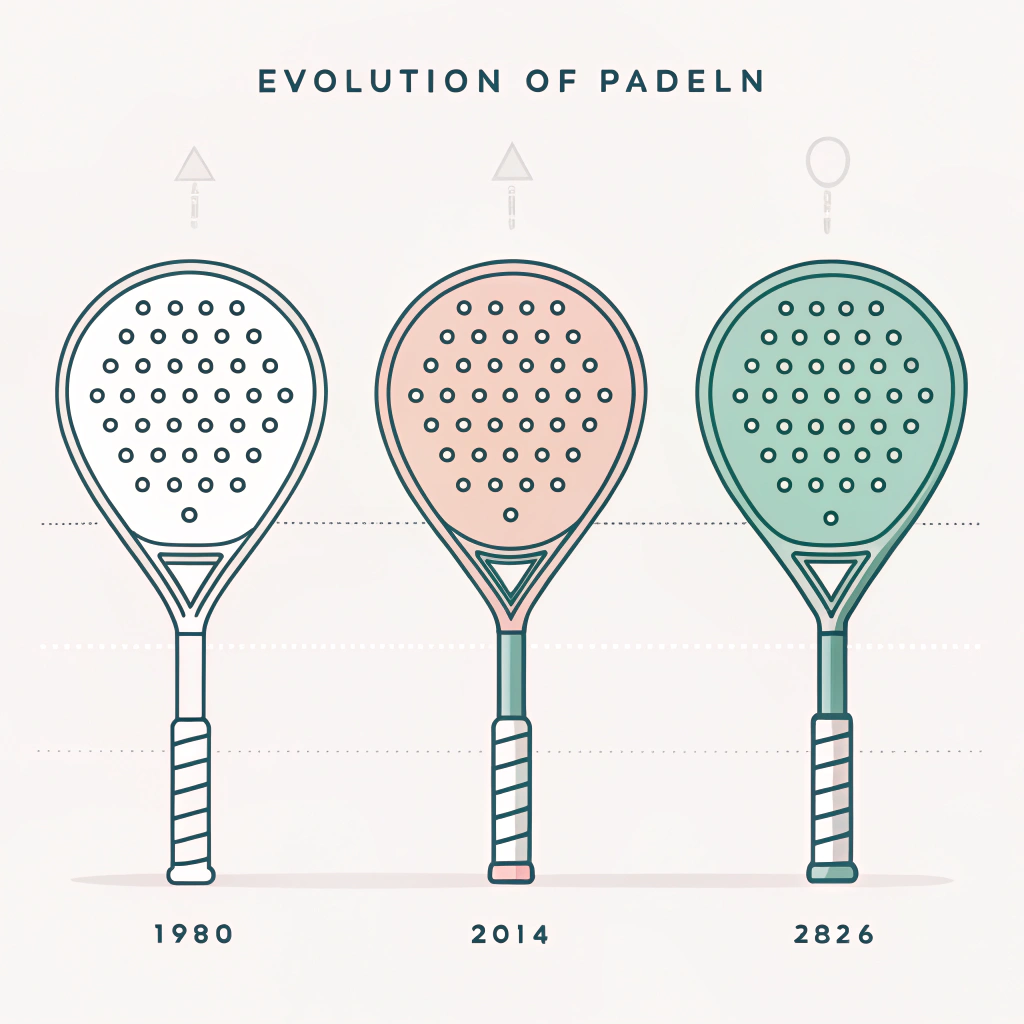

The quick answer: Padel racket design has evolved significantly over the decades, driven by material innovations and design trends. Today’s rackets integrate advanced carbon fiber1 and fiberglass2 techniques with varied shapes—Diamond, Round, and Teardrop—to enhance performance, durability, and playability, providing manufacturers with valuable insights for optimizing production and meeting market demands.

The history of padel racket design is a fascinating journey that mirrors broader trends in sports equipment manufacturing. In the early days of padel, rackets were relatively simple, relying on basic materials and traditional design principles. Over time, as the sport grew in popularity, manufacturers began to use advanced materials like fiberglass and different grades of carbon fiber—from 3K and 12K to 18K—to improve performance. Today, the evolution of padel rackets incorporates data-driven design techniques3, customizability, and performance enhancements that not only satisfy players but also offer B2B buyers strategic advantages in production planning.

Historically, padel rackets have shifted from uniform, one-size-fits-all designs to more specialized forms that cater to various playing styles and performance demands. In the early years, simplicity was key, but increasing competition and player feedback pushed manufacturers to experiment with new materials and innovative shapes. The three primary designs—Diamond, Round, and Teardrop—each offer unique benefits:

- Diamond: Focuses on power with a more angular design that distributes impact forces differently.

