Padel rackets require high-performance materials that balance durability, flexibility, and weight. In this article, we explore how advanced materials and production techniques meet these requirements, empowering technical purchasing managers and product developers to make informed decisions in the sporting goods industry.

The design of a high-performance padel racket is a balancing act between several factors: weight, strength, vibration damping, and cost. Manufacturing teams must consider the unique properties of materials such as EVA foam1, various grades of carbon fiber2 (3K, 12K, 18K), and glass fiber3. Each material comes with its own set of benefits and trade-offs.

Many purchasing managers face the challenge of selecting the optimum material combinations to meet customer demands while maintaining production efficiency. As new technologies and innovative production techniques emerge, researchers and product developers need to keep up-to-date with the latest industry benchmarks and scientific findings.

When evaluating materials for padel rackets, several properties are critical:

- Stiffness & Flexibility: The stiffness of the racket frame influences the power and control provided to the player. Higher-grade carbon fiber (like 12K and 18K) generally offers more rigidity, leading to better energy transfer and ball speed.

- Weight and Balance: Lighter materials such as glass fiber or lower-grade carbon fiber help maintain agility but might sacrifice some strength.

- Vibration Damping: EVA foam is crucial for vibration damping during impact. This material improves comfort and reduces the risk of injuries during prolonged play.

- Durability and Impact Resistance: Complex playing conditions require racket frames that can withstand repeated high-force impacts without degrading performance.

The table below summarizes a comparative overview of various padel racket materials in terms of performance metrics, cost, and applicative areas.

| Material | Stiffness | Weight | Vibration Damping | Durability | Cost |

|---|---|---|---|---|---|

| EVA Foam | Low-Med | Low | Excellent | Moderate | Low |

| 3K Carbon Fiber | Low | Very Low | Good | Moderate | Lower |

| 12K Carbon Fiber | Med | Low | Good | High | Medium |

| 18K Carbon Fiber | High | Moderate | Moderate | Very High | High |

| Glass Fiber | Low-Med | Moderate | Good | Moderate to High | Low to Medium |

This table provides a snapshot of the advantages of each material. Four key aspects guide a decision-maker: performance, manufacturing feasibility, cost implications, and long-term maintenance. Companies like NEX Padel leverage these insights to offer custom racket design that meets the precise specifications of various market segments.

