When evaluating ODM1 padel racket suppliers, the key is to find a partner who delivers high-performance, customizable products with reliable quality assurance and efficient production. NEX Padel offers advanced production techniques and versatile customization options for padel rackets and gear, making us an ideal ODM partner for sports equipment brands seeking exclusive, high-quality solutions.

In today’s competitive padel sports industry, procurement managers and product development specialists require suppliers who not only meet technical specifications but also provide a seamless, customizable production process. NEX Padel stands out in the market by offering state-of-the-art manufacturing of padel rackets and ball equipment using premium materials like glass fiber and various grades of Carbon Fiber2—3k, 12k, and 18k. Our expertise supports both standard and fully customized orders from elite brands such as Hirostar, Reebok, and Starvie, ensuring that you receive products that align perfectly with your market needs.

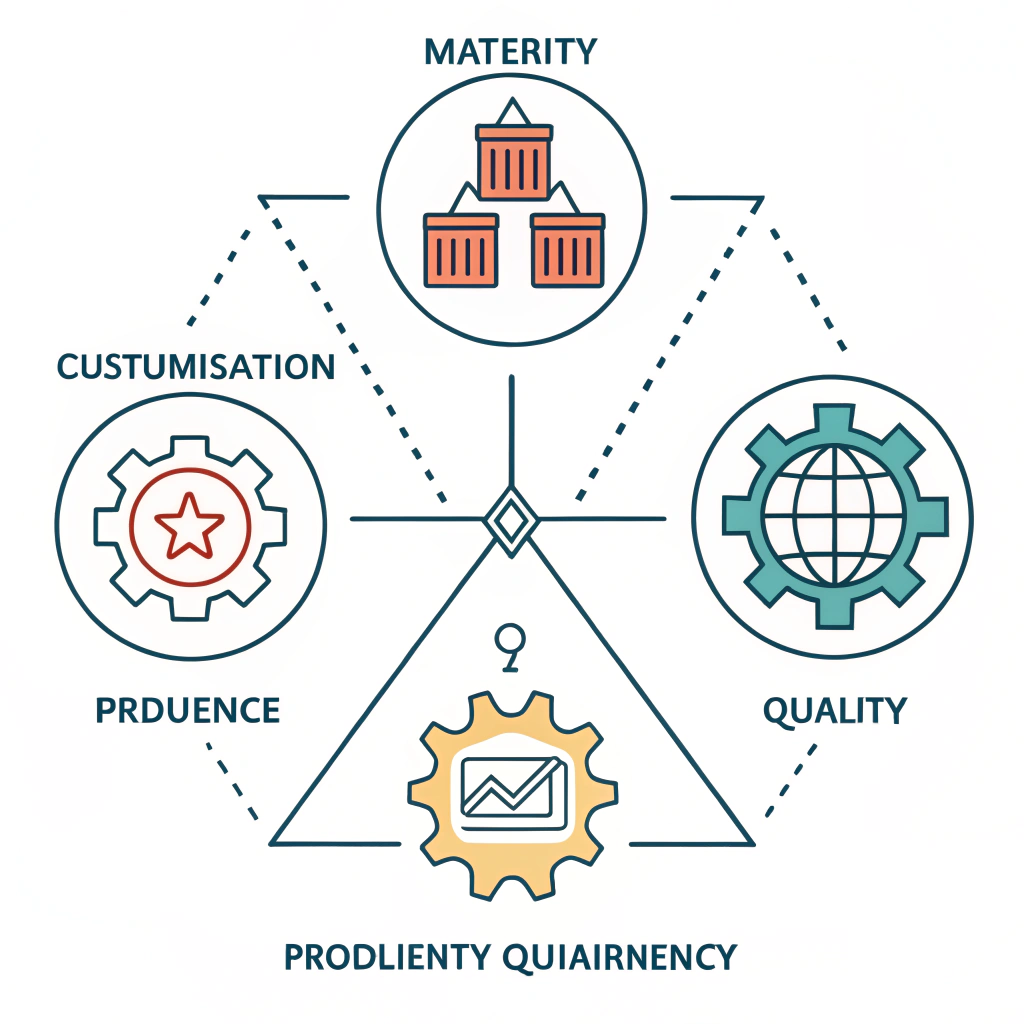

Selecting an ODM partner is a strategic decision that involves comparing several critical factors:

- Material Quality: The choice of materials (e.g., carbon fiber grades and glass fiber) influences durability and performance.

