Choosing the right padel racket grip size is crucial for optimizing performance and ensuring comfort. In this article, we quickly answer the overarching question: a well-matched grip size not only improves power and precision but also minimizes the risk of injury. By understanding the technical parameters and customization options available through OEM manufacturing1, such as those provided by NEX Padel, procurement managers can make informed decisions and achieve better athlete performance.

In today’s competitive sports equipment market, padel racket grip size is a key technical specification that directly influences the racket’s ergonomic design2 and overall performance. Many sports equipment distributors often face challenges when selecting the appropriate grip size due to variations in hand dimensions, playing styles, and the need for customization. As the demand for high-performance padel gear increases, so does the need for grip sizes that maximize both power and control during gameplay.

One of the primary challenges in padel racket manufacturing and procurement is ensuring that the grip size meets the ergonomic demands of different players. Incorrect grip sizing can lead to several issues, including:

- Reduced maneuverability on the court.

- Increased risk of wrist and forearm injuries.

- Compromised control that affects accuracy and ball placement.

- Lower overall player satisfaction and performance.

These issues necessitate a rigorous approach in design, testing, and customization to cater to both recreational players and professional athletes.

The selection of the ideal padel racket grip size is influenced by several factors, including:

- Hand Measurements and Player Preference: Every player has unique hand dimensions. A smaller grip may offer better agility and precise control, while a larger grip can provide enhanced stability and power.

- Ergonomic Design Principles: Modern padel racket designs incorporate ergonomic principles that focus on reducing strain. This often involves designing handles that conform to the natural hand shape.

- Material Properties: The materials used in the grip, such as carbon composite or fibreglass, play an essential role in determining durability and impact performance. Different material compositions like 3k, 12k, and 18k carbon fibers offer varying degrees of stiffness and strength. In some instances, advanced materials such as high-performance carbon composite3 are employed to ensure the racket remains lightweight while delivering superior strength.

- Manufacturing Techniques: Advanced production methods ensure that each padel racket meets precise specifications. For instance, high-performance manufacturing at NEX Padel ensures consistency even in custom orders. The rapid prototyping4 and quick turnaround times significantly reduce the risk of delays in the supply chain.

- Customization Options: The ability to customize not just the grip size, but also related features like hand grip printing, colors, and logo placement, has become a valuable asset. Custom OEM solutions allow distributors to offer products that cater specifically to their customer base.

To address these challenges and optimize padel racket performance, companies can adopt several strategies. The following table offers a quick-choice guide for the most common solutions related to grip size selection:

| Factor | Consideration | Recommendation |

|---|---|---|

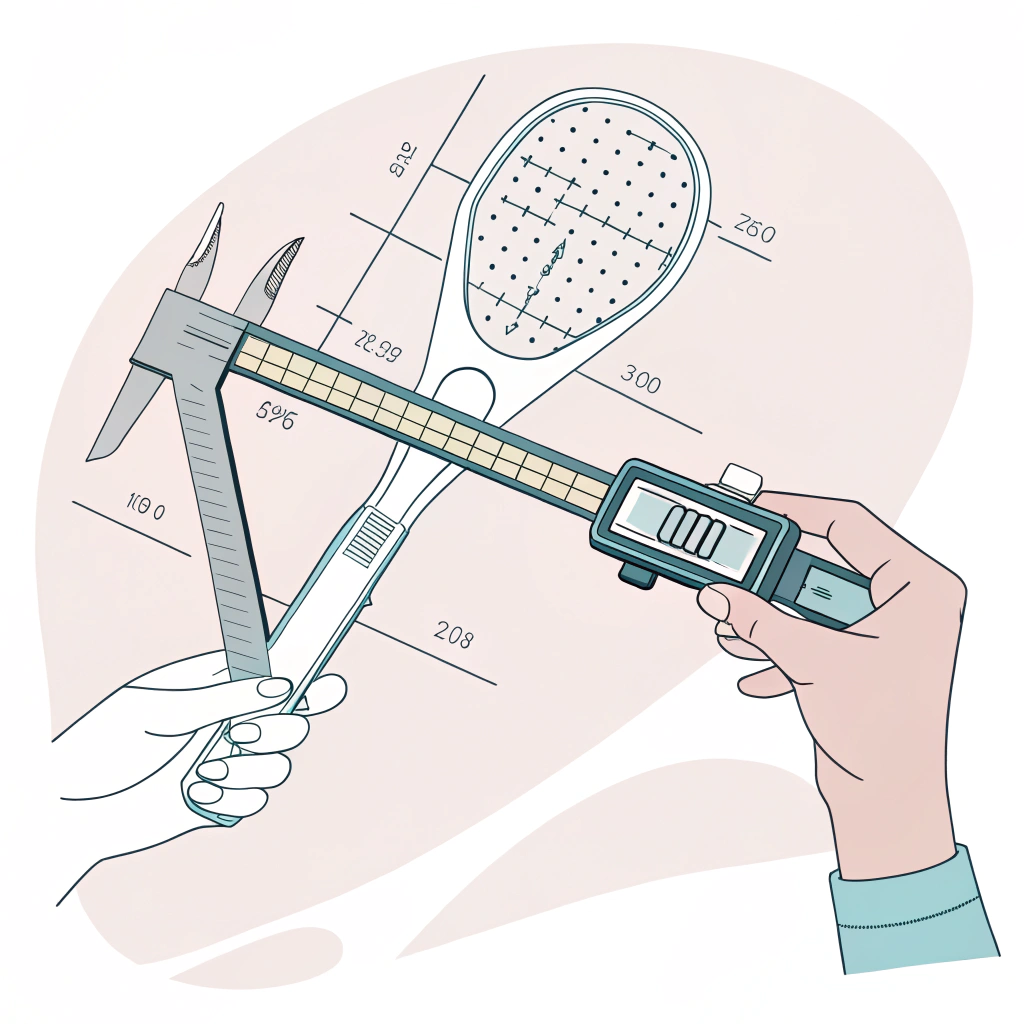

| Hand Measurement | Accurate measurement of hand size is essential. | Use a standardized guide or digital measuring tools. |

| Ergonomic Design | Design should follow ergonomic principles to reduce fatigue. | Incorporate molds or shapes that fit natural hand curves. |

| Material Selection | Different materials influence durability and performance. | Evaluate options such as carbon composite and fiberglass. |

| Manufacturing Precision | Consistency in production ensures reliability. | Collaborate with reliable OEM manufacturers like NEX Padel. |

| Customization Features | Customization improves market differentiation. | Offer personalized grip sizes, hand grip prints, and colors. |

By focusing on these strategies, procurement managers can find a balanced solution that fits a wide spectrum of user needs, from recreational players to elite professionals.

An essential aspect of selecting the appropriate grip size is understanding that every player's hand is different. Modern measurement tools and ergonomic studies have shown that a difference of just a few millimeters in grip diameter can significantly affect a player's comfort and performance. For instance, players with smaller hands might experience increased wrist mobility, leading to better control, whereas larger hands might favor a slightly thicker grip for enhanced stability. It is essential that manufacturing procedures allow for custom sizing5. This can be achieved through adjustable design prototypes and feedback loops with athletes during testing.

The performance of a padel racket is not solely dependent on the grip size but also on the material used. Advanced materials such as high-performance carbon composite ensure that the racket remains lightweight without compromising on strength. Our partners at NEX Padel use materials ranging from fiberglass to various grades of carbon fiber including 3k, 12k, and 18k to tailor each product to specific performance characteristics. The right material choice can improve vibration dampening and provide better energy transfer from the racket to the ball, which is crucial for meeting rigorous competitive standards.

For sports equipment distributors, the capacity for tailored alterations is a major competitive advantage. Customization goes beyond the grip size – it includes aesthetics like colors, printing details, and even personalized logos on the hand grip and handle cover. OEM manufacturers like NEX Padel provide extensive customization options, ensuring that the final product not only meets performance standards but also aligns with brand identity. These customization capabilities help companies differentiate their offerings in a crowded market.

