In today’s rapidly evolving sports equipment market, selecting the right padel racket is crucial for distributors seeking to offer high-performance, quality products. This guide quickly clarifies that the best choice is one backed by proven production precision, innovative customization1 options, and reliable supply chain management2—qualities that NEX Padel consistently delivers.

Padel equipment purchasers face a complex decision-making process. With numerous racket designs, materials, and customization features across the industry, understanding the underlying factors behind racket performance can seem overwhelming. This article explains the challenges, analyzes the technical aspects, and outlines clear actionable solutions to help you choose the best padel racket for your portfolio.

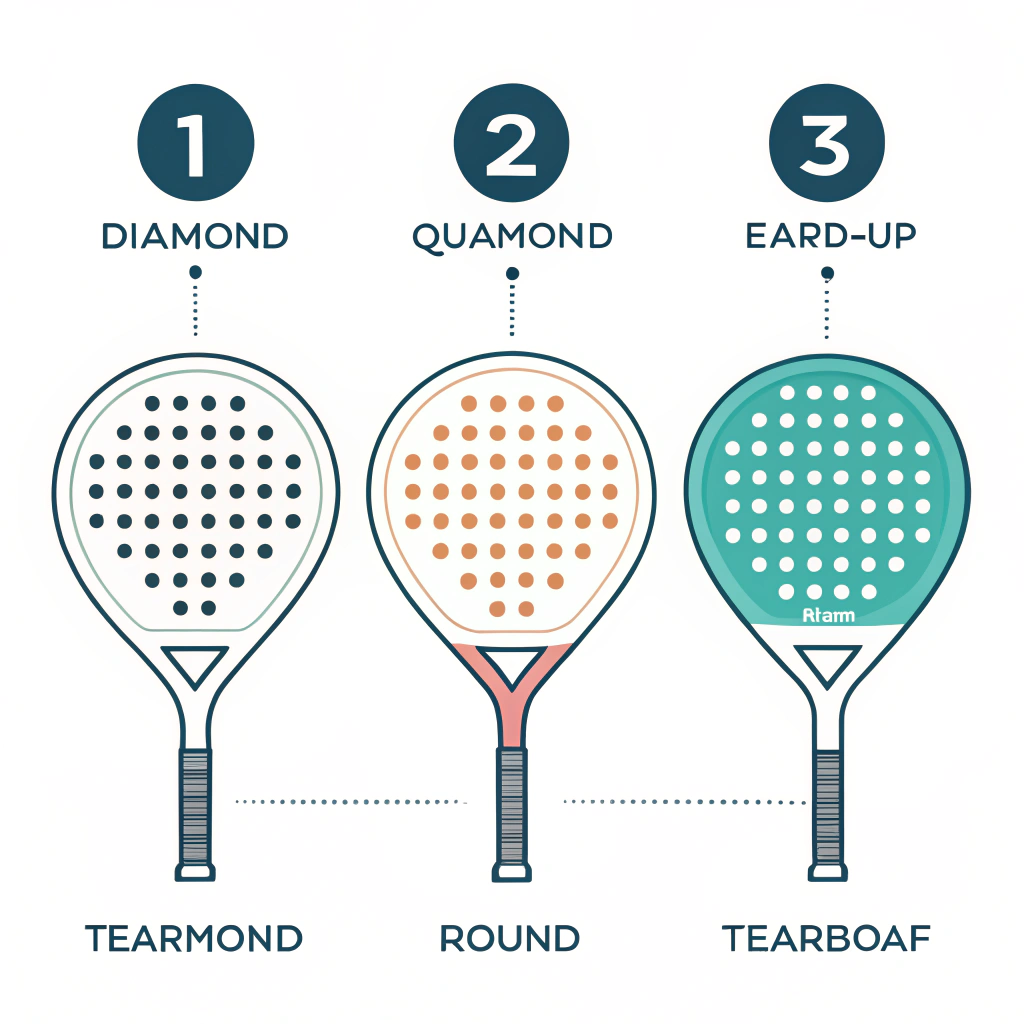

The primary challenges in choosing the ideal padel racket include understanding the nuances of construction materials, design shapes, and the benefits of customization. Many manufacturers offer similar products on the surface, yet the technical details such as the type of carbon fiber3 (3k, 12k, 18k), the use of fiberglass, and the specifics of design shapes like Diamond, Round, and Teardrop can make a significant difference in performance and durability. Moreover, efficient rapid prototyping4 and precision manufacturing5 are essential to ensuring product consistency in large volume orders.

