Quick Answer: China has become the hub for high-performance padel equipment production due to its advanced production techniques, strict quality control, and extensive customization options. Manufacturers like NEX Padel offer tailored solutions—from diverse material selections such as fiberglass1 to various grades of carbon fiber2 (3k, 12k, 18k)—ensuring that procurement managers can meet market demands without compromising on quality or lead time3.

For procurement managers and sourcing specialists, choosing the right manufacturing partner is critical. In today's competitive sporting goods market, ensuring a reliable supplier is essential for maintaining product quality and meeting customers' expectations. The main challenges include:

- Verifying the consistency and reliability of production techniques.

- Evaluating the ability to customize padel equipment.

- Ensuring competitive pricing while maintaining high quality.

- Coordinating timely lead time3 in a dynamic global supply chain.

Many companies have faced issues such as production delays, quality inconsistencies, or limited customization options, which can ultimately impact brand reputation and market penetration.

Several factors contribute to the challenges in sourcing padel equipment:

-

Quality Assurance: High-performance padel rackets require precision in manufacturing. Manufacturers must adhere to strict tolerances and quality benchmarks. A slight deviation in the production process can affect the overall performance of the racket.

-

Material Selection and Production Techniques: The choice of raw materials—from glass fiber1 for entry-level models to various grades of carbon fiber2 for high-performance versions—directly influences product durability and performance. Each material demands specialized production techniques to ensure the final product meets the required standards.

-

Customization Demands: Today's market requires products that can be tailored to specific brand aesthetics and performance needs. Custom engraving, hand grip customization, and unique shape design are examples of features that buyers demand.

-

Supply Chain Reliability: In a market where competition is fierce, ensuring timely delivery and adaptable production processes is crucial. Suppliers must have robust logistics and quality control systems in place to guarantee that the lead time3 remains competitive while mitigating risks related to production fluctuations.

These issues require suppliers who are not only skilled in high-performance manufacturing but also highly adaptable and transparent in their production processes.

