In today’s high-performance sports equipment market, a control padel racket is defined by its round shape, low balance, and finely engineered sweet spot1. This article explores why selecting the right control padel racket is critical, the technical nuances behind design and material choices, and how partnering with a high-precision manufacturer like NEX Padel can support your custom procurement needs.

The padel market is evolving rapidly, and control rackets have emerged as a key solution for players who value precision and responsiveness on the court. For procurement managers and product developers, understanding the engineering principles and production techniques behind these rackets is fundamental before committing to a supplier. The challenges lie not only in balancing performance aspects but also in ensuring manufacturing consistency, material quality, and customization capabilities.

A key challenge in the padel industry is aligning game performance with robust production capacities. Many players find themselves torn between rackets designed for power and those optimized for control. While power rackets typically feature a diamond shape with head-heavy balance to generate forceful strokes, control rackets focus on stability and maneuverability. Players with a blend of defensive and tactical play styles benefit from control rackets because of their evenly distributed weight and enhanced handling attributes. For a distributor, ensuring that a supplier’s manufacturing process can consistently deliver such precision is paramount.

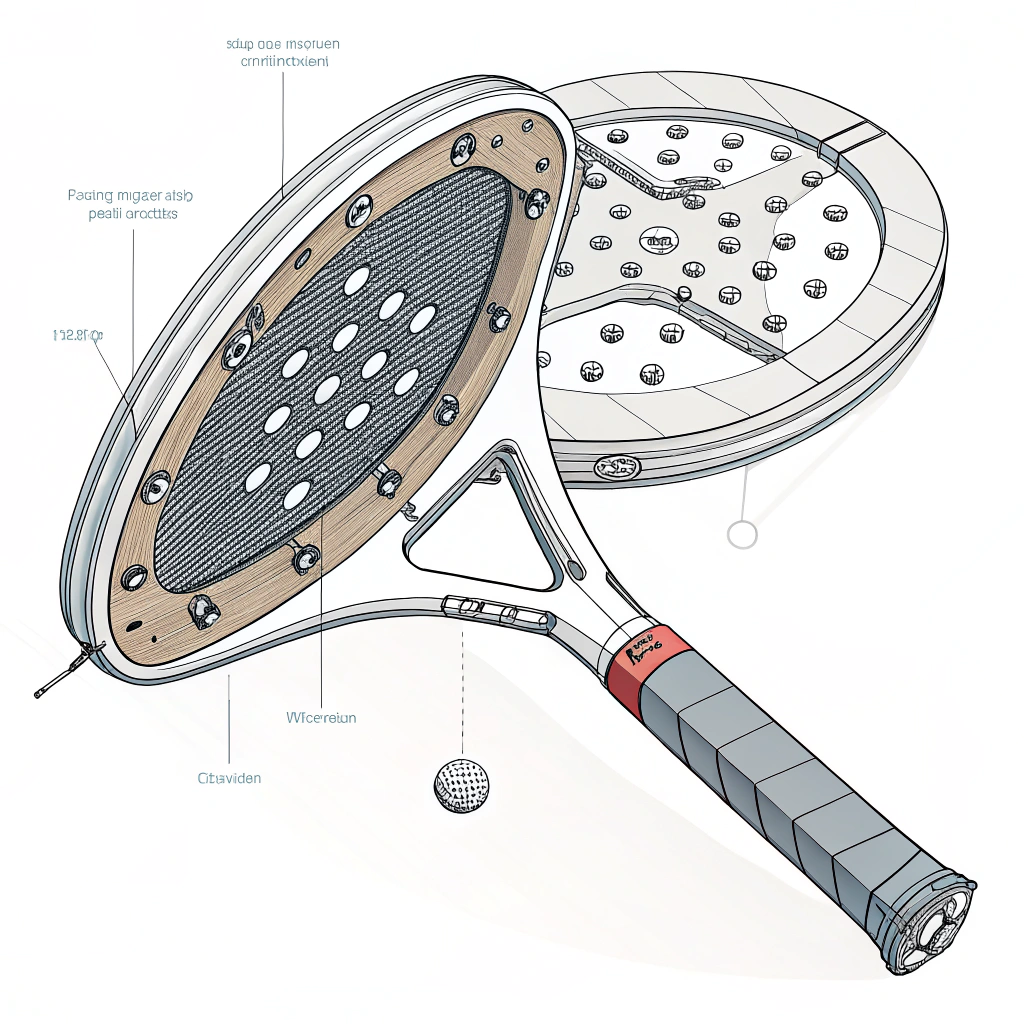

From a production standpoint, control padel rackets involve detailed material selection and precision engineering. Manufacturers such as NEX Padel leverage advanced production techniques and high-quality materials, including fiberglass and various grades of carbon fiber2 (3k, 12k, and 18k), to tailor the performance attributes of the rackets. These materials are not only chosen for their performance benefits but also for their durability in high-impact play. The round shape, typically associated with control rackets, provides a centralized weight distribution, enhancing player control and maneuverability. This becomes especially important for OEM partnerships3 where customized design is a deciding factor.

