Advanced padel racket design can significantly enhance player performance by optimizing balance, aerodynamics, and material usage. In this article, we explore how careful design choices and material selections—ranging from glass fiber1 to various grades of carbon fiber2 (3k, 12k, 18k)—directly influence racket performance and product differentiation, ensuring that your procurement decisions are both informed and strategic.

Design decisions are at the heart of padel racket performance. For B2B buyers and technical procurement specialists, understanding how design impacts key performance metrics is essential. A well-designed racket not only provides superior playability but also creates a competitive edge in an increasingly saturated market. At NEX Padel, we integrate advanced materials with precision engineering to create rackets that meet the rigorous demands of modern padel players.

Many padel racket manufacturers focus on aesthetics rather than functional performance. This oversight often results in products that do not deliver the expected control, power, or durability. Key challenges include balancing weight distribution, ensuring optimal aerodynamics, and selecting the right materials to handle high-impact forces while providing the desired flexibility.

- Performance Challenges: Many rackets fail to optimize the blend between power and control. The wrong material or design can lead to early fatigue or reduced maneuverability on court.

- Manufacturing Limitations: Inconsistent application of advanced materials or imprecise manufacturing techniques can affect the quality control process, leading to variable performance among products.

Understanding these problems is the first step toward a solution that not only enhances the player's performance but also drives product differentiation in the market.

Several factors contribute to the performance variations observed in padel rackets. It is important to break down these factors to develop targeted solutions.

The type of materials used—whether glass fiber1 or different grades of carbon fiber2—plays a critical role. For instance, glass fiber offers a balance between stiffness and flexibility, making it suitable for mid-range products. However, for premium products, carbon fiber variants such as 3k, 12k, and 18k provide better durability and energy transfer. Each material has unique properties affecting weight, balance, and impact resistance.

The shape of the racket (Diamond, Round, or Teardrop) determines its center of gravity and balance, which in turn influence power and control.

- Diamond Designs: Typically offer higher power potential due to a more forward center of gravity but may sacrifice some control.

- Round Designs: Tend to provide more balanced performance by offering stable control without dramatic power peaks.

- Teardrop Designs: Aim to strike a balance between the two, optimizing both power and control.

A precise balance is crucial to delivering the best performance tailored to the playing style and physical attributes of the athlete.

