Teardrop padel rackets offer an excellent balance between power and control, making them an ideal choice for mid-level to advanced players who also demand high customizability1 and performance reliability in their game equipment.

Procurement managers and product developers in the sporting goods industry face a significant challenge: selecting padel rackets that not only deliver on performance but also allow for full customization to meet branding and market differentiation needs. Among the available designs, the Teardrop Padel Rackets2 has emerged as a promising option. However, many decision-makers struggle to understand its technical advantages compared to traditional Round and Diamond shapes. This challenge becomes even more complex when considering the use of advanced materials like various grades of carbon fiber3 such as 3K, 12K, and 18K.

Several factors contribute to this decision-making complexity:

-

Technical Specifications and Material Differences

The choice of carbon fiber grade, such as 3K, 12K, or 18K, directly impacts the racket's flexibility, rigidity, and overall performance. Each grade has its merits in terms of comfort versus power delivery. Procurement managers need to balance their product line’s expectations with technical parameters that meet different player skill levels. -

Design Impact on Gameplay

The shape of the racket influences the sweet spot location, weight distribution, and swing dynamics. Teardrop rackets typically position the sweet spot in a place that balances power delivery with precise control, while round and diamond shapes may push these characteristics to one extreme or another. -

Customization Demands

In today’s competitive market, offering unique features like customizable graphics, colors, hand grips, and handle covering is essential. Product developers need manufacturing partners who can support rapid prototyping and maintain high production quality while offering extensive customization options. -

Production Reliability and Timely Delivery

Meeting market demand means that production partners must excel in rapid prototyping and just-in-time delivery4 with consistent quality. A delay or inconsistency in manufacturing can impact market launches and brand reputation.

At NEX Padel, our expertise lies in delivering high-performance padel rackets that incorporate advanced production techniques, ensuring consistency and durability. Below is a detailed breakdown of how our Teardrop Padel Racket addresses the challenges faced by procurement managers and product developers:

-

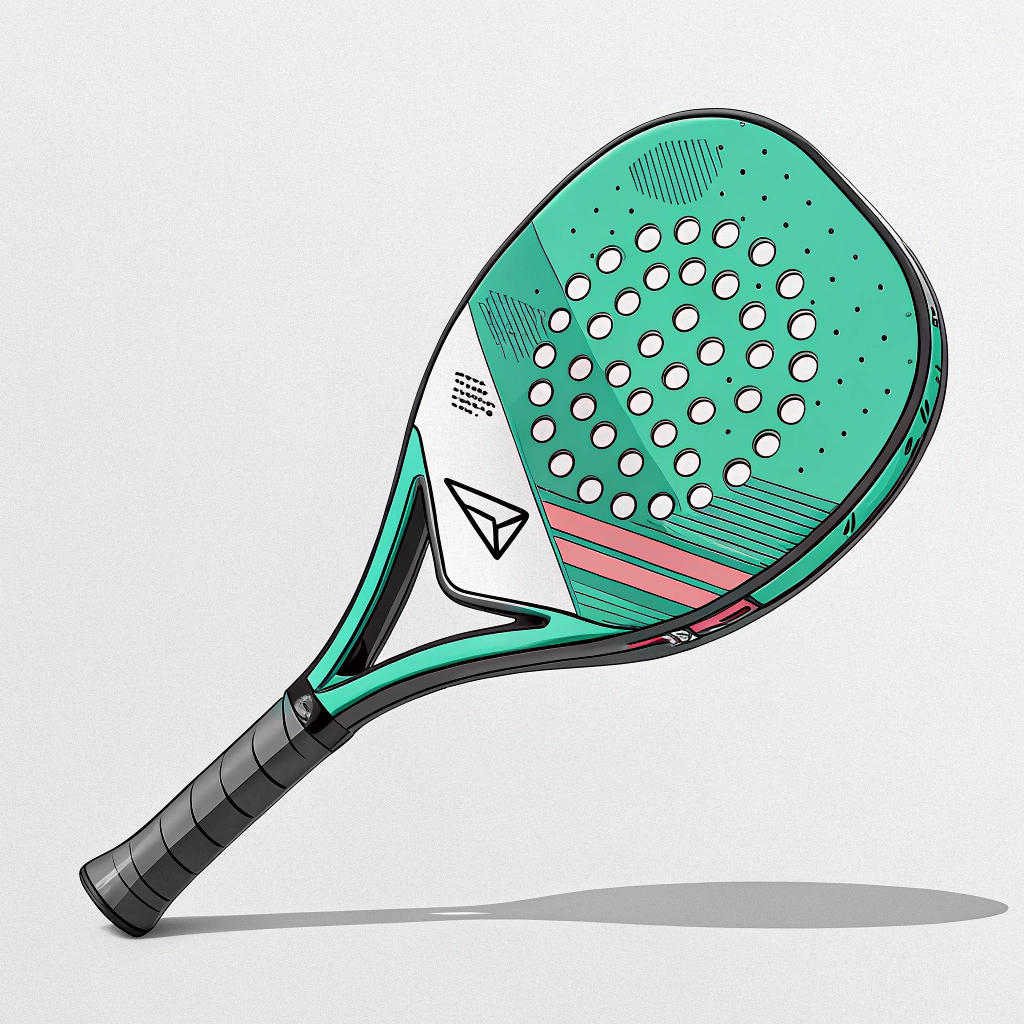

Balanced Performance:

The teardrop shape is engineered to offer a balanced distribution of power and control. Its design positions the sweet spot at an optimal location—slightly higher than round rackets and lower than diamond designs—providing versatility for diverse playing styles. -

Customizability:

Our manufacturing capabilities include full customization of shape, graphics, colors, and even details like hand grip logos and handle covers. This allows brands to align their product with specific market identities and customer expectations. -

Advanced Material Use:

We deploy advanced grades of carbon fiber including 3K, 12K, and 18K, allowing our customers to select the specific performance characteristics that meet their requirements. This selection directly influences racket flexibility, shock absorption, as well as power delivery. -

Rapid Prototyping and Quality Assurance:

Partnering with industry leaders such as Hirostar, Reebok, and Starvie, our rapid prototyping5 and manufacturing process ensures that every custom order meets stringent quality controls. Our commitment to timely delivery and consistent production quality minimizes the risks associated with production delays.

Understanding the difference between various carbon fiber grades is crucial for choosing the right racket material. The table below summarizes the key differences:

| Carbon Fiber Grade | Key Characteristics | Performance Impact | Typical Application |

|---|---|---|---|

| 3K Carbon | Softer touch, more elasticity | Greater comfort, forgiving impact | Entry-level to intermediate |

| 12K Carbon | Moderate rigidity, balanced feel | Offers a blend of power and control | Intermediate to advanced |

| 18K Carbon | Highest rigidity, precise feedback | Maximum power and precision for skilled players | Advanced/professional |

This table helps illustrate why selection depends on both user skill level and desired performance attributes. For a teardrop design, choosing 12K carbon fiber often provides the ideal balance for many players, but options remain available for custom performance needs.

To ensure that our rackets not only perform exceptionally but also resonate with brand identity, we offer extensive customization options:

-

Shape Customization:

While our focus here is on the teardrop design, our manufacturing line can also produce round and diamond shapes. This flexibility allows clients to diversify their product portfolios with unique designs that cater to various playing preferences. -

Graphics and Color Customization:

Custom graphics printing is available on both the racket face and the handle. This capability is particularly useful for brands looking to distinguish their products in a competitive market. -

Additional Custom Elements:

Our customization options extend to incorporating logos on the hand grip and handle covers. This attention to detail allows for a coherent brand presentation across all elements of the padel racket.

At NEX Padel, we pride ourselves on state-of-the-art production techniques that include rapid prototyping. This speed combined with a rigorous quality control process ensures that every product is built to last. Our production process involves:

-

High-Precision Manufacturing:

Utilizing modern machinery, each racket is produced to exact specifications. This minimizes variability and ensures that every racket delivers consistent performance. -

Durability Testing:

Every batch of rackets undergoes comprehensive durability testing. This process ensures that even with advanced customizations, the product maintains high performance throughout its lifecycle. -

Timely Delivery and Scalability:

Our ability to quickly scale up production ensures that orders are delivered on time, even when custom orders are involved. This reliability is key in maintaining strong relationships with leading padel brands.

To illustrate the impact of our teardrop design and customization capabilities, consider a recent collaboration with a renowned sporting goods brand. The client sought a padel racket that could cater to both mid-level and advanced players while also allowing significant brand differentiation through custom graphics and design elements.

