Padel rackets are built using advanced materials and production techniques designed to optimize performance, durability, and cost efficiency. This article provides a detailed analysis of the manufacturing cost breakdown1, components, and production techniques to empower procurement managers, product development specialists, and technical sourcing experts to make informed decisions.

In today's competitive sporting goods market, understanding the technical and cost aspects of padel rackets is essential. High-performance padel rackets are not only about aesthetics but also about the materials used, production precision, and customization capabilities. Suppliers like NEX Padel offer premium options with varying materials such as glass fiber and carbon fiber variants2 (3k, 12k, and 18k), each influencing the overall performance and pricing. In this article, we break down key aspects of padel racket manufacturing: material choices, design intricacies, detailed cost allocations, and customization factors.

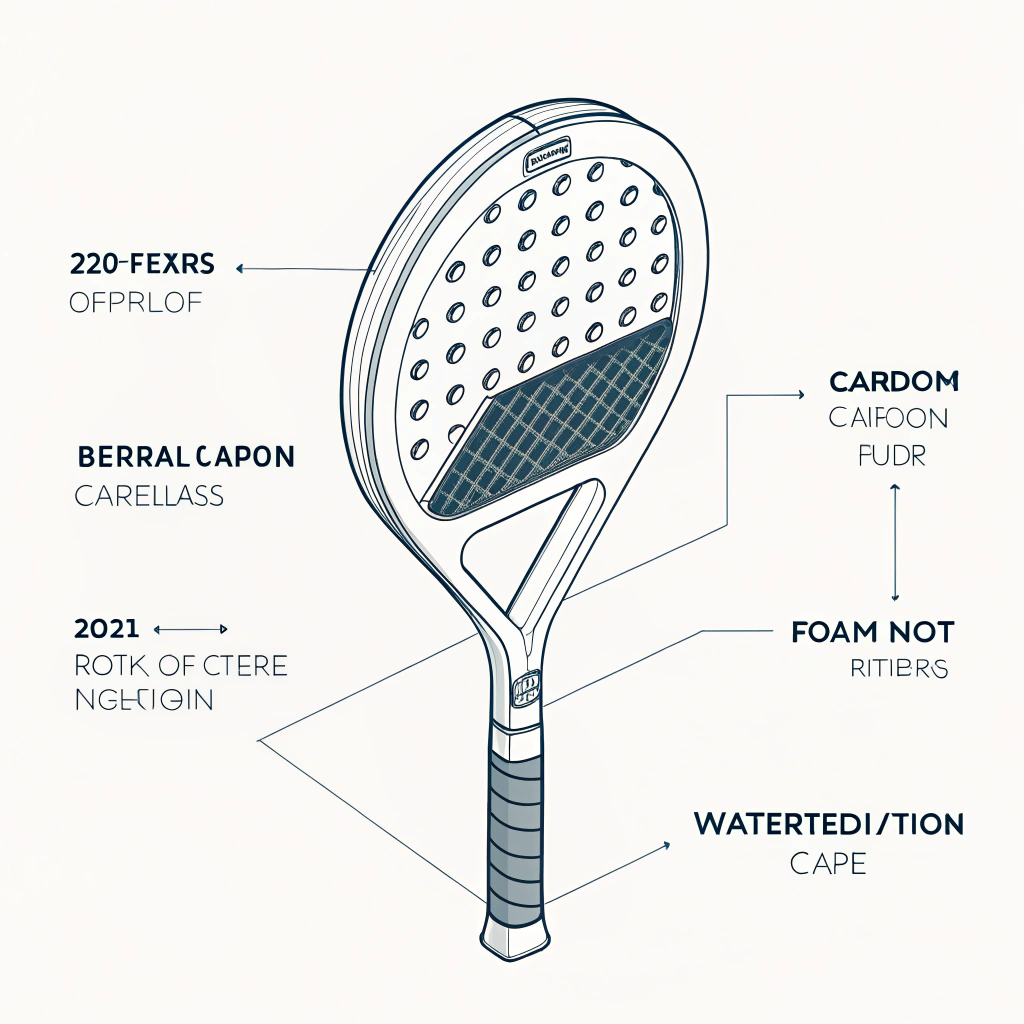

Understanding the fundamental components of a padel racket is key for a successful procurement strategy. The primary materials include:

• Fiberglass: Generally used in lower-cost, beginner rackets, fiberglass offers a cost-effective solution while maintaining sufficient strength.