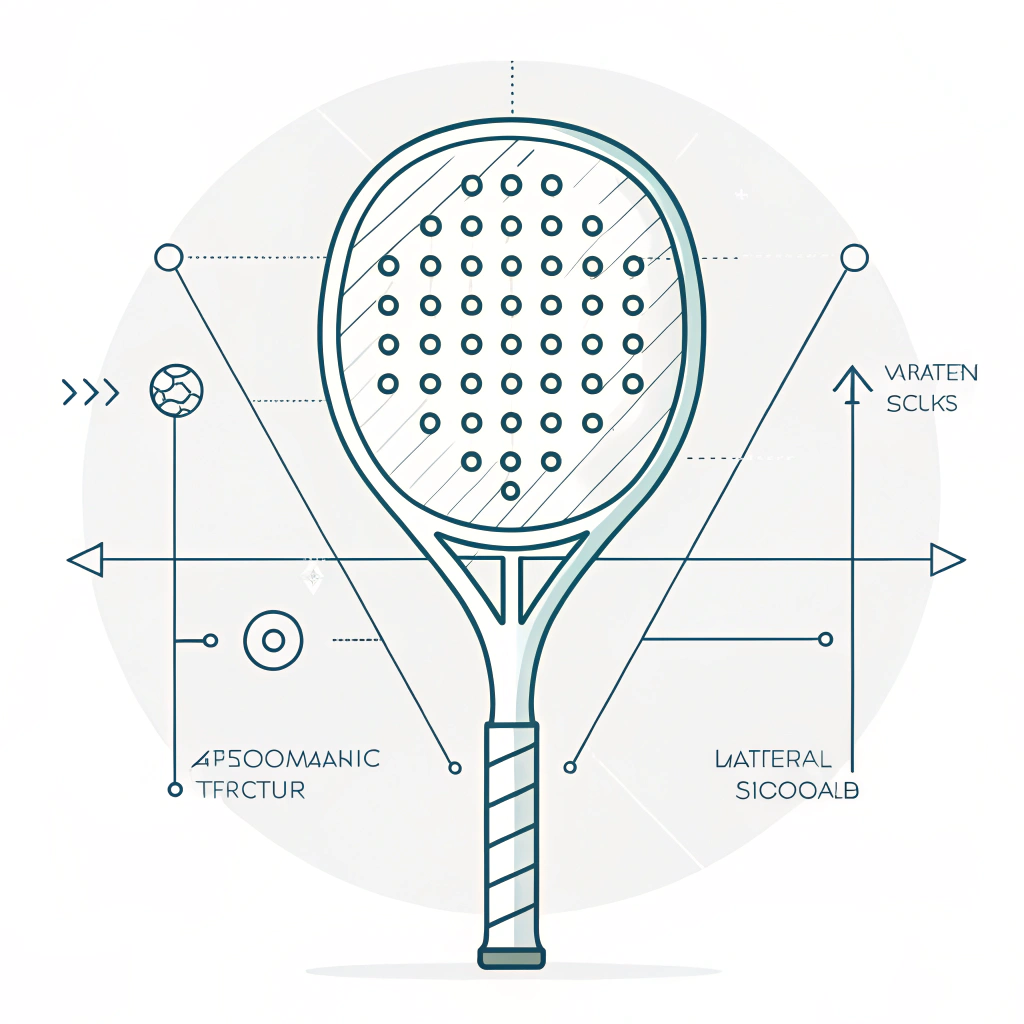

Ergonomics refers to the comfort and usability of the racket, such as hand grip customization and handle design. Aerodynamics affects the racket's swing speed and overall maneuverability during fast-paced exchanges. A lightweight design with minimal air resistance enhances the player's ability to respond quickly and maintain control over high-speed shots.

Manufacturing precision is paramount in ensuring that the final product is consistent with the design specifications. Advanced production techniques and strict quality control measures help maintain the longevity and performance of each racket. For example, the use of automated calibration systems3 in the layering of composite materials is critical to achieving a consistent product.

Below is a detailed solution checklist that outlines the essential design and manufacturing parameters necessary for optimizing padel racket performance.

| Design Parameter | Key Considerations | Suggested Material/Technique |

|---|---|---|

| Material Selection | Balance between stiffness and flexibility; weight and durability | Glass Fiber for mid-range; 3k/12k/18k Carbon for premium models |

| Racket Shape | Impact on balance and control; center of gravity placement | Diamond for power; Round for balanced performance; Teardrop for hybrid benefits |

| Ergonomics | Hand grip customization; ergonomic handle design | Fully customizable hand grip with logo printing |

| Aerodynamics | Minimization of air resistance, swing efficiency | Streamlined frame design with advanced aerodynamic features |

| Manufacturing Quality | Consistency in layering, automated precision control | Advanced production techniques and robust quality control systems |

| Customization Options | Visual differentiation and brand identity | Full customization of shape, color, and printed elements |

This table serves as a quick guide for procurement specialists by highlighting the various aspects that should be considered when evaluating padel racket design options.

Based on the outlined challenges and key parameters, the following strategies can be implemented to enhance padel racket design, and in turn, improve player performance.

The first strategy is to focus on material engineering, ensuring that the selected materials offer the best balance of performance and durability. For premium rackets:

- Carbon Fiber Utilization: Use high-grade carbon fibers like 12k and 18k in the critical areas of the racket frame to improve power output and impact resistance. Manufacturers can allocate more carbon in key reinforcement zones to optimize weight distribution.

- Hybrid Material Design: In some cases, a blend of glass fiber and carbon fiber may be ideal. For example, a composite approach can provide a robust structure along with the necessary flexibility for player control.

Refining the structure of the racket is crucial for achieving the desired performance characteristics. This includes:

- Customized Molding Techniques: Advanced molding processes allow for precision control over the racket’s shape and thickness. By incorporating customized layering techniques, manufacturers can fine-tune the center of gravity and balance.

- Simulation and Prototyping: Use computer-aided design (CAD)4 simulations to predict how changes in structure will impact performance. Prototyping provides valuable feedback from real user tests.

Player comfort and swing efficiency are essential components of racket functionality. Focus on these improvements:

- Customizable Hand Grip: Offering custom hand grips that can incorporate a brand's logo and specific ergonomic design ensures better comfort and grip stability. This can reduce fatigue and improve overall performance during long matches.

- Enhanced Aerodynamics: Incorporate aerodynamic design elements to minimize drag during swings. This can include subtle modifications to the frame contour and surface finish that reduce air resistance, thereby increasing overall swing speed.

