Custom Padel Rackets combine precision engineering1 with advanced production capabilities – our custom OEM2 solutions deliver unmatched performance, design flexibility, and fast turnaround times for discerning B2B buyers.

Procurement managers and product specialists face a common challenge: selecting a supplier that not only meets high-performance standards but also provides the customization and reliability required in the sports equipment industry. In today’s rapidly evolving padel market, customization and technical excellence are paramount. Our expertise in manufacturing custom padel rackets leverages advanced techniques and rigorous quality control to provide products that meet the needs of high-performance athletes and sports equipment brands alike.

Custom padel rackets offer several advantages:

- Precision Engineering: High-quality materials such as 3K, 12K, and 18K carbon fiber or fiberglass ensure that the rackets provide the right balance of rigidity, power, and control.

- Customization Options: From unique shapes like Diamond, Round, and Teardrop to tailor-made printing finishes and hand grip personalization, our products cater to the aesthetic and performance requirements of any brand.

- Advanced Production Techniques3: Rapid Prototyping4 and streamlined production processes ensure that sample approval and full production run on time, every time.

- OEM Partnership Reliability: Numerous established brands like Hirostar, Reebok, and Starvie have trusted us for our high standards and technical know-how.

When comparing suppliers, procurement managers typically weigh the following factors:

- Material Quality: The choice between fiberglass and various grades of carbon fiber is crucial. Lower K values (e.g., 3K carbon) offer greater elasticity and comfort; higher K values (e.g., 12K or 18K) improve rigidity, power, and precision.

- Production Speed and Consistency: Fast sample prototyping and reliable full production deliveries ensure that the supply chain remains uninterrupted.

- Customization Flexibility: Options include full shape customization, unique printing capabilities, and even the personalization of hand grips and handle caps, which are important for branding and tailored performance.

- Case Studies and Performance Data: Real-life case studies and technical data help prove that a supplier’s products perform as expected under rigorous conditions.

| Specification | Fiberglass | 3K Carbon Fiber | 12K/18K Carbon Fiber |

|---|---|---|---|

| Rigidity | Moderate | Lower compared to high-K | High rigidity for precision |

| Elasticity & Comfort | Good | High elasticity & forgiveness | Requires good technique for optimal performance |

| Production Cost | Cost effective | Moderate cost | Higher cost due to materials and processing complexity |

| Customization Flexibility | Limited shapes/colors | Medium customization | Extensive customization options including shape, printing, and grip |

| Target User | Entry-level players | Intermediate players | Advanced and professional players |