Let’s break down the production elements and quality assurances that make control padel rackets a reliable choice:

-

Material Composition:

• Fiberglass – Often used in the initial prototypes and mid-tier options for its flexibility and cost-effectiveness.

• 3k, 12k, 18k Carbon Fiber – These variations in carbon fiber technology allow customization of stiffness, weight, and durability to optimize control performance. -

Design Customization:

• Shapes – Control rackets are often manufactured in a round shape, which offers a lower balance point compared to diamond-shaped power rackets.

• Customization Options – Manufacturers provide full shape customization, including the option for custom prints, color schemes, and hand grip personalization such as logo placements. -

Production Techniques:

• Precision Manufacturing4 – Advanced techniques ensure that each racket meets tight tolerances, which is essential for controlling the sweet spot and overall response during play.

• Rapid Prototyping5 & Quick Sampling – A high-performance supplier can quickly adjust design features based on feedback from OEM partners, ensuring timelines are met without sacrificing quality. -

Durability Testing:

• Lab Testing – Ensuring high-quality production through stress tests and performance validation.

• Field Trials – Many suppliers use real-world trials to ascertain that the design delivers the intended control performance in play conditions.

To help you make a well-informed purchasing decision, the table below compares key attributes of three main types of padel racket shapes that influence control performance:

| Racket Shape | Balance & Weight Distribution | Material Usability | Customization Capabilities | Recommended For |

|---|---|---|---|---|

| Round | Central balance, low weight | Fiberglass, various carbon fiber grades | High (logo, grip, color) | Players needing precise control and maneuverability |

| Diamond | Head-heavy, power-focused | Predominantly high-grade carbon fiber | Moderate customization | Players seeking maximum stroke power and follow-through |

| Teardrop | Hybrid balance | Mix of fiberglass and carbon fiber | Extensive (custom shapes and prints) | Players who desire a mix between control and power |

This table serves as a quick comparison guide for procurement managers who need to evaluate performance requirements against cost and production capabilities.

