Quick Answer: NEX Padel is a leading Chinese manufacturer in the padel racket1 market, offering advanced production techniques, a high level of customization2 and rigorous quality assurance3 to meet the evolving needs of sports equipment distributors and procurement managers worldwide.

In today’s fast-paced sports equipment market, finding a reliable manufacturer of high-performance padel rackets can be challenging. Companies need a supplier that not only guarantees precision and durability, but also offers efficiency in production and a wide range of customization options. This article explores the challenges in the padel racket manufacturing landscape and provides practical, data-supported solutions developed by NEX Padel—a trusted partner for brands such as Hirostar, Reebok, and Starvie.

The global sports equipment market, particularly for padel, has seen exponential growth in recent years. As the sport expands its influence internationally, procurement managers are faced with several key challenges:

• Ensuring product quality and durability

• Maintaining production efficiency

• Adhering to tight production timelines

• Meeting diverse customization needs

Procurement professionals must tackle these issues when evaluating potential suppliers. At NEX Padel, we address these concerns by focusing on advanced materials, precision manufacturing techniques, and comprehensive quality control measures.

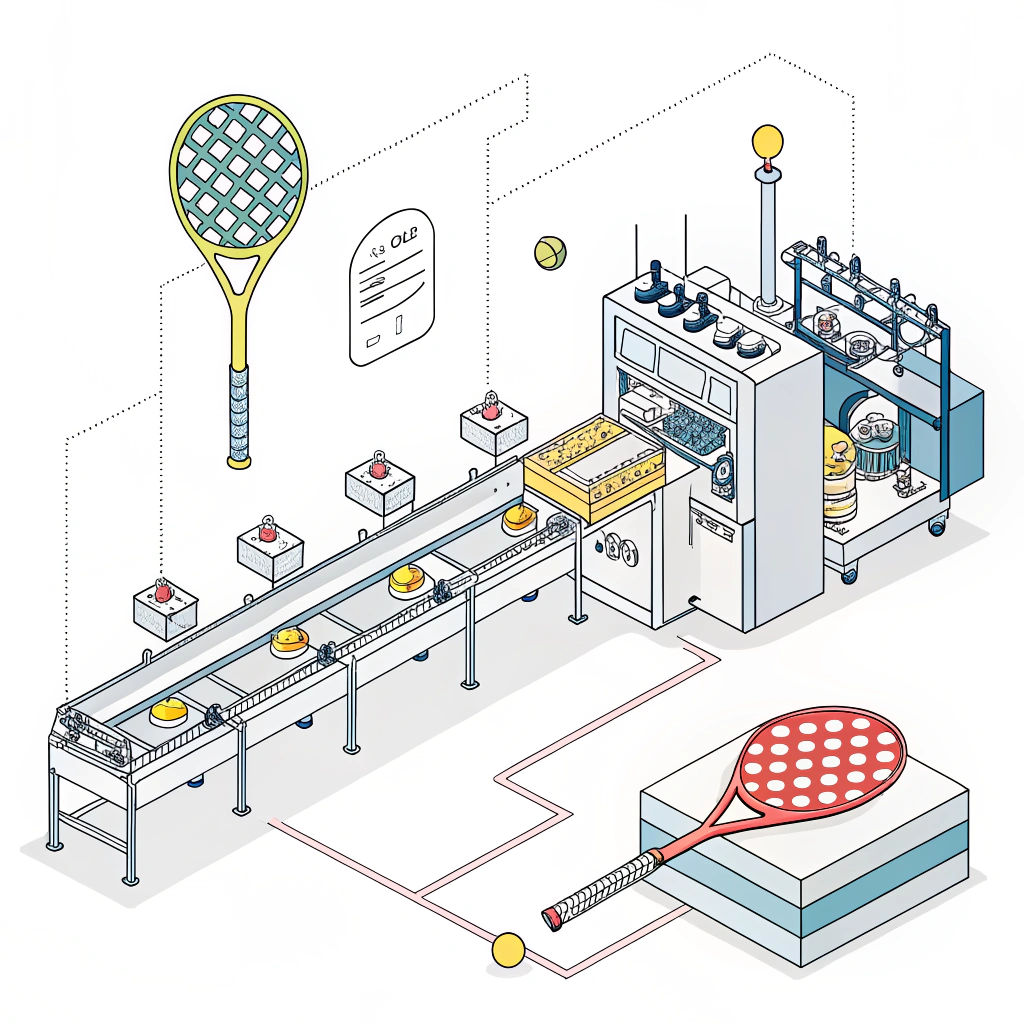

For many companies, the ability to quickly turn prototypes into production models is essential. Fast sampling and timely deliveries are critical, especially during dynamic market conditions. Our production process leverages state-of-the-art machinery and lean manufacturing methods4 that help accelerate turnaround times. This approach minimizes lead times and makes large-scale orders manageable without compromising product quality.

