Quick answer — Pick the foam that matches the play profile and manufacturing constraints: use EVA foam1 (higher density, firmer Asker C2) or cross‑linked EVA3 for power and durability; choose softer PE/soft foam or low‑density EVA for control and dampening; consider hybrid cores (layered or blended) to tune rebound vs damping. Set density, hardness and thickness early in specs (e.g., 0.30–0.50 g/cm³ and Asker C 28–44 as starting bands) and require supplier test data (density, Asker C, compression set4, rebound5) with samples before pilot runs.

Introduction — why foam matters for padel rackets

Foam is the heart of a padel racket. The core foam controls how energy is stored and returned on impact, how much vibration reaches the hand, and how the racket ages under repeated compression. Choosing the right foam is a trade‑off among power, control, damping, durability, manufacturability, and unit cost. For procurement and engineering teams, specifying the right foam—its chemistry, density, hardness and processing requirements—determines player experience and production reliability.

Foam types and compositions

Key foam families used in padel cores:

- EVA (ethylene-vinyl acetate): Most common. Comes in virgin, cross‑linked, and blended grades. Offers a range from soft to firm depending on density and vinyl content. Cross‑linked EVA improves resilience and compression set.

- PE (polyethylene) / soft foams: Lower density, softer feel, strong damping; used for control‑oriented rackets. Can be linear PE or cross‑linked variants.

- Cross‑linked foams: Made by chemical or irradiation cross‑linking; give higher rebound, lower compression set, and better thermal stability.

- Hybrid / layered cores: Two or more foam layers (e.g., a soft inner layer + firmer outer layer) to combine control and power.

- Closed‑cell vs open‑cell morphology: Closed‑cell foams resist moisture and show more consistent rebound; open‑cell are more dampening but absorb moisture—usually avoided for padel cores.

Quick comparison table

| Foam type | Typical feel | Manufacturing notes |

|---|---|---|

| EVA (standard) | Balanced; tunable | Easy to laminate, wide supply |

| Cross‑linked EVA | Firmer, responsive, durable | Higher cost; needs controlled heating |

| PE / soft foam | Very soft, high damping | Lower rebound, careful moisture control |

| Hybrid layered | Tuned power + control | Requires precise lamination and cutting |

First occurrences: EVA foam, PE foam, cross‑linked emphasized above.

Key material properties and test metrics

Define these in your specs and require supplier test reports:

- Density (g/cm³): Dictates mass, stiffness and energy return. Typical padel core range: 0.28–0.55 g/cm³ depending on foam type.

- Asker C hardness: Industry standard for padel cores. Lower Asker C = softer, more damped feel. Typical ranges discussed below.

- Rebound / ball restitution (%): Measures energy return; higher = more power. Test method: standard ball drop or instrumented impact. Provide test speed/geometry.

- Compression set (%): Indicates permanent deformation after prolonged load; lower is better for longevity. Target < 12% after 24‑hr compression at specified strain for durable rackets.

- Tensile strength & elongation: Important for handling during lamination and CNC cutting.

- Thermal/aging behavior: Measure hardness and compression set after accelerated aging (e.g., 70°C for 72 hours) to predict stability.

- Moisture uptake: Closed‑cell foams should show <0.5% mass gain under humidity test.

- Cell size / morphology: Finer closed cells give more consistent elasticity.

Specify test standards and conditions (temperature, specimen size, dwell time). Require raw material certificates and batch traceability.

How foam influences playability and player profiles

Linking material to on‑court feel:

- Power: Driven by density and rebound. Denser/firm foams and cross‑linked EVA return more energy on impact. Suited for aggressive players seeking fast drives and smashes.

- Control: Achieved with softer foams (lower Asker C) and multi‑layer cores that absorb some energy. Slower ball exit gives more placement precision for beginners and control‑focused players.

- Spin / feedback: Surface shells and core stiffness together influence spin; a slightly softer core can increase dwell time, allowing better ball bite for spin.

