Our high-performance padel rackets combine advanced material science, innovative designs, and precision craftsmanship to offer a tailored solution for sports equipment professionals looking to enhance their product offerings.

For any procurement manager or product developer, choosing the right padel equipment goes far beyond just price or brand recognition. It involves a deep understanding of design specifications, material properties, and manufacturing techniques that directly affect performance. In the competitive field of padel technology1, selecting or customizing a padel racket requires addressing several technical challenges:

• Balancing performance with durability

• Ensuring consistent precision during manufacturing

• Offering versatility in design – including Diamond, Round, and Teardrop shapes

• Incorporating the right materials such as fiberglass and various grades of carbon fiber (3k, 12k, 18k)

• Managing customization options2 (printing, color variations, hand grip logos, etc.)

These challenges become especially significant when partnering with a manufacturer that provides quick sample development and reliable delivery schedules. At NEX Padel, our integrated production process is designed to overcome these hurdles while maintaining exceptional quality control3.

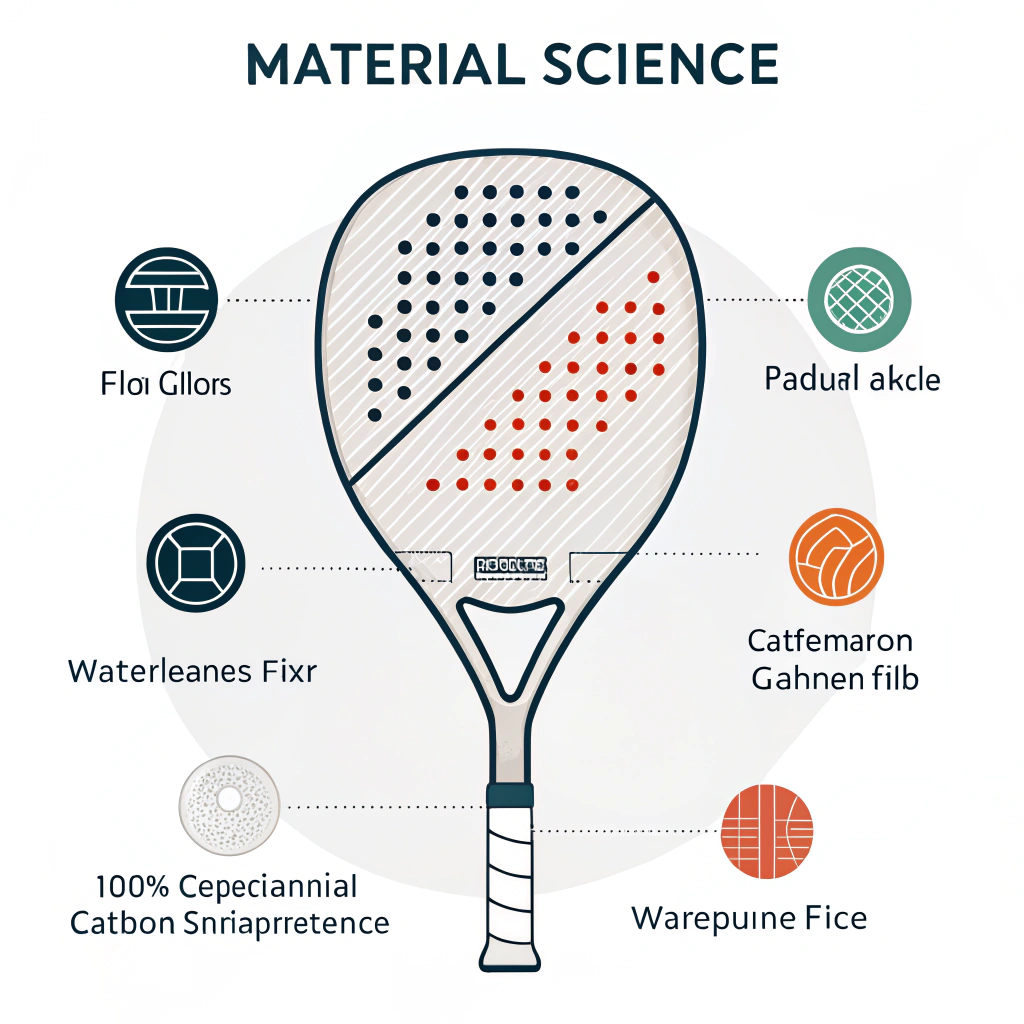

Materials are at the core of padel racket performance. Each material has distinct properties that affect weight, balance, power, and durability. Our manufacturing process leverages high-grade carbon fibers4 and fiberglass to create rackets that cater to different playing styles and performance requirements.

| Material Type | Properties | Benefits |

|---|---|---|

| Fiberglass | Lightweight, good flexibility | Ideal for balance and control |

| 3k Carbon Fiber | High flexibility, moderate stiffness | Suitable for intermediate gamers |

| 12k Carbon Fiber | Increased stiffness and power conversion | Preferred for a balance between power and precision |

| 18k Carbon Fiber | Superior stiffness, maximum power, and minimal deformation | Best for advanced players needing ultimate performance |

Choosing the correct material involves understanding the playing style and performance preference. Manufacturers and brands relying on our expertise appreciate these competitive differentiators, which ultimately enable them to position their products better in the marketplace.

