In short: for B2B procurement the single most practical way to compare padel racket suppliers is to insist on clear material specs (fiberglass vs 3k/12k/18k carbon1), EVA core2 hardness (Shore A3), precise weight & balance targets with tolerances, documented mold precision, and a written QC & testing protocol — then validate with 2–3 prototyping rounds and measured test reports before placing an MOQ production order.

Problem: why procurement decisions stall or fail

- Many sourcing processes rely on product photos, brand claims or price only. That leads to surprises at sample or production stage: feel, durability, or inconsistent weight distribution.

- Technical aspects that most affect performance and returns are often unspecified or misunderstood: carbon weave and layup, EVA core density/hardness, mold tolerances, and surface finish.

- Without measurable acceptance criteria and supplier-provided test data, MOQ runs can produce high rejection rates, delayed launches, and warranty costs.

Why this happens (root-cause)

- Suppliers use different raw materials with the same marketing names (e.g., “carbon” vs 3k carbon) but different weave counts, resin systems, or prepreg4 quality.

- Core hardness is rarely quantified in RFQs; “soft” or “medium” is subjective and changes playability.

- Balance and weight are set per racket but not controlled at batch level; lack of per-unit tolerance leads to customer complaints.

- Molds, printing and edge finishing are often outsourced/shared; tolerance stack-ups create cosmetic or fitting issues.

What procurement should control (high-impact checklist)

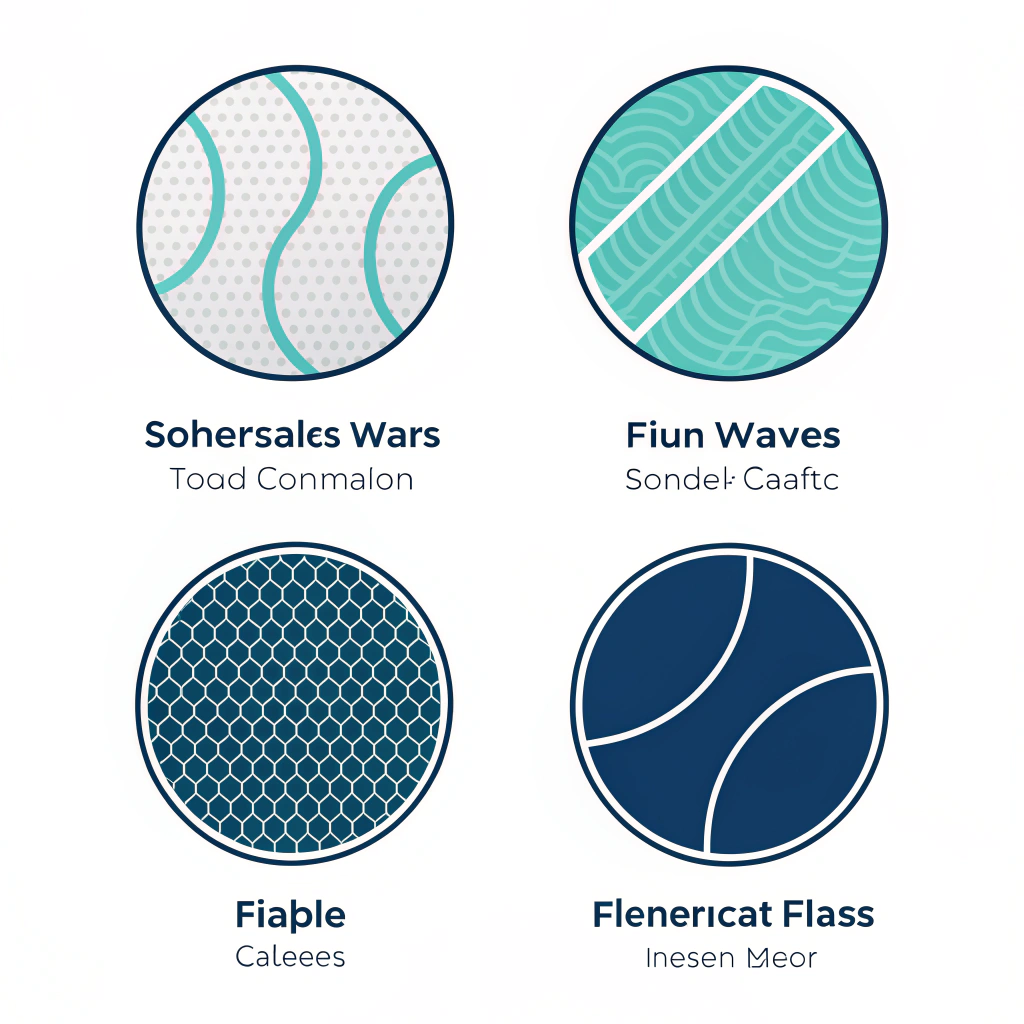

- Material: exact fiber type and weave (e.g., 3k twill carbon, 12k plain, 18k satin, or fiberglass). Ask for datasheets or sample swatches.

