In summary, premium padel rackets produced on advanced OEM1 lines not only enhance brand image but also deliver unmatched performance. By leveraging various high-performance materials and offering extensive customization options from shape to printing, manufacturers like NEX Padel empower B2B clients to meet diverse market demands efficiently.

In today’s competitive sports equipment market, selecting the right manufacturing partner is crucial for enhancing your brand’s lineup. As procurement managers and brand owners, you are tasked with ensuring that your products stand out in performance and design. This article provides a solution-oriented guide on sourcing high-end padel rackets using advanced manufacturing techniques that guarantee precision, durability, and customization flexibility.

The padel market is evolving rapidly. With increasing customer expectations, brands must provide high-performing rackets that mix durability with innovative design. However, sourcing such equipment poses several challenges:

- Material specification: Manufacturers may use a variety of materials—from fiberglass to different grades of carbon fiber2 (3K, 12K, and 18K)—each with unique performance characteristics.

- Customization needs: Brands seek to offer individualized designs such as Diamond, Round, or Teardrop shapes along with personalized hand grip logos and handle covers.

- Production efficiency: Delivery speed, prototyping agility, and overall production precision are vital for meeting market deadlines.

- Quality assurance: Ensuring consistency in performance under high-stress conditions remains a key concern.

Understanding these challenges starts with an analysis of market demands and production constraints. The primary factors include:

-

Quality and Performance Expectations

Customers now expect padel rackets that combine both flawless performance with a contemporary aesthetic appeal. The use of advanced materials such as high-grade carbon fiber contributes significantly to improved racket strength and performance. -

Customization and Branding Requirements

In a crowded market, product differentiation plays a key role. The ability to offer fully customized racket shapes, imprint logos, and choose from multiple color combinations not only enhances brand identity but also allows for tailored marketing strategies. -

Rapid Innovation and Prototyping

With trends shifting quickly, time-to-market is critical. Manufacturers that offer rapid prototyping3 and timely deliveries meet the growing needs of brands keen to introduce the latest designs faster than their competitors. -

Supply chain transparency4 and Cost-Effectiveness

B2B sourcing clients need robust supply chain management to ensure that production schedules are maintained while also balancing cost-effectiveness. Every stage from raw material sourcing to final quality checks must be meticulously managed.

To overcome these challenges, partnering with a manufacturer that adopts advanced production techniques is essential. Here’s a detailed look at the solutions:

Manufacturers like NEX Padel use state-of-the-art production methods with a variety of materials. Below is a comparison table that outlines key features of common materials used:

| Material | Key Attributes | Applications |

|---|---|---|

| Fiberglass | Affordable, moderate rigidity | Entry-level models, training rackets |

| 3K Carbon | Enhanced durability, good strength | Intermediate and advanced playing levels |

| 12K Carbon | Lightweight, high performance | Premium rackets for competitive and elite players |

| 18K Carbon | Exceptional stiffness and control | Top-tier, high-performing models for professionals |

This table not only highlights the technical differences but also aids in aligning your product offering with the desired performance levels and budget.

Customization goes beyond just choosing a shape; it extends to incorporating distinct brand identities into every detail of the racket. Consider the following attributes:

-

Shape Customization:

Manufacturers can produce padel rackets in various shapes such as Diamond, Round, and Teardrop. Each design offers unique balancing characteristics; for instance, Diamond shapes may provide higher power due to their head-light design while Round shapes offer greater control. -

Logo and Print Customization:

Tailor-made printing on racket surfaces, hand grips, and handle covers allows brands to proudly display their logos and adhere to unique color schemes. This level of personalization is crucial for both branding and customer loyalty. -

Hand Grip Engineering:

Customization options extend to the hand grip, where varying textures and sizes can impact playability and comfort during extended matches. Manufacturers ensure that the hand grip not only fits ergonomic standards but also complements the overall racket design.

Implementing rigorous quality control alongside advanced production techniques is paramount. Manufacturers maintain quality assurance through methods such as:

- In-line inspections at every stage of production

- Stress and fatigue testing for material endurance

- Consistency checks across batches to ensure uniform performance

The result is a product that delivers on performance expectations repeatedly, reducing the risks associated with product recalls or brand damage.

