The efficient production of high-performance padel rackets for bulk orders relies on a robust manufacturing process, meticulous quality control, and flexible customization options to meet precise and timely delivery requirements.

Our industry faces unique challenges when it comes to large-scale procurement of padel rackets. From ensuring the right blend of materials such as carbon fiber1 and glass fiber to managing complex production timelines and customization, every step of the process must be scrupulously managed. In this comprehensive guide, we provide the procurement manager and sports equipment distributor with clear insights into how bulk orders for padel rackets are processed, the advanced manufacturing techniques employed, and our strict quality control measures that ensure reliability and performance.

Bulk orders present several logistical and technical challenges. First, there is the intricate coordination between various production stages—from raw material sourcing to crafting distinct padel racket shapes like Diamond, Round, and Teardrop. Second, there is significant demand for customization, from shape design to personalized printing and even logo placements on hand grips. Lastly, maintaining product integrity and high performance throughout the production run is paramount.

Our facility in Jiaxing, Zhejiang, leverages state-of-the-art technology to address these challenges. We craft our rackets using advanced production techniques that focus on precision engineering2. Every order is tailored to customer specifications and undergoes rigorous quality checks to ensure that each racket performs at its peak.

The quality of a padel racket is determined primarily by the materials used and the production process. The main materials we use include:

- Glass Fiber: Offers a reliable option for entry-level and mid-range rackets.

- 3k, 12k, and 18k Carbon Fiber: Provide varying degrees of strength, weight reduction, and responsiveness. Higher carbon counts typically equate to superior precision and durability, making them ideal for high-performance applications.

To clearly compare these materials, consider the following table:

| Material Type | Features | Customization Options |

|---|---|---|

| Glass Fiber | Cost-effective, moderate durability | Limited custom printing |

| 3k Carbon Fiber | Lighter weight, increased strength | Custom shape, color, and slight performance tweaks |

| 12k Carbon Fiber | Enhanced balance between strength and weight | Full design customization, acceptable for multiple play styles |

| 18k Carbon Fiber | Superior strength, optimal strength-to-weight ratio | Maximum customization including hand grips and handle caps |

This table provides a quick reference for procurement managers to evaluate the different materials according to their specific needs.