Quality assurance in padel racket manufacturing is paramount. Our facilities implement stringent quality control protocols, supported by continuous process monitoring. Each stage, from selecting raw materials to final inspections, is documented and verified. These practices ensure that every padel racket, whether it features fiberglass or the more advanced carbon fiber5 variants such as 3k, 12k, or 18k, meets high-performance and durability standards.

Modern padel players have unique requirements, from the racket’s shape to printed logos on hand grips. NEX Padel offers full customization through various racket shapes such as Diamond, Round, and Teardrop. In addition, we provide options for personalized printing and color matching. This level of customization means that distributors can differentiate their product offerings without compromising on quality.

Choosing the right material is crucial for both performance and longevity. Here, we compare the common materials used in padel rackets with a focus on their benefits:

| Material Type | Characteristics | Best For |

|---|---|---|

| Fiberglass | Lightweight, flexible, and cost-effective | Players prioritizing ease and comfort |

| 3k Carbon Fiber | Balanced performance with moderate durability and weight | Intermediate performance and customization |

| 12k and 18k Carbon Fiber | High durability, superior stiffness, and enhanced strength | High-level performance and professional play |

The material selection impacts production processes, customization approaches, and the overall performance of the racket. Our factory’s versatile production capabilities allow us to seamlessly adjust production lines to meet the material-specific requirements for each order type and model specification.

To meet the demands of modern padel players and distributors, here are the key solutions provided by NEX Padel:

-

Advanced Production Techniques:

Our factories utilize automated production lines, ensuring both precision and speed. This minimizes human error and ensures uniform quality. All production stages are continuously tracked, this way issues are resolved instantly to maintain batch consistency. -

Customizable Product Options:

With three main models—Diamond, Round, and Teardrop—and the capability to customize shapes, colors, and even the hand grip logos, our solutions are designed to cater to diverse market needs. This customization allows brands to maintain their distinct identity in a competitive marketplace. -

Quality Assurance Measures:

We implement rigorous testing procedures, including impact resistance tests and durability analysis, to ensure each padel racket performs under competitive conditions. Our quality control extends beyond manufacturing—it includes post-production evaluations and compliance with relevant international sports equipment standards. -

Efficient Turnaround Times:

Fast sampling and guided production schedules allow for efficient order fulfillment. We understand that market conditions can change rapidly, and our production agility ensures that our partners can always stay ahead. -

Cost Competitiveness:

By leveraging economies of scale and optimized production operations, we provide high-quality products at competitive prices. This cost advantage supports distributors in achieving strong returns on their investment.

To better visualize these solutions, consider the following table:

| Key Focus Area | Challenge Addressed | NEX Padel’s Solution |

|---|---|---|

| Production Efficiency | Slow turnaround times | Automated production lines and lean manufacturing processes |

| Quality Assurance | Inconsistent product performance | Rigorous quality control and testing protocols |

| Customization | Limited product differentiation | Fully customizable designs (shape, color, logos) |

| Material Versatility | Inability to address varied playing styles | Multiple high-performance material options (fiberglass to advanced carbon fibers) |

| Timely Execution | Delays impacting market launch | Rapid sampling and expedited shipment processes |