• Carbon Fiber (3k, 12k, 18k): Used in intermediate to advanced rackets, these carbon variants provide enhanced performance. The numbers indicate fiber count and weave density which directly affect stiffness and weight.

• Core Materials: The racket core is typically comprised of foam or E.V.A. For instance, foam cores offer a softer feel and added comfort, beneficial for beginner players.

Different types of carbon fiber reflect various performance profiles:

• 3k Carbon Fiber: More flexible, which might reduce vibrations and improve comfort.

• 12k Carbon Fiber: Typically used to achieve higher stiffness and durability, making them preferred by advanced players.

• 18k Carbon Fiber: Top-tier option offering superior durability and performance.

The choice of material directly influences the cost breakdown, production complexity, and ultimately, the market positioning of the racket. Engineers and designers must balance these findings with the end-user's performance expectations.

Design and shape are integral to the racket’s performance, impacting both handling and power transmission. Manufacturers offer designs primarily in three styles:

• Diamond Shape: Known for its aggressive performance, the Diamond shape offers a larger sweet spot for enhancing power transfer.

• Round Shape: Favored for its balance, the Round design ensures uniform weight distribution, making it suitable for all player types.

• Teardrop Shape: This style blends the advantages of both round and diamond shapes, optimizing control and maneuverability.

Customizations can tailor the design even further. Production techniques now allow for fully customizable shapes and printing options, including hand grips and handle covers that can include company logos. Customization is an important factor in the manufacturing process, providing procurement managers with the flexibility to meet specific market demands.

Customization has an impact on both production timelines and budgets. With rapid prototyping and advanced machine-controlled production lines, suppliers like NEX Padel ensure that even bespoke designs meet stringent quality standards—all while maintaining efficient delivery times.

A clear cost breakdown helps procurement managers understand how each factor contributes to the final price of a padel racket. A typical cost analysis includes:

-

Raw Material Costs:

- The price variance between fiberglass and various types of carbon fiber is significant. High-end carbon fibers (12k, 18k) can increase the overall cost but also enhance racket performance.

- Core materials like foam or E.V.A also require careful pricing. Foam cores tend to be less expensive compared to high-performance alternatives, which in turn influence the overall cost.

-

Manufacturing Processes:

- Techniques such as layup methods, resin infusion, and precision cutting affect production efficiency and quality.

- Automated production lines, particularly those operating at advanced levels, drastically reduce wastage and ensure faster turnaround times.

-

Customization and Finishing:

- Custom printing, logo placements, and unique handle designs must be integrated into the production cycle.

- Hand grip customization does add marginal costs but also adds value through brand differentiation.

-

Labor and Overhead Costs:

- Skilled labor required for quality control, complex assembly processes, and design modifications will naturally reflect on the pricing.

- Overheads such as energy, facility leasing, and machine maintenance are also factored in.

The following table provides a sample cost breakdown for producing a high-performance padel racket:

| Cost Component | Percentage of Total Cost | Details |

|---|---|---|

| Raw Materials | 40% | Carbon fiber variants, foam core, resin |

| Production Processes | 30% | Automated layup, resin infusion |

| Customization & Finishing | 15% | Printing, logo embedding, hand grip design |

| Labor & Overhead | 15% | Quality control, facility operational costs |

Understanding this breakdown enables procurement specialists to identify opportunities for cost optimization where appropriate, such as using alternative suppliers or investing in advanced manufacturing processes that could lower marginal costs.