Technology in production has advanced considerably over the past decade. High-precision CNC machines, digital design software, and rapid prototyping ensure that each padel racket is produced to exacting standards. As the padel market grows globally, the demand for high-performance and highly customized equipment has increased significantly. According to market research, players are now more inclined towards equipment that offers both ergonomic comfort and durability. Investing in advanced production techniques can lower production costs over time and provide a clear competitive edge in the market.

Consider a scenario faced by many procurement managers: a consistent complaint from players about hand fatigue during extended matches. By addressing the grip size and material composition issues, our partner sports equipment distributor was able to lower injury rates significantly and boost player performance. The solution involved:

- Measuring player hand size accurately using digital calipers.

- Testing various ergonomic designs to determine which handled prolonged stress best.

- Collaborating with a reliable OEM manufacturer like NEX Padel, who provided real-time production adjustments and rapid prototyping.

The result was a lightweight padel racket featuring a balance of a 12k carbon fiber grip with ergonomically tailored dimensions that improved both performance and user comfort. Such improvements led to increased sales and a higher satisfaction rate among professional players and enthusiasts alike. This case clearly illustrates how technical details, when managed effectively, can provide a tangible competitive advantage.

Procurement managers in the padel market need to consider several actionable steps to ensure their product portfolio remains competitive:

- Invest in detailed ergonomic research: Collaborate with sports scientists to understand the nuances of hand grip demands.

- Leverage technology for measurement: Implement high-precision tools to measure hand dimensions and simulate ergonomic impact.

- Partner with established OEM manufacturers: Trust companies like NEX Padel that have a proven track record in high-performance, custom padel racket manufacturing.

- Focus on consistent quality: Ensure that every production batch maintains the same specification standards irrespective of the scale.

- Stay ahead with market trends: Keep an eye on emerging materials and design technologies that can further enhance performance benefits.

Adopting these measures ensures not only that the equipment meets current market demands but also that it adapts to future trends and technological advancements.

In summary, the padel racket grip size is a critical parameter that affects both athlete performance and comfort. Through detailed analysis of hand measurements, material selection, manufacturing precision, and customization options, companies can address common ergonomic challenges associated with padel equipment. By partnering with leading OEM manufacturers like NEX Padel, businesses can take advantage of state-of-the-art production techniques and advanced materials to produce high-performance, ergonomic rackets that stand out in the market.

For procurement managers, the decision process is streamlined by understanding these key factors and applying a methodical approach to product specification. Embrace the opportunity to differentiate your offerings by focusing on the technical aspects of grip size customization, and be sure to communicate the real value these optimizations bring to both athletes and end users. With informed decisions, your product lineup will not only meet but exceed performance expectations, creating long-term competitive benefits.

People Also Ask

Q: What is the ideal padel racket grip size?

A: The ideal grip size depends on the player’s hand measurements and playing style. A correct match improves comfort, control, and overall performance by reducing unnecessary strain and the risk of injury.

Q: How do ergonomic design and material choice influence padel racket performance?

A: Ergonomic design ensures that the racket fits naturally in the player’s hand, while high-performance materials such as carbon composites help reduce vibration, enhance durability, and improve energy transfer during play.

Q: Can OEM manufacturers customize padel racket grips to suit different player needs?

A: Yes, many OEM manufacturers, including NEX Padel, offer comprehensive customization options such as adjusting grip size, selecting materials, and even personalizing aesthetics like colors and logos to meet specific performance and brand requirements.

-

OEM manufacturing: Reading this article will help you understand how original equipment manufacturer processes streamline production, ensure product quality, and facilitate customizable solutions in the sports equipment industry. ↩ ↩

-

Ergonomic design: Click here to learn how ergonomics is applied to product design to enhance user comfort, reduce fatigue, and improve overall performance in high-demand environments. ↩ ↩

-

High-performance carbon composite: Explore how advanced composite materials are engineered to balance lightweight properties with superior strength, critical for high-impact sports equipment. ↩ ↩

-

Rapid prototyping: Discover the benefits of rapid prototyping in reducing development time and iterating design improvements for precision-engineered products. ↩ ↩

-

Custom sizing: This article explains the importance of adapting product dimensions to individual needs, optimizing both functionality and user comfort through tailored solutions. ↩ ↩