- Layup: number of layers, orientation, and use of hybrid layups (e.g., carbon + fiberglass).

- Core: EVA core type and Shore A hardness range. Ask for measured Shore A values and a compressive modulus if available.

- Weight: target grams and tolerance per unit (e.g., 360g ±5g).

- Balance: specify balance point measured from butt cap in mm (or state head-light / even / head-heavy with numeric center).

- Mold precision: allowed dimensional tolerance (request CMM reports5 or sample measurement).

- Surface finish and paint/printing method (UV print, pad print, transfer).

- Accessories and packaging: handgrip type, overgrip, tube balls, barcode/labeling, and packaging specs.

- Certifications: CE, REACH, or other market-specific certs.

Materials and performance: comparison table

| Material | Typical feel | Durability | Performance impact | Cost delta vs fiberglass |

|---|---|---|---|---|

| Fiberglass | Softer, more elastic | Good flex fatigue | More comfort, larger sweet spot, less power | Lowest |

| 3k carbon | Controlled stiffness, crisp feel | High strength | Balanced power/control, good value | Moderate |

| 12k carbon | Stiffer, firmer feel | Very good | More power, slightly less vibration damping | Higher |

| 18k carbon | High stiffness, premium feel | Excellent | Max power and precision, minimal flex | Highest |

Notes:

- Hybrid layups (carbon + fiberglass) are common for tuning feel and cost.

- Weave counts (3k/12k/18k) describe fiber bundle width and influence surface pattern, stiffness and price.

EVA core guidance (practical)

- Specify hardness by Shore A rather than subjective terms:

- Soft: ~30–40 Shore A — maximum comfort, slower response.

- Medium: ~40–55 Shore A — balanced feel for most players.

- Hard: ~55–70 Shore A — more rebound and power, less cushion.

- Also request density or compressive modulus when available; two cores at the same Shore A can behave differently.

- Provide a target rebound test (e.g., ball rebound height under defined drop test) or impact energy dissipation metric if your brand needs consistency.