Modern production techniques offer several critical advantages, including precision, reliability, and scalability. Some key techniques include:

• Resin Infusion Technology3: This process ensures enhanced bonding of fibers which leads to better racket performance.

• Automated Layup Systems4: These systems optimize fiber placement to achieve consistent quality and reduce material wastage.

• Quick Prototyping5: Rapid sample production minimizes lead time, enabling suppliers to quickly adapt to market trends and customer specifications.

For instance, NEX Padel leverages cutting-edge technology to craft high-performance padel rackets that meet rigorous industry standards. With support for a wide range of customization—from racket shapes like Diamond, Round, and Teardrop to unique hand grip designs—manufacturers ensure that the final product aligns closely with both performance and aesthetic demands.

Furthermore, quality control systems play a significant role. Regular inspections at various production stages ensure that defects are caught early, and design iterations are refined before mass production, leading to fewer returns and higher customer satisfaction.

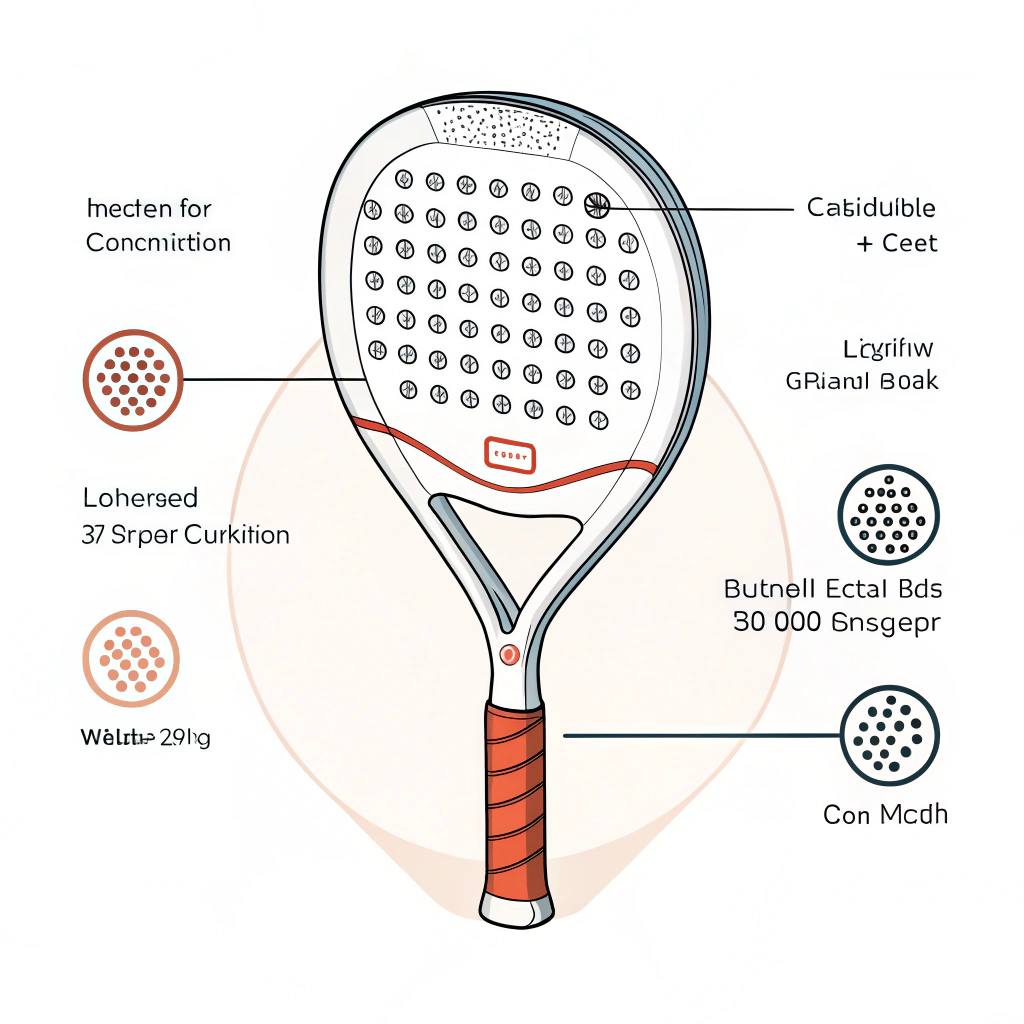

Customization in padel racket manufacturing goes beyond aesthetics. It is about fine-tuning performance characteristics to suit diverse skill levels and playing styles. Custom features often include:

• Unique color schemes and graphic designs that enhance brand value.

