Padel equipment manufacturing is a dynamic sector that must balance high-performance technology with customizable design. In simple terms, manufacturers face the challenge of delivering innovative padel rackets and accessories that meet strict technical standards while offering tailored options for diverse markets. This article explains the challenges of padel production, outlines actionable solutions using advanced materials and processes, and provides guidance for procurement managers seeking reliable B2B partners.

Manufacturers and procurement managers in the sporting goods industry need to ensure that padel rackets and related products meet high-performance and durability standards. With increasing demand for customization1, innovation, and quality control, the market faces several challenges:

- Managing the selection of premium materials such as carbon fiber (3k, 12k, 18k)2 and fiberglass.

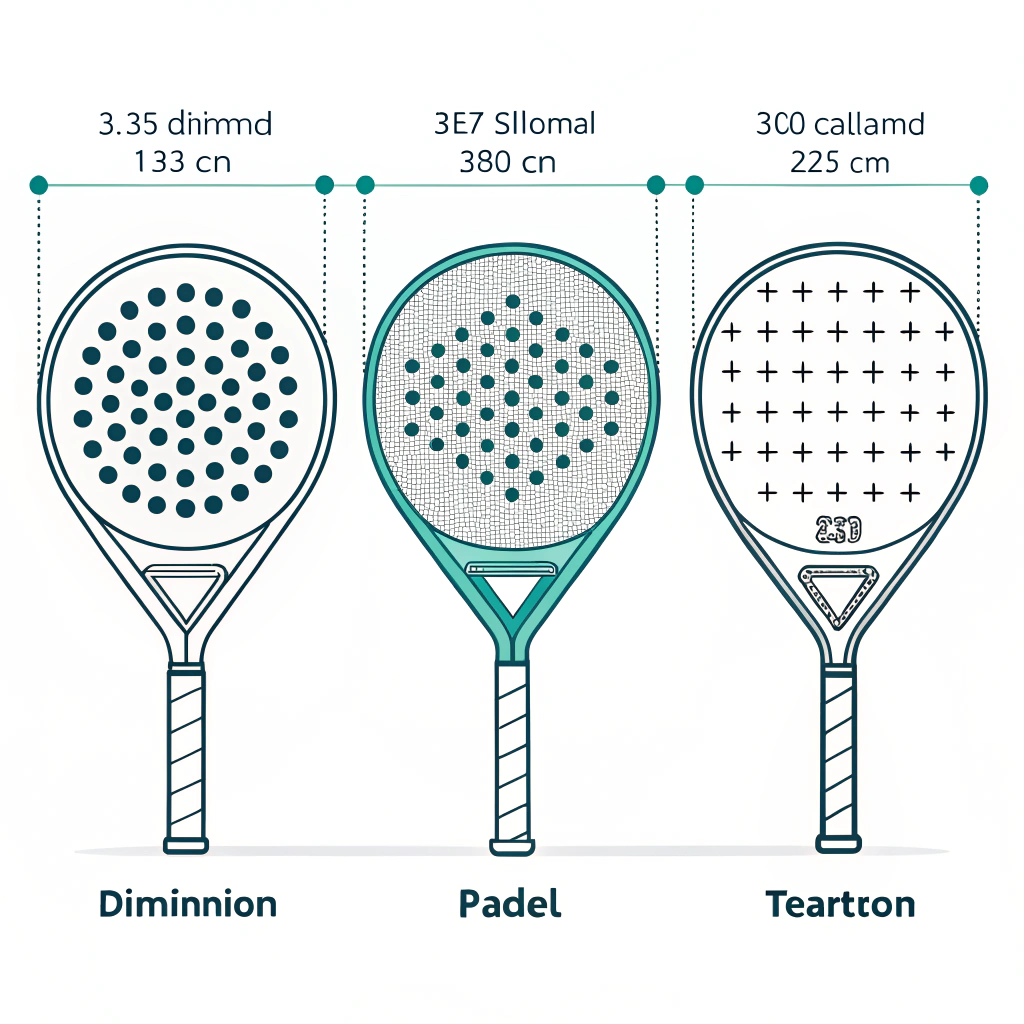

- Balancing production speed with customized design options like Diamond, Round, and Teardrop racket shapes.

- Ensuring production processes align with strict quality control measures so that end products remain durable and reliable on the court.

- Adapting to market trends in padel where players demand equipment that not only performs but also reflects a personalized style.

