Advanced padel racket manufacturing relies on advanced materials, precision engineering1, and flexible customization to optimize performance, and NEX Padel delivers these critical advantages through a commitment to quality and production innovation.

For purchasing managers and procurement specialists at sports equipment distributors and boutique sports retailers, selecting the right padel racket manufacturing partner is essential for meeting athlete performance needs while ensuring supply chain reliability2. In today’s competitive market, buyers face a complex decision: balancing advanced padel racket technology with competitive pricing and robust customization options. This article provides a comprehensive analysis comparing leading options and illustrates why NEX Padel stands out as the ideal partner for high-performance, custom padel rackets.

When evaluating padel racket manufacturers, procurement professionals must consider multiple factors to ensure they secure products that meet both technical and market requirements. The main challenges include:

• Quality of Materials and Construction: Rackets that combine fiberglass with various grades of carbon fiber (3k, 12k, and 18k) guarantee the strength, precision, and durability demanded by discerning athletes.

• Customization Capabilities: Buyers want the ability to choose from different racket shapes—such as Diamond, Round, and Teardrop designs—and further tailor options through custom printing, color schemes, and even customized grips and handle caps.

• Production Efficiency and Supply Chain Reliability: Fast prototyping and timely delivery are critical. Manufacturers must ensure that every stage of production is backed by robust quality control measures and streamlined processes.

• Competitive Differentiation and Brand Credibility: In a crowded market, partnering with a manufacturer with an established reputation, proven expertise, and strong relationships with notable global brands offers a competitive edge.

NEX Padel addresses these challenges head-on by combining advanced production techniques, a full spectrum of customization services, and a steadfast commitment to quality. This focus not only meets the tactical requirements of high-performance sports equipment but also offers long-term strategic benefits for your business.

In deciding on a padel racket supplier, it is useful to conduct a multi-dimensional comparison focusing on material quality, customization options, production speed, and overall reliability. The table below outlines key differentiators between a typical competitor and NEX Padel:

| Feature | Typical Competitor | NEX Padel |

|---|---|---|

| Material Options | Limited to basic fiberglass or lower-grade carbon fiber | Offers a full range from fiberglass to premium carbon fiber (3k, 12k, 18k) ensuring optimal performance |

| Design Flexibility | Standard designs with minimal customization support | Provides comprehensive options with Diamond, Round, and Teardrop designs plus full shape and color customization |

| Production Efficiency | Longer lead times due to less agile processes | Quick prototyping and timely delivery to meet dynamic market demands |

| Quality Control3 | Basic quality checks may lead to variability | Rigorous quality control processes ensuring consistency and precision in every batch |

| Brand Partnerships | Limited partnerships | Trusted by globally recognized brands such as Hirostar, Reebok, and Starvie, underscoring proven credibility |

This comparative analysis highlights how NEX Padel’s integrated focus on advanced materials, customization, and efficient production delivers tangible benefits that address the common bottlenecks experienced by many procurement specialists.

At NEX Padel, high-performance padel rackets are engineered utilizing a range of materials precisely chosen for their technical advantages. Our use of fiberglass combined with multiple grades of carbon fiber provides flexibility in achieving the perfect balance between rigidity and shock absorption. This layered approach ensures that rackets deliver superior power and control while minimizing vibrations during high-impact plays.

Key material benefits include:

- Customizable stiffness and flexibility: Different carbon fiber layups (3k, 12k, 18k) allow tailoring the racket’s performance characteristics.

- Enhanced durability: Innovative composite construction methods ensure prolonged product life, essential for competitive play.

- Weight optimization: Strategic material distribution reduces overall weight without compromising strength, leading to improved maneuverability.