• Tailored weight distributions achieved through material placement and carbon fiber layering.

• Personalized handle and grip options designed to optimize player comfort.

These customization options also mean that manufacturers can cater to niche markets and exclusive brands. For B2B customers, the availability of custom preset components allows for quick modifications without compromising product integrity. This flexibility is invaluable in competitive markets where differentiation can be a critical driver of revenue growth.

In addition to improving market appeal, customization allows manufacturers to experiment with production processes that offer a blend of automation and craftsmanship. This marriage of technology and creativity is essential to achieving both cost efficiency and high-quality outcomes.

When evaluating padel rackets for large-scale procurement, consider the following actionable insights:

- Assess Material Quality: Compare the trade-offs between fiberglass and various grades of carbon fiber. While carbon fiber typically offers superior performance, it does come at a higher cost.

- Analyze Cost Components: Use detailed cost breakdowns to negotiate better pricing with suppliers or identify areas for cost optimization.

- Embrace Customization Benefits: Opt for suppliers capable of high-level customization to ensure your products stand out in crowded markets.

- Prioritize Production Efficiency: Look for manufacturers that leverage advanced, automated systems—this not only supports quality but also ensures timely delivery.

- Validate Supplier Credentials: Choose partners with a proven track record in manufacturing padel rackets for renowned brands, as their expertise often translates directly into product reliability.

By combining these considerations, procurement managers can make informed decisions that balance quality, performance, and cost.

A thorough understanding of the materials, design options, and production techniques behind padel rackets is vital for making informed procurement decisions. Suppliers like NEX Padel illustrate how cutting-edge manufacturing and advanced customization capabilities can be leveraged to meet the evolving demands of the sporting goods market. By carefully reviewing detailed cost breakdowns and appreciating the nuances of material differences, technical sourcing experts can select the right balance between performance excellence and cost efficiency.

Integrating modern production techniques with flexibility in customization, padel racket manufacturing is a field that continues to evolve rapidly. Staying updated with these trends and understanding the technical underpinnings will provide a competitive edge when negotiating with suppliers and planning product development strategies.

People Also Ask

Q: What material are padel rackets made of?

A: Padel rackets are typically made using high-quality materials such as carbon fiber or fiberglass. Fiberglass is generally used in lower-end, entry-level rackets due to its cost-effectiveness, while carbon fiber, available in variants like 3k, 12k, and 18k, is favored for intermediate to advanced performance due to its superior strength and precision.

Q: What is the core material of a padel racket?

A: The core of a padel racket usually consists of foam or Ethylene Vinyl Acetate (E.V.A). Foam cores offer a softer, more comfortable feel suitable for beginners, while other advanced materials may be used for increased performance in high-end models.

-

Manufacturing cost breakdown: Click here to discover a detailed explanation of how various cost elements from raw materials to labor contribute to the overall pricing in manufacturing. ↩

-

Carbon fiber variants: Read this article to learn about the different types of carbon fiber, including factors like fiber count and weave density, and how they impact the performance and cost of sporting goods. ↩

-

Resin Infusion Technology: Explore this resource to understand how resin infusion improves fiber bonding and enhances the structural integrity of composite products. ↩

-

Automated Layup Systems: Learn about automated layup systems to see how precision automation ensures consistent quality while minimizing material wastage during production. ↩

-

Quick Prototyping: Discover the benefits of quick prototyping, a process that accelerates sample creation and enables faster adaptation to market trends. ↩