NEX Padel’s 18K Carbon1 Padel Rackets are engineered with advanced production techniques to deliver unmatched performance, durability, and customization flexibility. This article explains the challenges in sourcing high-performance padel equipment, analyzes production methods and material quality concerns, and demonstrates how our state-of-the-art manufacturing process provides a reliable solution for sports equipment distributors and padel clubs seeking competitive quality and value.

Procurement managers and product sourcing specialists face several hurdles when evaluating OEM partners2 for high-performance padel rackets. The key challenges include:

• Ensuring material quality that meets both performance and durability standards.

• Achieving precise customization and branding3 to resonate with different market niches.

• Balancing production efficiency with the need for technologically advanced materials such as 18K carbon fiber.

Traditional suppliers may fall short due to inconsistent quality controls and limited customization options. Often, manufacturers use lower-grade materials or compromise on production precision that directly affects racket performance and longevity.

The root causes of production and sourcing challenges in the padel equipment industry are multifaceted:

-

Material Inconsistency:

Low-grade carbon fiber (such as 3K or 12K) may be used when high stiffness and durability are required. When suppliers do not use premium 18K carbon, the final product might not offer the enhanced resilience and lightweight performance demanded by professional players. -

Limited Customization Capabilities:

Some manufacturers are not equipped to provide tailor-made solutions. Whether it’s producing unique racket shapes like Diamond, Round, or Teardrop, or customizing features like hand grip logos and handle covers, limited options can hinder market differentiation. -

Outdated Production Techniques:

Without investments in Precision Engineering4 and modern production techniques, manufacturers risk producing rackets that lack consistent performance characteristics. Variability in product design translates to an unpredictable sporting experience for end-users.

At NEX Padel, we have invested in advanced production methods that address each of these challenges. Our manufacturing process is designed to exceed market expectations through precision engineering, rigorous quality control, and tailor-made customization options. Below are key components of our solution:

We utilize a range of carbon fiber materials—from 3K to 18K carbon—ensuring that every racket meets predetermined performance criteria. For high-end models, our 18K carbon padel rackets offer superior rigidity and lighter weight, providing the perfect balance between power and control.

Understanding that every market segment is unique, we offer full customization options. Our product range includes:

- Shape Variability: Diamond, Round, Teardrop, and fully custom shapes.

- Print and Color Customization: Tailor the aesthetics to align with branding guidelines.

- Accessory Customization: Hand grips and handle covers can be customized with logos, offering an extra branding opportunity.

These customization options allow our partners, such as well-known sports brands and OEM clients like Hirostar, Reebok, and Starvie, to create a product uniquely suited to their market.

Our production process is marked by Fast Prototyping5 and a strict quality control system. We ensure each padel racket is produced with consistent precision so that every racket meets the rigorous demands of professional padel play. In addition to product performance, our fast sampling and reliable delivery time ensure that partners can plan procurement and roll-out strategies effectively.

To better understand how our solution differentiates from traditional suppliers, consider the following table that compares key production aspects:

| Feature | NEX Padel (18K Carbon) | Typical Manufacturer |

|---|---|---|

| Carbon Fiber Grades | 3K, 12K, 18K plus fully customizable options | Limited to 3K or 12K |

| Customization Capabilities | Full-scale customization (shape, color, logo) | Basic color printing only |

| Production Techniques | Advanced precision engineering with fast prototyping | Conventional, slower production cycles |

| Quality Control | Rigorous, data-driven quality checks at every stage | Inconsistent quality checks |

| Delivery Timeliness | Quick sampling and guaranteed on-time delivery | Longer lead-times with potential delays |

| Partnership History | Trusted by major brands (Hirostar, Reebok, Starvie) | Limited collaboration history with top brands |

This table illustrates not only the technological edge of our production process but also highlights the importance of customization and quality control in securing a highly competitive supply chain advantage.

