The role of high-performance padel rackets in today’s competitive sports market cannot be understated. Quickly put, advanced Chinese manufacturers such as NEX Padel have built manufacturing systems that combine superior materials like carbon fiber1 in 3k, 12k, and 18k variants with cutting-edge production techniques to deliver quality, customization, and timely delivery that meets the rigorous demands of procurement managers and sports equipment distributors.

Procurement managers in sports equipment distribution and padel clubs face several challenges when sourcing padel rackets:

• Ensuring technical excellence and product durability

• Balancing high-performance materials with competitive pricing

• Meeting customization requirements for shape, logo printing, and additional accessories such as hand grips and handle covers

• Verifying production reliability and adherence to delivery timelines

Traditional suppliers often compromise on one of these criteria, causing delays or quality inconsistencies. This problem is especially acute during the supplier comparison stage, where every manufacturing detail is critically important for successful market positioning.

The difficulties in acquiring high-performance padel rackets often stem from the following underlying issues:

-

Material Variability:

Suppliers may offer different types of carbon fiber ranging from lower-grade (3k) to advanced forms (12k and 18k). It is vital that procurement managers clearly understand the advantages and performance differences of each to ensure the chosen material aligns with performance targets. -

Inconsistent Production Techniques:

Not all manufacturers use the latest production technology. Outdated techniques can lead to imprecise designs and variable quality. In contrast, companies like NEX Padel employ advanced production techniques2 to guarantee precision and durability. -

Customization Complexity:

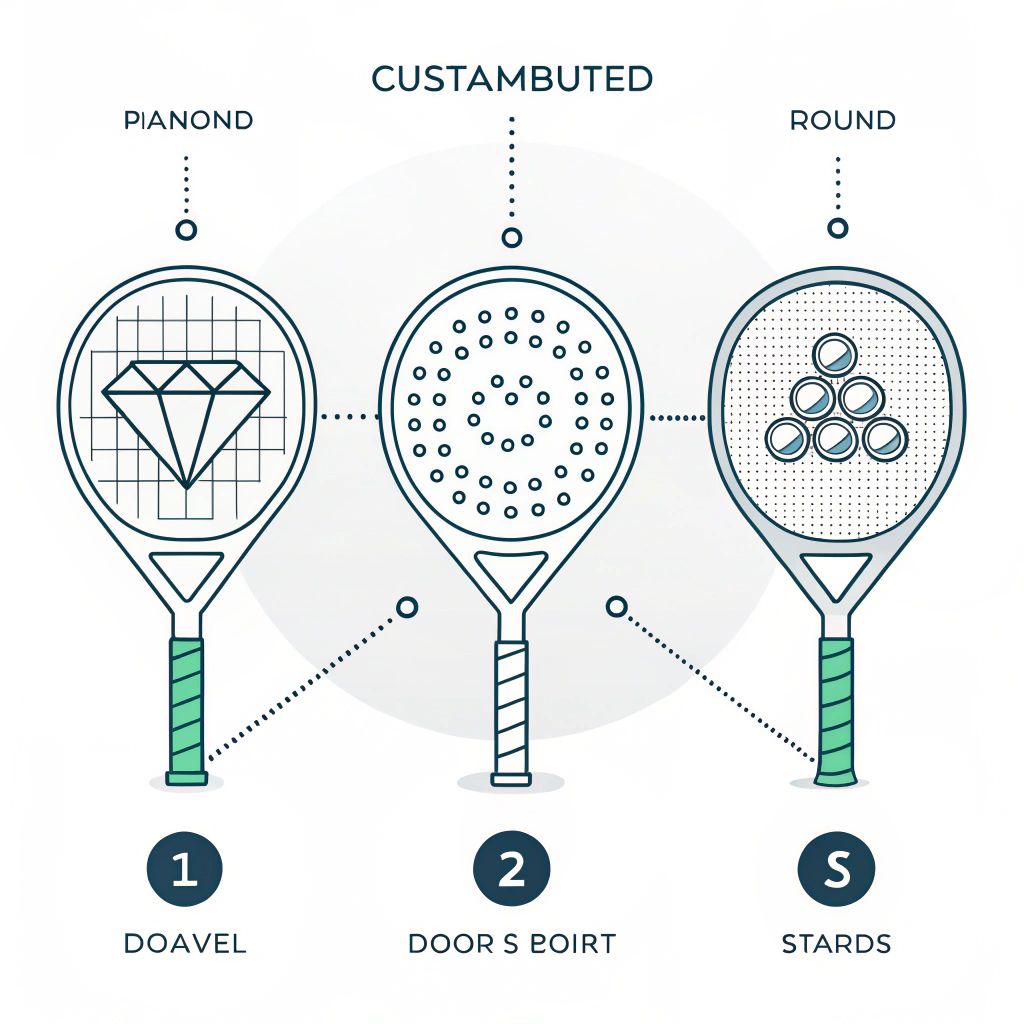

Many suppliers struggle to provide tailor-made solutions. From varying racket shapes (Diamond, Round, Teardrop) to detailed logos and special handle grips, ensuring these custom orders are accurate and delivered on time is often a significant challenge. -

Logistics and Timely Delivery:

Even superior products can lose their market edge if delivery timelines are not met. Efficient production planning, combined with reliable logistics networks, is crucial for timely delivery in a competitive market.

Addressing these challenges requires a thorough evaluation and strategy tailored to the specific needs of your business. Below are actionable solutions supported by technical details and industry insights:

Action Item: Evaluate the specific performance requirements for your padel rackets and choose the appropriate carbon fiber type.

