A concise answer: choose a flex profile1 by specifying the target frame flexibility (measured by static deflection and modal frequency), then match that target to a layup2 that balances power vs control—for example, a stiffer carbon-dominant layup (12k–18k) for power-oriented Diamond frames, and a more compliant fiberglass or mixed-carbon layup for control-focused Round frames. Validate with a 3‑prototype rapid iteration (static bending, dynamic frequency, impact and on-court ball-machine tests) and lock tolerances for production and QC.

If you're specifying new padel SKUs, the flex profile1 of the frame is central to player-perceived power, control, and feel. Flex profile is not a single number: it’s the distribution of stiffness across the head, throat and beam, plus how the core density and surface laminates interact dynamically. Getting it wrong can mean long and costly rework cycles—retooling molds, changing layups, or worse, missing seasonal launch windows.

This guide gives a decision framework you can use with an OEM (like NEX Padel) to:

- Translate player-segmentation into testable stiffness targets.

- Choose layup materials (fiberglass, 3k/12k/18k carbon) and arrange plies to meet those targets.

- Define prototype and QC tests with pass/fail criteria.

- Understand the cost, lead-time and durability trade-offs.

- Power-oriented rackets typically have a stiffer frame and higher energy return—they flex less on impact, so more ball energy returns as ball speed.

- Control-oriented rackets are more compliant (softer), increasing dwell time, enlarging the effective sweet spot and improving precision and feel.

- Maneuverability is affected by both mass distribution (balance) and perceived stiffness; a heavier, stiffer head increases power but can reduce quick reactions.

Your job is to pick a flex profile that aligns with your target player (aggressive attacker, all-rounder, beginner) while meeting cost and manufacturing constraints.

