High-performance control carbon padel rackets provide enhanced precision, stability, and extensive customization options that meet the needs of today's adult players. In this article, we explore the technical intricacies, material differences, and production techniques that make these rackets ideal for competitive play and a smart purchase for B2B sports equipment distributors.

Introduction and Market Context

The modern padel market demands high-performance equipment that combines innovation, durability, and versatility. As a leading manufacturer specializing in high-performance padel rackets, we at NEX Padel have honed our expertise in crafting rackets using advanced production techniques. Our rackets are built with carefully selected materials—from fiberglass1 to 3k, 12k, and 18k carbon fiber2—ensuring each product performs at the highest level while offering customizable options. For procurement specialists and product managers in sporting goods distribution, understanding the benefits of control-focused rackets can lead to better purchasing decisions and market positioning.

Challenges in Padel Racket Manufacturing and Material Selection

The padel racket manufacturing process involves addressing several key challenges:

• Achieving the right balance between weight and stability

• Ensuring material integrity and consistent performance under various play conditions

• Integrating advanced production techniques like precision molding3 and layer alignment

• Meeting commercial demands for product customization

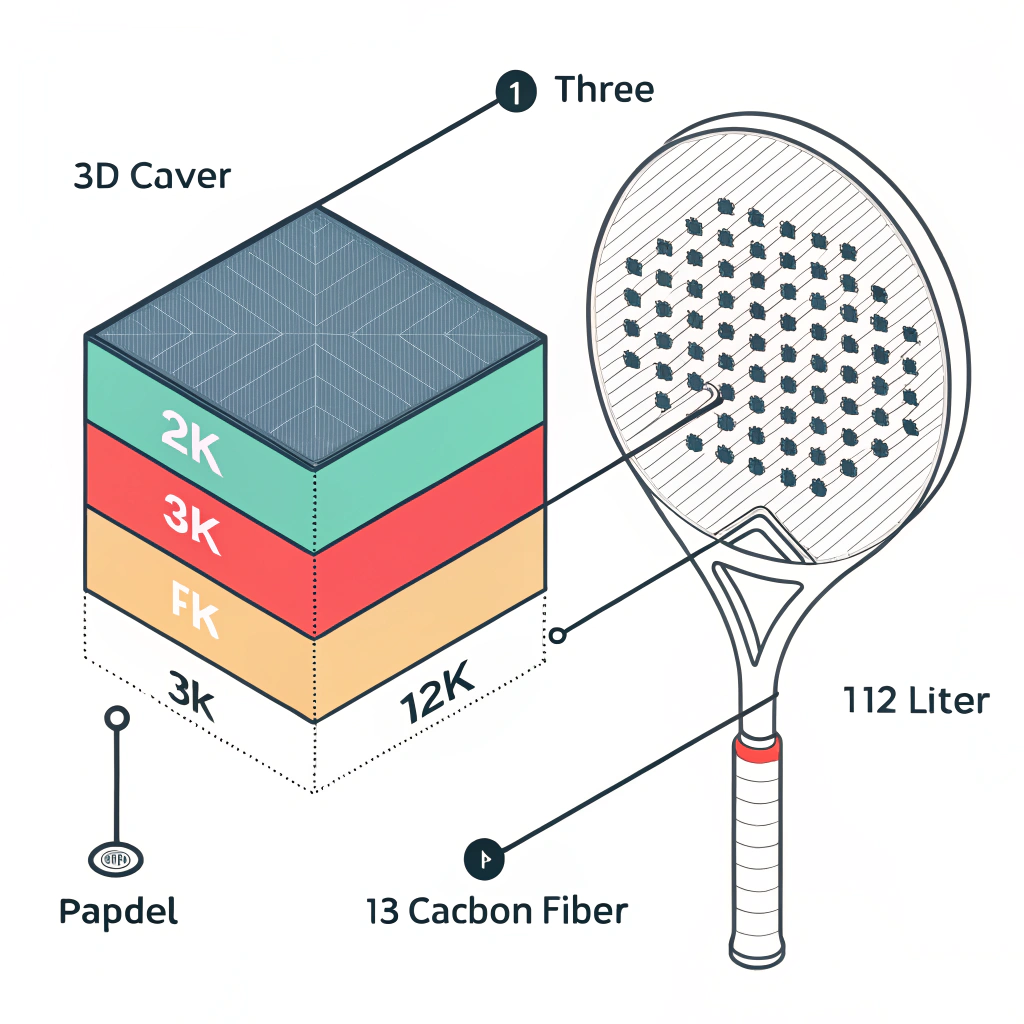

These challenges become critical when designing a control-oriented carbon padel racket. Such rackets require a meticulous combination of material grade selection and precise manufacturing processes to deliver consistent control and responsiveness during high-intensity gameplay. In this context, each material variant (3k, 12k, 18k carbon fiber) offers unique benefits that influence the racket’s performance, cost profile, and customization potential.

