The emerging trend in padel racket manufacturing is driven by the integration of advanced materials1 and production processes that boost performance, durability, and customization—all essential for maintaining a competitive edge in the global sports equipment market.

The padel racket industry is witnessing a dramatic transformation. Innovations in advanced carbon fibers2 and production techniques are empowering manufacturers to produce rackets that are not only durable but also offer superior performance and customization options. As procurement managers and R&D specialists explore ways to optimize sourcing and production, understanding these advancements is essential.

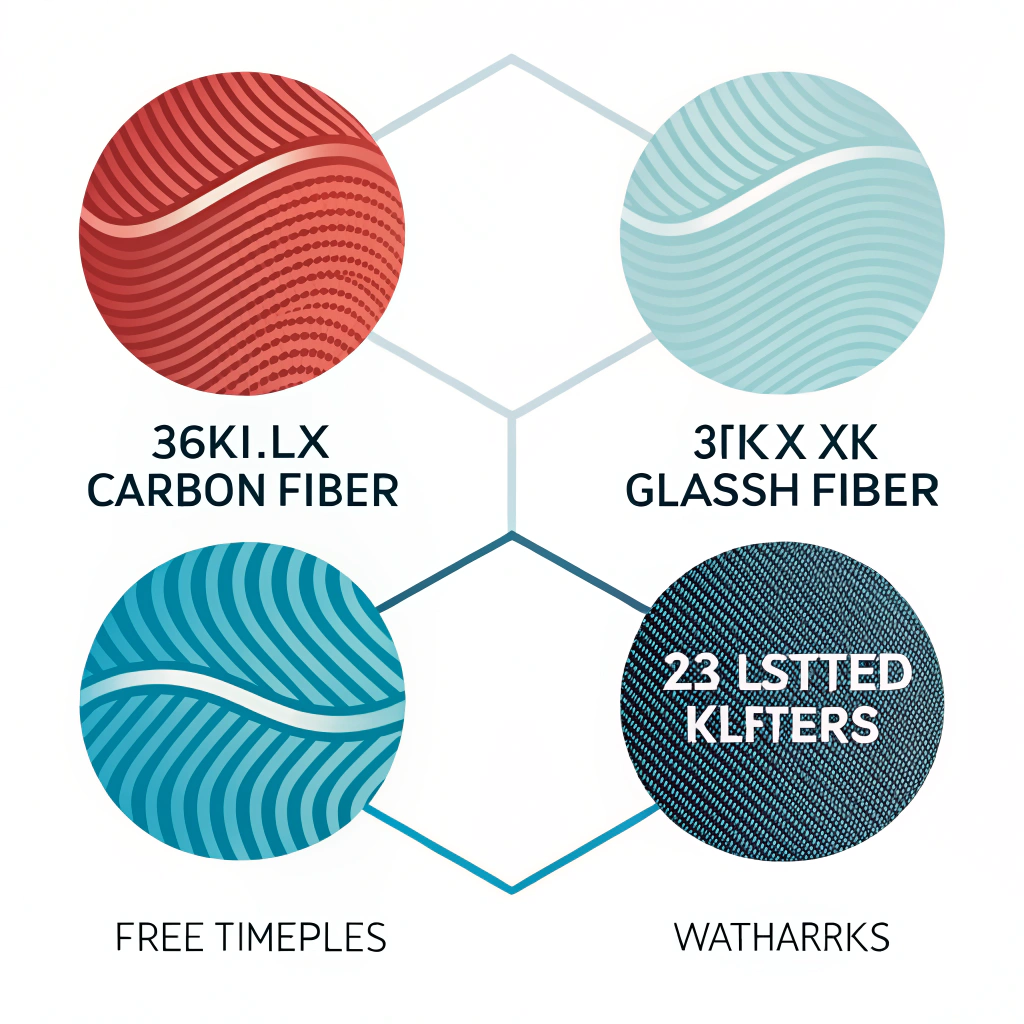

One of the most significant drivers behind these innovations is the use of advanced carbon fibers2—including 3k, 12k, and 18k variants—as well as the incorporation of durable glass fiber. These materials offer distinct benefits:

- Durability and Strength: With higher tensile strength, carbon fibers significantly boost the life span and resilience of the racket.