• 3k Carbon Fiber: Ideal for entry-level to mid-tier products, providing a balance of strength and cost-effectiveness.

• 12k Carbon Fiber: Offers better stiffness and durability; suitable for mid to high-end products.

• 18k Carbon Fiber: Delivers superior performance attributes and is typically reserved for top-tier rackets where maximum strength and lightweight characteristics are mission-critical.

Best Practice: Insist on rigorous quality control protocols from your supplier. Manufacturers like NEX Padel ensure quality through consistent certification, on-site production monitoring, and adherence to international standards.

Action Item: Partner with manufacturers that implement modern automated processes and precision engineering in padel racket manufacturing.

• Automation and Precision: Modern production lines reduce human error, ensuring that each racket meets exact specifications consistently.

• Customization Capability: Advanced production systems allow for high levels of customization, whether you require unique shapes or personalized components like hand grips and handle covers.

Table: Comparison of Production Techniques

| Production Technique | Benefits | Typical Applications |

|---|---|---|

| Traditional Manual Methods | Lower cost, basic customization | Entry-level product lines |

| Semi-Automated Processes | Improved precision, moderate customization | Mid-tier padel rackets |

| Advanced Automated Systems | High precision, multiple custom options | High-performance, premium lines |

Best Practice: Request detailed production process documentation and quality certifications from potential suppliers to validate their capabilities.

Action Item: Ensure your chosen manufacturer supports OEM and ODM services to match your specific design requirements.

• Racket Shapes: Options such as Diamond, Round, and Teardrop allow for diversity in playing styles and market positioning.

• Printing and Logo Application: Customization isn’t only about shape; incorporating your brand’s identity through custom prints, logos on hand grips, and personalized color schemes boosts market differentiation.

• Accessory Integration: Beyond the racket, additional accessories like custom-designed hand grips and handle covers are part of the comprehensive customization service.

Best Practice: Provide clear and detailed design specifications along with possibly a sample or prototype request to ensure precise execution during bulk production.

Action Item: Evaluate supplier logistics, production lead times, and after-sales support.

• Rapid Prototyping: A robust manufacturer should offer quick prototype samples to confirm design parameters before mass production.

• Scale of Operation: High-volume orders should not compromise quality. Verify that the supplier’s production capacity aligns with your order volume and deadlines.

• Supply Chain Monitoring: Establish clear communication channels for progress updates, quality checks, and resolution of any unforeseen issues.

Best Practice: Negotiate specific delivery schedules and penalty clauses for late deliveries during contract formulation to enforce accountability.

One leading sports equipment distributor recently faced challenges sourcing high-performance padel rackets that needed to satisfy both high durability standards using advanced carbon fiber and extensive customization options. After evaluating multiple suppliers, they partnered with NEX Padel. The decision was largely influenced by:

• NEX Padel’s proven track record in meeting tight production schedules without sacrificing quality.

• The ability to produce high-quality, customized products that precisely matched the distributor’s requirements.

• Their transparent quality control processes, which included on-site inspections and detailed production process documentation.

The collaboration resulted in a 30% reduction in production lead times and a significant uptick in customer satisfaction due to the enhanced performance and personalized design of the rackets.

Below is a concise checklist that procurement managers can follow to ensure a smooth supplier selection process for custom production of high-performance padel rackets:

| Step | Action | Considerations |

|---|---|---|

| 1 | Define Technical & Custom Requirements | Material type, production style, customization specifics |

| 2 | Evaluate Supplier Capabilities | Production technologies, quality control certifications |

| 3 | Request Samples & Prototypes | Proof of concept and design fidelity |

| 4 | Negotiate Terms & Delivery Schedules | Pricing, lead time, logistics, after-sales support |

| 5 | Monitor Production & Quality Assurance | Regular updates, on-site inspections, iterative feedback |

This systematic approach helps procurement managers mitigate risks and ensure that every aspect of the padel racket production aligns with market demands and brand standards.

Procurement managers and business development executives seeking reliable Chinese manufacturers for high-performance padel rackets must look beyond price alone. The focus should be on the technical excellence of materials, precision in manufacturing, capacity for high-level customization, and proven logistics management. NEX Padel stands out by meeting these criteria, providing advanced production techniques, detailed quality control measures, and flexible OEM/ODM services that cater to diverse needs.

By adopting these best practices, you can ensure that your product offerings not only meet market expectations but also deliver a competitive edge. Consider reaching out to specialists for a consultation, pilot project, or sample order to experience firsthand the difference that a dedicated manufacturing partner can make in elevating your product lineup.

People Also Ask

Q1: What advantages does carbon fiber offer in padel racket performance?

A1: Carbon fiber offers a lightweight yet strong structure, which enhances playability, durability, and overall racket performance. This material minimizes vibration and increases stability, proving crucial for high-performance sports equipment.

Q2: How do advanced production techniques impact the quality of padel rackets?

A2: Advanced production techniques, such as automated processes and precision engineering, ensure consistent design, high-quality finishes, and reliable performance. Manufacturers who use these methods benefit from reduced errors and improved product specifications.

Q3: What customization services are typically available for padel rackets?

A3: Customization services include options for different racket shapes (Diamond, Round, Teardrop), personalized color schemes, custom logo printing on various surfaces including hand grips, and configurable accessory options.

-

Carbon fiber: Click to read an article on the properties and industrial applications of carbon fiber, which explains its benefits in enhancing performance and durability in sports equipment. ↩ ↩

-

Advanced production techniques: Click to learn more about modern automated manufacturing processes that ensure precision engineering and high quality in production. ↩ ↩

-

OEM/ODM: Click to understand how OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) services work together to offer customized product solutions in various industries. ↩ ↩