Quick answer (snippet)

Carbon offers higher stiffness, durability and power-per-weight than fiberglass, so full carbon faces (3k1/12k/18k) are the right choice for advanced lines where performance and perceived value matter. Composite constructions (fiberglass + carbon hybrid) deliver better dampening, lower cost and gentler feel for beginner and mass-market SKUs. Choose by target player level, price point and OEM constraints (MOQ2, lead time, customization).

Introduction — why material choice matters

Choosing between a composite padel racket (typically fiberglass or mixed glass/carbon layups) and a full carbon racket is one of the earliest, most impactful product decisions for a new SKU. Material selection determines:

- Player-facing performance: power, control, feel, vibration.

- Durability and warranty exposure.

- Manufacturing complexity, sample cycles and rejection rates.

- Unit cost and the retail price tier you can target.

For procurement leads and product managers deciding line architecture (beginner → pro tiers), the right material map reduces rework, aligns margin expectations and speeds time-to-market.

Quick comparison snapshot: playability, stiffness, weight, durability, price

| Attribute | Fiberglass / Composite | Full Carbon (3k / 12k / 18k) |

|---|---|---|

| Playability (feel) | Softer, more forgiving, better dampening | Crisper, faster response, more power |

| Stiffness | Lower | Higher (depends on weave and ply) |

| Weight control | Easy to hit target weights with foam core | Precise but requires tighter QC |

| Durability | Good impact resistance, may delaminate under heavy use | Higher tensile strength, better fatigue life if manufactured well |

| Cost (OEM finished FOB est.) | Low: typically $12–$30/unit depending on finish | Mid-high: $40–$90+/unit depending on carbon grade and tech |

| Player target | Beginners, mass market, recreational | Advanced, competitive, premium retail |

| Manufacturing complexity | Easier layup, lower scrap | Requires cleaner process control, higher scrap risk during ramp |

| This snapshot helps you map material choice to price tiers and player segments. |