- Vibration damping / comfort: Low density, high damping foams reduce shock transmission—preferred for recreational players or those with arm issues.

- Responsiveness: Cross‑linked foams and higher densities give crisp feedback favored by advanced players.

Player profile mapping (simplified):

- Beginner / Club player: soft foam, Asker C ~28–32, density 0.28–0.36 g/cm³

- Intermediate: medium foam, Asker C ~32–36, density 0.34–0.42 g/cm³

- Advanced / Power player: firm/cross‑linked, Asker C ~36–44+, density 0.40–0.55 g/cm³

Foam selection by racket design (Diamond / Round / Teardrop)

Design interacts with core properties. Below are recommended starting bands; finalize via prototyping and playtests.

| Racket shape | Primary goal | Hardness (Asker C) | Density (g/cm³) | Typical core thickness |

|---|---|---|---|---|

| Diamond | Max power / head‑heavy | 36–44 | 0.40–0.55 | 36–38 mm |

| Teardrop | Balanced power/control | 32–40 | 0.36–0.48 | 36–38 mm |

| Round | Control / maneuverability | 28–36 | 0.30–0.42 | 34–36 mm |

Notes:

- For Round shapes aimed at beginners, prioritize damping over rebound.

- Diamond rackets may benefit from cross‑linked outer layers to improve ball exit velocity.

- Adjust thickness and outer skin (fiberglass vs 3K/12K/18K carbon) to tune stiffness and feel.