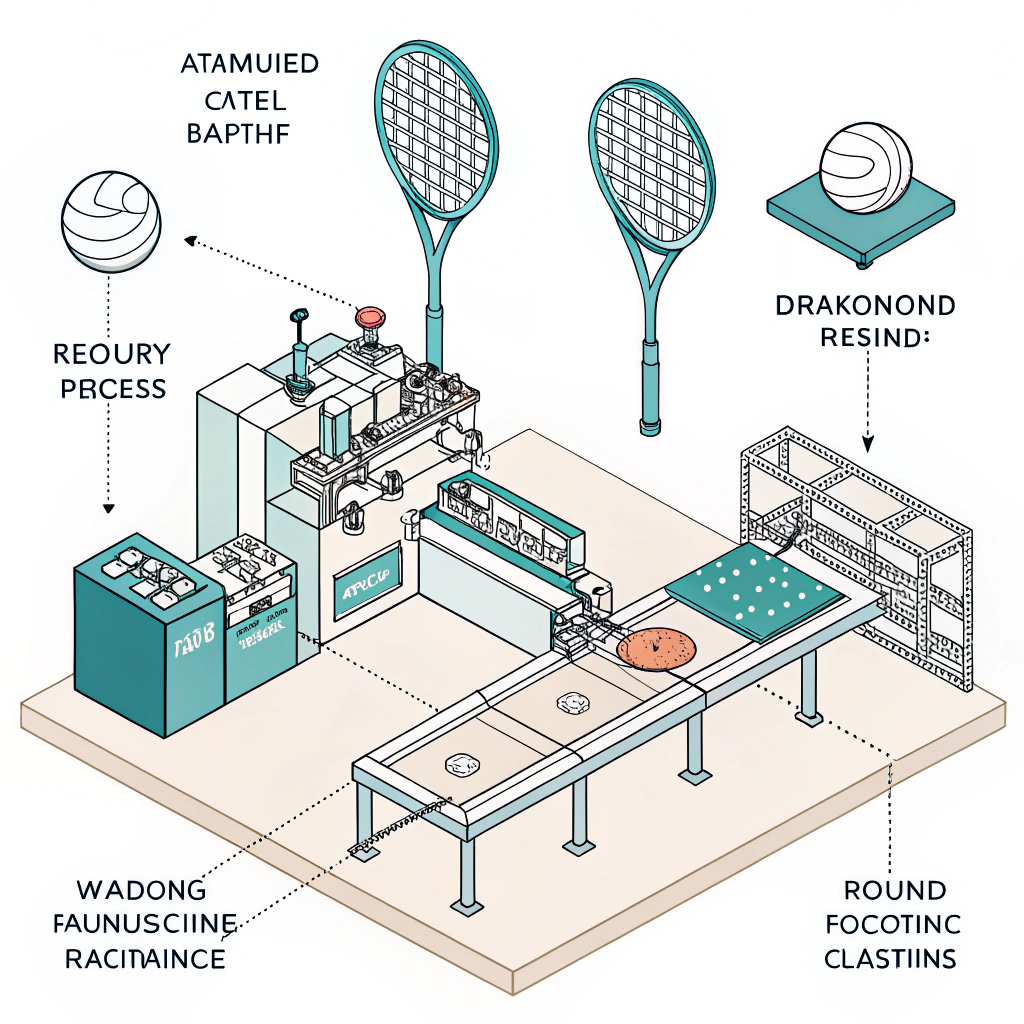

Advancements in production are a major factor behind the improved performance of modern padel rackets. For instance, NEX Padel utilizes advanced layup techniques4 and precise molding to ensure that every racket meets strict quality controls. By integrating high-speed manufacturing with quality assurance systems, the production process minimizes material waste and optimizes performance outcomes.

Key production improvements include:

- Automated Layup Processes: Automation in fiber placement ensures consistency and accurate resin distribution.

-

- Quality Assurance Protocols5: Rigorous testing at every production stage ensures that each product meets pre-set durability and performance benchmarks.

- Enhanced Molding Techniques: Customized molds for Diamond, Round, and Teardrop shapes improve consistency and performance.

Efficiency in production is measured not only by the quality of the final product but also by the speed and flexibility in the manufacturing process. The ability to quickly produce samples, as well as timely delivery, positions companies like NEX Padel as leaders in high-performance padel equipment production. The benefits of fast prototyping and custom orders are significant in reducing lead times and adapting to dynamic market demands.

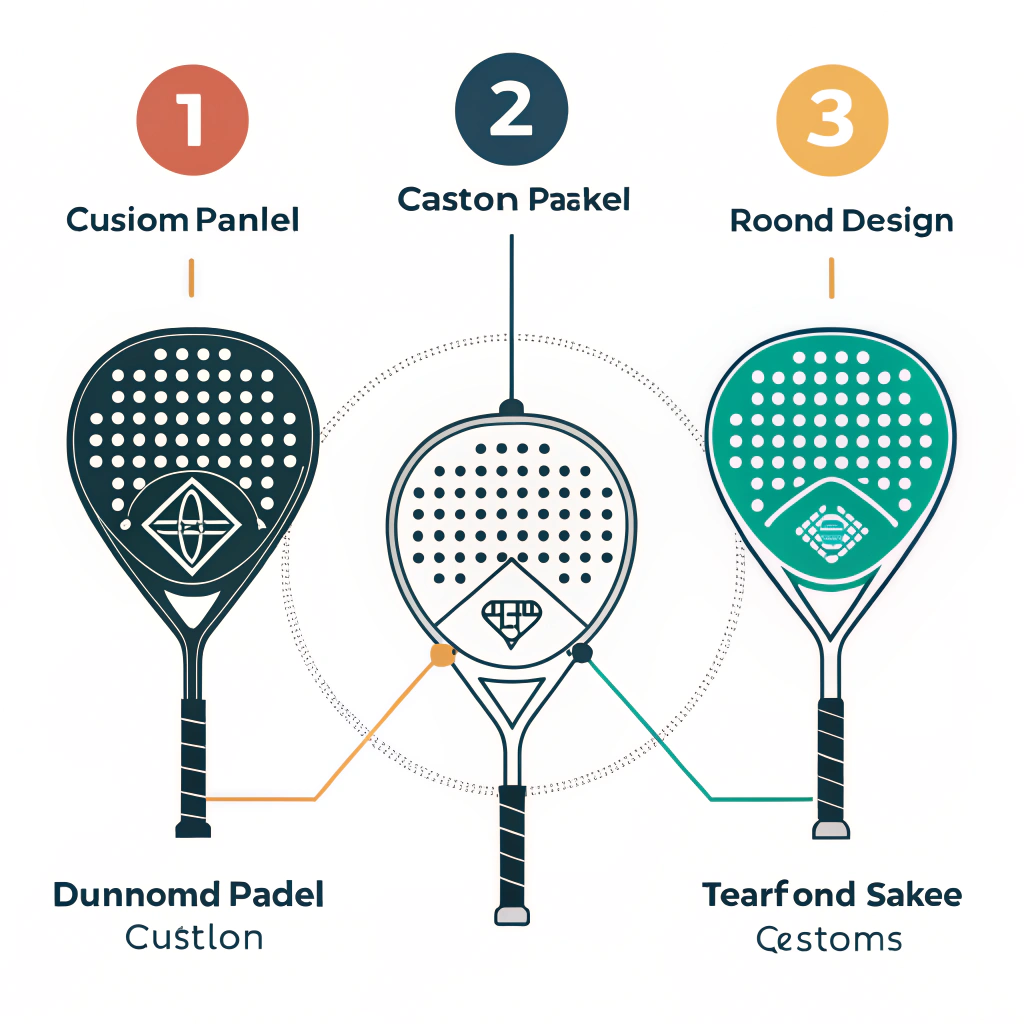

Customization is at the heart of success in the sporting goods industry. With diverse consumer needs ranging from recreational players to professionals, the ability to tailor a racket’s design is a competitive edge. Companies now offer bespoke solutions including:

- Tailored Shapes: Production lines that support multiple forms—Diamond, Round, and Teardrop—allow clients to choose designs that best suit their play style.