- Customization Options: From racket shapes—Diamond, Round, or Teardrop—to custom prints, colors, and even add-on components like hand grips and handle covers, flexibility is key.

- Production Efficiency: Fast prototyping and timely deliveries are essential in the fast-paced sports equipment market.

- Quality Assurance: Rigorous production and testing standards ensure that each product meets global performance expectations.

- **Supply Chain Reliability3: An established production network ensures consistency and minimizes risks of delays or quality issues.

When comparing ODM partners, the core differences typically revolve around three major elements: quality, customization, and production efficiency. Below is an overview table to distinguish these factors:

| Factor | NEX Padel Advantage | Industry Average |

|---|---|---|

| Material Quality | Uses premium 3k, 12k, 18k carbon fiber and high-grade glass fiber ensuring both performance and durability. | Variable quality with occasional compromises. |

| Customization Options | Fully customizable shapes (Diamond, Round, Teardrop), colors, prints, and logo placements on racket surfaces, hand grips, and covers. | Limited standard templates with minor variations. |

| Production Efficiency | Fast prototype sampling with timely deliveries and lean production cycles. | Longer lead times and inconsistent delivery. |

| Quality Assurance | Advanced production techniques with multi-level quality checks and performance testing. | Basic quality inspections resulting in lower consistency. |

| Supply Chain Reliability | Established network ensuring a consistent supply of high-quality materials and timely order fulfillment. | Supply variability and risk of delays. |

This comparison clearly reveals that selecting a partner with proven strengths in these areas can dramatically enhance product quality and market competitiveness.

For a high-performance ODM padel racket, material selection is crucial. At NEX Padel, our engineering teams leverage advanced production methods combined with the finest materials:

- Carbon Fiber Padel: We manufacture rackets using 3k, 12k, and 18k carbon fiber. The choice of fiber grade directly impacts the stiffness, durability, and weight distribution of the racket.

- Glass Fiber Alternatives: For different performance characteristics or cost considerations, our glass fiber options provide excellent strength and flexibility.

- Customization in Material Mix: By carefully controlling the composite ratios, our padel rackets achieve a balance between power and control, making them ideal for both professional athletes and enthusiasts.

This meticulous attention to material selection ensures that our clients receive a product that is not only visually appealing but also technically superior.

A significant advantage of partnering with NEX Padel is our extensive customization options. We understand that your brand identity matters, and our production process is designed to support unique customizations that help you stand out in the market.

- Racket Shape: Customize the design between Diamond, Round, or Teardrop shapes, or even propose a new shape tailored to specific client needs.

- Design & Colors: Our state-of-the-art printing technology supports full-color customization, allowing you to imprint logos, graphics, or even personal designs.

- Accessory Customization: Beyond rackets, we customize hand grips and handle covers with your brand logo and colors, ensuring a cohesive product line.

- Exclusive Product Variants: We can produce exclusive padel gear that is designed to match your market’s aesthetic and performance demands.

- Differentiation in a crowded market.

- Strengthening your brand identity through consistent design.

- Fulfilling niche consumer requirements for premium and personalized products.

This level of customization ensures that your product stands out by not only meeting but exceeding consumer expectations.

Quality assurance is at the heart of our production process. Our commitment to excellence is demonstrated in every stage of manufacturing, from material selection and prototyping to final product testing.

- Multi-Level Inspections: Our products undergo several rigorous tests at different production stages to ensure consistency and performance.

- Performance Testing: Rackets are tested for balance, shock absorption, and overall durability, ensuring they meet global sports standards.

- Material Traceability: Every batch of materials, including high-grade carbon fiber, is carefully sourced and traceable, mitigating risks of quality variance.

- Customized Feedback Loops: We work closely with our brand partners to incorporate feedback and continuously improve product design and quality.