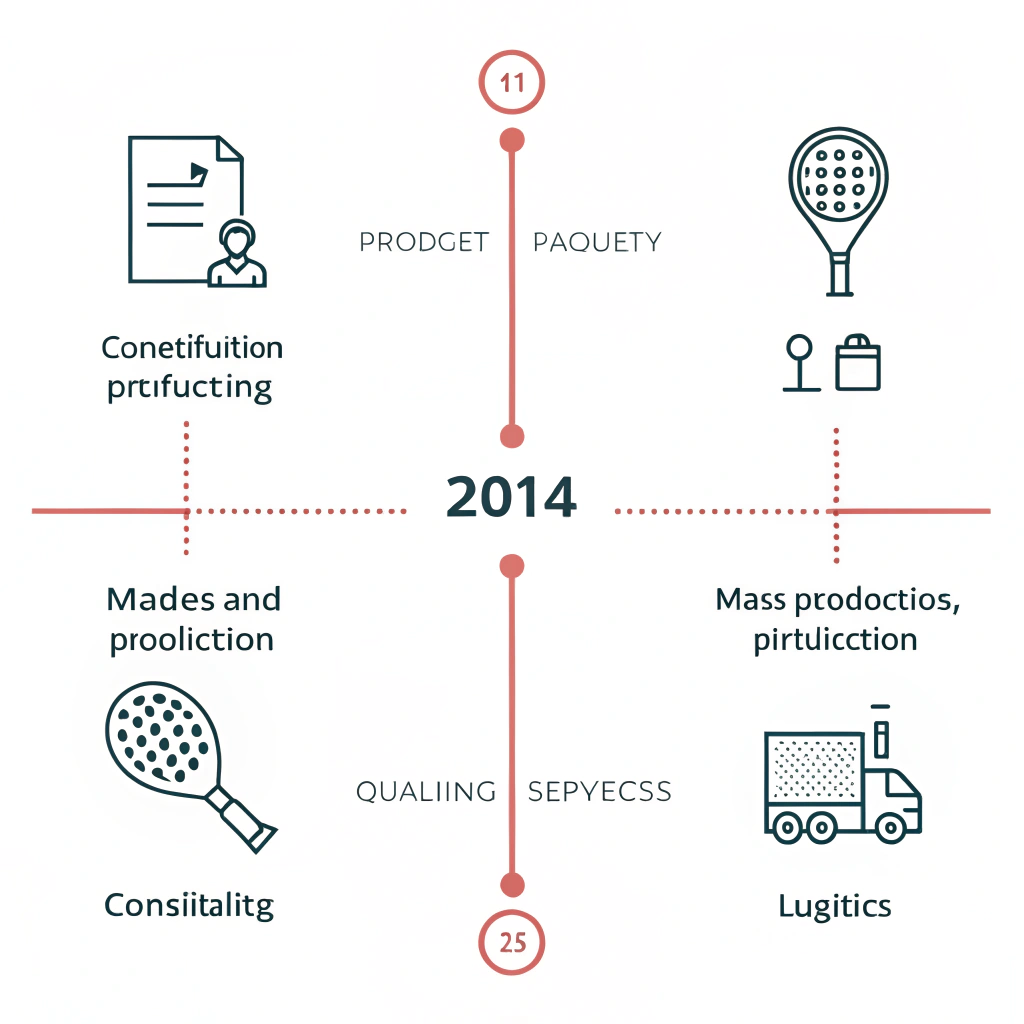

A detailed and methodical approach is essential when handling bulk orders. Below, we present a step-by-step breakdown of our manufacturing process:

-

Initial Consultation and Customization Confirmation:

- Procurement managers engage with our expert team to outline specifications including racket shape (Diamond, Round, Teardrop) and required materials.

- Order details such as custom printing, color schemes, and logo placement on hand grip or handle cover are finalized.

- We discuss production timelines, sample approvals, and quality benchmarks.

-

Prototype Development and Approval:

- Once customization parameters are confirmed, we develop prototypes using the selected materials.

- Rapid prototyping3 enables fast sample production. The samples are tested for durability, balance, and overall performance.

- Procurement managers are encouraged to review these samples and provide feedback for any final adjustments.

-

Mass Production Phase:

- Production is initiated after sample approval. Our advanced machinery, leveraging automation and precision calibration, ensures that every padel racket meets strict industry standards.

- We operate under continuous quality control protocols, conducting regular inspections at key production milestones. This includes verifying the integrity of the carbon fibers (whether 3k, 12k, or 18k), ensuring accurate customization, and confirming that design specifications are met.

-

Quality Assurance and Testing:

- Each batch undergoes comprehensive testing to simulate playing conditions. Key performance indicators such as vibration dampening, weight consistency, and impact resistance are carefully monitored.

- Our quality assurance team documents every detail, ensuring that any deviation from expected outcomes is immediately corrected.

-

Logistics and Timely Delivery:

- After final inspections, the rackets are packed using secure logistics methods. We maintain strong relationships with global logistics partners to ensure timely delivery4.

- Our integrated supply chain5 management system allows tracking of every order, with real-time updates available for procurement managers.

- The entire process is designed to ensure that bulk orders are delivered on schedule, reducing risks and delays.

A summarized view of our bulk order process is provided below:

| Process Stage | Key Actions | Outcome |

|---|---|---|

| Consultation & Customization | Define specifications, custom printing, and overall design details | Clear order brief |

| Prototype Development | Rapid sample production and testing | Validation of concept |

| Mass Production | Automated and precision-controlled manufacturing | High-volume quality production |

| Quality Assurance | Continuous monitoring, performance testing, and certification | Consistent high standards |

| Logistics | Secure packaging and reliable transportation | Timely, on-schedule delivery |

This systematic approach helps to minimize errors and ensures each bulk order meets the high-performance standards expected in the sport.

Our production process is optimized to meet the rapid turnaround times required by our clients, without compromising on quality. Here are some key aspects that contribute to our efficiency:

- Rapid Prototyping: Our quick-hitting sample process enables us to finalize designs faster.

- Customized Production Lines: We maintain specialized lines for different materials and customization levels, ensuring maximum efficiency.

- Scalable Operations: Whether a small batch or a full-scale production run, our operations are scalable, facilitating smooth transitions between order sizes.