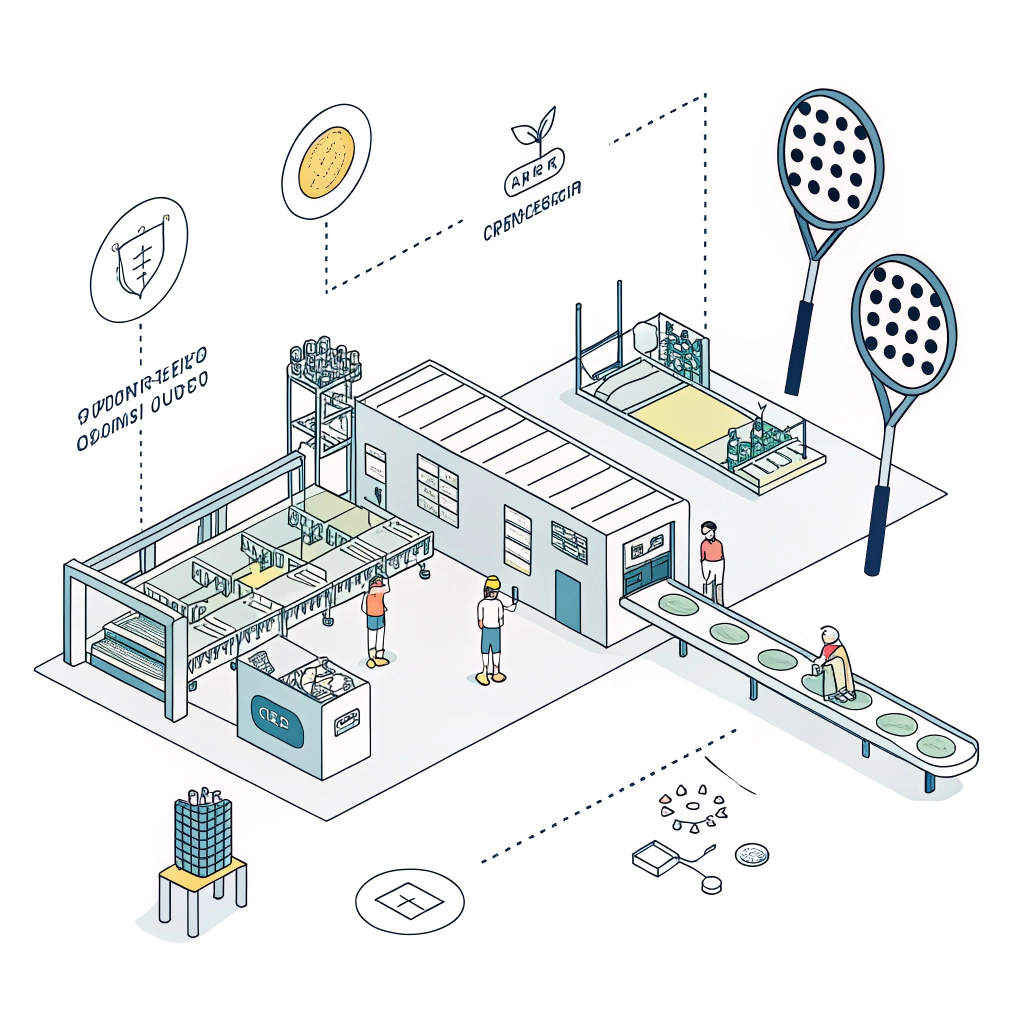

To navigate these complexities, partnering with a reliable manufacturer like NEX Padel can be invaluable. Below is a detailed solution checklist designed to address sourcing challenges:

Solution Checklist for Sourcing High-Performance Padel Equipment

| Step | Key Considerations | Benefits |

|---|---|---|

| Evaluate Manufacturing Capabilities | Review production techniques, machinery, and quality control measures | Ensures consistent high-quality production |

| Customization Options | Check the ability to produce various types: Diamond, Round, Teardrop, and custom shapes | Meets the unique branding and performance needs |

| Material Diversity | Confirm access to advanced materials: fiberglass, 3k, 12k, 18k carbon fiber | Allows creation of products for different market tiers |

| Quality Assurance Protocols | Understand testing procedures, tolerance levels, “in-house” quality checks | Reduces production risks and improves product reliability |

| Lead Time & Logistics | Assess production timeframes, sample turnaround, and shipping logistics | Enhances supply chain efficiency and trustworthiness |

| Pricing Structure | Compare competitive pricing for order quantity and customization fees | Ensures cost efficiency without compromising quality |