The complexity arises largely due to the following reasons:

- The variety of material options and their associated performance metrics.

- The impact of design shape on the racket’s balance, sweet spot, and handling.

- The trade-offs between customization options and production scalability.

- Rapid prototyping processes that affect delivery timelines and supply chain reliability.

Understanding these challenges is the first step toward making informed procurement decisions.

To address these challenges, consider the following solution checklist when evaluating padel rackets:

-

Evaluate Material Quality and Manufacturing Process

• Check if the racket utilizes advanced production techniques with proven quality control.

• Compare the types of materials used, such as fiberglass versus various grades of carbon fiber (3k, 12k, 18k), ensuring the chosen material aligns with your performance expectations and price point. -

Examine Design and Performance Specifications

• Look closely at the design shape: Diamond, Round, or Teardrop, as each impacts playing style differently.

• Assess the balance between power, control, and maneuverability.

• Consider customization capabilities such as printing, logo branding, and tailored hand grip design. -

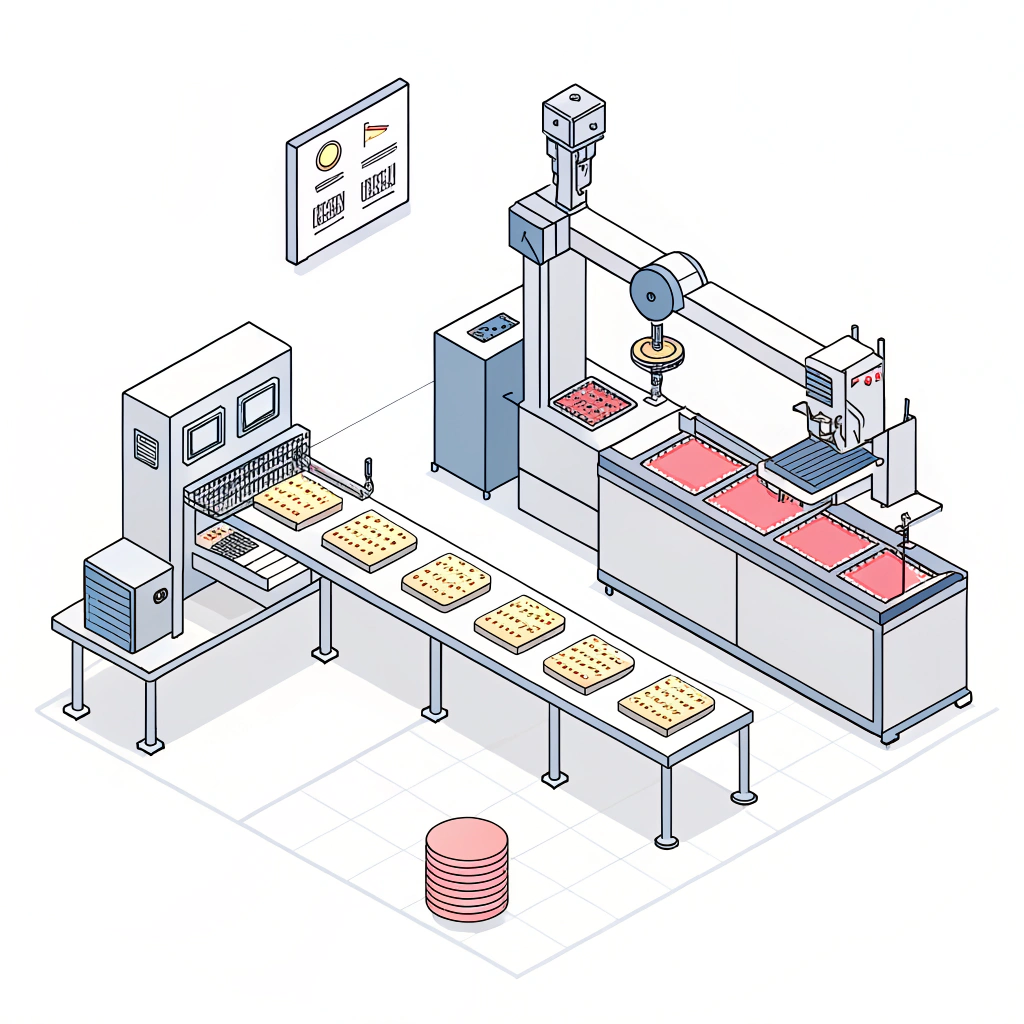

Assess Supply Chain Reliability and Rapid Prototyping

• Confirm that the manufacturer has a proven track record of fast prototyping and timely delivery.

• Ensure there is transparent quality control and adherence to production standards. -

Compare Technical Specifications with Industry Benchmarks

• Verify performance data against industry standards and real-world usage reports from professional associations or well-known brands.

Below is a table that summarizes the core features to compare:

| Feature | Key Considerations | Benefits |

|---|---|---|

| Material Quality | Fiberglass vs. Carbon Fiber (3k, 12k, 18k) – Higher grades offer increased durability and strength | Optimized performance under varied conditions |

| Design Shape | Diamond, Round, Teardrop – Each shape offers different balance and control characteristics | Tailored product for specific playing styles |

| Customization Options | Logo branding, color, printing, hand grip design | Brand differentiation and personalized customer appeal |

| Production Precision | Advanced techniques and rapid prototyping methods | Consistency and reliability in large orders |

| Supply Chain and Delivery | Proven track record in timely deliveries and robust quality control systems | Enhanced operational efficiency and customer trust |

Incorporating advanced production techniques not only enhances product performance but also aligns with the evolving demands of B2B procurement. At NEX Padel, our commitment to excellence is reflected in our meticulous attention to every technical detail. Our rackets are engineered using state-of-the-art machinery and strict quality control protocols. This precision manufacturing ensures that each racket, whether built with fiberglass or high-grade carbon fiber, meets the highest standards required by competitive sports equipment.