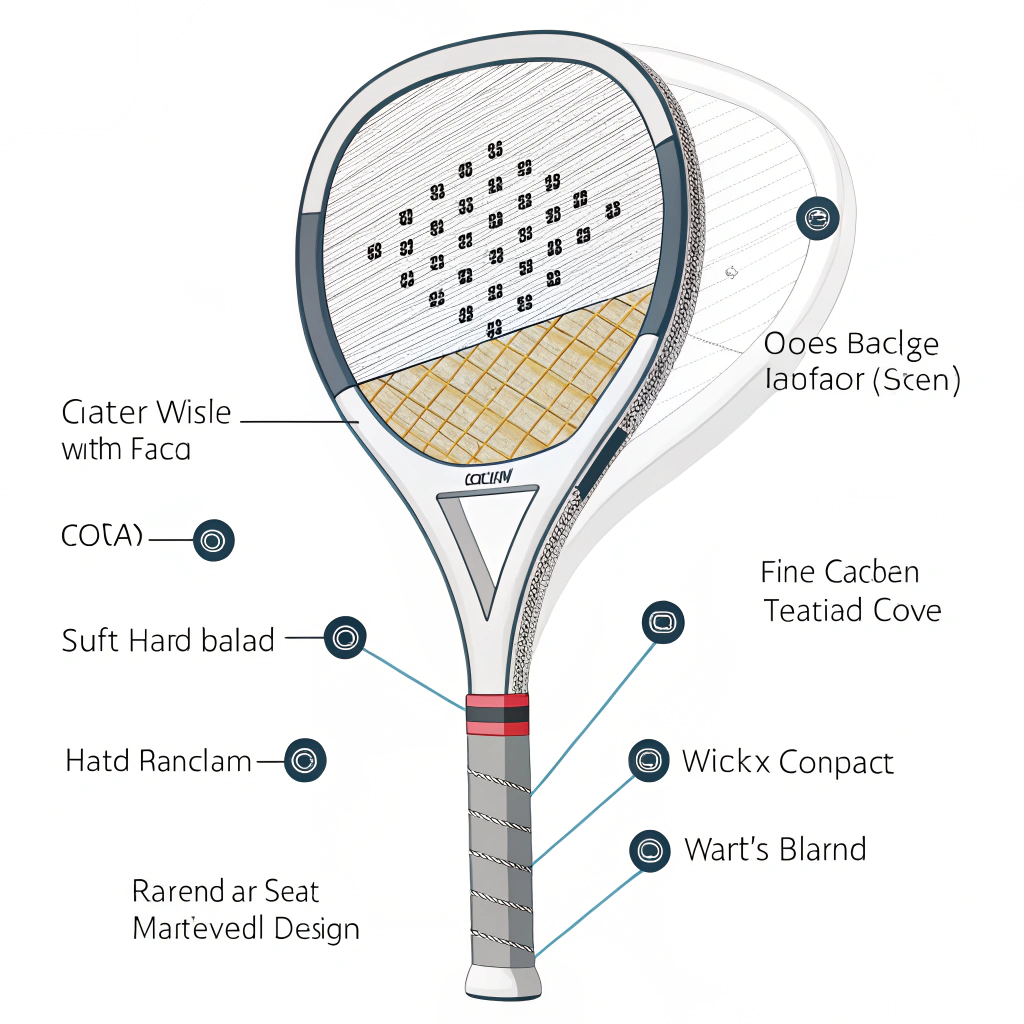

Materials & layups explained: fiberglass, hybrid composite, full carbon

Key terms (first use bolded):

- Fiberglass: woven E-glass sheets — cheaper, flexible, and forgiving. Often used on faces and even full frames for entry-level rackets.

- Carbon fiber: woven/UD sheets — higher modulus, lighter laminates for the same stiffness. Common weaves: 3k (fine weave), 12k (medium), 18k (coarser). 3k gives a premium tactile feel; 12k/18k reduce cost and produce slightly different aesthetics and stiffness.

- Hybrid layup: combinations such as glass outer face + carbon inner layers or carbon face + glass core skins to balance feel and cost.

- Prepreg3 vs wet layup: Prepreg carbon (pre-impregnated with resin) gives more consistent mechanical properties but costs more and often needs oven/autoclave-style curing. Wet layup uses dry fabric + measured resin, is cheaper but more variable.

Representative layup examples:

- Entry-level (cost-focused): Face – 2x fiberglass; Frame – fiberglass; Core – soft EVA 30–35°; Surface – polyurethane paint.

- Mid-tier (hybrid): Face – 1x 3k carbon outer + 1x fiberglass inner; Frame – fiberglass + adhesive; Core – EVA 35–40°.

- Premium (full carbon): Face – 2x 3k carbon or 1x 3k + 1x 12k; Frame – UD carbon; Core – denser EVA 40–50° or multilayer; Optional carbon stringers for sweet spot tuning.

Why weave counts matter:

- 3k: finer weave, better surface finish, perceived premium, slightly higher cost.

- 12k/18k: coarser, cost-saving, still provides stiff behavior; often used on secondary faces or decorative layers.

Core & internal specs: EVA hardness, density, impact on response and control

The core is as important as the face.

- EVA hardness4 is measured in degrees (Shore A equivalent). Typical ranges:

- Soft: 30–35° — very forgiving, more control at low swing speeds, less power.

- Medium: 35–40° — balanced power/control for intermediates.

- Hard: 40–50° — more power and rebound for advanced players.

- Density and rebound behavior: Higher density EVA yields faster rebound (more power) but less dampening.

- Dual-density cores: Softer inner core + harder outer shell can provide control and a crisp sweet spot.

Selection guidance: - Beginner line: Soft EVA 30–35° + fiberglass face for plush feel and lower arm strain.

- Intermediate: Medium EVA 35–40° + hybrid layup for improved power without harsh feedback.

- Advanced/pro: Hard EVA 40–50° + full carbon face + possible PVC inserts for targeted sweet spot.