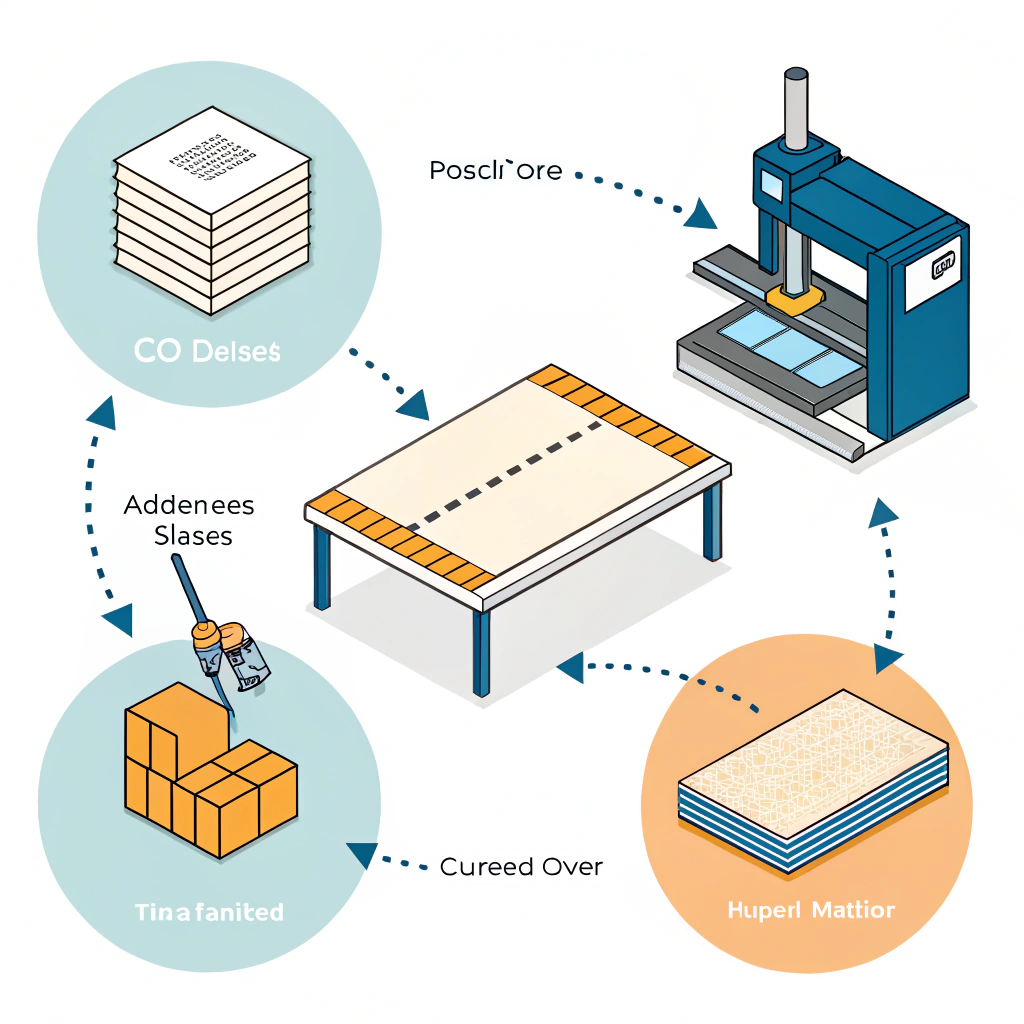

Manufacturing considerations

Practical production points that affect cost, quality and lead time:

Lamination and adhesives

- Use adhesives compatible with foam chemistry and face skins (epoxy-based for carbon/glass; polyurethane adhesives for EVA). Adhesive choice impacts cure temperature and cycle time.

- Pre‑bonding vs in‑line lamination: Budgets and volumes dictate which to use. Pre‑bonded foam sheets improve consistency.

Curing and thermal limits

- Cross‑linked foams may require controlled heating; specify maximum cure temperature for resin systems to avoid foam degradation.

- Avoid sudden temperature ramps that cause trapped gases or delamination.

CNC cutting tolerances

- Specify flatness, cut edge quality and tolerance (±0.2 mm typical for padel cores). Soft foams may compress during cutting—use knife or waterjet settings accordingly.

Bonding to skins

- Carbon (3K–18K) and fiberglass have different surface energies—pre‑treatment (plasma, sanding) improves adhesion.

- Consider adhesive beads or grooved cores for mechanical interlock in higher torque rackets.

Tooling and sample cycles

- Allow 2–4 weeks for initial tooling; rapid prototyping (CNC foams + protos) can be done in days for shape trials.

- Require 5–10 playtest samples before a pilot run.

Quality of core sheets

- Specify straightness, thickness tolerance (±0.3 mm), and lamination quality (no voids).

Durability, aging and quality control

Key QC checkpoints and tests to require on incoming cores and finished rackets:

Incoming inspection (foam):

- Density verification (gravimetric).

- Asker C hardness across multiple locations.

- Visual inspection for inclusions, cell rupture, color variance.

- Dimensional checks (thickness, shape tolerance).

Finished product tests:

- Compression set test (24 hr at defined strain).

- Ball rebound / instrumented impact.

- Adhesion test (peel strength between core and skin).

- Thermal aging (e.g., 70°C for 72 hr) followed by hardness and compression set.

- Environmental storage (high humidity) to verify moisture resistance.

Batch consistency:

- Require lot numbering and chemical certificates. For high-volume SKUs, sample every batch for hardness and density.

Common failure modes to watch:

- Permanent softening (high compression set).

- Delamination under fatigue.

- Edge blowouts from weak bonding.

Cost, lead times and customization options

Cost drivers

- Base polymer price, cross‑linking process (adds cost), density (more material per piece), and special treatments (anti‑UV, flame retardants).

- Adhesive systems, tooling, and prototyping cycles.

Typical lead times

- Standard core grades (stock): 2–4 weeks for MOQ shipments.

- Custom compounds, tooling and color matching: 4–8 weeks for samples; 8–14 weeks for first production depending on volume.

MOQ and pricing levers

- Higher MOQ reduces unit price. Negotiate tiered pricing with clear volume bands.

- Co‑development increases one‑time costs but reduces iteration time and improves specs.

Customization options

- Full shape customization, printed skins, custom edge tape and grip logos are supported.