In today’s B2B sports equipment market, customization is no longer an option; it is a prerequisite. We work closely with industry leaders like Reebok, Starvie, and Hirostar to provide uniquely designed padel rackets that stand out in a competitive landscape. Customization can include:

• Shape Variations: Options such as Diamond, Round, and Teardrop cater to different styles and ergonomics. Each shape influences the sweet spot, balance, and swing dynamics.

• Material Combinations: Mixing fiberglass with various grades of carbon fiber can optimize performance, ensuring a consistent material quality that suits targeted player profiles.

• Aesthetic Customization: Apart from functional attributes, custom printing, color schemes, and even branded hand grips and handle covers add a unique identity to the product line.

• Performance Specifications: Tailoring design elements to meet the rigors of professional training, tournaments, or match play involves a close review of competitive data and material stress tests.

Custom solutions not only elevate product performance but also enhance brand identity, allowing companies to distinguish themselves in a crowded market. Integrating custom padel racket design within your product strategy can drive market penetration and increase customer loyalty.

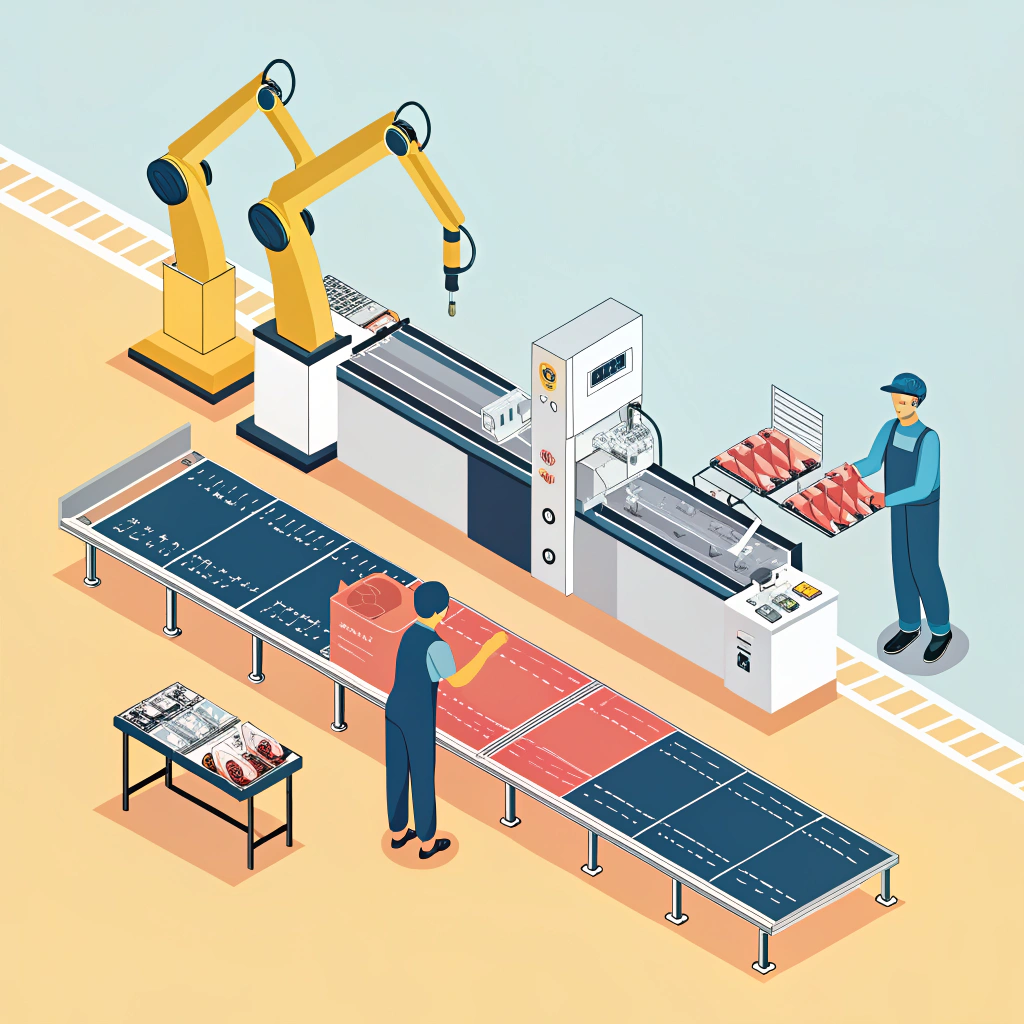

At NEX Padel, our manufacturing process is rooted in precise production techniques and strict quality control measures. Our approach encompasses every stage of production—from initial design to final quality checks—ensuring that each rackets meets defined performance criteria.