Understanding Material Grades: 3k, 12k, and 18k Carbon Fiber

When evaluating padel rackets, material grade plays a decisive role in performance:

• 3k Carbon Fiber: This grade is generally lighter and provides higher elasticity. It is ideal for players who emphasize agility and quick reaction times without sacrificing power.

• 12k Carbon Fiber: Offering a balanced performance, 12k carbon fiber combines rigidity with flexibility. This grade is suitable for players requiring a mid-level balance between control and power.

• 18k Carbon Fiber: Known for its stiffness and durability, 18k carbon fiber is best suited for precision control. Players who rely on steady ball control and minimal vibration often prefer this material.

To help decision-makers quickly compare these options, consider the following table:

| Material Grade | Weight & Flexibility | Impact on Control | Ideal for Player Type |

|---|---|---|---|

| 3k Carbon Fiber | Lightweight, high elasticity | Moderate control with enhanced agility | Quick, agile play style |

| 12k Carbon Fiber | Balanced weight and rigidity | Consistent control with balanced power | Versatile techniques |

| 18k Carbon Fiber | Stiffer, heavier | Maximum precision and control | Control-oriented players |

Understanding these differences helps procurement specialists match product specifications to market demand and target specific customer segments effectively.

Customization and Production Techniques for Advanced Padel Rackets

Customization is a major trend in the sporting goods industry today. High-performance padel players often seek equipment that reflects their personal playing style and brand identity. Our rackets are available in three primary shapes—Diamond, Round, and Teardrop—each designed to offer distinct control dynamics and power distribution. Moreover, full customization is supported, including personalized shape modifications, logo printing on the racket frame, custom color schemes, and even bespoke hand grip designs.

Key aspects of our customization process include:

- Precision production techniques ensuring dimensional accuracy

- Advanced printing technology for vibrant, long-lasting logo and color applications

- Flexible order size management, enabling both small-batch orders and large-scale production runs

- Quality control measures that monitor every step from raw material selection to final packaging

Our commitment to rapid prototyping4 and on-time delivery further enhances our appeal to B2B clients, ensuring short lead times without compromising quality. For example, when working with brands like Hirostar, Reebok, and Starvie, we consistently deliver products that meet and exceed high industry standards.

A simplified flow of our production process is as follows:

| Step | Activity | Quality Assurance Focus |

|---|---|---|

| Material Selection | Sourcing high-grade carbon fiber and fiberglass | Supplier vetting and material tests |

| Design & Prototyping | Using CAD and rapid prototyping techniques | Precision modeling and performance simulation |

| Customization Options | Offering bespoke printing and engraving options | Color matching, durability assessments |

| Final Assembly & Testing | Assembling components and rigorous performance tests | Vibration damping and control consistency |

| Packaging & Delivery | Secure packaging and timely delivery scheduling | Compliance with delivery schedules |

This systematic approach ensures that every product meets the rigorous standards expected in competitive padel while providing flexibility for market-specific customization.

Balancing Performance, Control, and Durability

Control in a Padel racket is not just about material properties—it also involves the design of the racket head, grip, and overall balance. A control-oriented padel racket should offer:

• Enhanced maneuverability to facilitate rapid directional changes

• Vibration dampening to minimize shock during ball impact, ensuring player comfort

• A stable yet flexible framework for precise ball placement

• Customizable grip options to suit various hand sizes and playing styles

From an engineering perspective, these factors are achieved by fine-tuning the racket’s center of gravity and optimizing the distribution of mass within the frame. A strategic placement of high-density carbon fiber in the racket’s core significantly improves control by reducing unwanted flex and vibration. Moreover, integrating layered composite structures allows the balance between stiffness and flexibility to be adjusted to meet specific playing conditions.

Our technical team continuously monitors these parameters during production, using data-driven methodologies to adjust the layering and resin infusion processes. This attention to detail guarantees that every unit not only performs consistently but also meets the evolving expectations of high-level competitive play.