- Weight Reduction: Lighter materials improve maneuverability without compromising stability.

- Enhanced Flexibility: Options for different carbon grades allow for fine-tuning the flex and balance, catering to varied playing styles.

Modern production techniques allow manufacturers to combine these materials optimally. By integrating glass fiber with carbon fiber reinforcement, companies can offer rackets that balance performance, durability, and cost. This material innovation is central to many of the design enhancements we are seeing in the market today.

Advanced production techniques are reshaping how padel rackets are manufactured. Rapid Prototyping3 and precision engineering are at the forefront of this evolution. The following points highlight these cutting-edge practices:

- Rapid Prototyping: Leveraging computer-aided design (CAD) and 3D printing, modern facilities can create prototypes rapidly. This not only accelerates the product development cycle but also allows for quick iterations and improvements.

- Custom Molding and Printing: Techniques that support full customization—including unique shapes (Diamond, Round, Teardrop) and personalized colors or logos—are now common. This trend enables brands to offer exclusive products to their customers.

- Enhanced Quality Control: Automation in manufacturing ensures that every racket meets high precision and durability standards. Quality control processes are bolstered by real-time monitoring, reducing defect rates and improving consistency.

These advancements make it possible for manufacturers like NEX Padel to meet the high expectations of top brands such as Hirostar, Reebok, and Starvie, ensuring that every product reflects the latest in technology and design.

Below is a table that compares key characteristics of the most common advanced materials used in padel racket production:

| Material | Strength | Weight | Flexibility | Cost Impact | Application Focus |

|---|---|---|---|---|---|

| Glass Fiber | Moderate | Medium | Stable | Low to Medium | Entry-level and mid-range rackets |

| 3k Carbon | High | Low | Enhanced | Medium | Performance and budget-friendly |

| 12k Carbon | Very High | Very Low | Customizable | High | High-end and pro-level rackets |

| 18k Carbon | Highest | Ultra-light | Ultra-flexible | Premium | Cutting-edge and top-tier products |

This table illustrates that while the material costs may increase with higher carbon thread counts, the benefits in terms of racket performance and customization options often justify the expenditure, particularly for brands targeting professional players.

For procurement managers and product development leads, understanding the supply chain4 dynamics is critical. Several key considerations include:

- Supplier Reliability: With advanced materials like carbon fiber requiring strict quality controls, partnering with reputable suppliers—especially those with a track record of serving industry leaders—is essential.

- Lead Times and Rapid Prototyping: Companies that offer rapid prototyping and expedited sampling processes allow for faster iterations, leading to improved time-to-market.

- Customization Capabilities: OEM5 manufacturers like NEX Padel can offer full customization, which is a significant value-add for brands seeking to differentiate their product offerings. From unique shapes to custom logos on hand grips and grip tapes, these options help align products with market trends and customer preferences.

Furthermore, strategic collaboration across the supply chain can also mitigate risks associated with fluctuations in raw material prices. Consistent supply and quality assurance are fundamental to maintaining competitive production schedules and meeting customer demands.

Recent data indicates that the global market for sports equipment, especially specialized products like padel rackets, is expanding steadily. Several trends supporting this growth include:

- Performance-Oriented Design: As players demand equipment that enhances their game, manufacturers are innovating to offer rackets with optimal balance, power, and control.

- Increased Investment in R&D: Companies are investing in research to explore novel materials and technologies, which not only improve product performance but also reduce long-term production costs.

- Sustainability: There is a growing trend towards sustainable manufacturing. Even within advanced materials, manufacturers are finding innovative ways to reduce waste and energy consumption during production.

- Market Differentiation: In a crowded marketplace, customization and performance differentiation play a crucial role. OEM manufacturers are thus focusing on offering customizable features and rapid production cycles to stay ahead.

These trends are not just predictions—they are happening right now. By adapting to these market shifts, companies can ensure their product portfolios remain innovative and competitive.

