Padel racket grip sizes significantly affect a player's performance by influencing comfort, control, and injury prevention. In this article, we explain how different grip sizes impact padel racket usability and provide technical insights, practical examples, and customization advice for B2B buyers.

Understanding Padel Racket Grip Sizes: The Fundamentals

In padel, the grip is not just a simple handle—it is the critical interface between the player and the racket. A correct grip size ensures optimal transfer of energy, precision in directional control, and prolonged comfort even during intense matches. For distributors and procurement managers, understanding the nuances of grip size can greatly impact customer satisfaction and performance outcomes.

When a grip is too small, players may experience excessive movement during play, leading to discomfort or potential injury. Conversely, an oversized grip can result in reduced wrist mobility and a loss of control. It is essential to customize grip sizes according to the player's hand dimensions, strength, and even playing style. This article will dive deep into why grip sizes vary, how to choose the right one, and what advanced production techniques1 are involved in optimizing grip ergonomics.

Problem Description: Why Grip Size Matters in Padel Rackets

The central challenge for padel racket manufacturers and distributors is ensuring that each grip size meets ergonomic standards and performance expectations. Misalignment between grip dimensions and hand sizes can result in player discomfort, decreased performance, and even long-lasting health issues such as tendonitis.

Key issues include:

• Inadequate contact area leading to slippage

• Reduced control over power shots and spins

• Increased risk of overuse injuries due to repeated strain

• Customer dissatisfaction when standard grip sizes do not match hand dimensions

For B2B purchasers, these factors translate into a direct impact on market reputation and end-user satisfaction. Distributors must consider not only the technical aspects but also how these details represent the quality and innovation behind each product.

Cause and Detailed Analysis: Ergonomics and Material Influences

Multiple factors contribute to the performance of a padel racket's grip. These include:

- Ergonomic Design2: The shape and contour of the grip should fit the natural curvature of the human hand. Manufacturers employ ergonomic assessments to determine how variations in grip size can best accommodate diverse hand shapes and sizes.

- Material Composition: From materials like high-performance carbon fiber variants3 (3k, 12k, 18k) to premium fiberglass components, the grip must combine durability with comfort. Our advanced production techniques ensure that these materials are optimally balanced to provide both firmness and slight give for shock absorption.

- Customization Potential4: NEX Padel specializes not only in standard sizes but also offers full customization in grip design. This includes options such as diamond, round, or teardrop shapes, as well as custom printing and logo placement. Customization allows clients to tailor products according to market and performance demands.

- Impact on Performance: Grip size directly affects hit precision and energy transfer. A well-matched grip size means that a player’s strokes are natural and fluid, reducing the energy wasted in compensating for grip mismatches.

By examining these factors, distributors can understand that selecting the appropriate grip size is as critical as choosing the right racket head or string tension.