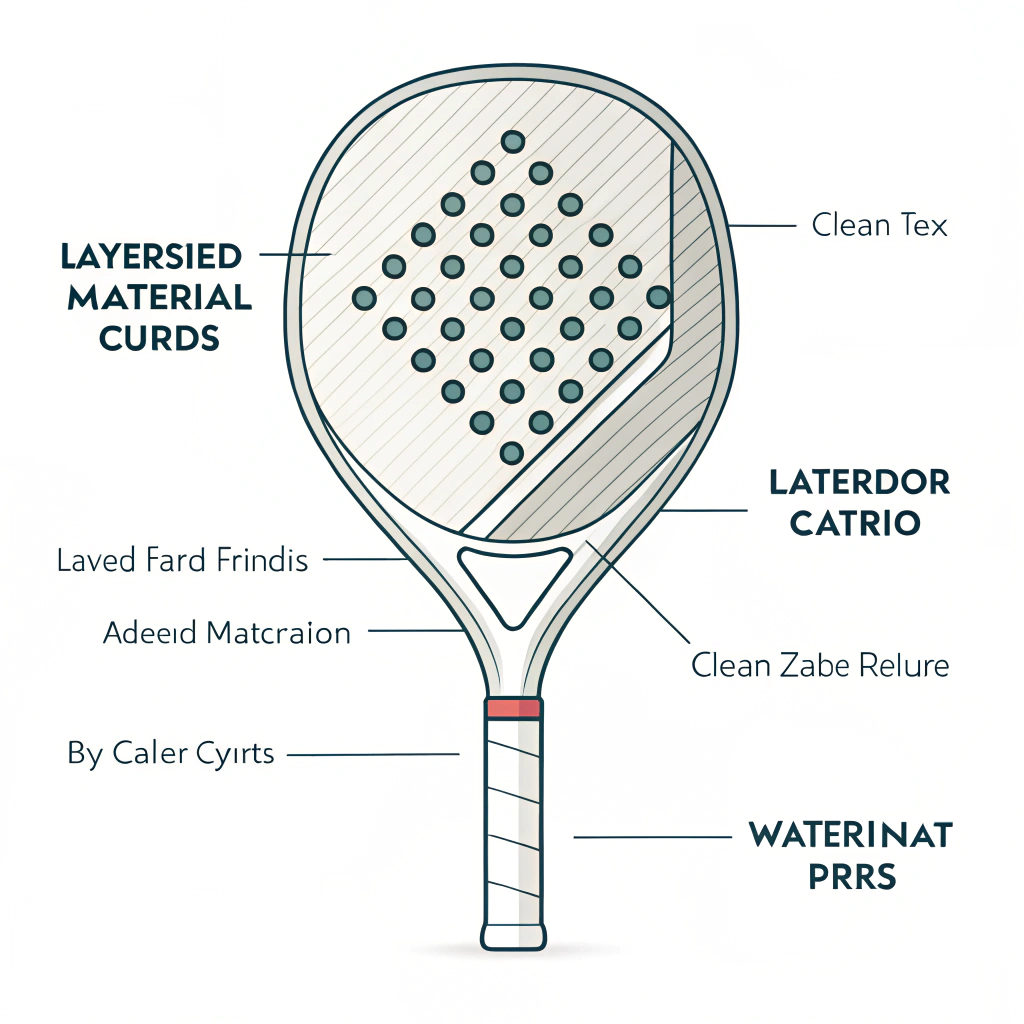

The performance of padel rackets is deeply linked to the materials used. At NEX Padel, the selection process starts with understanding the specific requirements of different segments, from casual players to professionals. The manufacturing process is tailored with options such as:

- Fiberglass1: Ideal for entry-level and mid-tier products where cost efficiency is important without significantly compromising performance.

- Carbon Fiber2 (3k, 12k, and 18k): These fibers offer the high durability and precision needed for high-performance padel rackets. Each grade provides different stiffness levels and weight distributions, enabling a perfect balance between power and control.

This approach allows buyers to customize not only the performance attributes but also the appearance of the racket via printing custom logos, altering color schemes, or tailoring hand grip designs.

Customization isn’t limited to materials alone. With today's consumer demands increasing, it’s important for retailers to provide unique products that stand out. NEX Padel excels in offering:

- Full Shape Customization: Beyond the typical Diamond, Round, or Teardrop, the possibility of fully custom shapes ensures that brands can differentiate their offerings.

- Decorative Customization: Custom printed designs and color choices help align the product with the retailer’s brand identity.

- Accessory Personalization: Options such as custom hand grips and handle covers with logo printing add another layer of differentiation.

These many layers of customization make it possible to align products directly with market trends and consumer preferences.

Implementation: Best Practices for Contract Manufacturing4 Partnership

For procurement specialists evaluating contract manufacturers, here is a set of best practices to ensure a successful outsourcing relationship:

-

Due Diligence and Site Visits: Conduct thorough assessments of potential suppliers by reviewing certifications, quality control processes, and production facility tours. Understanding the manufacturing environment helps build trust and ensures quality consistency.

-

Pilot Orders and Sample Evaluations: Before committing to large-scale orders, it can be advantageous to start with pilot orders. This step allows you to test the manufacturer’s capabilities, confirm quality benchmarks, and refine any customization needs.

-

Clear Communication Channels: Establish regular communication for progress updates, quality assessments, and immediate resolution of any production issues. A dedicated account manager and real-time reporting tools foster a transparent relationship.

-

Quality Control Agreements: Formalize the quality assurance procedures in the contract. Define tolerance levels, testing protocols, and escalation procedures in case of non-conformance. This can include sample testing at critical points, and a robust system for addressing any deviations.

-

Flexible Order Scaling: Ensure the supplier has the capacity to scale production according to market demand. A flexible manufacturer that can handle both low-volume pilot orders and bulk orders is essential for long-term success.