- Custom Prints and Colors: Beyond the technical components, visual aesthetics such as racket color and custom printing play an important role in brand differentiation.

- Component Customization: Options for custom hand grips and handle covers, complete with logo engravings, enhance brand identity and add value in competitive markets.

Material costs vary significantly based on the chosen technology. Lower-end materials like EVA foam and glass fiber offer cost-effective alternatives but might not deliver the performance required by high-end professional players. Higher-end carbon fibers (12K/18K) provide superior performance but at a higher cost, which is a crucial factor in strategic purchasing decisions.

A detailed cost-benefit analysis is essential. For instance, while 18K carbon fiber enhances durability and performance, its production cost is significantly higher. Manufacturers need to balance these aspects alongside market pricing, customer expectations, and long-term product lifespan.

Decision-makers should consider data from internal quality tests, customer feedback, and industry benchmarks to drive purchasing strategy. For example, controlled stress-testing and longevity tests provide measurable data that help compare materials across performance metrics such as impact resistance and vibration control.

NEX Padel, a leading manufacturer based in Jiaxing, Zhejiang, China, has become synonymous with high-efficiency production and technological innovation in padel equipment. Our expertise is showcased in our collaborations with global brands such as Hirostar, Reebok, and Starvie. Key factors that contribute to our success include:

- Advanced Material Integration: By offering a range from 3K to 18K carbon fiber, we tailor our products to match diverse performance requirements.

- Rapid Prototyping and Customization: Our fast sampling process enables us to deliver bespoke solutions quickly, meeting the custom design needs of various market segments.

- Quality Assurance: Continuous monitoring during the production process ensures that every racket built meets strict industry standards, guaranteeing durability and optimal play performance.

This case study illustrates how combining technical innovation with industry experience can lead to products that not only meet but exceed market expectations. Manufacturers aiming to upgrade their product lines can take cues from these practices, applying similar quality control measures and customization options to cater to evolving market demands.

In summary, choosing the right materials for padel rackets is a multifaceted decision that involves understanding material properties, balancing performance trade-offs, and leveraging innovative manufacturing methods. Here are the actionable recommendations for purchasing managers and product developers:

- Conduct a thorough analysis of material properties, focusing on stiffness, vibration damping, durability, and cost performance.

- Evaluate your production capabilities and decide whether advanced techniques (like automated layup and custom molding) can be integrated or upgraded.

- Align material choices with the target market segment—whether cost-effective solutions for recreational players or high-performance options for competitive sports.

- Leverage quality control and data analytics to continuously improve material performance and maintenance schedules.

- Consider customization and branding aspects as part of the overall design strategy to offer unique value propositions in the marketplace.

By following these recommendations, decision-makers can ensure that their product lines remain competitive, innovative, and responsive to market demands.

-

What are the main considerations when choosing materials for padel rackets?

Decision-makers must evaluate material stiffness, weight, vibration damping, durability, and cost. This includes comparing options like EVA foam, various grades of carbon fiber, and glass fiber to ensure the final product meets the desired performance characteristics. -

How does carbon fiber grade affect padel racket performance?

Different carbon fiber grades, such as 3K, 12K, and 18K, influence the racket's stiffness and durability. Higher grades typically provide better rigidity and energy transfer but come with increased cost. The choice depends on the balance between performance needs and budget constraints. -

What benefits do advanced manufacturing techniques offer in padel racket production?

Advanced manufacturing techniques such as automated layup processes and precision molding enhance production consistency, reduce material waste, and improve overall product quality. These methods also enable fast prototyping and customization, which are critical in meeting varied market demands.

-

EVA foam: Reading this article will provide insights into the properties and benefits of EVA foam in sports equipment manufacturing, including its role in vibration damping and cost efficiency. ↩ ↩

-

carbon fiber: Reading this article will explain the various grades of carbon fiber, how they affect racket performance, and their trade-offs between cost and durability. ↩ ↩

-

glass fiber: Reading this article will help you understand the characteristics of glass fiber, its impact on weight and strength, and its cost-effectiveness in racket production. ↩ ↩

-

advanced layup techniques: Reading this article will provide details on advanced layup techniques in composite manufacturing, highlighting applications in ensuring material consistency and structural performance. ↩ ↩

-

Quality Assurance Protocols: Reading this article will outline the importance of quality assurance protocols in manufacturing, detailing testing methods and benchmarks to ensure consistent product quality. ↩ ↩