The complex environment means that a procurement manager must look for a manufacturer who can offer both advanced production techniques and flexibility across specifications to cater to local market needs.

Several factors contribute to the challenges in padel equipment manufacturing:

- Material Variability: The use of different grades of carbon fiber and fiberglass requires precision in processing. Each material type (e.g., 3k, 12k, 18k carbon fiber) has unique properties that can influence racket performance and durability.

- Customization Complexity: Offering fully customizable products—racket shapes, colors, printed logos on both the racket and accessories like hand grips—adds layers of complexity to production. This customization means that standard assembly lines must be able to switch between multiple product variants rapidly.

- Quality Assurance Demands: High-performance padel gear demands rigorous quality control. Even minor inconsistencies in material or construction can affect the game performance and the overall reputation of a brand.

- Supply Chain Coordination: The sourcing of raw materials and components, including pressurized padel balls with specific packaging (Pressurized tube) and different wool compositions (45% or 57%), requires efficient supply chain management.

- Market Pressures: Increasing global popularity of padel leads to a high demand that sometimes outpaces supply. This imbalance, along with installation costs for padel courts and specialized facilities, further complicates price setting and production planning.

These reasons underscore the critical need for a strategic, solution-driven approach in managing padel equipment production.

3. The Solution: Advanced Production Techniques3 for High-Performance Padel Equipment

To address the challenges mentioned above, manufacturers like NEX Padel adopt several innovative strategies. Our approach focuses on using the right materials, implementing advanced production techniques, and delivering rapid customization with reliable quality control. Below are key solutions that modern manufacturers employ:

Manufacturers must choose materials that guarantee durability and high game performance. For instance:

-

Fiberglass vs. Carbon Fiber:

- Fiberglass is ideal for beginner and intermediate levels due to its cost-effectiveness and forgiving play characteristics.

- Carbon fibers (3k, 12k, 18k), particularly at higher counts, offer unmatched performance, stiffness, and durability, which is crucial for advanced players.

-

Customization of Materials:

- By varying the mix and orientation of layers, manufacturers can tailor the stiffness, flexibility, and resistance of the racket. This allows procurement managers to source products that meet specific performance criteria.

Custom fabrication processes now allow production lines to offer fully customized solutions without significant delays:

-

Three Primary Racket Shapes:

- Diamond Racket: Optimized for aggressive play, providing a balance of power and control.

- Round Racket: Focuses on control and ease-of-use, often preferred by players seeking a forgiving hitting area.

- Teardrop Racket: Blends power and maneuverability, catering to all-around performance needs.

-

Customization Capabilities:

Manufacturers offer full customization in terms of:- Shape: Bespoke designs beyond standard Diamond, Round, or Teardrop.

- Print and Color: Custom prints and colors allow brands to maintain their unique identity.

- Accessory Customization: Hand grips and handle covers can be imprinted with logos, ensuring a cohesive brand appearance.

Ensuring consistent high quality is non-negotiable in this competitive arena:

-

Advanced Inspection Techniques:

- Automated in-line inspections help detect anomalies in the layering of carbon fibers and the uniformity of the fiberglass composite.

- Sample testing on finished products guarantees that each batch meets strict durability standards.

-

Quality Certification Processes:

- Adopting international quality standards and certifications helps assure clients of the product performance and longevity.

- For example, routine testing for pressure retention in pressurized padel balls and durability assessments of the printing on rackets contributes to enhanced reliability.

Rapid prototyping and short lead times are critical in meeting market demand:

-

Quick Sampling:

- Manufacturers, including NEX Padel, offer quick sampling of new designs. This enables clients to try and refine specifications before final mass production.

-

Efficient Supply Chain:

- A well-coordinated supply chain ensures that raw materials and final products are available as needed, reducing downtime and improving production schedules.

-

**Agile Manufacturing5 Setup:

- The capacity to produce diverse product variants in a single production run without significant retooling time is a major competitive advantage.