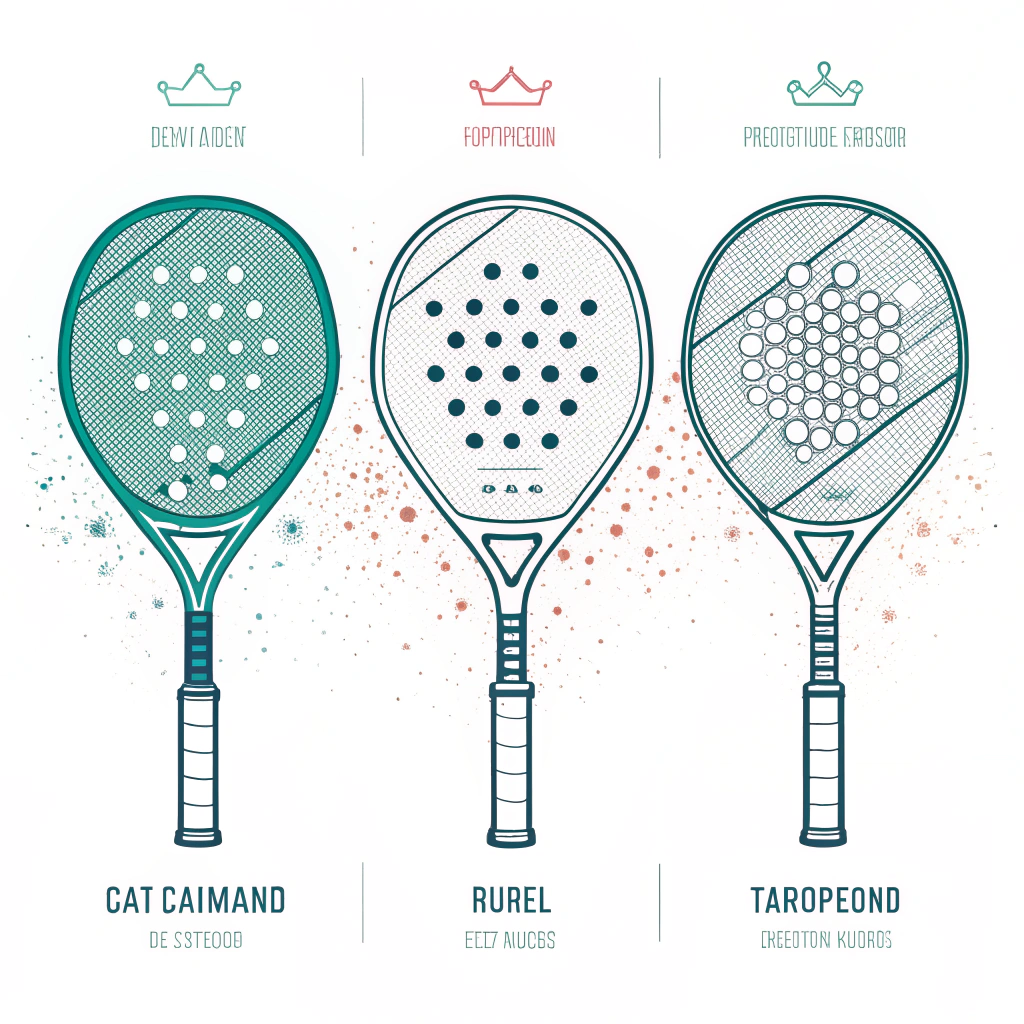

In today’s market, customization has emerged as a major differentiator. NEX Padel offers three primary racket shapes—Diamond, Round, and Teardrop—each engineered to cater to distinct playing styles:

- Diamond: Provides aggressive play with improved power; ideal for players who favor an offensive style.

- Round: Balances power and control, widely preferred by players prioritizing precision.

- Teardrop: Offers versatility, combining attributes of power with ease of handling.

Additionally, our customization extends beyond shape:

- Custom printing and color options allow brands to maintain visual consistency with their marketing strategies.

- Personalized grip and handle modifications including custom logo engraving on hand grips and handle caps further solidify brand identity.

- Advanced CAD Technologies4 and fast prototyping ensure that even bespoke designs can be efficiently produced without compromising quality.

Efficiency in production directly impacts inventory management and time-to-market. NEX Padel leverages cutting-edge manufacturing techniques designed to reduce lead times while maintaining strict quality standards:

- Fast Prototyping5: Enables clients to test and validate new designs rapidly, ensuring that their market offerings evolve in step with dispatch demands.

- Streamlined Supply Chain Processes: Our agile methods allow us to fulfill large volume orders without compromising on quality or delivery timelines.

- Rigorous Quality Control: Every production stage undergoes comprehensive quality checks. Continuous monitoring at each stage ensures that every racket delivered meets industry-leading performance standards.

Our commitment to consistent quality control not only safeguards product reliability but also builds trust among our clients and, by extension, the end athletes who rely on these advanced sporting goods.

Real-world success stories underscore the value of partnering with an innovative manufacturer like NEX Padel. For instance, one leading sports equipment distributor reported a 20% reduction in order fulfillment delays after transitioning to a supplier with quicker prototyping and stringent quality measures.

A boutique sports retailer sought high-performance rackets that could be customized to match their brand identity. They needed rackets that not only performed well on the court but also conveyed an image of premium quality through bespoke design elements.

NEX Padel responded with a tailored solution:

- Consultation & Design: Our design experts collaborated with the client to select the ideal racket shape and material combination.

- Rapid Prototyping: Utilizing our efficient production process, we delivered sample rackets within days, allowing for rapid feedback and design tweaks.