Our commitment to excellence is backed by success stories and industry data:

Case Study: Custom Tournament Rackets

A leading sports distributor once faced challenges with inconsistent racket performance and delayed shipments. After switching to NEX Padel, they benefited from:

- Consistent performance verified by professional players.

- Custom-designed designs tailored for their tournament series.

- On-time delivery that improved scheduling and inventory management.

Industry Data Point:

Recent market analysis indicates that padel clubs and distributors value manufacturing partners who provide timely delivery and reliable product performance. With an increasing global demand for high-performance padel equipment, companies employing advanced 18K carbon technology capture a significant market edge.

For procurement managers in the padel industry looking to minimize risk and maximize product performance, consider the following steps:

-

Evaluate Material Quality:

Ensure that your supplier is transparent about the grade of carbon fiber used and has a robust quality control process. High-performance padel rackets should incorporate the latest materials—especially 18K carbon—to ensure the best playing experience. -

Prioritize Customization Options:

Select partners who offer a range of product customization. This flexibility not only enhances brand differentiation but also empowers you to respond quickly to market trends. -

Assess Manufacturing Efficiency:

Speed to market is critical. Confirm that your potential supplier can provide rapid prototyping and adhere to strict delivery timelines to prevent supply chain disruptions. -

Review Partnership History and Industry Reputation:

Look for manufacturers with established collaboration with top-tier brands. This history indicates a proven track record in meeting high-quality standards and delivering consistent performance.