- NEX Padel capabilities: rapid prototyping, compatibility with fiberglass through 18K carbon faces, and in‑house sample cycles to accelerate go‑to‑market. NEX can also supply matched balls (45% or 57% wool) to create a full product ecosystem.

Practical spec checklist and supplier questions

Use this checklist when asking for samples and quotes—include exact values you will verify.

Minimum spec checklist to request:

- Foam type and grade (e.g., cross‑linked EVA, trade name)

- Density (g/cm³) — specify tolerance

- Asker C hardness — specify test method and locations

- Compression set (%) — test conditions

- Rebound / impact energy return — test setup details

- Thermal aging data (ΔAsker C after X hours at Y°C)

- Adhesive system recommended for lamination

- Recommended cure temperature and time

- Dimensional tolerances (thickness, flatness)

- Certificate of analysis (COA) and lot traceability

- Lead time for samples and production MOQ

- Price per unit at specified volumes and packaging terms

Supplier questions to get answers to:

- Do you offer cross‑linked or blended cores? Can you provide comparative samples?

- What is your batch variability for Asker C and density?

- Which adhesives and cure regimes do you recommend for carbon 12K / 18K skins?

- Can you perform adhesion and compression set tests and share reports?

- What are your prototype/sample lead times and costs?

- Do you support private‑label co‑development and will you sign an NDA?

Pilot run tips

- Start with 50–200 units for a pilot run with full labeling/packaging to uncover production issues.

- Record batch numbers of cores and skins to correlate any variability.

- Run accelerated aging on a subset to identify early failures.

Summary and recommended actions

- Translate player targets (power/control/comfort) into three core parameters: foam chemistry, density, and Asker C.

- Require specific test data (density, Asker C, compression set, rebound) and set tolerances in RFQs.

- Use hybrid or layered cores to tune conflicting goals and leverage NEX Padel’s rapid prototyping and material experience to accelerate iteration.

- Begin with small pilot runs, insist on lot traceability, and include adhesion and aging tests in acceptance criteria.

People Also Ask

Q: Which material is best for padel rackets?

A: There is no single “best” material—choice depends on player level and design goals. Fiberglass faces paired with a softer foam core give comfort and forgiveness for beginners; carbon faces with firmer or cross‑linked foam favor power and responsiveness for advanced players. Specify face and core together rather than picking one material in isolation.

Q: What is the core material of a padel racket?

A: Padel cores are typically made from EVA foam, PE/soft foams, or a hybrid of both. Foam cores control rebound, damping and durability. EVA tends to be firmer and more powerful; soft PE foams provide greater shock absorption and control. Many manufacturers use layered cores to capture both benefits.

Q: What are foam‑filled tennis rackets?

A: Foam‑filled rackets use a foam core to absorb impact and reduce vibration transmitted to the hand. The foam acts like a shock absorber, improving comfort and reducing strain. In padel, foam cores are engineered to balance damping with energy return to match player needs and racket shape.

-

EVA foam: Read to understand EVA chemistry, common grades (virgin, cross‑linked, blends), how vinyl content and density affect stiffness and production handling, and why EVA is the industry default for padel cores. ↩ ↩

-

Asker C: Reading explains what the Asker C durometer measures, how to test and report locations, how values map to player feel, and how to specify tolerances in RFQs. ↩ ↩

-

cross‑linked EVA: The article covers cross‑linking methods (chemical vs irradiation), benefits for rebound and compression set, manufacturing constraints (curing temps, thermal limits), and cost/lead‑time tradeoffs. ↩ ↩

-

compression set: Learn the meaning of compression set tests, standard test conditions, target acceptance levels (e.g., <12%), and implications for racket longevity and supplier QC. ↩ ↩

-

rebound: The linked material explains rebound/ball restitution metrics, common test methods (ball drop vs instrumented impact), how to specify geometry and speed, and how results correlate with perceived power. ↩ ↩