Quality Control and Data-Driven Production

The production of high-performance padel rackets involves a robust quality control5 system designed to catch and correct any deviations early in the manufacturing process. Our quality assurance practices include:

• Material testing for tensile strength and durability

• On-line inspection during production to monitor layer alignment

• Vibration and impact tests to evaluate shock absorption and control capabilities

• Final inspection procedures to ensure visual and structural consistency

Using data-driven insights and real-time testing results, our production teams can swiftly address issues, maintaining a high standard for each batch produced. This rigorous quality control framework ensures that every padel racket released into the market delivers both reliability and exceptional performance, thereby reinforcing our reputation among industry leaders.

Comparing Racket Types: Applications and Usage Scenarios

When discussing padel rackets, it is crucial to compare the three main racket shapes available: Diamond, Round, and Teardrop. Each design offers a unique playing experience suited to different skill levels and tactical preferences.

• Diamond-shaped rackets emphasize power and control. Their design is optimal for players who prefer an aggressive style of play. They are generally more balanced toward advanced users who have experienced the nuances of high-performance padel.

• Round-shaped rackets are tailored for beginners to intermediate players. Their enhanced sweet spot and forgiving design provide ease of play, making them ideal for players seeking a blend of power and control without the steep learning curve.

• Teardrop-shaped rackets offer a compromise between control and power. They provide a more central balance point, catering to players who need versatility in their game strategy.

A comparative side-by-side review can aid procurement specialists in understanding which product line aligns with their target customer segment. For instance, advanced players favoring control carbon rackets might lean toward the Diamond or Teardrop versions built using 18k carbon fiber, while a broader market may require a range of options to cover various skill levels.

Market Trends and Strategic Recommendations

The demand for high-performance, customizable sporting goods is on the rise. As competitive padel gains popularity globally, distributors face increased pressure to offer the latest in innovative equipment. Here are key trends influencing the market:

- Customization: Retailers increasingly seek products that reflect unique brand identities and cater to specific player needs. Offering customization on key elements—like racket shape, color, and grip—provides a vital competitive edge.

- Quality and Consistency: With players demanding high levels of performance, maintaining consistent quality through rigorous production and testing is essential.

- Material Innovation: Ongoing research into composite materials and production techniques continues to drive advancements in racket performance, particularly in terms of control and durability.

For procurement specialists, considering these trends means investing in products that not only satisfy immediate performance needs but also position your portfolio for long-term market leadership. By choosing suppliers like NEX Padel, who combine technical expertise, innovative customization options, and strict quality control measures, companies can ensure a superior product offering that meets both current and future market demands.

Conclusion and Call to Action

In summary, control-oriented carbon padel rackets offer the precision, stability, and versatility that adult competitive players demand. With advanced production processes, a range of material grades, and extensive customization options, these rackets are uniquely positioned to meet the diverse needs of sporting goods distributors. The ability to adapt product specifications—from the shape to the carbon fiber grade—ensures that every unit delivers optimal performance and durability.

For procurement specialists and product managers evaluating new suppliers, NEX Padel represents a trusted partner committed to quality, speed-to-market, and innovative product solutions. Embracing these advanced rackets not only addresses the technical requirements of high-level play but also supports a strong market strategy that can elevate your brand and satisfy end-user expectations.

We invite you to explore our comprehensive range of products and experience the benefits of partnering with a manufacturer that prioritizes precision and customer success. Reach out to our team for further information or to request a sample, and let us help you drive your market success with cutting-edge padel equipment.

People Also Ask

Q1: What factors influence the performance of a carbon fiber padel racket?

A1: Key factors include the material grade (3k, 12k, 18k), the racket design (Diamond, Round, Teardrop), and the precision in manufacturing that ensures proper weight distribution and vibration control.

Q2: How does customization benefit padel racket performance?

A2: Customization allows manufacturers to adjust shape, grip, and material layering to match specific playing styles, thereby improving control, enhancing player comfort, and providing a unique product tailored to precise market demands.

Q3: What role does quality control play in ensuring high performance?

A3: Quality control involves rigorous testing of materials, real-time production monitoring, and final product inspection, which together ensure consistent performance, durability, and precision in every padel racket produced.

-

fiberglass: Reading this article will provide insights on the material properties and manufacturing benefits of using fiberglass in sports equipment production. ↩ ↩

-

carbon fiber: Reading this article will offer a detailed understanding of carbon fiber grades and how each impacts strength, weight, and performance in sporting goods. ↩ ↩

-

precision molding: Reading this article will explain the precision molding process and its role in achieving high-quality, dimensionally accurate padel rackets. ↩ ↩

-

rapid prototyping: Reading this article will explore rapid prototyping techniques that help in reducing product development time while ensuring innovation and market agility. ↩ ↩

-

quality control: Reading this article will provide an overview of quality control methods and their importance in maintaining high standards in the production of sporting equipment. ↩ ↩