NEX Padel custom padel paddle manufacturing offers a clear competitive advantage by providing high-performance, fully customizable solutions that meet the rigorous demands of global sporting goods distributors. In this article, we compare key differentiators and offer insights into why choosing NEX Padel as your manufacturing partner is a strategic decision.

Procurement managers and product development specialists often face a significant challenge: how to choose a manufacturer1 that not only has the technological capabilities but also offers extensive customization, rapid prototyping, and consistent quality control. With an increasing demand for high-performance padel equipment, it becomes crucial to evaluate factors such as material quality, production turnaround times, and flexibility in design.

When considering a new manufacturer, decision makers typically compare multiple factors:

- Material Quality: The use of high-grade materials like glass fiber, 3k, 12k, and 18k carbon fibers2.

- Customization Ability: Options for various designs including Diamond, Round, and Teardrop shapes with full custom branding.

- Production Efficiency: Rapid Prototyping3 and timely delivery schedules to meet market demands.

- OEM Capabilities: Trusted by renowned brands like Hirostar, Reebok, and Starvie, ensuring scalability and reliability. In this case, OEM Capabilities4 further illustrate the commitment to quality and brand integrity.

By understanding these key factors, you can compare manufacturing partners on an informed basis to ensure your products meet both performance and market expectations.

While several manufacturers claim to offer custom padel paddle solutions, NEX Padel stands out because of our advanced production techniques and deep industry insights. Below is a detailed comparison of the key factors you should consider:

| Criteria | NEX Padel | Other Manufacturers |

|---|---|---|

| Material Quality | Uses premium glass fiber, 3k, 12k, and 18k carbon | Varying quality; may not offer full spectrum |

| Customization Options | Fully customizable designs (Diamond, Round, Teardrop) including logo imprinting on grip and handle covers | Limited design templates and branding options |

| Production Speed | Rapid prototyping with fast sample confirmations and timely delivery | Typical turnaround times may delay market entry |

| OEM Partnerships | Trusted by major brands like Hirostar, Reebok, Starvie | Less evidence of partnerships with renowned brands |

| Quality Assurance | Rigorously monitored quality control with advanced production techniques | Inconsistent quality checks, often resulting in variability |

| Scalability | Flexible production lines to meet varying order sizes | Fixed production capabilities may not match dynamic demand |

In this comparison, NEX Padel clearly demonstrates its commitment to maintaining high performance and meeting the bespoke needs of procurement managers seeking reliability and consistency in production.