-

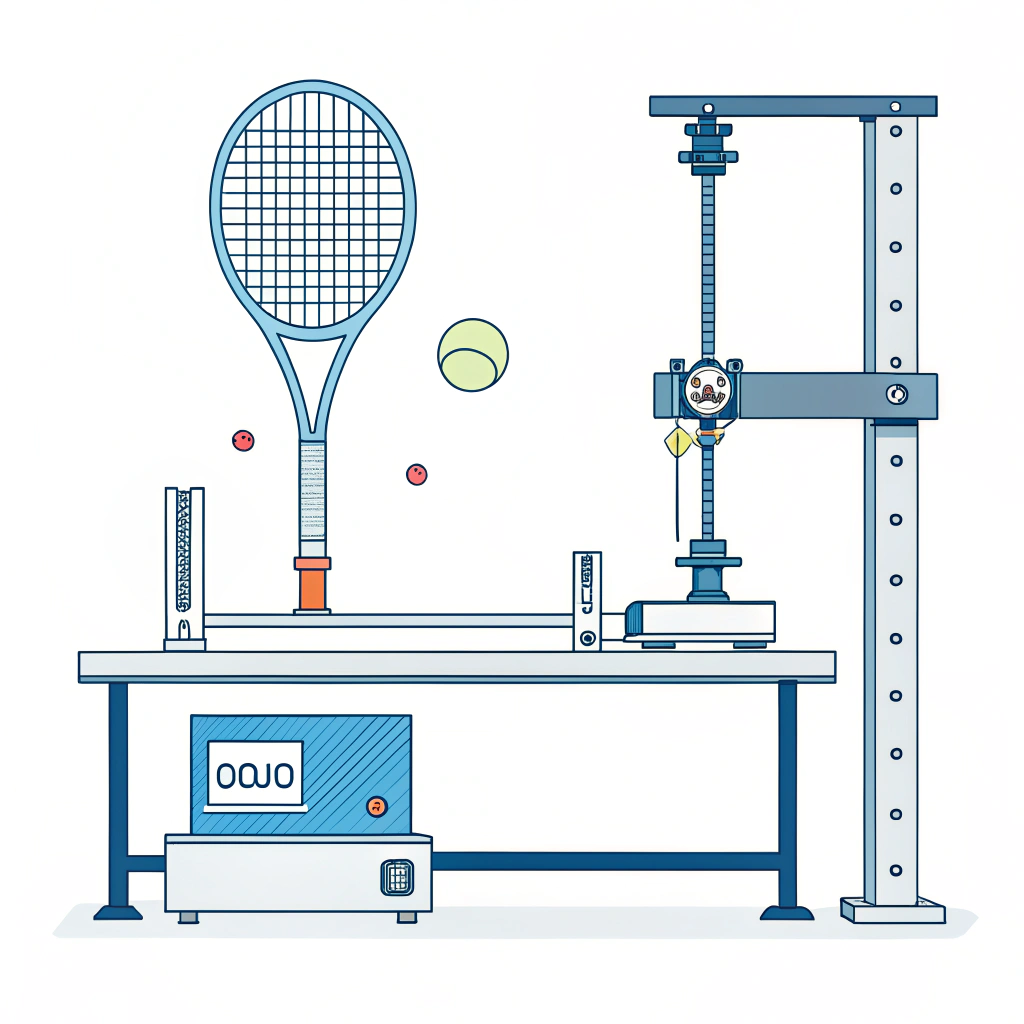

Static bending response

- Provide a standard test: e.g., apply X N at the center of the head with a support span of Y mm and record deflection (mm). (This is repeatable and easy at factory.)

- Example target: “Center-head deflection under 50 N = 2.5 ±0.3 mm” (adjust per your player-target).

-

Modal / dynamic frequency

- Natural frequency of the head (Hz) correlates to perceived stiffness and “ping”. Specify the measured dominant flex frequency using an accelerometer or impact hammer test.

-

Impact energy return

- Measure ball rebound speed or coefficient of restitution (CoR)3 from a standardized ball-machine test.

-

Damping

-

Fatigue / durability

- Define cycles (e.g., 100,000 impacts at X J) with acceptance criteria (no delamination, no change in static stiffness >5%).

-

Mass and balance

- Overall weight range and head/handle balance affect perceived flexibility and maneuverability.

-

Aesthetic/print constraints

- If you require visible carbon weave (3k/12k/18k), flag this early as it affects finishing and price.

Below is a practical comparison for quick supplier conversations.

| Material / Layup | Typical stiffness feel | Sweet spot / feel | Cost & lead-time | Durability notes |

|---|---|---|---|---|

| Fiberglass (full) | Soft / compliant | Larger effective sweet spot, forgiving | Low cost, fast | Good impact tolerance but lower energy return |

| Glass + carbon hybrid | Moderate | Balanced feel; tunable | Mid cost | Good compromise between feel and power |

| 3k Carbon | Stiff but with some weave flexibility | Precise feel, good control | Mid-high cost | Good fatigue life |

| 12k Carbon | Stiffer, higher energy return | More power, slightly harsher feel | Higher cost | Standard for performance racquets |

| 18k/UD High-modulus Carbon | Highest stiffness & crisp feel | Max power, precise | Highest cost, longer layup time | Needs careful shock management (potential for brittle failure) |

Bold: 3k/12k/18k carbon and fiberglass are your main levers. Use hybrids to create compliance zones (e.g., fiberglass around the perimeter, carbon at impact zones).

- Use compliant perimeter: A thin fiberglass outer ply increases perceived sweet spot and reduces harshness. Good for control models.

- Use stiff impact patch: Add local carbon patches (2–4 plies) behind the sweet spot for power bursts without globally increasing stiffness.

- Use throat reinforcement: Heavier laminates in the throat increase stability on volleys and overheads.

- Gradually vary ply orientation to tune torsional stiffness vs bending stiffness—+45/-45 plies give shear stiffness and damping; 0° plies add bending stiffness.

Work with your OEM to produce a layup drawing (ply schedule) with ply type, orientation and thickness so it can be quoted precisely.

- Translate player profile to measurable spec sheet (see “Core parameters”).

- Ask OEM for 3 prototype layups: Target (spec), + softer (-1 level), + stiffer (+1 level). Limit MOQ by negotiating sample molds or using an existing shape.

- Lab tests:

- Static bending (N vs mm) at defined points.

- Modal analysis (impact hammer + accelerometer).

- Ball-machine CoR and rebound mapping across ±20% strike positions.

- Drop-weight / impact absorption for edge and face impacts.

- Fatigue cycling to detect delamination.