For brands aiming to stay ahead in the competitive padel racket market, here are some actionable steps:

- Assess Your Material Suppliers: Re-evaluate your current supplier relationships. Look for manufacturers with proven capabilities in handling advanced materials like high-grade carbon fibers.

- Leverage Rapid Prototyping: Collaborate with partners who offer CAD-integrated design and rapid prototyping. This will allow you to test and iterate new designs faster, aligning with market demands.

- Explore Customization Options: Work with manufacturers that provide extensive customization capabilities. Whether it’s the shape of the racket or custom-printed logos on hand grips, personalized products can command higher customer loyalty.

- Focus on Quality Control: Ensure that your manufacturing partners use robust quality control systems. This is especially important when integrating multiple advanced materials.

- Plan for Future Trends: Stay informed about emerging technologies in sports equipment manufacturing. Participate in industry workshops, subscribe to trend reports, and engage with manufacturers to anticipate market needs.

By taking these steps, procurement managers can better align their sourcing strategies with current industry trends and technological advancements.

At NEX Padel, our commitment to innovation drives every aspect of our production process. Our advanced methodologies in padel racket manufacturing are tailored to meet the evolving needs of professional athletes and high-end brands. We understand that investing in the right materials and production techniques is not just about creating superior products—it’s about positioning your brand at the forefront of industry innovation.

We continue to push the boundaries of design and technology by:

- Collaborating with global leading sports equipment brands.

- Implementing rigorous quality assurance protocols for every production batch.

- Investing in R&D to explore sustainable yet high-performance materials.

These initiatives are designed to ensure that our partners can confidently offer products that meet the highest standards of performance and durability.

In summary, the future of padel racket manufacturing is bright and full of opportunities. Key factors such as advanced carbon fiber technology, innovative production techniques, and comprehensive quality control are reshaping the industry landscape. For procurement managers, product development leads, and R&D specialists, staying informed about these trends is critical.

We recommend a proactive approach that includes close collaboration with OEM manufacturers who not only understand the technical nuances of materials like 3k, 12k, and 18k carbon fibers but also offer customizable production solutions. Engage with partners who provide rapid prototyping services, robust supply chain management, and a commitment to quality control. By doing so, your organization will be well-equipped to deliver products that meet and exceed market expectations.

Take action today by reviewing your current procurement strategies and exploring how advanced padel racket manufacturing can drive product differentiation and performance improvements. The integration of cutting-edge techniques and materials is not just an enhancement—it's a necessity in an increasingly competitive market.

Q1: What factors are driving innovation in padel racket manufacturing?

A1: Innovation is being driven by the need for enhanced performance and durability, leading manufacturers to adopt advanced materials like high-grade carbon fibers and glass fiber, as well as techniques such as rapid prototyping and custom molding.

Q2: How do advanced carbon fibers influence padel racket performance?

A2: Advanced carbon fibers, including 3k, 12k, and 18k, offer superior strength, reduced weight, and enhanced flexibility. These properties contribute to improved racket balance, durability, and overall performance on the court.

Q3: What customization options are available for OEM padel racket manufacturing?

A3: OEM manufacturers offer a variety of customization options such as full shape customization (Diamond, Round, or Teardrop), personalized logo printing on racket surfaces and hand grips, and bespoke color schemes to match branding strategies.

-

advanced materials: Click to explore how innovative raw materials are transforming product performance and operational efficiencies in sports equipment manufacturing. ↩ ↩

-

advanced carbon fibers: Click to learn about the properties and benefits of various carbon fiber grades and their role in enhancing product durability and performance. ↩ ↩ ↩2

-

Rapid Prototyping: Click to understand how rapid prototyping accelerates the design process, allowing for faster iterations and more efficient product development cycles in manufacturing. ↩ ↩

-

supply chain: Click to delve into the dynamics of supply chain management, focusing on strategies to improve supplier reliability and production scheduling in a global market. ↩ ↩

-

OEM: Click to get insights into the role of Original Equipment Manufacturers in delivering customizable and high-performance products, along with strategies for effective collaboration. ↩ ↩