To further illustrate the advantages of advanced OEM manufacturing, consider the success stories of well-known brands:

- Hirostar: Leveraged high-performance padel rackets produced with advanced 18K carbon fiber, positioning themselves as a premium brand with superior product durability.

- Reebok: Benefited from customizable designs that allowed for unique collaborations and special edition releases.

- Starvie: Focused on integrating cutting-edge technology into their product line-up, underscoring the importance of precision and production efficiency.

These partnerships reflect how tailored production capabilities and strict quality control standards contribute to building long-term brand success. By aligning your product specifications with proven manufacturing techniques, you create a strong competitive edge in the market.

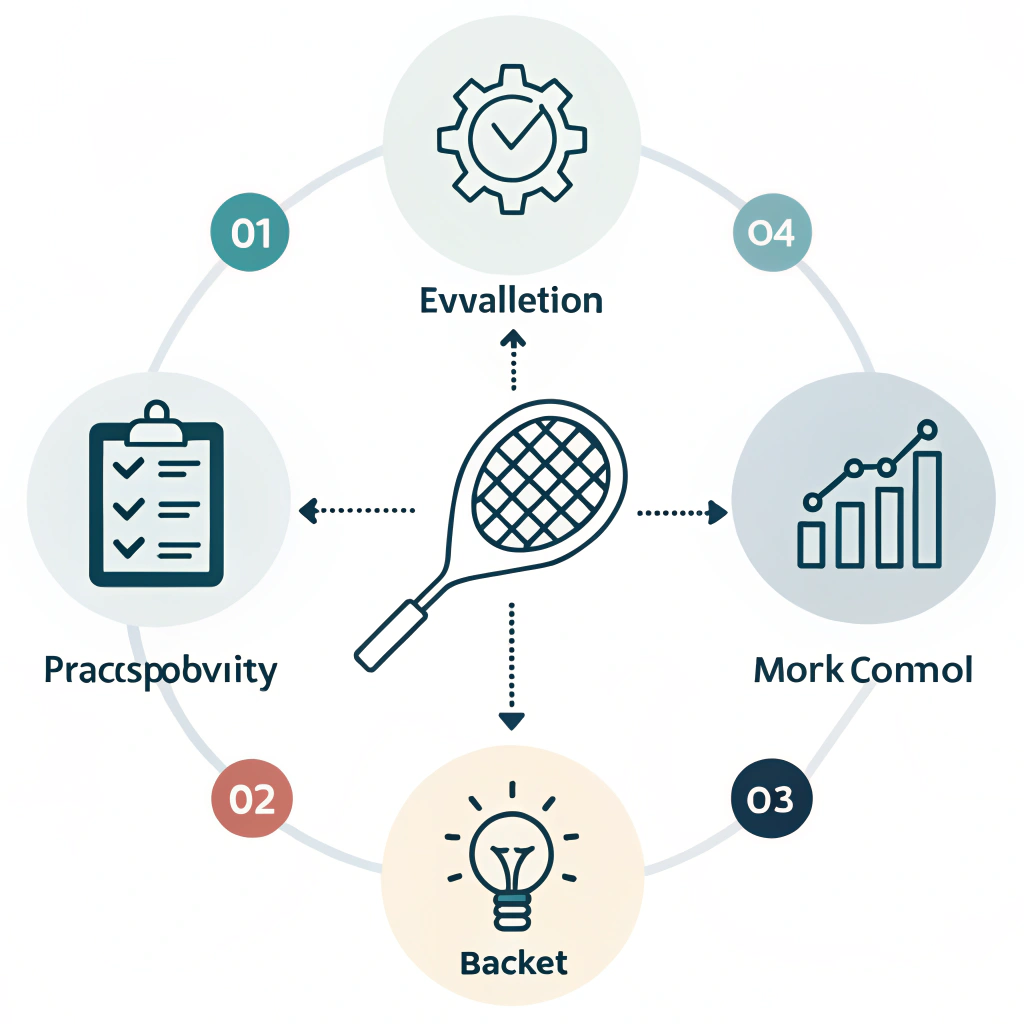

For B2B procurement managers considering a switch to advanced padel racket manufacturing, consider the following step-by-step strategy:

-

Evaluate Your Product Specifications

Once you have a clear understanding of your product needs – whether it is power, control, or a balance of both – align these with the material differences shown in the above table. A detailed specification document helps in communicating your needs precisely. -