-

Balancing Performance Characteristics:

The client required a racket that provided an optimal mix of power and control. Traditional designs either leaned too much towards control or power, making it difficult to satisfy the diverse needs of their customer base. -

Customization Demands:

The brand needed to imprint its identity through custom graphics, colors, and grip designs. The challenge was to incorporate these elements without compromising the overall performance of the racket.

-

Design Refinement:

We refined our teardrop design to ensure that the sweet spot was optimally positioned, balancing the requirements for both power and control. -

Material Optimization:

By opting for a 12K carbon fiber build, we provided a medium level of rigidity that offered a comfortable yet responsive feel, suited to a broader range of players. -

Customization Integration:

Our production line incorporated client-specific customizations, including full-color graphics, logo placement on hand grips, and custom handle covers. -

Quality Assurance:

Rigorous testing ensured that the customized designs did not negatively impact the racket's performance, maintaining high standards across all production batches.

The client reported significant improvements in customer satisfaction and brand recognition. The balanced performance of the teardrop racket, combined with its striking appearance, set the product apart from competitors in the market. This case demonstrates how technical precision and customization can harmonize to yield a product that not only meets market demands but also builds long-term brand loyalty.

For procurement managers evaluating padel racket options, particularly the teardrop design, the following steps are recommended:

-

Conduct In-depth Material Analysis:

Evaluate the differences between 3K, 12K, and 18K carbon fiber. Ensure that the chosen material matches the playing style and market positioning of your target customer. -

Assess Design Requirements:

Compare various racket shapes. Consider a table like the one below, which summarizes each design’s core benefits:

| Racket Shape | Sweet Spot Position | Performance Emphasis | Recommended Player Level |

|---|---|---|---|

| Round | Centrally located | Superior control and comfort | Beginners to intermediates |

| Diamond | Higher sweet spot | Enhanced power, less forgiving | Advanced players |

| Teardrop | Optimally balanced (mid-level) | Balanced power and control | Mid-level to advanced |

-

Utilize Customization Options:

Leverage customization capabilities to differentiate your product line. Integrate custom graphics and brand logos without compromising on performance. -

Review Production Capabilities:

Ensure your manufacturing partner offers rapid prototyping and strict quality testing protocols. This is crucial for managing production timelines and ensuring product reliability. -

Client and Market Feedback:

After product launch, gather feedback from end-users to continuously improve design and performance characteristics. -

Stay Updated on Technological Advances:

As material sciences and manufacturing processes evolve, keep abreast of the latest trends and integrate new techniques that could further enhance performance and customization.

Our team at NEX Padel is committed to helping brands achieve these goals. By choosing our teardrop padel racket, you benefit from a solution that is backed by technical expertise, customization flexibility, and reliable production standards.

PAA1: Is teardrop padel racket good?

A teardrop-shaped padel racket offers the perfect balance of power and control. Its design strategically positions the sweet spot to provide a versatile performance suited for mid-level and advanced players seeking an all-around playing experience.

PAA2: Which is better, 3K or 12K carbon?

Generally, higher K values indicate more rigidity. A 3K carbon racket offers a softer, more forgiving touch with enhanced elasticity, while a 12K carbon racket provides a balanced blend of power and control, making it ideal for players with developed techniques.

PAA3: Is there a fake padel racket?

Yes, distinguishing real padel rackets from fakes involves checking for high-quality materials and precise branding. Authentic rackets feature consistent logos without misspellings and use premium materials verified for superior performance.

-

[customizability]: Click to discover how customizability in sports equipment can drive brand differentiation, enhance customer engagement, and meet specific market needs. ↩ ↩

-

[Teardrop Padel Rackets]: Click to read an article detailing the design advantages of a teardrop racket shape, including its impact on balance, swing dynamics, and performance compared to traditional shapes. ↩ ↩

-

[carbon fiber]: Click to explore an in-depth guide on carbon fiber, including the differences between grades like 3K, 12K, and 18K and how they influence racket performance. ↩ ↩

-

[just-in-time delivery]: Click to understand the concept of just-in-time delivery, its role in reducing inventory costs, and its importance in maintaining consistent production quality. ↩ ↩

-

[rapid prototyping]: Click to learn about rapid prototyping in manufacturing, its benefits for custom sports equipment, and how it ensures product quality and speedy market entry. ↩ ↩