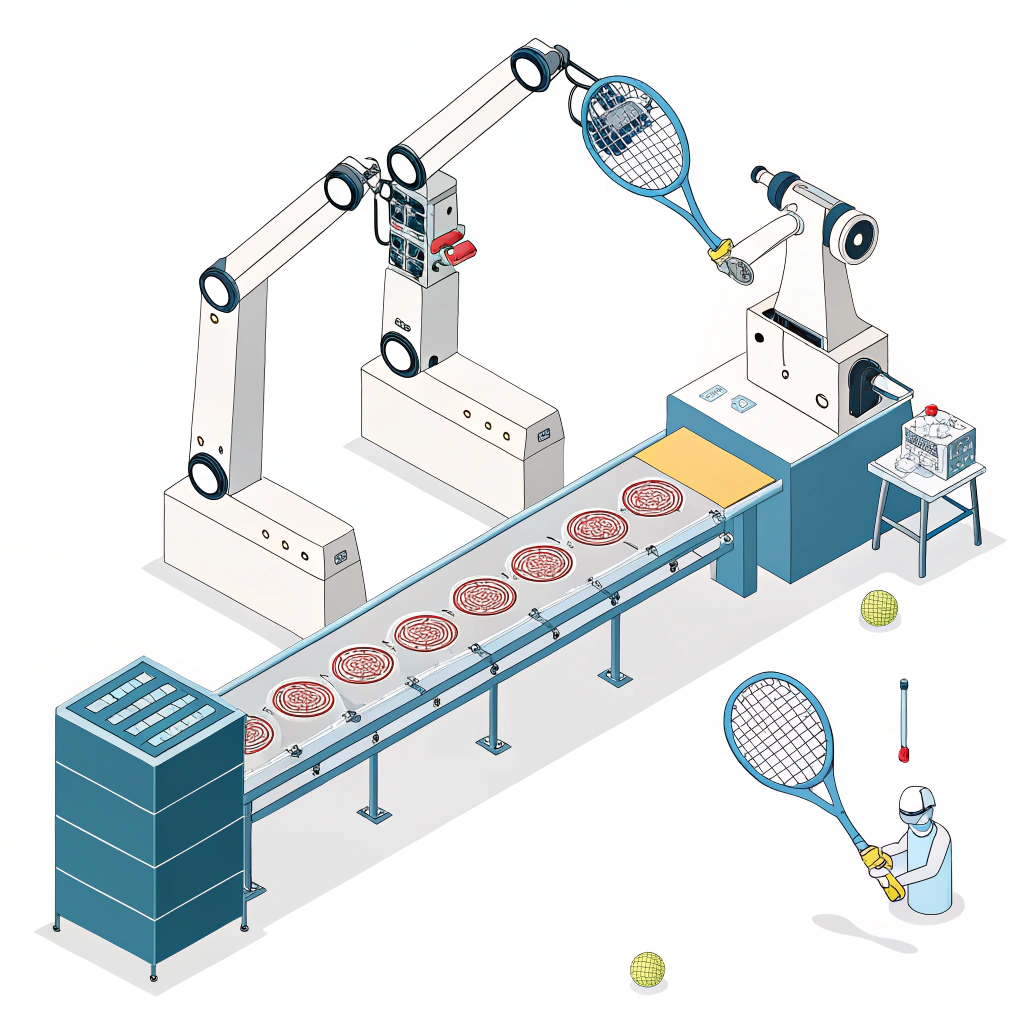

Our production process employs a fully integrated Quality Control5 system that continuously monitors each phase—from material selection to the final product assembly—to ensure that every rackets lives up to its high-performance promise.