A notable aspect of our strategy is our ability to offer full customization. By enabling custom shapes, colors, and even hand grip designs, we provide retailers and distributors with a unique opportunity to differentiate their product offerings in the competitive padel market. This level of customization is particularly valuable for exclusive retailers looking to enhance brand identity. The ability to adjust even minor details—such as the logo placement on the hand grip or the design on the racket head—can ensure that the final product meets both performance and aesthetic standards unique to each client.

Evaluating padel rackets from a B2B perspective also involves understanding the market trends and how they relate to player performance. For instance, the shape of the racket not only affects the hitting power but also influences the sweet spot size. A Diamond-shaped racket often offers an optimal balance of power and control for experienced players, while Round shapes tend to offer greater maneuverability and a larger sweet spot, making them more forgiving for a broader range of players. The Teardrop design strikes a balance between these two characteristics, which can cater to diversified game styles.

The choice of material further compounds these differences. Carbon fiber options, available in varying grades (3k, 12k, and 18k), offer a spectrum of performance benefits. For example, 18k carbon fiber provides superior stiffness and durability that high-performance players often demand, while the 3k carbon fiber version might be more cost-effective and lighter yet still highly reliable. By understanding these variations, B2B purchasers can tailor their orders to meet both budgetary constraints and performance requirements.

Customization capabilities extend to the aesthetic and branding aspects of the racket. In today’s competitive market, visual appeal plays an essential role. Customized color schemes and branding are not just marketing tools but integral parts of a total sports equipment strategy that resonates with the end user's identity. For distributors and exclusive retailers, offering a product that stands out not only creates a competitive edge but also facilitates a stronger connection with their customer base.

Supply chain reliability remains a primary concern. A robust, proven supply chain ensures that the high-performance rackets you rely on are produced with consistency and delivered on time. In a market where product lifecycles are short and consumer expectations high, ensuring zero compromise on product quality is critical to maintaining brand reputation. Our manufacturing process, marked by rapid prototyping and strict quality control standards, minimizes production delays and streamlines customization. This agility is critical, especially when addressing last-minute changes in market demand or special orders.