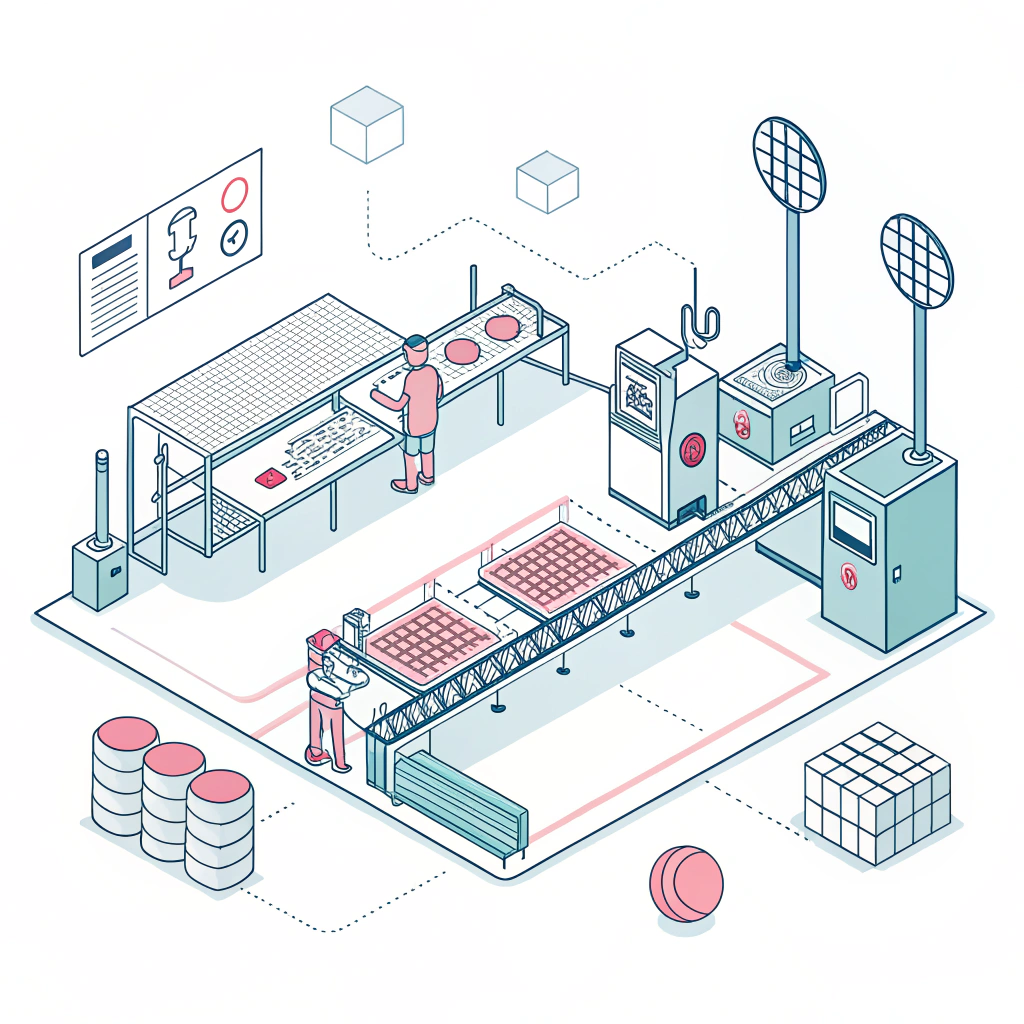

At NEX Padel, our manufacturing process is designed to deliver superior custom padel paddle solutions that excel in durability, performance, and aesthetic appeal. Our production process involves multiple stages to ensure every padel racket meets rigorous quality standards:

-

Material Selection:

We start by selecting high-grade materials, including various forms of carbon fiber such as 3k, 12k and 18k carbons. Each type brings different benefits – from enhanced flexibility and control to superior rigidity and power transfer. -

Precision Molding and Assembly:

Our state-of-the-art molding techniques ensure that every paddle design (Diamond, Round, or Teardrop) is formed with precision. This stage is critical to achieving the desired balance and performance on the court. -

Customization Process:

Customization is at the heart of our production. Clients can customize paddle shapes, design prints, and even components such as hand grips and handle covers. By integrating client logos and colors, we help create a unique product identity that resonates with end consumers. -

Rapid Prototyping:

To keep up with market dynamics, our rapid prototyping stage allows customers to visualize and experience product iterations early in the process, enabling adjustments that guarantee the final product aligns with expectations. -

Quality Assurance:

Every padel racket is subjected to rigorous quality control measures. Our process includes stress testing, performance validation, and thorough inspections to ensure each product meets international quality standards.

This structured and robust production process is why leading brands entrust us with their manufacturing needs, ensuring their market success by offering equipment that performs at the highest level.

One of the key reasons procurement professionals choose NEX Padel is our exceptional customization capability. In today’s competitive sporting goods market, having a unique product can significantly influence buyer decisions. Our customization process covers several aspects:

-

Shape and Design:

We offer three primary paddle shapes—Diamond, Round, and Teardrop. Each shape is engineered to suit different player styles and performance goals. For instance, the Diamond shape is ideal for aggressive play, while the Round design promotes excellent balance and control. -

Material Optimization:

Depending on the intended use and player level, materials can be selected to optimize the balance between power, weight, and durability. Our diverse material options, including various carbon fibers and glass fiber composites, allow us to fine-tune the performance characteristics of each racket. -

Branding and Aesthetics:

Custom printing options extend from the paddle surface to the hand grip. This means brands can seamlessly integrate their visual identity into the equipment, reinforcing brand presence on and off the court. Customization is not limited to visual elements; functional components like hand grip textures and handle covers can also be tailored to suit consumer preferences. -

OEM Production:

Our ability to produce padel paddles under OEM arrangements means that your branded products are made with the same high standards as our in-house offerings. This ensures that every product reflects the premium quality and design sophistication necessary to excel in today’s sports market.