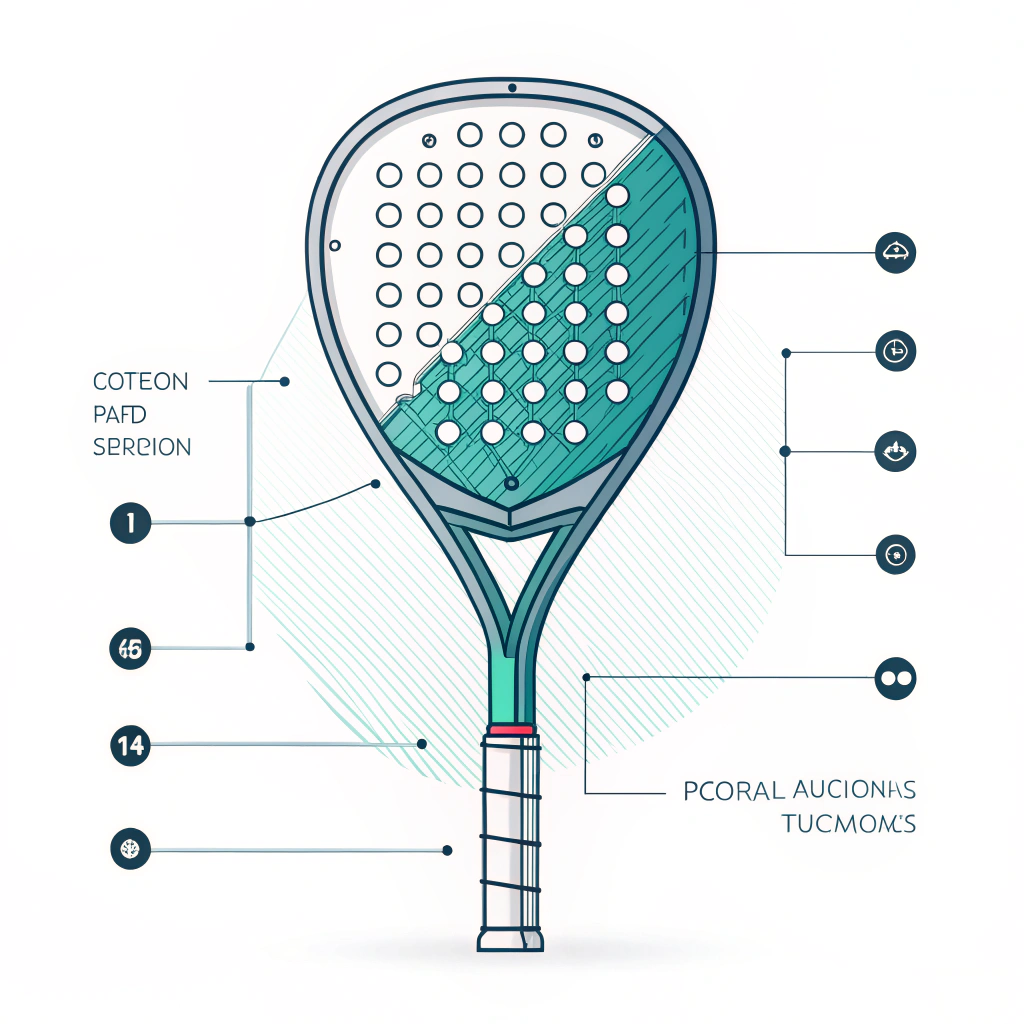

Our manufacturing process harnesses several state-of-the-art production techniques. Here are the essential components that support our high-performance custom padel rackets:

Selecting the right material is crucial for the rackets’ performance. We work with:

- Fiberglass: Excellent for cost efficiency and initial product ranges.

- 3K Carbon Fiber: Provides a balance of elasticity and control, suited for players who need additional comfort.

- 12K and 18K Carbon Fiber: Ensure a harder face, improved power, and precise ball control for advanced players.

By choosing materials that are tailored to performance needs, we help our clients cater to a spectrum of sporting capabilities. This emphasis on material quality directly translates into enhanced durability, superior playability, and long-term customer satisfaction.

Our design process is not “one-size-fits-all.” We offer:

- Custom Shapes: Among our popular designs are Diamond, Round, and Teardrop, but we also support full shape customization to meet brand-specific requirements.

- Printing and Visual Customization: From logo placement to unique color applications, our in-house printing capabilities ensure that each racket is both functional and visually appealing.

- Hand Grip and Handle Cap Personalization: Custom logos and branding extend to every component of the racket, reinforcing brand identity even to the smallest detail.

These customization options give our partners the freedom to align product aesthetics with their brand image and market needs—ensuring each product not only performs well but also stands out on the shelf.

Time-to-market is a crucial factor:

- Swift Sampling: We can produce quick samples that allow our partners to evaluate the design, feel, and performance ahead of a full production run.

- Strict Quality Control: Using advanced monitoring techniques on every unit, we ensure consistent quality across batches. Our rigorous testing protocols simulate game conditions and stress tests to confirm durability and performance.

Our commitment extends beyond production:

- Collaboration with Renowned Brands: Our experience as an OEM for brands such as Hirostar, Reebok, and Starvie reinforces our reliability and technical expertise.

- After-Sales Support: We ensure continuous feedback, addressing any quality or design concerns promptly to help our partners maintain market competitiveness.

- Scalable Production: Our facilities are designed to scale quickly as demand grows, ensuring that delivery timelines are maintained without compromising quality.

These advanced production techniques and robust quality assurance methods enable us to produce custom padel rackets that not only meet but exceed the demanding standards of professional padel players and top-tier brands.

A leading European sports brand needed a more rigid and powerful racket to cater to high-level players. Our rapid prototyping process allowed them to test 12K carbon fiber rackets under real game conditions. The shift from 3K to 12K carbon significantly improved the racket’s precision and power output, resulting in positive feedback from professional users, and ultimately drove increased sales and brand loyalty.