Moreover, aligning technological innovation with production efficiency means you are not only investing in a product but in a long-term, strategic partnership. Manufacturers like NEX Padel support your supply chain with reliable logistics, competitive pricing, and scalable production capabilities. This holistic approach to production and delivery reduces risks associated with stockouts or quality inconsistencies, thereby maintaining high customer satisfaction.

When evaluating padel rackets for a competitive market, it is also wise to look at the insights from industry trends and experienced players. Studies have shown that while the price of a racket can be an indicator of performance characteristics, expensive does not always equate to better performance for every player. A well-designed racket with optimal balance and customization can provide a more significant competitive advantage than a higher-priced alternative with a smaller sweet spot or less ergonomic design. For example, expensive rackets may be harder to maneuver for beginners or intermediate players due to their stiffer construction, which may inadvertently compromise a player's comfort and effectiveness during play.

Using a data-driven approach to these comparisons can be particularly helpful. By benchmarking against industry leaders and analyzing technical specifications, B2B procurers can make decisions grounded in proven performance outcomes. This type of evaluation is essential when facing a wide range of options in the marketplace, thereby ensuring that every investment not only meets immediate technical demands but also supports long-term strategic planning.

To summarize, here are the key takeaways for informed procurement:

• Understand the core differences in materials—identifying the right balance between cost and performance with clear choices between different types of carbon fiber and fiberglass.

• Evaluate design shapes and customization options to match the specific needs of your target market and differentiate your offerings.

• Rely on manufacturers with a proven track record in rapid prototyping, precision manufacturing, and robust supply chain management.

• Utilize comparison data and industry benchmarks to make decisions that ensure both product quality and competitive pricing.

• Recognize that ultimate performance is a blend of technical specifications, design innovation, and market-appropriate customization.

Acting on these points, we recommend taking a close look at your current product portfolio and identifying gaps where advanced, customizable, and high-performance padel rackets could drive significant growth. Consider reaching out to established manufacturers like NEX Padel, who offer both comprehensive technical expertise and the agility required in today’s fast-paced sporting goods industry. Reinforcing your procurement strategy with reliable, innovative products will not only strengthen your market position but also meet the evolving demands of professional padel players.

People Also Ask

Q1: Which brand is the best padel racket?

A: The best padel racket is defined by a blend of high-quality materials, innovative design, and dependable manufacturing processes. In 2025, models such as Starvie, Adidas, and Nox have been recognized for their performance and have received favorable reviews from industry experts, combining aesthetics with technical precision.

Q2: What rackets do top padel players use?

A: Top padel players tend to use rackets that balance power, control, and maneuverability. Leading choices often include high-performance models from brands featuring advanced carbon fiber technology and optimized shapes, ensuring a precise sweet spot and consistent performance during competitive play.

Q3: Do expensive padel rackets make a difference?

A: While expensive padel rackets often incorporate premium materials and advanced features, higher cost does not always equate to better performance, especially for beginners or intermediate players. The key is selecting a racket that suits the player’s skill level and playing style, ensuring optimal performance without unnecessary complexity.

-

Customization: Discover how customization options allow businesses to tailor products to specific market needs, enhancing brand differentiation and customer appeal. Back to customization ↩

-

Supply Chain Management: This article explains how effective supply chain management integrates sourcing, logistics, and quality control to guarantee reliable product delivery. Back to supply chain management ↩

-

Carbon Fiber: Reading this article will help you understand the properties and various grades (3k, 12k, 18k) of carbon fiber that contribute to racket stiffness, durability, and overall performance. Back to carbon fiber ↩

-

Rapid Prototyping: Click here to learn how rapid prototyping accelerates product development, allowing manufacturers to quickly iterate designs and meet market demand. Back to rapid prototyping ↩

-

Precision Manufacturing: Explore the benefits of precision manufacturing in ensuring product consistency, optimal performance, and scalability in large volume orders. Back to precision manufacturing ↩