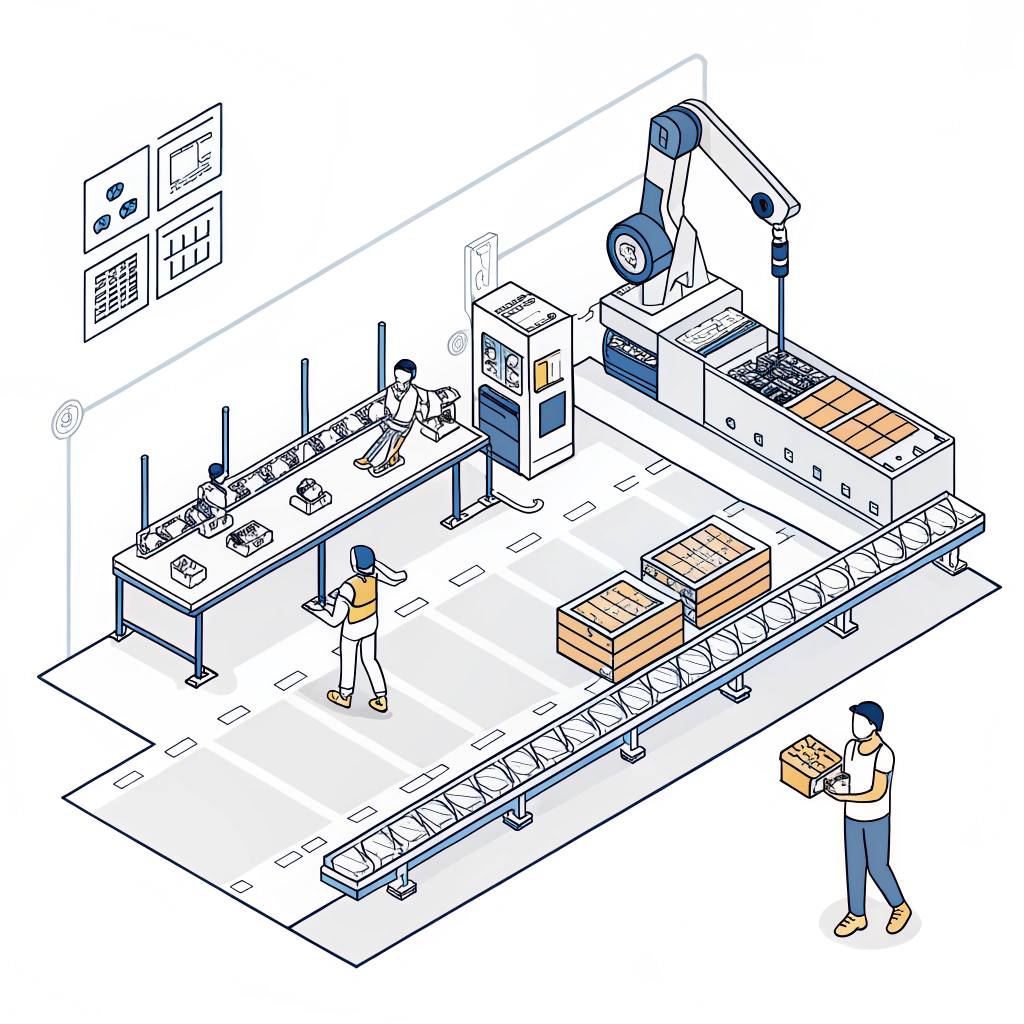

Manufacturers in other sports sectors have adopted similar strategies to overcome production challenges. In industries such as tennis and badminton racquet manufacturing, adopting advanced robotic systems and precise quality tests have proven crucial. By borrowing and refining these techniques, NEX Padel has significantly improved production cycles and product performance.

For example, one major client faced challenges related to inconsistent production quality and extended lead times, leading to missed market opportunities. After switching to a partnership with NEX Padel, implementation of agile production methodologies and enhanced quality checkpoints resulted in a 30% reduction in turnaround times and improved product consistency. This success story underscores the value of aligning modern manufacturing processes with reliable quality controls.

For procurement managers evaluating potential suppliers for padel rackets, consider the following steps:

• Define your performance criteria: Clearly outline product specifications, durability standards, and required customization features before initiating a supplier comparison.

• Investigate production capabilities: Ask potential suppliers about their production processes, quality assurances, and material sources. Look for certifications and documented testing procedures.

• Evaluate turnaround times: Ensure that the supplier has an efficient sampling and production schedule that can accommodate market demands.

• Assess customization flexibility: Determine if the manufacturer supports varied designs, from racket shape customization to personalized printing for logos and colors.

• Verify cost competitiveness: Request detailed quotes and compare them against market standards, without compromising on quality and service.

By following these steps, procurement managers can make an informed decision, ensuring long-term success and a mutually beneficial partnership.

In summary, NEX Padel stands out as a top choice for brands looking for reliable, high-performance padel racket manufacturing. Through our advanced production techniques, robust quality assurance protocols, and flexible customization options, we meet the strict requirements of today’s competitive sports equipment market. Our commitment to precision and fast delivery ensures that your procurement needs are met efficiently, maintaining product excellence at every step.

Partnering with NEX Padel means choosing a manufacturer with extensive experience, innovative production capabilities, and a customer-centric approach. If you are looking to source padel rackets that deliver exceptional performance and durability for your brand, we invite you to explore the solutions we have developed and see how they can support your business growth.

-

Who manufactures padel rackets?

NEX Padel is a leading manufacturer of high-performance padel rackets in China, offering advanced production techniques, precise quality control, and extensive customization options to meet both professional and amateur needs. -

Is padel popular in China?

Padel is rapidly growing in popularity across China. Despite being a relatively new sport in the region, it is gaining traction with the emergence of top-tier clubs and increased interest from sports enthusiasts, driving demand for high-quality equipment. -

What are the best padel rackets made of?

The ideal material for a padel racket depends on play style. Fiberglass offers comfort and ease, while carbon fiber options such as 3k, 12k, and 18k provide enhanced durability, stiffness, and performance for competitive play.

-

padel racket: Click to learn about the evolution of padel rackets, key design features, and their impact on performance and market trends. ↩

-

customization: Click to discover the advantages of product customization in sports equipment manufacturing and how tailored designs can differentiate market offerings. ↩

-

quality assurance: Click to read about quality assurance processes, testing protocols, and standards that ensure product reliability and consistency. ↩

-

lean manufacturing methods: Click to understand lean manufacturing principles that drive efficiency, reduce waste, and accelerate production cycles in modern factories. ↩

-

carbon fiber: Click to explore how carbon fiber is used in sports equipment manufacturing, its benefits in strength-to-weight ratio, and application in high-performance gear. ↩