- Full-Scale Production: Following final approval, full orders were processed with guaranteed timelines, ensuring complete alignment with the client’s market launch schedule.

- After-Sales Support: Continuous quality monitoring and a dedicated support team helped sustain the beneficial impact on the end consumer experience.

This case not only illustrates our technical capabilities but also reinforces the strategic benefits of working with a partner who understands the critical touchpoints in the procurement process.

When evaluating suppliers in the high-performance sports equipment sector, consider the following strategic elements:

-

Technical Customization & Material Excellence:

- Ensure that your manufacturer offers a comprehensive range of materials and design options. The ability to choose between premium carbon fiber grades and custom shapes facilitates product differentiation in competitive markets.

-

Production Agility & Responsiveness:

- Timely delivery is paramount. A supplier with fast prototyping and scalable production processes can help your business meet market demands promptly without sacrificing quality.

-

Quality Assurance & Continuous Improvement:

- A robust quality control system is essential. Look for partners who commit to rigorous inspections and continuous quality improvement initiatives to protect your brand reputation.

-

Integration into Your Supply Chain:

- A reliable partner who understands your business processes reduces risks and enhances overall operational efficiency. Proven track records and industry partnerships are critical factors in establishing trust.

Below is a simplified table summarizing these strategic points:

| Strategic Factor | Key Considerations | NEX Padel Advantage |

|---|---|---|

| Material Excellence | Variety of high-performance materials; precise layup options | Full range including fiberglass, and 3k, 12k, 18k carbon fiber |

| Customization & Design | Flexibility in racket shapes and personalized branding | Customizable Diamond, Round, Teardrop designs plus bespoke printing and grip options |

| Production Agility | Fast prototyping and reduced lead times | Advanced techniques ensuring short production cycles |

| Quality Assurance | Consistent quality control measures and monitoring | Rigorous testing at all stages ensuring superior product quality |

| Supply Chain Reliability | Timely delivery and operational integration | Proven partnerships with well-known global brands ensuring reliability |

In summary, NEX Padel offers a blend of technical expertise, flexible production capabilities, and proven reliability that makes it the strategic choice for B2B procurement professionals focused on high-performance sports equipment. Our capability to deliver custom padel rackets using precision materials and advanced production techniques ensures that your sourcing decision aligns with both immediate performance needs and long-term business objectives.

By partnering with us, you benefit from:

- A dedicated team that understands the nuances of modern padel racket design.

- End-to-end support—from design consultation and rapid prototyping to large-scale production and after-sales service.

- A trusted and credible brand that has already earned the confidence of industry leaders such as Hirostar, Reebok, and Starvie.

For businesses looking to gain a competitive edge by offering innovative, high-performance sports equipment, NEX Padel stands ready to deliver products that truly resonate with the demands of professional athletes and discerning retail partners alike.

Choosing the right manufacturing partner for padel rackets involves assessing technical details, production capabilities, and quality control measures alongside visible brand credibility. With its comprehensive material options, extensive design customization, expedited production processes, and robust quality assurance, NEX Padel is uniquely positioned to support your strategic sourcing decisions.

To enhance your product offering and secure a competitive advantage in the dynamic sports equipment market, consider partnering with NEX Padel. For additional insights and a personalized consultation tailored to your specific requirements, do not hesitate to get in touch with our team.

• What materials are in advanced padel rackets?

Advanced padel rackets often combine fiberglass with various grades of carbon fiber—such as 3k, 12k, and 18k—to optimize strength, durability, and performance.

• How does customization impact padel racket performance?

Customization allows for optimal weight distribution, balance, and ergonomic design, tailoring the racket to the player's specific style for enhanced control and overall performance.

• What quality control measures are essential in padel manufacturing?

Essential quality control measures include rigorous material inspection, precise production techniques, and continuous monitoring throughout the manufacturing process to ensure consistency and high performance.

-

Precision Engineering: Click to learn how precise design and manufacturing processes enhance product performance and reliability in high-tech industries. ↩ ↩

-

Supply Chain Reliability: Click to explore strategies for building resilient supply chains that minimize risk and ensure timely delivery in a competitive B2B environment. ↩ ↩

-

Quality Control: Click to discover methods for implementing rigorous quality control processes that guarantee product consistency and excellence. ↩ ↩

-

Advanced CAD Technologies: Click to see how state-of-the-art CAD tools streamline design customization and improve manufacturing efficiency in complex production systems. ↩ ↩

-

Fast Prototyping: Click to understand how rapid prototyping accelerates product development cycles and enables swift market adaptation. ↩ ↩