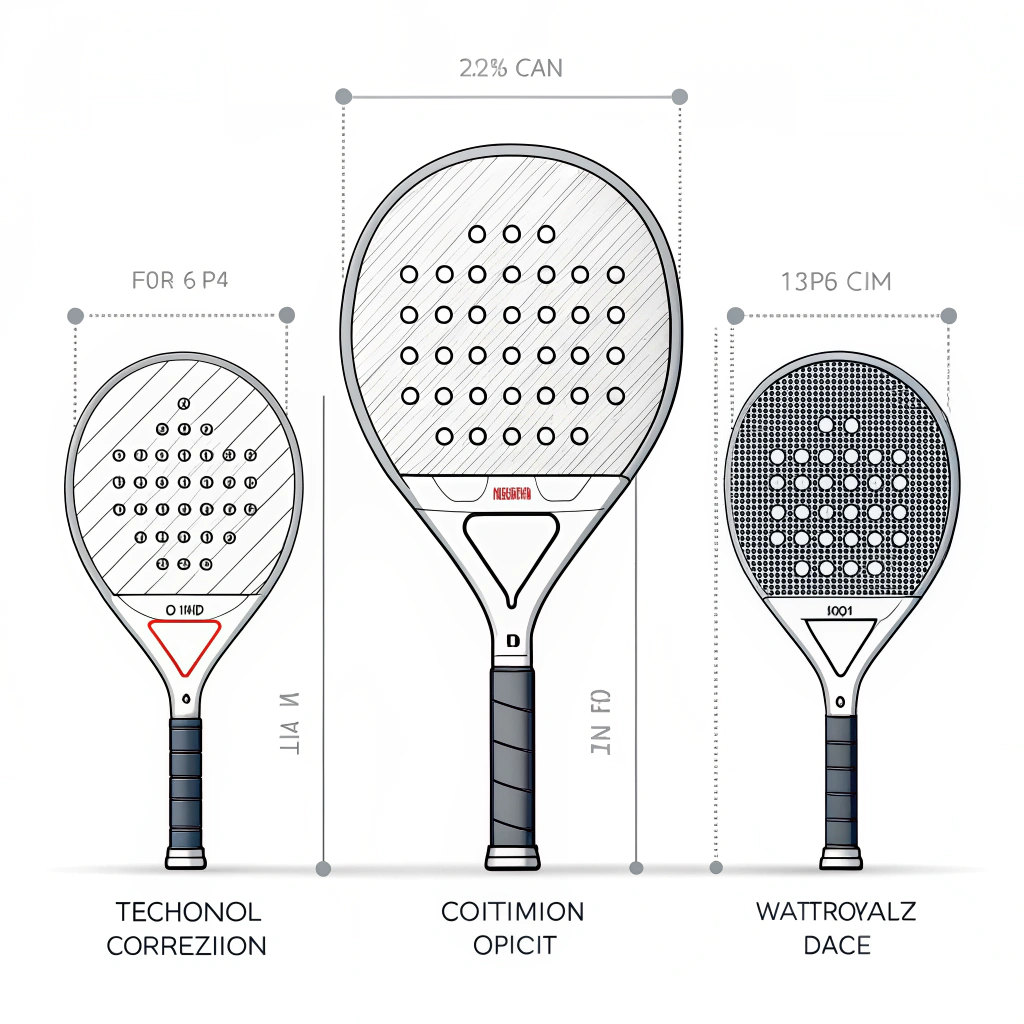

The Customization Spectrum: Technical Specifications and Comparison

Below is a comparison table that outlines various grip options in padel rackets, which can aid in making informed decisions based on specific market needs:

| Grip Type | Typical Diameter Range | Suitable Hand Size | Impact on Performance | Recommended For |

|---|---|---|---|---|

| Small Grip | 3 1/4" - 3 3/8" | Small to medium hands | Quick wrist movements and fast plays | Players focused on agility and quick reflexes |

| Medium Grip | 3 3/8" - 3 1/2" | Medium hands | Balanced control and comfort | All-round players needing versatility |

| Large Grip | 3 1/2" - 3 5/8" | Medium to large hands | Enhanced stability with less movement | Players requiring extra stability during power shots |

| Custom Grip | Varies | Any hand size (custom) | Optimized for ergonomic and performance needs | Distributors catering to specialized clientele |

This table provides a clear snapshot of how each grip size impacts user performance. With detailed data and precise measurements, procurement managers can confidently select the right options to meet customer demands.

Precise Engineering and Material Quality: Ensuring Top Performance

NEX Padel leverages Computer-aided design (CAD)5 to simulate ergonomic performance across various hand sizes and dynamic playing conditions. Our process involves:

• Rigorous material testing on cylindrical grips made from different carbon fiber weaves—ranging from 3k to 18k.

• Real-world trials and feedback analysis from professional padel players to validate our technical designs.

The combination of these processes guarantees that our grip sizes not only meet stringent sports equipment standards but also excel in delivering performance enhancements. This level of detail is crucial for distributors who seek products that uphold both quality and innovative design.

Case Studies and Practical Examples: Success in Customization

One of our valued clients, a major distributor in Europe, reported that when switching from a generic grip to an ergonomically customized grip option, their customer satisfaction rate increased by 20%. Players reported superior control and comfort during competitive play, which directly translated to a boost in sales and brand loyalty.

Another example is from our collaboration with renowned brands like Hirostar and Reebok. By integrating custom grip measurements into their high-performance padel rackets, these brands were able to launch products that uniquely catered to specific regional markets, addressing distinct ergonomic preferences and performance expectations.