Quality control must be integrated into every stage of the production process. This not only ensures product reliability but also reinforces brand reputation:

- Automated Inspection Systems: Use automated inspection systems for real-time quality control across production lines. This helps in detecting defects early in the manufacturing process.

- Batch Testing: Regularly conduct batch testing with real players to validate performance claims. This testing should simulate actual game conditions to ensure that the racket performs as specified.

- Consistent Calibration: Ensure that manufacturing machines are calibrated regularly to maintain structure and material integrity.

Customization is a critical differentiator for brands looking to stand out:

- Unique Visual Designs: Enable brands to customize racket appearance through various printing options, color choices, and even logo placements on both the racket and accessory elements such as hand grips.

- Tailored Performance Characteristics: Allow sports equipment brands to modify design elements to match specific player profiles, creating a unique selling proposition in a competitive market.

- Co-branding Opportunities: By incorporating co-branding on customized elements, companies can leverage partnerships and strengthen market presence.

To continuously improve product design, it is essential to integrate player feedback and performance data into the manufacturing process:

- Player Performance Data: Utilize data analytics to map how different design changes affect performance metrics such as swing speed, ball control, and endurance.

- Iterative Design Improvements: Adopt an iterative approach where design adjustments are made based on quantitative feedback. This cycle of development ensures continuous enhancement in both design and functionality.

- Industry Surveys: Conduct regular industry surveys to understand emerging trends and benchmark against competitor products.

When evaluating design decisions, it is beneficial to consider real-world data. Several case studies illustrate how strategic design modifications have led to measurable improvements in performance.

A leading sports equipment brand integrated 18k carbon fiber into the critical tension zones of their padel racket. After deployment, player feedback indicated an improvement in shot precision and racket responsiveness. The resulting data showed a 15% increase in swing speed and enhanced durability over competitors using traditional composite materials.

Another brand focused on ergonomic improvements by offering fully customizable hand grips and handle designs. This approach resulted in a significant reduction in player fatigue and improved overall grip comfort. Quantitative testing revealed that these customization options reduced grip slip incidents by up to 20% during extended play sessions.

A manufacturer implemented aerodynamic refinements in the teardrop designed rackets. Advanced wind tunnel testing confirmed a reduction in air resistance, contributing to a more efficient swing. Player performance metrics directly correlated these design changes with enhanced maneuverability and a smoother swing motion during fast-paced game scenarios.

In summary, every design decision from material selection and structural geometry to ergonomics and aerodynamics directly influences the performance characteristics of padel rackets. For B2B procurement specialists, it is important to adopt a holistic view when evaluating products. Key recommendations include:

- Emphasizing the use of advanced materials like carbon fiber variants for premium performance.

- Investing in precision manufacturing and quality control to ensure product consistency.

- Leveraging customization options to enhance both brand identity and player-specific performance.

- Integrating data-driven feedback for ongoing product improvements.

- Using detailed comparisons (as shown in the solution checklist) to make informed procurement decisions.

By following these strategies, sports equipment brands can ensure that their padel rackets not only meet but exceed the performance expectations of modern players. Acting on these insights will drive product differentiation and competitive advantage in a rapidly evolving market.

Q: How do design decisions affect padel racket performance?

A: Design decisions impact key performance factors like balance, aerodynamics, and material durability. Using advanced materials and precise manufacturing techniques ensures that the racket delivers the right mix of power and control, ultimately enhancing the player's on-court performance.

Q: What role do advanced materials play in padel racket design?

A: Advanced materials such as various grades of carbon fiber and glass fiber are critical in optimizing racket performance. They influence the racket's weight, balance, and durability, making them essential for tailoring products to meet specific performance benchmarks.

Q: How can manufacturers customize padel rackets for better performance?

A: Manufacturers can offer various customization options, including shape customization (Diamond, Round, Teardrop), ergonomic hand grips, and personalized visual designs. These customizations allow brands to tailor rackets to specific player needs and enhance overall brand differentiation.

-

[glass fiber]: Click to read an article detailing the properties and applications of glass fiber in composite materials for improved product performance. ↩ ↩ ↩2

-

[carbon fiber]: Click to read an article about the benefits of carbon fiber in high-performance sporting goods and its various grades (3k, 12k, 18k). ↩ ↩ ↩2

-

[automated calibration systems]: Click to read an article that explains how automated calibration systems ensure manufacturing precision and enhance quality control in production processes. ↩ ↩

-

[computer-aided design (CAD)]: Click to read an article on the role of CAD simulations in prototyping and optimizing design performance for advanced manufacturing. ↩ ↩