Testing points (QC):

- Thickness tolerance ±0.3 mm

- Weight tolerance ±5 g

- Bounce/rebound tests for consistent force-deflection

- Bond strength between face and core (peel test)

Performance by player level: recommended specs for beginner/intermediate/advanced lines

| Player level | Material | EVA hardness | Weight target | Shape | Key benefit |

|---|---|---|---|---|---|

| Beginner | Fiberglass / composite | 30–35° | 355–370 g | Round | Soft feel, arm-friendly, lowest price |

| Intermediate | Hybrid (glass + 3k carbon) | 35–40° | 360–375 g | Teardrop | Balanced power and control, mid price |

| Advanced | Full carbon (3k +/- UD) | 40–50° | 360–375 g (or lighter for pro) | Diamond | Maximum power, precision, premium retail |

Notes:

- Weight distribution (balance point) matters: head-heavy gives more power; head-light gives maneuverability. Carbon allows tighter control of balance during molding.

- Surface treatments (rough texture for spin) are available across materials but may add cost.

Manufacturing & QC implications: layup methods, curing, tolerances, testing, failure modes

Process choices affect lead time, yield and cost.

Layup & curing

- Compression molding with vacuum bagging5 is the standard for padel rackets. Prepregs require controlled ovens and sometimes autoclaves; wet layups can be cured in heated presses.

- Tighter tolerances require controlled temperature ramps, consistent resin ratios and automated cutting for plies.

Critical tolerances & typical targets

- Weight tolerance: ±5 g

- Balance tolerance: ±3–5 mm

- Face flatness: no visible waves or resin pooling

- Cosmetic: paint/print registration ±1–2 mm

Common failure modes

- Delamination (face peeling from core): usually caused by poor bonding or voids in resin.

- Resin-rich or resin-starved zones: cause weak points or brittle spots.

- Fiber wrinkling: from poor ply placement, reduces mechanical performance.

- Impact cracks: especially on harder EVA cores with stiff faces if edge protection is insufficient.

Recommended QC tests

- Peel/adhesion test between face and core.

- Impact testing (drop weight) at representative temperatures.

- Static bending/stiffness measurement for each batch.

- Visual and dimensional inspection on every piece (or statistically sampling at high volume).

- Play testing protocol: random accelerated life test simulating 1–2 months of club use.

Ramp-to-production considerations

- Expect higher initial scrap rates when switching to full carbon or new prepreg materials.

- Pre-production run (200–500 pcs depending on complexity) helps stabilize process parameters.

- Keep tooling for molds and dies consistent; minor mold wear changes balance and weight.

Commercial considerations: cost breakdown, MOQ, sample cycles, lead times

Cost breakdown (indicative, FOB China finished racket)

- Raw materials (face fabrics, core EVA, adhesive, paint): Fiberglass $3–6; Carbon (3k) add $6–20 per unit depending on grade/weight.

- Molding and labor: $3–10

- Finishing (printing, grip, logo, packaging): $2–8

- QA and waste allocation: $1–5

Total FOB rough ranges: - Budget fiberglass racket: $12–30/unit

- Hybrid mid-tier: $25–45/unit

- Full carbon premium: $45–90+/unit

MOQ & lead times

- Typical MOQ per SKU/color: 300–1,000 pieces. Full custom tooling or complex finishes may push MOQ higher.

- Sample cycle: 2–4 weeks for basic samples; 4–6 weeks if custom molds, prepreg or unusual finishes.

- Mass production lead time: 45–75 days after sample approval depending on order size, seasonality and shipping.

- Shipping & logistics: Be sure to plan for container consolidation and customs lead times to avoid retail launch delays.

Price vs performance trade-offs

- Upgrading from fiberglass to hybrid carbon often adds $8–20/unit but lifts perceived value significantly.

- Going to full 3k carbon with premium finishes adds $20–50+/unit and increases QC burden.

Customization: printing, shapes (diamond/round/teardrop/full custom), grips, logos — how NEX Padel supports these

NEX Padel capabilities (practical points for procurement):

- Shapes: Diamond, Round, Teardrop; also full-custom mold service available.

- Face materials: Fiberglass, 3k/12k/18k carbon, UD carbon, hybrid layups.

- Printing: Full-color transfer, thermoset paint, matte/gloss finishes, textured anti-spin skin.

- Branding: Custom logos on hand grip and butt cap; custom hand grip material and color.

- Balls: We also supply padel balls via our partners (45% wool and 57% wool options) in pressurized tubes for price-quality control.