Below is a summary table comparing key factors influencing padel equipment production:

| Factor | Key Considerations | Benefit |

|---|---|---|

| Material Selection | Carbon Fiber (3k, 12k, 18k) vs. Fiberglass | Performance tuning and durability |

| Customization Options | Racket shape, prints, color customization, accessory branding | Brand distinctiveness and market fit |

| Quality Control | Automated inspections, pressure tests for padel balls | Consistency and reliability |

| Production Efficiency | Quick sampling, agile manufacturing, supply chain coordination | Reduced lead time and production cost |

| Market Demand | High demand, evolving player requirements, installation costs | Pricing and production planning |

Based on our experiences at NEX Padel, here is a structured action plan to address the challenges in padel equipment manufacturing:

-

Material and Technology Assessment:

Evaluate available materials based on their extent of performance and durability. Consider initiating pilot tests with different carbon fiber orientations to determine optimal specifications for your target market. -

Customization and Design Review:

Form a cross-functional team that includes technical designers, production managers, and market analysts. This team should work closely to design products that align with current market trends and customer preferences. -

Integrated Quality Assurance Setup:

Invest in advanced quality control systems. Introducing digital solutions for production monitoring ensures that any defects are identified early and addressed in the production cycle. -

Agile Production Scheduling:

Develop flexible production schedules that allow rapid switching between different product variants. This can be achieved by modular production lines that reduce downtime during changeovers. -

Close Communication with Clients:

Regularly update procurement managers and other stakeholders on production timelines, sampling results, and quality test outcomes. Transparent communication builds trust and ensures that product modifications can be made early in the production cycle. -

Continuous Improvement:

Collect feedback from the market and end-users. Use data analytics to monitor product performance and continually tweak production processes to meet evolving market demands.

These steps ensure that every stage of production from raw materials selection to final product assembly is optimized for performance, durability, and customization.

Consider a scenario where a retailer was seeking a high-performance padel racket that was both durable and highly customizable. The client needed a product that could withstand intense play and also be uniquely branded to enhance their market presence.

- High-Performance Requirements: The ordered rackets needed to perform at an elite level, employing premium materials for enhanced stiffness and control.

- Customization Demands: The client requested a distinctive shape, customizable color finishes, and customized printing on hand grips and handle covers.

- NEX Padel conducted a materials analysis to determine the proper mix between different carbon fiber weaves and fiberglass layers.

- Advanced production techniques were employed to integrate client-specific customization without compromising on the quality and performance of the rackets.

- Agile production methods allowed for rapid sampling and feedback integration, ensuring the client’s specifications were met with precision.

- The final product not only met the high performance standards required by elite players but also provided the retailer with a customized product that differentiated their offerings in the market.

- This approach led to improved customer satisfaction, repeat orders, and enhanced brand reputation in the region.

To succeed in the competitive arena of padel equipment manufacturing, procurement managers must partner with suppliers who not only provide high-performance products but also understand the critical importance of customization and quality control. By employing advanced production techniques and streamlining supply chain management, manufacturers can deliver products that meet specific market demands.

Key recommendations for stakeholders include:

- Prioritizing manufacturers that invest in advanced production technologies and quality control systems.

- Embracing flexible, customizable solutions that cater to the unique needs of different market segments.

- Ensuring close collaboration between production teams and procurement managers to maintain transparency and improve product outcomes.

These strategies help build a sustainable supply chain that responds promptly to market trends and supports long-term business success.

Q: What is the 40 40 rule in padel?

A: The 40 40 rule means that when the score reaches 40-40, the receiving team has the option to choose which side they would like to receive the serve. The point winner at this stage ultimately wins the game.

Q: Why is padel so expensive?

A: Padel can be expensive due to high demand that exceeds the available supply and the additional costs associated with specialized installation, such as glass walls and tailored facilities required for padel courts.

Q: What is the best padel brand?

A: The best padel brand often depends on performance needs and personal preference. Top brands, including those that manufacture high-quality rackets like Babolat, NOX, HEAD, and Bullpadel, are known for their advanced technology, durability, and customization options.

-

customization: Click to learn more about advanced customization techniques in manufacturing, including methods to tailor products for specific market demands and enhance brand uniqueness. ↩ ↩

-

carbon fiber (3k, 12k, 18k): Click to explore detailed insights into the various grades of carbon fiber, their unique structural properties, and how these affect performance and durability in high-performance sporting equipment. ↩ ↩

-

advanced production techniques: Click to delve into modern production methodologies that integrate innovative technologies and materials to deliver premium sporting equipment. ↩ ↩

-

Integrated Quality Control Systems: Click to discover how robust quality control systems and automated inspections ensure consistent product performance and adherence to strict industry standards. ↩ ↩

-

agile manufacturing: Click to understand agile manufacturing practices that allow for flexible production scheduling, minimized downtime, and rapid switching between product variants. ↩ ↩