Assess the Manufacture’s Customization Capabilities

Ensure that your partner can handle all aspects of customization, from shape design to logo printing. Request samples or prototypes that align with your brand requirements. -

Analyze Production Speed and Inventory Flexibility

Determine the supplier’s lead times and ability to deliver products within critical deadlines. Fast prototyping and on-time delivery can be significant factors in maintaining product competitiveness. -

Review Quality Control Measures and Testing Protocols

Inquire about the manufacturing partner’s quality assurance processes. A robust system includes both pre-production material tests and post-production performance evaluations. This transparency reduces supply chain risk and ensures every product meets industry standards. -

Discuss Pricing Models and Volume Discounts

Transparent pricing models that cater to volume discounts without compromising quality are essential. Compare quotes from multiple manufacturers but also consider their technical capabilities and reputational factors.

- Pilot Run and Feedback Collection

Before full-scale production, conducting a pilot run allows you to gather feedback and adjust order volumes or specifications as needed. This trial phase is integral to building a reliable long-term relationship with the manufacturing partner.

When partnering with an OEM manufacturer, remember to consider the following:

-

Documentation and Compliance:

Ensure that all product specifications, quality control protocols, and customization details are thoroughly documented. This minimizes misunderstandings and legal disputes later on. -

Supplier Communication:

Regular and clear communication with your supplier facilitates quick problem resolution and continuous improvement. Scheduled reviews of production metrics can enhance collaboration. -

Scalability:

Choose a partner that not only meets your current production needs but can also scale up operations as your brand expands. A scalable supply chain is vital in a growing market. -

After-Sales Support and Warranty Provisions:

Product quality assurance should extend beyond the factory floor. Discuss after-sales support options and warranty terms for added confidence in the longevity of your merchandise.

Advanced manufacturing of high-performing padel rackets is a pivotal strategic decision that can significantly boost your brand’s standing in the competitive sports equipment market. By carefully analyzing material quality, customization capabilities, production speed, and precision through robust testing procedures, you ensure that your products not only meet but exceed market expectations.

Our extensive experience with brands like Hirostar, Reebok, and Starvie underscores the success of using high-grade carbon fibers and customized enhancements to create products that resonate with both players and consumers. We recommend acting swiftly to evaluate your current supply chain and consider partners with proven expertise in advanced OEM manufacturing. Tailor your specifications to leverage modern technological advances and position your brand as a leader in the padel market.

Moving forward, prioritizing clear, documented communication and maintaining flexibility in production volumes are essential. By adopting these best practices, procurement managers can confidently transform their padel lineup into a market-leading product series that emphasizes performance, durability, and brand identity.

• Are expensive padel rackets worth it?

While higher-priced rackets often incorporate advanced materials and technologies, the improved performance may not necessarily boost gameplay for every player. For brands, the additional cost can align with superior design and customized features that set premium products apart, making them a valuable investment for a competitive market approach.

• Does a good padel racket make a difference?

Yes, choosing the right padel racket is crucial. A well-designed racket, which is built using precise manufacturing techniques and high-grade materials, can significantly enhance playability. For brands, offering such products can translate into improved customer satisfaction and stronger market positioning.

• What is the best padel racket for power?

The best padel racket for power typically combines cutting-edge material technology with a design optimized for force and control. Manufacturers using high-performance carbon fibers and innovative shape designs—such as those implemented in models like the Adipower series—demonstrate that a product aimed at power must balance material stiffness, weight distribution, and ergonomic design to truly stand out.

-

OEM: Click to learn more about Original Equipment Manufacturer processes, which detail how third-party manufacturers produce products under a brand’s specifications, ensuring quality, innovation, and scalability in production. ↩ ↩

-

Carbon fiber: Click to explore detailed information on carbon fiber, including its grades (3K, 12K, 18K) and how these variations affect performance, weight, and durability in high-performance products. ↩ ↩

-

Rapid prototyping: Click to understand the concept of rapid prototyping, its benefits in reducing time-to-market, and how it fosters iterative design and innovation in manufacturing processes. ↩ ↩

-

Supply chain transparency: Click to read more about supply chain transparency, which explains how maintaining clear, accessible production and logistical data can enhance efficiency, trust, and cost-effectiveness in B2B operations. ↩ ↩