- Sampling & turnaround: Rapid prototyping and small-batch sampling for initial validation; transparent BOM and factory test reports provided.

NEX Padel emphasizes fast sampling and consistent deliveries and has OEM experience with brands like Hirostar, Reebok and Starvie.

Decision matrix & final recommendation checklist for procurement

Decision matrix (simplified)

| Use-case | Target retail price | Recommended material | EVA | MOQ advice |

|---|---|---|---|---|

| Club/recreational bundle | <$50 | Fiberglass | 30–35° | MOQ 500–1000; keep simple prints |

| Mid-range retail line | $60–120 | Hybrid (glass + 3k) | 35–40° | MOQ 300–600; allow 2 colorways |

| Premium/pro line | $130+ | Full carbon (3k/UD) | 40–50° | MOQ 300+; expect longer sample time |

Procurement checklist before P.O.

- Define player profile and price target per SKU.

- Lock material spec: face fabric type, ply sequence, core hardness, frame construction.

- Approve physical sample and perform play & lab tests (impact, adhesion, weight, balance).

- Confirm cosmetic specs: paint, print registration, grip logos, packaging.

- Agree QC criteria, sampling plan and rejection thresholds.

- Plan logistics & lead time buffer (add 2–3 weeks for shipping/customs).

- Negotiate MOQ and tooling amortization (who pays for molds? split?).

Sample plan (recommended)

- Concept mockup with CAD and visuals.

- 1–2 quick proof samples (2–3 weeks) for fit and cosmetic.

- 5–10 play samples with full layup (4–6 weeks) for performance tests and player feedback.

- Pre-production batch (200–500 pcs) to stabilize process and QA sampling.

- Full production after sign-off.

Final recommendations

- Use fiberglass/composite for entry lines where cost and comfort are primary.

- Use hybrid for most mid-tier SKUs: best balance of cost, feel and perceived quality.

- Reserve full carbon for premium/pro lines where performance, brand positioning and margin justify extra cost and QA effort.

- Work with your OEM to define a clear sample approval protocol and an agreed plan for addressing early production rejects.

People Also Ask

Q: Are carbon padel rackets better?

A: Carbon-based rackets generally provide higher stiffness and better power-to-weight, making them better suited to advanced players who can exploit sharper response and higher rebound. They also tend to last longer under repeated high loads if manufactured with good bonding and QC. For recreational players, the increased stiffness can feel harsh and is not always better.

Q: Do expensive padel rackets make a difference?

A: Yes — but primarily for intermediate and advanced players. Lower-cost rackets (often 100% fiberglass) are cheaper to produce and feel softer, but can feel "dead" and may lack power and rebound, sometimes causing discomfort. Expensive rackets use higher-grade carbon, advanced layups and tighter tolerances that deliver measurable benefits in power, control and consistency. Many premium features benefit skilled players more than beginners.

Q: Are composite and carbon the same?

A: No. "Composite" is a broad term for materials made from fibers embedded in a resin matrix. A carbon composite is a specific type of composite that includes carbon fiber as its reinforcement. Many padel rackets are composites combining fiberglass and carbon layers—these hybrids aim to balance feel, cost and stiffness.

-

3k: Read to learn how weave count affects surface finish, perceived quality, directional stiffness and cost — and why 3k is commonly used on premium faces versus coarser 12k/18k layers. ↩

-

MOQ: Read to understand minimum order quantities, how they impact unit economics, inventory risk and negotiation levers (price breaks, colorway limits, tooling amortization) when sourcing rackets. ↩

-

Prepreg: Read to compare prepreg vs wet layup for consistency, resin control, curing equipment (ovens/autoclaves), higher upfront costs and implications for yield, testing and sample cycles. ↩

-

EVA hardness: Read to clarify how EVA hardness (Shore A-equivalent) and density influence feel, power, rebound and arm strain—helpful when specifying cores per player tier and test protocols. ↩

-

vacuum bagging: Read to understand vacuum-bag consolidation benefits (void reduction, better fiber-resin ratio, improved mechanical properties), required shop equipment and effects on yield and QC during ramp-up. ↩