A startup retail brand aimed to launch a unique line of padel rackets with custom shapes and branded aesthetics that would differentiate them in a competitive market. By leveraging our advanced customization options, from tailored shapes to custom printing, the final product ranged achieved a distinct brand signature. Their success was evidenced by rapid market adoption and enhanced consumer engagement at major sporting events.

These cases demonstrate that when the production process is aligned with market needs and technical excellence, it is possible to deliver products that satisfy the most demanding performance and aesthetic criteria.

When selecting an OEM partner for custom padel rackets, consider the following steps:

- Conduct a Detailed Technical Evaluation: Assess the material specifications, customization options, and production quality control measures. Ensure the supplier provides rigorous testing data and real-world performance case studies.

- Review Production Capabilities: Confirm that the supplier is equipped to handle both rapid prototyping and full-scale production with a focus on meeting delivery timelines consistently.

- Request Demonstrative Samples: Implement a sample trial phase that allows stakeholders to verify the performance and quality of the products under consideration. This step is vital to ensure that the products meet your end-user expectations.

- Verify After-Sales and Collaborative Support: A reliable OEM partner should offer comprehensive after-sales support and be open to iterative product refinements based on feedback. This level of engagement is critical to long-term partnership success.

| Consideration Factor | Importance | Our Advantages |

|---|---|---|

| Material Quality & Options | High | Variety from fiberglass to advanced carbon fiber types |

| Customization Flexibility | High | Full shape, printing, and grip customization available |

| Production Speed | Essential | Rapid sampling with consistent, scalable production |

| Post-Production Support | Critical | Dedicated after-sales support and collaborative approach |

| Technical Data & Case Studies | Highly supportive | Proven case studies and performance data on all products |

This table encapsulates how our tailored solutions meet the exacting demands of procurement managers looking for a quality OEM supplier in the padel racket market.

In summary, custom padel rackets crafted with high-performance materials and advanced production techniques present a compelling choice for sports equipment distributors and padel clubs. For procurement managers faced with the vendor selection decision, our comprehensive approach—from meticulous material selection and precision engineering to rapid prototyping and robust quality assurance—provides both the reliability and technical excellence required in today’s competitive market.

We invite you to analyze your current supply chain requirements and consider an OEM partner that prioritizes quality, speed, and innovation. Empower your brand by choosing a supplier that not only meets technical specifications, but also delivers on the promise of high performance, ensuring your products excel in both playability and durability.

Take the next step towards elevating your product line by reaching out to us for a comprehensive consultation and to explore how our custom solutions can be tailored to your specific market needs.

Q: What padel rackets do professionals use?

A: Professional players often use high-performance models made with advanced materials. Leading rackets are typically constructed using high-grade carbon fiber like 12K or 18K for precision and power. Options range among brands such as Nox, Bullpadel, and others, where the focus remains on a balance of rigidity, control, and game-enhancing performance.

Q: Do expensive padel rackets make a difference?

A: Yes, expensive padel rackets are typically built with superior materials and advanced manufacturing techniques that can improve performance, comfort, and durability. They are particularly beneficial for experienced players who can fully utilize these performance enhancements, although beginners may not notice as drastic a difference.

Q: Which is better, 3K or 12K carbon?

A: The choice depends on the player’s needs. 3K carbon is generally softer, offering more elasticity and a forgiving play, which benefits casual players and those seeking comfort. Conversely, 12K carbon delivers greater rigidity, power, and precision, making it an ideal choice for advanced players with refined techniques.

-

Precision Engineering: Click to explore the principles behind precision engineering and its critical role in ensuring consistent, high-performance product manufacturing. ↩ ↩

-

OEM: Click to learn about Original Equipment Manufacturing processes and how OEM partnerships streamline production, quality assurance, and market scalability for B2B businesses. ↩ ↩

-

Advanced Production Techniques: Click to delve into state-of-the-art production methods that boost manufacturing efficiency and deliver superior product quality in competitive markets. ↩ ↩

-

Rapid Prototyping: Click to understand how rapid prototyping accelerates product development cycles and helps businesses reduce time-to-market with iterative testing. ↩ ↩

-

Quality Control: Click to discover robust quality control strategies and technologies that ensure product reliability and uphold industry standards. ↩ ↩