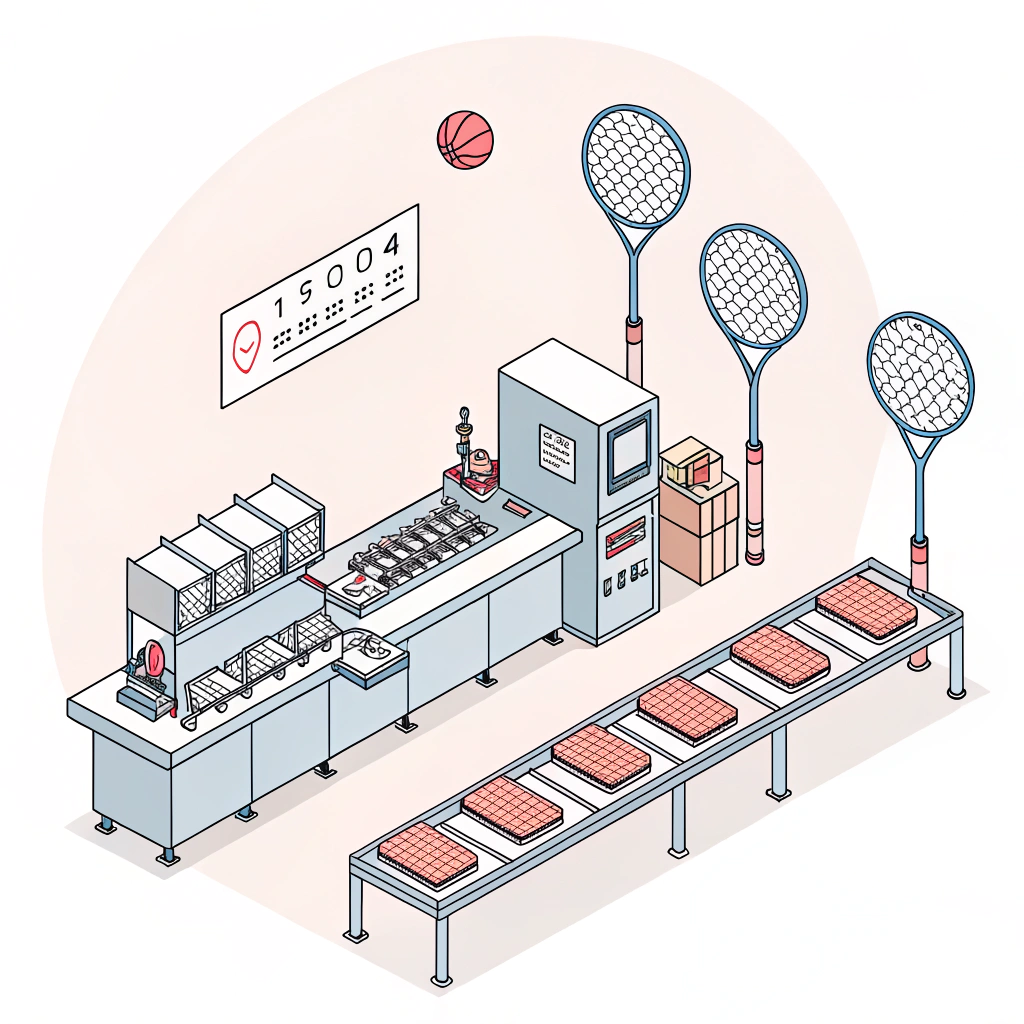

For sports equipment distribution companies, making a strategic decision means partnering with manufacturers who understand both the technical and market aspects. At NEX Padel, we bring decades of expertise in precision manufacturing and custom design solutions to the table. Our collaboration with market leaders like Hirostar, Reebok, and Starvie underscores our commitment to quality and performance consistency. Tailoring our production processes to meet the stringent standards required for control padel rackets, we ensure that every piece from our factory passes rigorous quality control tests before shipment.

An important element in mitigating risk when investing in padel equipment is understanding how production techniques translate into real-world performance on the court. Consider these production best practices:

• Integrated Quality Checks: Our manufacturing includes multi-stage quality assessments using both automated and human inspection. This procedure ensures that the final product not only meets the specified design parameters but also maintains a consistently high performance across all orders.

• Timely Delivery & Rapid Prototyping: Quick sampling and flexible production schedules are crucial. For instance, when a new market trend emerges, our ability to quickly adjust the design without compromising on material quality is a competitive advantage.

• Customization & Branding Options: In the competitive landscape of padel sports, brand differentiation is key. With options like custom hand grips and racket covers, companies can ensure their products reflect their unique identity while still enjoying the performance benefits of our control design. This flexibility is essential for aligning with individual and regional market preferences.

By ensuring that each padel racket is tailored to the player’s unique style and technical needs, manufacturers can offer a performance edge that attracts both new and experienced players. Advancements in design coupled with precision manufacturing techniques create a product that is not just an equipment choice, but a strategic asset for sports clubs and distribution channels.

Furthermore, industry data shows that players who choose control-oriented rackets report fewer instances of mishits due to the centralized sweet spot. For distributors, emphasizing features such as weight distribution and material quality in technical literature can help develop consumer trust. Peer reviews and performance analyses are significant factors influencing buying decisions. With NEX Padel’s established track record, you gain not only reliable products, but also a partner who understands the evolving needs of today's padel players.

In summary, a control padel racket is engineered to offer a remarkable balance between precision and responsiveness. With its round shape and centralized weight, it is ideal for players demanding ease of manipulation and a large sweet spot. From material composition utilizing advanced carbon fiber technology to extensive customization options, these rackets meet the high standards for performance and durability demanded by the competitive padel market.

For procurement managers seeking to balance innovation with cost-effectiveness, our approach at NEX Padel ensures that every product is a fine blend of engineering excellence and market insight. By integrating rigorous production processes with flexible, client-centric design options, we help you secure a consistent supply of high-performance equipment that enhances player satisfaction and market competitiveness.

We invite you to explore our custom design capabilities further and see how our commitment to quality and rapid production timelines can support your next procurement project. With detailed quality control, proven manufacturing expertise, and a rich portfolio of OEM partnerships, NEX Padel is uniquely positioned to be your trusted supplier in the world of high-performance padel equipment.

People Also Ask

• What is a control padel racket?

A control padel racket is typically a round-shaped racket characterized by a low balance and a large sweet spot. This design makes the racket easier to handle and ideal for both beginners and advanced players who need precision control.

• What is the difference between control and power padel racquets?

Control padel racquets focus on balanced weight distribution and maneuverability, typically with a round shape and a grip-centered weight. In contrast, power racquets usually have a diamond shape with a head-heavy balance designed to enhance stroke force.

• Which NOX padel racket is best for control?

For players seeking optimal control, models like the Equation Light and certain versions of the ML10 Pro Cup Series are highly recommended. These rackets provide a balance between precise control and comfortable play, making them ideal for users who demand both control and ease of play.

-

sweet spot: Click to read more about how optimizing the sweet spot can enhance performance by maximizing both power and control in sports equipment. ^Return ↩

-

carbon fiber: Click to learn about the properties of carbon fiber, its different grades, and its critical role in producing high-performance sports equipment. ^Return ↩

-

OEM partnerships: Click to understand how OEM partnerships work, their benefits in custom manufacturing, and strategies for successful B2B collaborations. ^Return ↩

-

Precision Manufacturing: Click to explore the advanced techniques behind precision manufacturing and how they ensure consistent, high-quality production in the sports equipment industry. ^Return ↩

-

Rapid Prototyping: Click to discover the benefits of rapid prototyping in reducing design cycles, improving product quality, and accelerating time-to-market in manufacturing. ^Return ↩