-

Design and Material Selection:

Our expert design team collaborates with clients to determine the optimal balance between performance, durability, and aesthetics. We assess material properties, considering the desired mix of fiberglass and carbon fibers (3k, 12k, or 18k) to meet specific performance requirements. -

Prototype Development:

Rapid prototyping5 is a key capability, enabling us to quickly produce test models with custom shapes (Diamond, Round, Teardrop) and branding features. This stage involves validating the design through performance testing and simulation analysis. -

Production and Quality Assurance:

Advanced production machinery and skilled operators work together to produce rackets consistently. Rigorous quality control ensures that every racket meets industry standards in dimensions, balance, and overall performance. Our tests simulate real-match conditions and diverse training scenarios to guarantee durability. -

Customization and Final Touches:

After mass production, the custom elements such as printed logos, color finishes, and specially designed grip accessories are added. This phase is crucial in aligning the final product with the client’s brand identity. -

Packaging and Delivery:

Each racket is carefully packaged, ensuring that it remains in pristine condition during transit. By streamlining the supply chain, we ensure prompt delivery, meeting even the tightest production schedules.

- Material Testing: Every batch of materials undergoes extensive testing to ensure consistency in weight and strength.

- Performance Simulation: We simulate stress and impact scenarios to ensure that each product can withstand long-term usage in various playing environments.

- Customer Feedback Loop: Continuous improvements are made using data collected from partners and end-users.

This comprehensive approach not only builds trust with our B2B partners but also aligns with market expectations for high-performance equipment.

When making procurement decisions for padel equipment, several factors must be considered to ensure the selected product meets both performance and market demands. Below is a checklist that outlines the essential criteria:

• Material Quality: Always verify the composition and grade of materials (e.g., carbon fiber variants and fiberglass).

• Design Versatility: Look for options that allow shape customization and ergonomic features suitable for various play styles.

• Manufacturing Capabilities: Partner with manufacturers that offer rapid prototyping, strict quality control, and reliable delivery.

• Customization Options: Consider the extent of customization available – from aesthetic details to technical enhancements.

• Price vs. Performance: Understand where your target market stands; more expensive models aren’t necessarily better for all skill levels.

• Supplier Reliability: Rely on past performance data and industry reputations to decide your manufacturing partners.

| Feature | High-Performance Custom Rackets | Standard Padel Rackets |

|---|---|---|

| Material Variety | Fiberglass, 3k, 12k, 18k Carbon Fiber | Usually limited to basic composites |

| Customization Options | Full customization including shapes, colors, and grip logos | Minimal to no customization |

| Manufacturing Precision | Advanced techniques with rigorous QA | General mass production |

| Designed Use | Specific design for tournaments, training, and matches | Often generic design for casual play |

| Supplier Partnership | Proven track record with top brands | Varies widely, less industry integration |

Utilizing this table, procurement managers can quickly compare high-performance custom solutions against standard products, highlighting key differences that influence purchasing decisions.

For sports equipment firms looking to upgrade or expand their padel offerings, the key is to align product choices with both performance requirements and brand identity. Here are some actionable insights:

- Engage with manufacturers who offer versatile customization options to differentiate your product line.

- Prioritize material quality and production precision to ensure every racket performs consistently under competitive conditions.

- Use detailed performance data and quality control measures as key decision-making criteria when evaluating manufacturing partners.

- Stay informed about the latest trends in padel technologies and market preferences to continuously refine product offerings.

- Consider comprehensive partnerships that include rapid prototyping, reliable delivery, and effective after-sales service.

By implementing these strategies, you not only meet your procurement needs but also position your brand as a leader in innovative and high-performance sports equipment.

• How many padel rackets should you have?

Using more than one padel racket is recommended to match different playing scenarios. Many professionals opt to have separate rackets for matches, tournaments, and training sessions to optimize performance based on the type of play.

• What is the best padel racket to buy?

The best padel racket depends on the player’s needs. High-performance models designed for power, control, and durability—often featuring advanced materials like customized carbon fibers—tend to offer superior performance for competitive play.

• Do expensive padel rackets make a difference?

Not necessarily. More expensive rackets can offer enhanced features such as smaller sweet spots and stiffer designs beneficial for advanced players, but beginners or intermediate players might find these features less forgiving and may perform equally well with moderately priced options.

-

padel technology: Click to read an article that explains the latest innovations in padel equipment, including design trends and performance-enhancing technologies. ↩ ↩

-

customization options: Click to discover how customization options in sports equipment design can enhance brand identity and meet specific performance requirements. ↩ ↩

-

quality control: Click to read an article on quality control measures in manufacturing, highlighting how rigorous testing ensures product reliability and consistency. ↩ ↩

-

carbon fibers: Click to explore detailed information on carbon fibers, their manufacturing processes, and how different grades (3k, 12k, 18k) affect racket performance. ↩ ↩

-

rapid prototyping: Click to learn about rapid prototyping techniques used in the sports equipment industry to speed up product development and testing. ↩ ↩