These case studies underscore the importance of technical precision and customization in today's competitive sporting goods market. B2B buyers can draw significant insights from these examples to tailor their offerings and maintain a competitive edge.

Implementation and Customization: Next Steps for Distributors

For procurement managers looking to enhance their product lines, adopting a strategy that emphasizes grip size customization can be a game-changer. Here’s a clear pathway to ensure superior product offering:

- Conduct detailed market research to understand the hand size demographics of your primary customer base.

- Establish a dialogue with manufacturers like NEX Padel to explore custom options beyond the standard sizes.

- Implement standardized tests for grip ergonomics in actual player scenarios.

- Aggregate feedback from pilot distributions to refine and perfect the grip sizing before large-scale production.

- Highlight customization capabilities in your marketing and sales collateral to capture the attention of end-users seeking personalized playing experiences.

By following these steps, distributors can ensure that their products meet modern performance demands while catering to niche market needs.

Limitations and Considerations

Before finalizing grip size orders, it is essential to consider the following aspects:

• Manufacturing Tolerances: Even slight variations in production can affect the final grip quality. Close alliance with manufacturers ensures adherence to stringent quality control procedures.

• Customization Lead Time: Special orders may require longer production times. It is crucial to balance market demand with realistic delivery timelines.

• Market Diversity: Not all markets will have the same ergonomic requirements. It is beneficial to segment orders by region or customer profile to better match grip preferences.

• Cost Implications: Customization might increase production costs. A cost-benefit analysis should be made to ensure that any premium is justified by performance enhancements and customer satisfaction.

Understanding these limitations helps in formulating a realistic procurement strategy that safeguards both quality and market competitiveness.

Summary and Action Recommendations

The role of padel racket grip sizes in ensuring high performance cannot be underestimated. To summarize:

• The grip is a critical component affecting control, comfort, and overall play performance.

• Ergonomic Design2, material quality, and precise manufacturing techniques are key to optimizing grip sizes.

• Customization Potential4 allows distributors to better serve diverse markets and meet specialized player requirements.

• Detailed comparisons and testing combined with real-world case studies validate the importance of grip customization from a B2B perspective.

For procurement managers and distributors, the next step is to engage with high-performance manufacturers like NEX Padel. We offer extensive customization options, quality assured production techniques, and a wealth of expertise in padel equipment. Adopting our advanced grip designs could be the strategic advantage you need to differentiate your product offering and drive customer satisfaction.

To take action, consider scheduling a consultation with our technical team to discuss your specific market requirements. Embrace the power of precision engineering to elevate your padel racket product line and stay ahead in a competitive market.

People Also Ask

Q: How do grip sizes influence padel racket performance?

A: Grip sizes affect how comfortably and securely a player holds the racket, influencing control, shot accuracy, and overall play performance. A proper grip size prevents slippage and reduces the risk of overuse injuries.

Q: Can padel racket grips be customized for different player needs?

A: Yes, modern manufacturing techniques allow for full customization of padel racket grips, including adjustments in size, shape, color, and even custom logos to meet specific ergonomic and market demands.

Q: What factors should be considered when selecting a padel racket grip size?

A: Key factors include the player's hand dimensions, play style, Ergonomic Design2, material quality, and the balance between comfort and control. A well-selected grip size ensures improved performance and reduced injury risk.

-

Advanced production techniques: Click to discover how modern manufacturing methods enhance product quality and performance, ensuring that each component meets rigorous industry standards. ↩ ↩

-

Ergonomic Design: Click to read an in-depth explanation of how designing grips to match the natural curvature of the human hand can enhance performance, reduce strain, and improve overall playability. ↩ ↩ ↩2 ↩3

-

High-performance carbon fiber variants: Click to learn about the different grades of carbon fiber (3k, 12k, 18k) used in manufacturing, and how they contribute to the durability and performance of sports equipment. ↩ ↩

-

Customization Potential: Click to understand the benefits and processes behind customizing padel racket grips, allowing products to be tailored to specific market needs and individual player ergonomics. ↩ ↩ ↩2

-

Computer-aided design (CAD): Click to explore how CAD technology is utilized to simulate and optimize ergonomic performance in product design, ensuring precision and reliability. ↩ ↩