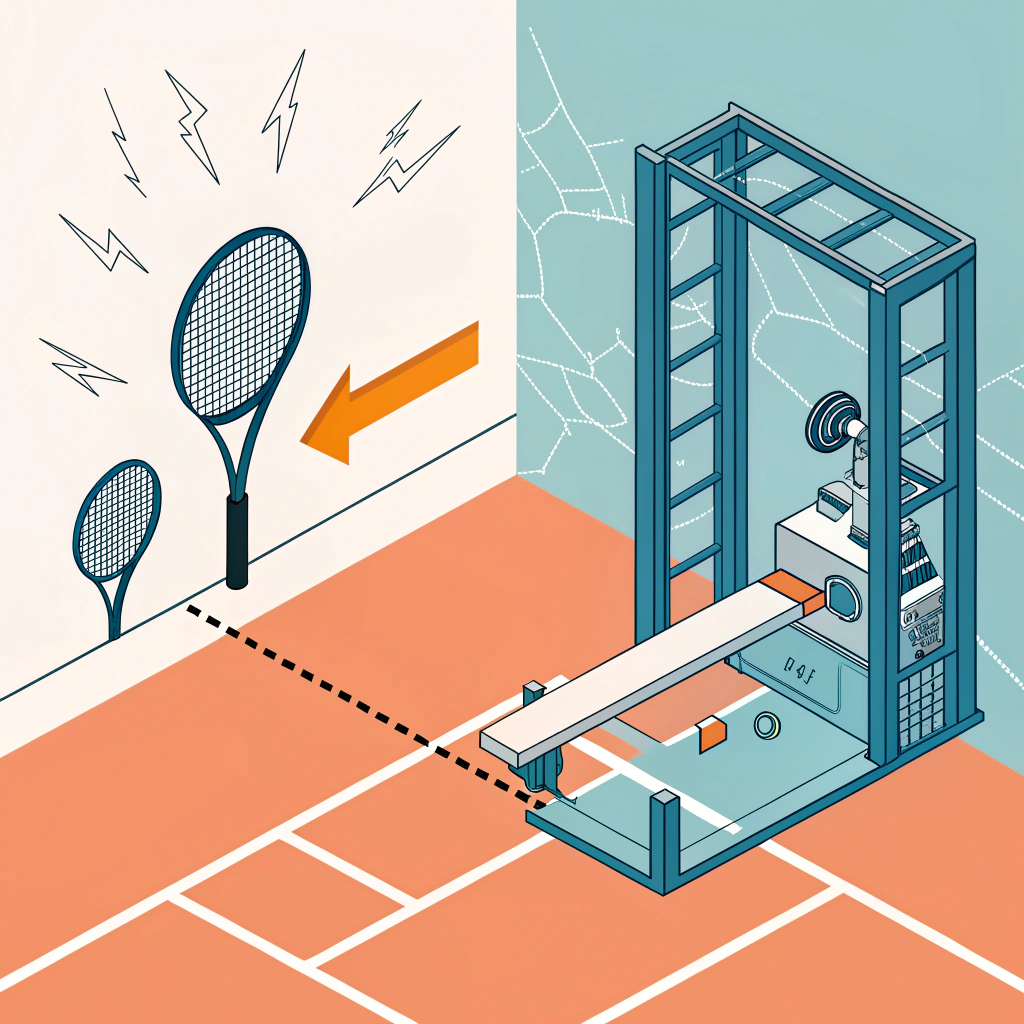

- On-court validation:

- Use a ball machine and sensor-equipped players to record shot speed, spin and subjective ratings.

- Collect torque/maneuverability ratings from target player pool.

- Iterate: pick the best candidate, tweak ply schedule, and freeze tooling.

When you move to mass production, lock these in the contract:

- Static deflection tolerance: ±X% (e.g., ±10% or ±0.3 mm depending on absolute target).

- Modal frequency tolerance: ±Y Hz (small percentage).

- Weight and balance tolerance: ±3 g, ±3 mm.

- Surface finish and visible weave acceptance.

- Impact/durability acceptance rate (e.g., maximum 2% failures in AQL5).

- Batch testing regime: 1 in 20 static and impact tests, plus random on-court checks.

Document acceptance criteria explicitly to avoid ambiguity during mass production.