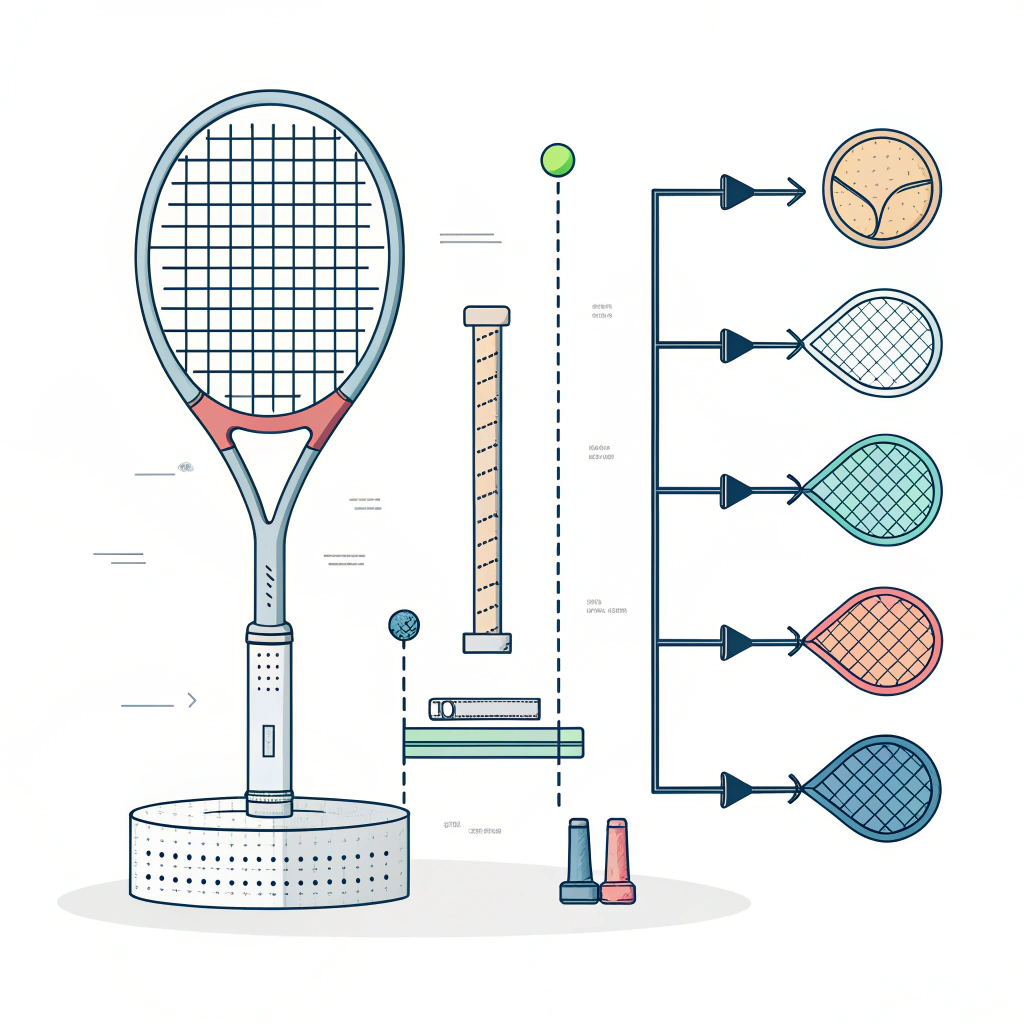

Weight, balance and sweet spot: what to ask for

- Weight: provide a table of SKUs with target weight and acceptance tolerance (e.g., SKU A 355 ± 5 g).

- Balance: request the measurement method (balance point by ruler/scale), the unit (mm from butt cap), and a tolerance band.

- Sweet spot: ask suppliers to provide internal layup notes that explain sweet spot placement (e.g., concentrated carbon patch in the sweet zone).

Practical weight/balance examples

- Control model: 345–355 g, head-light / balance < 260 mm.

- Allround model: 355–365 g, neutral balance ≈ 260–270 mm.

- Power model: 365–375 g, head-heavy / balance > 270 mm.

Mold precision, tooling and tolerances

- Request the following:

- Mold drawing and tolerance table.

- Typical dimensional tolerances for critical features (rim width, handle diameter, hole pattern). Ask for supplier’s CMM reports for sample parts.

- Warpage tolerance after demolding and post-curing.

- Suggested acceptance frame: ask supplier whether they can guarantee and measure to ±0.2–0.5 mm on critical dimensions — if they cannot provide CMM data, escalate.

Manufacturing and finishing: what matters commercially

- In-house vs outsourced processes: prefer suppliers that control core press, carbon layup and molding in-house for consistent layup quality.

- Printing: UV transfer or pad printing? Ask for color matching (Pantone), scratch and abrasion resistance reports.

- Edge tape and bumper: specify material and adhesion test requirements.

- Packaging: tube vs bulk; custom printed boxes; barcode and UPC needs.

Prototyping and lead times (typical guidance)

- Prototype timeline:

- First concept sample (visual/3D print): 3–7 days.

- Functional prototype with final layup and core: 7–21 days depending on complexity and tooling availability.

- Mass production lead time after sample approval: commonly 25–60 days depending on order size and factory schedule.

- MOQ: varies widely; typical OEM ranges 300–1000 pcs per SKU. Ask if the supplier offers lower MOQ for initial trial runs (NEX Padel notes faster sampling and flexible MOQ for brand partners).

QC & testing checklist (actionable)

- Pre-production:

- Raw material certificates: carbon/fiberglass datasheets, resin type.

- Core material certificate and Shore A test reports.

- Tooling verification: mold drawing + test coupon.

- During production:

- Per-unit weight and balance measurement — record into batch sheet.

- Visual inspection for surface defects, paint, printing alignment.

- Edge/bond integrity checks.

- Dimensional checks vs mold drawing (CMM spot checks).

- Post-production:

- Play tests: bounce test, sweet spot consistency across sample units.

- Durability tests: hammer/impact test, flex fatigue cycles (if required).

- Packaging inspection.

- Acceptance criteria (example table):

| Test | Method | Sample size | Acceptance |

|---|---|---|---|

| Weight | Digital scale | 5 pcs per 50 | Within ± specified tolerance |

| Balance | Balance beam/measure | 5 pcs per 50 | Within band (mm) |

| Surface finish | Visual & gloss meter | 5 pcs per 50 | No scratches / color ΔE ≤ 2 |

| Shore A core | Shore A durometer | 3 pcs per batch | Within specified range |

| Bonding | Pull/peel test | 3 pcs | No delamination under set load |

Questions to include in your RFQ (to differentiate suppliers)

- Do you manufacture molds in-house or outsource? Can you provide mold drawings and CMM reports?