A sample table outlining customization options is shown below:

| Customization Aspect | Options Offered | Benefits |

|---|---|---|

| Paddle Shape | Diamond, Round, Teardrop | Suit player style and performance needs |

| Material Selection | Glass fiber, 3k carbon, 12k carbon, 18k carbon | Optimize power, control, and durability |

| Branding Options | Custom logos, color printing on paddle surfaces | Enhance brand recognition and market differentiation |

| Accessory Customization | Hand grip and handle cover designs | Customize feel and improve grip comfort |

Such flexibility ensures that no matter the market segment or customer need, NEX Padel can deliver a product that fits perfectly into your portfolio.

In a market driven by trends and rapid consumer shifts, production speed is crucial. NEX Padel operates with a streamlined production process that significantly reduces lead times without compromising quality. Here are some components of our operational efficiency:

-

Rapid Prototyping and Testing:

Our advanced rapid prototyping capabilities allow for quick iterations. This means that as soon as design modifications are suggested, we can implement changes and provide samples for approval in a timely fashion. -

Integrated Supply Chain5:

Our close relationships with raw material suppliers ensure a consistent supply of high-quality materials. This integration minimizes production delays and allows us to maintain steady output. -

Flexible Production Capacity:

Whether you require a small batch of customized paddles for a niche market or large-scale production runs for major retail distribution, our production lines are adaptable. This flexibility is a key asset for procurement managers who need to scale production based on market demand. -

Quality and Compliance:

Every production cycle adheres to strict quality assurance protocols. We use both automated and manual inspection methods, ensuring that each paddle is fully compliant with international standards and performs reliably in real-world conditions.

Together, these operational strengths deliver not only efficiency but also peace of mind for partners who depend on timely and consistent product quality.

In summary, NEX Padel offers a comprehensive solution for businesses seeking high-performance, custom padel paddles. Our production and customization capabilities are backed by advanced manufacturing processes, rigorous quality control, and a commitment to meeting the tailored needs of our partners. Here are the key reasons procurement managers should consider NEX Padel:

-

Superior Material and Production Quality:

Our expertise in handling different carbon fibers and composite materials ensures that every paddle delivers top-tier performance and durability. -

Extensive Customization Options:

We provide a wide array of customization opportunities that not only enhance the product’s functionality but also strengthen your brand’s market presence. -

Efficient Turnaround Times:

With a robust rapid prototyping process and integrated supply chain, NEX Padel ensures that your design iterations are swiftly turned into market-ready products. -

Trusted OEM Partnerships:

Our track record as a trusted OEM manufacturer for brands like Hirostar, Reebok, and Starvie is a testament to our reliability and scalability.

For procurement managers and product development specialists who are in the decision comparison stage, these factors make NEX Padel the ideal partner for meeting your custom sporting goods requirements. By choosing NEX Padel, you secure a competitive edge with products that are engineered to excel and tailored to your brand’s unique story.

Now is the time to act. Consider deploying a pilot project or reaching out to our expert team for a detailed consultation. By taking these proactive steps, you can be assured that your next generation of padel equipment will not only meet industry standards but set new benchmarks in performance and aesthetics.

Q: Which brand makes the best padel rackets?

A: The best padel racket brand depends on individual preferences and performance needs. Leading brands, including those manufactured through trusted OEM partnerships like NEX Padel, are renowned for their quality construction and custom design options that serve professional-level performance.

Q: Are expensive padel rackets worth it?

A: Price does not always equate to better performance in padel. While high-end rackets offer advanced materials and craftsmanship, the best choice depends on player experience and personal playing style. Investing in a well-made, customized racket that suits your needs can often provide a better performance boost than simply choosing the most expensive model.

-

manufacturer: Read this article to explore the role of manufacturers, including how to assess their production capabilities and technological expertise for informed B2B decisions. ↩ ↩

-

carbon fibers: Learn about the different types of carbon fibers and their impact on the performance, durability, and weight of high-performance sporting equipment. ↩ ↩

-

Rapid Prototyping: Discover the benefits of rapid prototyping processes, which allow for fast iterations and quicker time-to-market for innovative product designs. ↩ ↩

-

OEM Capabilities: Click here to understand OEM (Original Equipment Manufacturer) concepts and how strategic partnerships can enhance product branding and scalability. ↩ ↩

-

Integrated Supply Chain: This resource explains how an integrated supply chain facilitates seamless material sourcing and production efficiency, vital for maintaining consistent product quality. ↩ ↩