- More carbon (12k/18k) increases raw-material cost and layup time—expect both unit price and sample lead-time to rise. High-modulus carbon can also increase scrap if tolerances are tight.

- Hybrid and fiberglass options reduce material cost and can shorten process time.

- Custom ply schedules and cosmetic finishes (visible 12k twill, varnished prints) add steps to finishing and increase lead time.

- Negotiate sample quotas and pilot runs to reduce full-tooling change costs.

NEX Padel supports rapid sampling and can produce tailored layups from fiberglass up to 18k carbon with quick turnarounds suitable for iterative prototyping.

- Stiffer, high-carbon frames deliver power but can be less forgiving under off-center hits and more prone to sudden failure if not properly toughened—mitigate with impact-absorbing core or external protector design.

- Softer fiberglass increases tolerance but lowers peak energy return. Consider mixed layups to get a middle ground.

- Specify fatigue testing cycles and require reporting; insist on visual/ultrasonic inspection samples from each batch.

- Target player: Competitive intermediate attacking player

- Target weight: 355 ± 3 g

- Balance: 270 ± 3 mm (head-light/head-heavy as required)

- Static center-head deflection: 50 N -> 2.4 ± 0.3 mm

- Dominant modal frequency: 170 ± 6 Hz

- Material: 12k carbon main plies + fiberglass perimeter wrap

- Fatigue test: 100,000 cycles at 25 J, no delam; stiffness change <5%

- Visual: 12k twill finish, custom color print

- MOQ: 500 units, pilot 50 samples

Use this template when briefing your OEM for a clear, testable contract.

- Convert player segmentation into measurable stiffness and frequency targets before talking layups.

- Always request at least three prototype variants (target, softer, stiffer) and a clear test matrix.

- Insist on production tolerances and batch testing protocols in the contract.

- Balance cost and time: use hybrid layups to achieve desirable feel without the highest carbon cost.

- Partner with an OEM that offers rapid sampling, clear lab testing and consistent QC — NEX Padel provides layup flexibility from fiberglass to 18k carbon and supports prototype cycles and QC reporting for brand partners.

If you need, we can prepare a customized spec sheet and a 3‑prototype program aligned to your player profile and launch timeline.

People Also Ask

Q: What is the frame of a padel racket?

A: The frame is the racket’s outer structure—the tube that defines the outline, accepts the protector, and houses the core and surface laminates. Frames are built from plies (fiberglass or carbon) wrapped into a hollow tube and determine durability, stiffness and impact resistance. Fiberglass gives a more compliant frame, while carbon increases stiffness and energy return.

Q: What makes a padel racket better?

A: “Better” depends on player goals. Key factors are weight (typically 340–375 g), balance, stiffness and surface layup. Heavier, stiffer rackets usually deliver more power; lighter or more compliant rackets improve speed and control. For a procurement decision, define the target player and then map weight, balance and flex profile to measurable specs (static deflection, modal frequency, CoR) rather than relying on vague descriptors.

Q: What is maneuverability in a padel racket?

A: Maneuverability is how easily the racket can be rotated and displaced. It’s driven by mass distribution (balance point and head weight) and perceived stiffness. A racket with less head mass and moderate flexibility will feel more maneuverable; higher head mass or stiffness reduces quick rotations. Specify both balance (mm) and perceived flex when targeting maneuverability.

-

flex profile: Read this article to understand how a frame’s spatial stiffness distribution (head, throat, beam) affects player-perceived power, control and feel, and how to convert player segments into measurable stiffness targets for procurement and testing. ↩ ↩2

-

layup: Read this article to learn how ply materials, orientations and local patches translate into bending, torsional stiffness and damping, and how to produce a ply schedule your OEM can quote and reproduce. ↩

-

coefficient of restitution (CoR): Reading this will explain standardized methods to measure energy return with ball machines, how CoR maps to on-court speed, and best practices for repeatable lab tests. ↩

-

DMA: Read about dynamic mechanical analysis (DMA) and related vibration-decay tests to quantify damping, predict harshness, and choose materials or layup strategies that improve player feel. ↩

-

AQL: Read this to understand Acceptance Quality Limit sampling plans, how to set acceptable failure rates for impact/durability testing, and how to define batch-testing regimes to control production quality. ↩