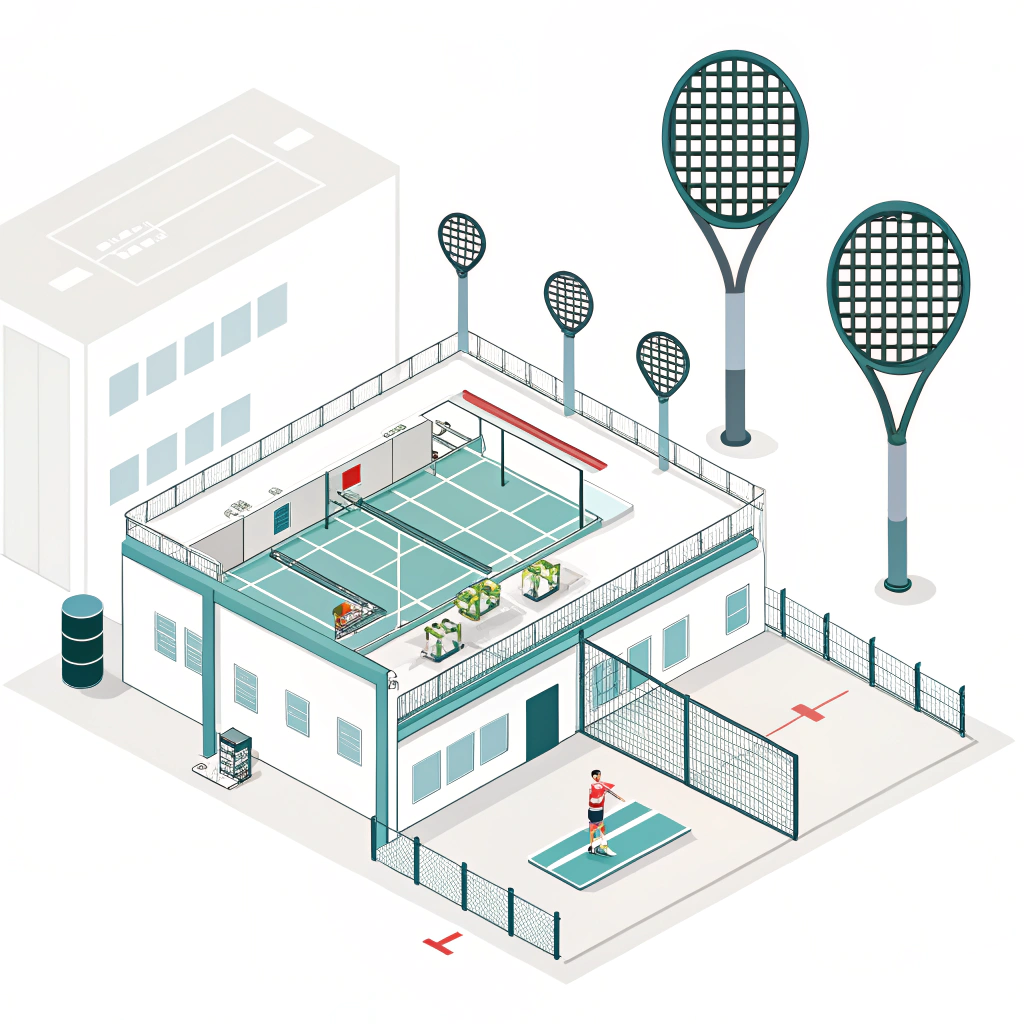

At NEX Padel, our state-of-the-art production facility in Jiaxing, Zhejiang, China, is purpose-built to serve the precise needs of professional sports equipment sourcing. Here are some strategic advantages that set us apart:

-

Customizable Solutions for Diverse Markets:

By offering full customization—from racket shape to decorative printing—we facilitate market entry for both emerging and established brands. -

Advanced Material Research and Production Techniques:

Our commitment to continuous improvement means investing in the latest carbon fiber technology. This focus on innovation enables us to produce rackets that push the boundaries of performance. -

Efficient Supply Chain Management:

With robust systems for rapid sampling and on-time delivery, our manufacturing process ensures minimal lead times, making us a reliable partner in the fast-paced world of sports equipment distribution. -

Comprehensive Support:

We not only manufacture rackets but also provide tailored consultation on product design and market positioning. This helps our partners to enhance their competitive edge through superior sports equipment innovations.

In summary, for B2B buyers looking for reliable, high-performance 18K carbon padel rackets, NEX Padel offers a compelling package. Our advanced production techniques, superior material choices, and extensive customization capabilities ensure that you receive equipment designed for both peak performance and brand distinction. These factors are critical in today’s competitive sports equipment market, where product quality, consistency, and timely delivery directly influence your market success.

We invite you to explore a potential partnership with us—where quality meets innovation, and every racket is a testament to precision engineering. Reach out to our team for a detailed consultation, product samples, and customized solutions that cater specifically to your market needs.

• Who manufactures padel rackets?

NEX Padel is a leading manufacturer of padel rackets, renowned for its advanced production techniques and commitment to customization. We provide a range of high-performance products that meet the demands of both professional and amateur players.

• Are padel rackets made in China?

Yes, NEX Padel manufactures its padel rackets in China. Our state-of-the-art facility in Jiaxing, Zhejiang, employs advanced manufacturing processes to ensure high-quality products featuring premium materials such as 18K carbon fiber.

• Which brand makes the best padel rackets?

While several brands offer competitive padel rackets, NEX Padel stands out due to our focus on precision engineering, comprehensive customization, and rapid production turnaround. Our commitment to quality and innovation makes us a trusted choice in the global sports equipment market.

-

18K Carbon: Learn how advanced 18K carbon materials contribute to enhanced rigidity, lightweight performance, and superior durability in high-performance sporting equipment. ^Back ↩

-

OEM partners: Reading this article will help you understand the role of Original Equipment Manufacturer (OEM) partnerships in ensuring quality, consistency, and timely production in the sports equipment industry. ^Back ↩

-

Customization and Branding: This article explains the importance of tailor-made solutions for product differentiation and market positioning in B2B industries, highlighting the impact of customization and branding strategies. ^Back ↩

-

Precision Engineering: Discover how precision engineering drives consistency and performance in manufacturing processes, ensuring products meet rigorous industry standards. ^Back ↩

-

Fast Prototyping: Explore the benefits of fast prototyping in reducing lead times and enhancing product innovation, helping businesses rapidly adapt to market demands. ^Back ↩