- Integrated Supply Chain: Our supply chain is designed to manage large-scale orders with minimal interruptions. Collaboration with globally distributed logistics partners ensures that raw materials and finished products flow seamlessly through each production stage.

By maintaining clear communication channels and detailed project timelines, we significantly reduce the risk of delays, which is a common concern among large-scale order buyers. Our experience with well-known brands such as Hirostar, Reebok, and Starvie underlines our capability in managing complex orders reliably.

Quality is a non-negotiable requirement when it comes to producing performance gear. Our rigorous quality control measures include:

- Material Verification: Each material, whether carbon fiber or glass fiber, is verified against industry standards on arrival and before production.

- Process Audits: Regular audits ensure that each production step adheres to our stringent protocols.

- In-Process Testing: Specialized tests simulate playing conditions and check critical parameters like anti-vibration features and power zones.

- Final Product Testing: Before shipment, rackets undergo final examinations to ensure they meet performance, durability, and design specifications.

The commitment to quality not only ensures that the products perform optimally but also builds trust with our B2B partners, providing the assurance that every unit delivered lives up to the brand promise of high performance.

Procurement managers often inquire about the cost-effectiveness of high-performance padel rackets. It is important to understand that the value lies not only in the immediate purchase price but in the overall longevity and performance of the equipment.

- High-Quality Materials: While carbon fiber1 options may come at a premium, they offer a significant performance advantage compared to economical glass fiber alternatives. Carbon fiber enhances durability, responsiveness, and overall playability, which is essential when performance is a priority.

- Customization and Branding: The ability to customize not just the racket design but also peripheral elements like hand grips and printed logos adds value through brand differentiation. For companies looking to strengthen their market presence, these tailored products serve as a strategic tool.

- Long-Term Durability: Although high-performance rackets may require a higher upfront investment, their lifespan and consistent performance translate into long-term savings as they do not need frequent replacement.

Our experienced team is dedicated to striking a balance between cost and performance, offering competitive prices for premium products that excel in both playability and durability. Transparent costing and a clear explanation of production timelines help decision makers make informed purchasing decisions.

For procurement managers ready to place a bulk order, the following steps can ensure a smooth process:

- Schedule an initial consultation to outline your specifications.

- Request sample production to validate customization options and material performance.

- Review our detailed production timeline and quality control measures.

- Confirm logistics arrangements to align with your inventory cycles.

- Engage in open communication for real-time updates throughout the production process.

By following these steps and partnering with a manufacturer who values precision and timely delivery, procurement managers can confidently secure high-performance padel rackets that reinforce brand reputation while meeting customer expectations.

People Also Ask

Q: What makes padel rackets so expensive?

A: High-performance padel rackets often use premium materials like carbon fiber1 that enhance strength, reduce weight, and boost responsiveness. These rackets also incorporate advanced technologies such as anti-vibration systems and optimized power zones, which further justify their higher cost compared to those using cheaper materials like fibreglass.

Q: What is the lifespan of a padel racket?

A: A padel racket typically sees a performance drop after approximately 100-150 games. However, the exact lifespan depends on the frequency of use and maintenance, with daily play potentially reducing the effective lifespan to around 4-6 months before noticeable wear occurs.

Q: How much should I pay for a padel racket?

A: For beginner players, a padel racket priced between £50 and £100 is usually adequate. This range offers reliable performance for entry-level play, ensuring ease of use and the necessary features while you grow your skills.

-

carbon fiber: Click to learn how carbon fiber production, its material properties, and usage in high-performance sporting goods contribute to improved durability and lightweight design. ↩ ↩ ↩2 ↩3

-

precision engineering: Click to understand how precision engineering enhances product consistency and performance through advanced manufacturing techniques. ↩ ↩

-

rapid prototyping: Click to discover the role of rapid prototyping in accelerating product development cycles and reducing time-to-market for customized orders. ↩ ↩

-

timely delivery: Click to read more about the logistics strategies and global partnerships that ensure products are delivered on schedule without compromising quality. ↩ ↩

-

integrated supply chain: Click to explore how an integrated supply chain management system optimizes production flow, minimizes disruptions, and ensures real-time tracking of orders. ↩ ↩