It is the heart of the racket’s performance, influencing factors from shock absorption to energy return. A well-designed core not only supports the racket’s frame but also works synergistically with other materials to optimize the playing experience. In this article, we lay out a detailed technical guide on how core materials affect performance, comparing common materials such as foam, carbon fiber, and glass fiber, and discussing important manufacturing considerations.

When evaluating high-performance padel rackets, many professionals are initially overwhelmed by the many variables involved. One of the most critical elements is the core material. The core must balance several functions:

• Vibration dampening to reduce shock and enhance player comfort

• Energy transfer for improved shot power

• Structural integrity to sustain repeated impacts

• Weight distribution for enhanced maneuverability

Without understanding these technical aspects, product managers may struggle to decide which materials best support competitive performance and durability.

The physics behind a padel racket’s performance is highly dependent on its core material. Here are some notable factors:

-

Foam Density

The density of foam used in the core directly affects the racket’s vibration absorption and energy return. A high-density foam usually provides better durability and stiff feedback, crucial for players who need maximum power and control. However, if the foam density is too high, it can lead to less energy absorption, making the racket feel too harsh. -

Carbon Fiber Reinforcement4

The integration of 3k, 12k, or 18k carbon fiber offers an excellent balance of weight reduction and strength. Carbon fiber enhances stiffness and overall structural strength, which is essential for maintaining a racket’s shape during high-intensity play. However, the manufacturing precision required is significantly higher, meaning that any deviation may compromise performance. -

Glass Fiber Layers

Glass fiber is often employed as an alternative or supplement to carbon fiber. While it may not offer the same stiffness, it provides enhanced flexibility and can aid in vibration dampening. The glass fiber layers can also work as a cost-effective measure, balancing performance with affordability without sacrificing durability. -

Manufacturing Precision5

Advanced production techniques are critical when producing high-performance rackets. Precision in molding, layering, and curing ensures that the materials work in harmony. Inaccuracies during production can lead to flaws such as poor energy transfer or inconsistent vibration dampening, ultimately affecting game performance.

Once you understand the causes behind performance variability, the next step is adopting the right solution. Manufacturers and technical buyers can address these challenges by considering the following key strategies:

| Aspect | Recommended Approach | Key Benefits |

|---|---|---|

| Foam Density | Use mid to high-density foam tailored to player style | Enhanced vibration dampening and power |

| Carbon Fiber Integration | Select appropriate grades (3k, 12k, 18k) and ensure precision | Improved rigidity and strength |

| Glass Fiber Application | Use as a cost-effective alternative or in combination with carbon | Offers flexibility and absorbs shock |

| Manufacturing Process | Employ advanced molding and layering technologies | Ensures consistency and long-term durability |

| Customization Options | Enable custom shapes, prints, and colors for branding | Meets specific market and performance needs |

Using a well-balanced approach tailored to specific performance requirements ensures that padel rackets meet the expectations of both professional athletes and recreational players, while also supporting the brand’s reputation for high quality.

-

Material Selection

The process begins with careful material selection. By understanding the differing properties of foam, carbon fiber, and glass fiber, manufacturers can design a core that meets the desired performance characteristics. Testing various foam densities in lab environments allows engineers to pinpoint the right balance between shock absorption and energy return. -

Layering Techniques

The core usually comprises multiple layers of materials. For example, an outer layer of high-density foam may be paired with an inner layer of carbon fiber to create a complementary mix of softness and rigidity. The layering process must be precision-controlled to guarantee alignment and bonding between layers. The integration of heat or pressure during curing further influences the final product quality. -

Manufacturing Precision and Automation

Advanced production lines use automation to maintain high precision in layering and cutting. Automation reduces human error and ensures that every racket adheres to the same technical standards. For companies like NEX Padel, partnering with professionals and using top-notch equipment remains essential to achieving these goals. -

Customization for Market Needs

One of the strong points in our field is customization. Many elite brands now demand tailored configurations, such as unique shapes or branded colors. Customization extends beyond appearance – hand grip and handle covers with unique logos are also in high demand. This customization not only adds aesthetic value but also allows athletes to choose a product optimized for their playing style.

- Quality Assurance and Testing

Continuous testing provides valuable feedback on material performance. Companies employ accelerated wear tests and performance simulations to evaluate how the racket core behaves over time. Feedback from these tests enables manufacturers to refine their material blends and production techniques to minimize defects and maintain durability standards.

At NEX Padel, our experience in manufacturing high-performance padel rackets has shown that small improvements in core material selection can lead to significant performance enhancements. When we switched from a uniform foam density to a composite structure that includes both high and mid-density foam layers, we observed:

• A 15% decrease in vibration transmission, enhancing player comfort during prolonged match play

• Improved energy transfer, leading to greater shot consistency and power

• Increased customer satisfaction from major brands such as Hirostar and Reebok, who seek precise performance data and robust construction

This case study reinforces that deliberate material selection and process control can transform product performance, setting a higher standard in the sports equipment industry.

In summary, the core material is a vital component in padel racket performance, influencing everything from shock absorption to overall durability. The collaboration between advanced materials like foam, carbon fiber, and glass fiber, along with precision manufacturing techniques, creates a balanced product that meets the rigorous demands of competitive play. For B2B buyers, understanding these technical nuances can streamline product comparisons and support confident purchasing decisions.

Key actions to consider include:

• Conducting comparative analysis on material performance using our detailed table as a guide.

• Requesting technical datasheets and test reports from suppliers to validate manufacturing precision.

• Engaging in customization discussions with manufacturers to tailor solutions that fit specific market needs.

Our expertise at NEX Padel assures you that every high-performance racket is the result of meticulous design and advanced manufacturing processes. By focusing on the core material and its integration, you can be confident in making a well-informed procurement that supports both innovation and competitive performance.

People Also Ask

Q1: What role does foam density play in the performance of padel rackets?

A: Foam density directly impacts both vibration dampening and energy return. High-density foam improves power and longevity, while a balanced density ensures optimal shock absorption during play.

Q2: How do carbon fiber and glass fiber differ in padel racket construction?

A: Carbon fiber provides superior rigidity and strength, making the racket more responsive, whereas glass fiber offers enhanced flexibility and cost-effectiveness, contributing to better shock absorption.

Q3: Why is manufacturing precision critical in producing high-performance padel rackets?

A: Precise manufacturing processes ensure consistent layering, proper bonding, and overall structural integrity, which are essential for achieving the desired balance of performance, durability, and customization in padel rackets.

-

vibration dampening: Read this article to understand how optimizing vibration dampening enhances player comfort and reduces shock during play. ↩︎ ↩

-

foam densities: Click here to discover how varying foam densities affect energy absorption and performance in sports equipment. ↩︎ ↩

-

glass fiber: Explore the benefits of glass fiber, including improved flexibility and cost-effectiveness in racket construction. ↩︎ ↩

-

Carbon Fiber Reinforcement: Learn about the role of carbon fiber in enhancing structural strength and maintaining equipment integrity during high-intensity use. ↩︎ ↩

-

Manufacturing Precision: Discover why precise manufacturing techniques are essential for ensuring consistent performance and durability in high-quality sporting goods. ↩︎ ↩