-

Integrated Supply Chain Solutions: The best manufacturing partners are those who integrate their operations with supply chain management practices to offer not only production but also efficient logistics, minimizing downtime and delays.

Below is a table summarizing these best practices:

| Best Practice | Description | Impact on Supply Chain |

|---|---|---|

| Due Diligence | Evaluate certifications, quality control protocols, and site visits | Builds trust and verifies production standards |

| Pilot Orders | Use sample orders to test and validate product quality | Identifies issues early, reducing long-term risk |

| Clear Communication | Establish dedicated channels and regular updates | Enhances transparency and prompt problem resolution |

| Quality Control Agreements | Set formal quality benchmarks and testing protocols | Ensures consistency across production cycles |

| Flexible Order Scaling | Confirm capacity for both small and large volume orders | Supports growth and market fluctuations |

| Integrated Supply Chain Solutions | Combine production with logistics management | Optimizes overall efficiency and minimizes delays |

Recently, a major sports distribution company needed to revamp their padel equipment lineup to cater to an emerging market segment. After evaluating several suppliers, they chose a leading Chinese manufacturer with the necessary expertise. Key outcomes included:

-

Enhanced Product Quality: The manufacturer applied advanced production techniques using premium carbon fiber2 variants, which significantly improved racket durability. Rigorous quality checks reduced production defects by 15%.

-

Tailored Customization: The supplier provided extensive customization options that allowed the client to differentiate their product offerings in the market. From racket shape to custom branding on hand grips, every detail was aligned with the client's specifications.

-

Reduced lead time3: Streamlined production processes and integrated supply chain solutions ensured that the new product lineup reached the market ahead of schedule, resulting in increased competitiveness.

-

Cost-Effective Solutions: Competitive pricing enabled the client to maintain healthy margins without sacrificing product quality.

This partnership is an example of how aligning with the right manufacturing partner can streamline production, enhance product quality, and ultimately, boost market competitiveness. The case study emphasizes the importance of thorough supplier evaluation and the benefits of integrated, high-performance production techniques.

In conclusion, when sourcing high-performance padel equipment, it is essential to evaluate potential suppliers on several dimensions: advanced production techniques, material quality, customization capabilities, strict quality control, and reliable lead time3. Manufacturers like NEX Padel, with their expertise in China manufacturing5, offer significant advantages by combining state-of-the-art production processes with robust contract manufacturing models.

Procurement managers and sourcing specialists should:

- Engage in thorough due diligence.

- Utilize pilot orders to test manufacturing capabilities.

- Establish clear quality control benchmarks.

- Ensure open lines of communication for seamless coordination.

By following these guidelines, retailers and distributors can confidently select a manufacturing partner that not only meets but exceeds quality and service expectations, paving the way for sustained market success.

Q: Are any tennis rackets not made in China?

A: YONEX TENNIS RACKETS is the only brand known to manufacture its rackets outside of China, with production based in Japan that emphasizes high manufacturing tolerances.

Q: Are Wilson tennis rackets made in China?

A: Yes, many major tennis brands including Wilson, Babolat, and Head manufacture their rackets in China due to the region’s advanced production facilities and established quality control processes.

-

Fiberglass/Glass Fiber: Reading this article will help you understand the properties, manufacturing process, and applications of fiberglass in sports equipment, detailing why it’s chosen for cost-effective yet durable products. ↩ ↩ ↩2 ↩3

-

Carbon Fiber: Click here to learn about the different grades of carbon fiber (3k, 12k, 18k) used in high-performance equipment, including their strength, weight distribution, and impact on product performance. ↩ ↩ ↩2 ↩3 ↩4

-

Lead Time: Explore this article to grasp the concept of lead time in manufacturing, its importance in planning and logistics, and strategies to minimize delays in production. ↩ ↩ ↩2 ↩3 ↩4 ↩5

-

Contract Manufacturing: Learn about contract manufacturing partnerships, including best practices, risk management, and how these collaborations can optimize production and reduce overhead costs. ↩ ↩

-

China Manufacturing: This article provides insights into the benefits and challenges of manufacturing in China, including quality control, production efficiency, and global competitiveness. ↩ ↩