- What exact carbon weaves do you offer (3k/12k/18k)? Provide prepreg/resin datasheets.

- What are your standard tolerances for weight and balance? How do you measure balance?

- Provide sample test reports: Shore A tests, impact/durability, play test feedback.

- What is MOQ per SKU and can you support pilot lots? Lead times for prototype and mass production?

- What QC checkpoints are standard? Can you perform third-party inspection?

- Can you do custom shapes beyond Diamond/Round/Teardrop? What’s tooling cost and lead time?

- Can you supply pressurized padel balls? What wool percentage options and packaging?

Case/data support (what to expect in practice)

- Switching from all-fiberglass to a 3k carbon face typically increases perceived stiffness and reduces flex, favored by intermediate players seeking more control.

- Producing 2 prototype revisions (different core hardness and carbon layup) before finalizing tooling reduces field returns by >50% for many brands.

- Asking for per-unit weight/balance logging during production helps maintain consistent feel across batches and reduces customer complaints.

Commercial implications (cost, lead time, tradeoffs)

- Higher carbon counts and premium prepregs increase unit cost but reduce weight and increase stiffness. Balance this with target player profile.

- Tighter tolerances (±2–5 g, ±0.2 mm) increase inspection time and rejection rates, so expect higher per-unit cost or longer lead time.

- Custom shapes raise tooling cost and sample iteration time but can give product differentiation; negotiate tooling amortization across MOQ.

Summary and recommended procurement actions (next steps)

- Prepare an RFQ template that includes: exact material specs (3k/12k/18k or fiberglass), EVA Shore A range, weight & balance targets with tolerances, mold tolerance requirements, printing/finish details, and required certifications.

- Shortlist 3 suppliers and request:

- Two functional prototypes with different layups (e.g., fiberglass + soft EVA; 3k carbon + medium EVA).

- Full material datasheets and one set of CMM/dimensional reports for a sample.

- Require a documented QC plan and per-unit weight/balance logging for the first production run.

- Validate performance with a small pilot order (low MOQ) and in-market player testing before scaling to full MOQ.

Why NEX Padel (how we help)

- We manufacture padel rackets with flexible layups from fiberglass to 3k, 12k, 18k carbon, fast prototyping, and OEM/ODM customization (shapes, printing, grips, logos).

- We support rapid sampling, consistent production, and QC controls — and supply pressurized padel balls (45% or 57% wool options) packaged in tubes for stable pressure retention.

- If you want measured samples, documented tolerances and a QC protocol for trials, request our RFQ template and sample checklist; we’ll respond with lead times and tooling costs.

People Also Ask

What makes a good padel racket?

- A good padel racket balances comfort, control and durability for the target player. For procurement, that means specifying materials (face weave and resin), EVA core hardness, weight and balance tolerances, and measurable QC tests. Playability is driven by layup and core; durability by material quality and mold precision.

What is the 40 40 rule in padel?

- The 40-40 rule (deuce) in padel means the next rally decides the game instead of playing advantage points. It speeds matches and increases the importance of consistency and control in racket feel — useful to consider when selecting rackets for competitive players.

Do expensive padel rackets make a difference?

- Price alone doesn’t guarantee better play; what matters is whether the racket’s materials, layup and tolerances match player needs. More expensive rackets often use higher-grade carbon, refined layups, and stricter QC, which can improve power and precision. For procurement, request specific material and test data to justify price differences.

-

3k/12k/18k carbon:Read to understand how weave count affects surface pattern, stiffness, weight and cost, so you can specify the right carbon count for desired power/control trade-offs. ↩

-

EVA core:Read to learn about different EVA formulations, density vs hardness trade-offs, and what test data (rebound, compressive modulus) to request so cores deliver consistent playability. ↩

-

Shore A:Read to learn how Shore A hardness is measured, why it’s more reliable than subjective terms, and how to specify acceptance ranges and sampling methods in RFQs. ↩

-

prepreg:Read to understand what prepreg is, how resin systems and prepreg quality affect cure, strength and surface finish, and what datasheets/cold-chain info to request. ↩

-

CMM reports:Read to learn what coordinate-measuring machine reports include, how to interpret tolerance tables and GD&T, and why CMM data reduces mold/fit issues in production. ↩