- **Rapid Prototyping4: Our advanced rapid prototyping capability ensures that design ideas are quickly turned into actionable samples.

- **Lean Manufacturing Techniques5: We employ lean production processes to minimize waste and optimize time-to-market.

- Timely Delivery: Consistency in production and a robust supply chain ensure that orders are delivered as per schedule, which is crucial for aligning with market launch calendars.

The production efficiency and quality assurance systems are fundamental strengths that support our reliability as an ODM partner.

Consider a scenario where a leading sports brand seeks to extend its product line with innovative and exclusive padel rackets. The procurement process involves evaluating multiple ODM partners based on technological capability, customization flexibility, and delivery assurance. Here, NEX Padel's comprehensive solution presents clear advantages:

- High Performance: Our use of advanced carbon fiber materials ensures that rackets deliver both power and control during play.

- Tailored Solutions: Through bespoke design capabilities, the brand can introduce exclusive gear that reflects its unique style and identity.

- On-Time Delivery: Our efficient manufacturing process supports strict delivery deadlines, critical for market success and seasonal launches.

- Quality Consistency: Advanced quality checks provide assurance that every product meets global performance standards, reducing the risk of product returns or customer dissatisfaction.

This case highlights how strategic partnerships with reliable ODM providers like NEX Padel can drive product innovation and market success.

For procurement managers and product development specialists looking for a high-performance ODM partner in the padel industry, consider the following steps:

- Define Your Product Requirements: Clearly outline the technical and design specifications you need, including material preferences, customization features, and production timelines.

- Compare Key Metrics: Use a comparison table to evaluate potential suppliers based on material quality, customization options, production efficiency, quality assurance, and supply chain reliability.

- Request Samples and Prototypes: Engage with suppliers who offer rapid prototyping to assess the product's performance and customization potential firsthand.

- Review Quality Assurance Processes: Ensure that the supplier has robust quality checks and traceability protocols for materials.

- Assess Delivery and Support Systems: A supplier with proven production efficiency and reliable logistics will help maintain consistent market supply and support future expansion.

Taking these steps will help you make a confident decision that aligns with your brand's values and market demands.

In the highly competitive sports equipment market, choosing an ODM partner who excels in technological innovation, material quality, and customization can significantly impact your brand's success. NEX Padel meets these critical criteria by offering cutting-edge production techniques, diverse customization options, and stringent quality assurance protocols. Partnering with us not only provides you with exclusive padel gear but also a reliable, efficient, and innovative production process that can boost your market position.

By focusing on the balance between high performance and tailored design, NEX Padel empowers you to meet the dynamic needs of the padel sports industry while ensuring that your products stand out. We invite you to explore our solutions further and take the next step towards an ODM partnership that prioritizes excellence and market success.

-

What are the top 5 padel racket brands in the world?

Top padel racket brands include Adidas, Bullpadel, Nox, Head, and Babolat. These brands are known for their high performance, reliability, and innovative designs that benefit both professional and amateur players. -

What is the premium padel brand?

Volt Padel is widely recognized as a premium padel brand, offering top-quality equipment and distinctive design features that set it apart from competitors. -

Is there a fake padel racket?

Yes, fake padel rackets do exist. To spot the difference, check for precise branding and logos; authentic rackets show clear, consistent branding with no misspellings. Additionally, genuine products utilize high-quality materials, ensuring superior performance compared to counterfeit options.

-

ODM: Read the article to understand how Original Design Manufacturer models work in product development and how they benefit B2B partnerships by streamlining production and customization processes. ↩

-

Carbon Fiber: Read the article to learn about the properties, production methods, and performance benefits of various carbon fiber grades used in high-performance sports equipment. ↩

-

Supply Chain Reliability: Read the article to understand the importance of a robust supply chain in ensuring consistent quality and timely deliveries, essential for successful B2B operations. ↩

-

Rapid Prototyping: Read the article to discover how rapid prototyping accelerates product development by enabling quick evaluation and iteration of design concepts. ↩

-

Lean Manufacturing Techniques: Read the article to understand lean production processes that minimize waste and boost efficiency, which are crucial for maintaining competitiveness in manufacturing. ↩