- Round: Prioritizes control and balance, making it easier for players to respond rapidly.

- Teardrop: Offers a blend of power and control, appealing to versatile players.

This progression demonstrates the industry's responsiveness to both technological advances and market preferences, underscoring the importance for procurement specialists to understand how these design trends developed over time.

Material innovations have driven much of the evolution in padel racket design. Early rackets primarily relied on fiberglass for their construction due to its lightweight and durability. As competitors in the market sought better performance, manufacturers began incorporating carbon fiber into the production process, which offers higher rigidity and improved vibration dampening. The introduction of different carbon fiber grades standardizes quality while allowing for customization according to performance needs.

Below is a table summarizing the key differences between common materials used in padel rackets:

| Material | Key Attributes | Impact on Performance | Typical Applications |

|---|---|---|---|

| Fiberglass | Lightweight, Cost-effective | Good flexibility and shock absorption | Entry-level to mid-range products |

| 3K Carbon Fiber | Fine weave, moderate stiffness | Balanced power and control | Recreational and competitive beginners |

| 12K Carbon Fiber | Higher stiffness, durable | Enhanced power without sacrificing comfort | Intermediate to advanced production lines |

| 18K Carbon Fiber | Extremely strong, high performance | Maximum power and precision, vibration dampening is improved | Premium and professional rackets |

Using such a table helps manufacturers and procurement managers quickly grasp the pros and cons of each material option, paving the way for informed decision-making when planning upgrades for production lines.

Design innovations have not only depended on material advancements but also on the geometry of the racket itself. Let us consider each design:

Diamond-shaped rackets have come to symbolize power play. Their innovative angular forms provide a unique weight distribution that favors aggressive strikes. However, with power often comes the challenge of maintaining balance and control. Manufacturers have optimized these designs to ensure that even the powerful hits remain stable and reduce unwanted vibrations.

Round-shaped rackets are favored for their balance and ease of use. Their symmetrical design allows players to easily adjust their strokes, making it a popular choice for those prioritizing control and precision. This design is particularly beneficial in situations that demand quick response times and sustainability during extended play.

Teardrop designs represent a fusion of the benefits from both Diamond and Round styles. They are engineered to deliver a moderate amount of power while still offering the control necessary for technical play. The transitional shape helps in spreading the ball impact smoothly, reducing shock and improving overall handling.

Manufacturers and designers continuously refine these shapes by integrating data-driven insights and testing feedback from professional players. This iterative process is crucial in developing rackets that meet the evolving performance requirements of the sport.

Modern B2B sports equipment manufacturing increasingly focuses on customization4 as a key value proposition. Companies like NEX Padel, for instance, offer customized printing, color variations, and even personalized logos on both the racket and accessories such as hand grips and handle covers. This level of customization not only augments brand identity but also meets the specific performance needs of end-users.

For procurement specialists, understanding the historical context of design innovation is instrumental in deciding whether to invest in personalized production lines. Customization allows businesses to respond to market trends faster and enhances the overall appeal of the product, particularly in competitive markets.

The integration of advanced production techniques such as automated design processes and rapid sampling ensures that customization does not compromise on quality or lead time. Many renowned brands, including Hirostar, Reebok, and Starvie, have leveraged these innovations to provide top-notch products that resonate well with their target markets.

Historically, recurring patterns in market demand have underscored the need for continuous innovation. Data indicates that the shift towards high-performance materials and custom designs was not random but rather a well-calculated response to athlete feedback and competitive sports trends.

For example, industry case studies reveal that companies adopting early adoption of carbon fiber technologies witnessed a notable improvement in product performance metrics such as vibration reduction and overall durability. Manufacturers who switched to using 12K or 18K carbon fiber managed to position themselves as premium brands that could offer both robust performance and aesthetic appeal. These metrics are crucial for product development managers and procurement specialists aiming to justify capital investments in new production methodologies.

Furthermore, the evolution of padel racket design is interlinked with the global trend of premiumization in sports equipment. The push for better performance has led to innovations that not only enhance the player experience but also drive brand differentiation in a crowded market. The historical perspective reinforces that keeping pace with technological advancements and customer expectations is essential for sustained market success.

Understanding historical trends and material evolution is a critical precursor for making strategic production decisions today. Here are some key recommendations for B2B buyers and product development managers looking to optimize their product lines:

-

Invest in Material Research: Stay updated on advancements in carbon fiber technology and innovative alternatives that might offer superior performance or cost benefits over traditional fiberglass.

-

Adopt a Flexible Production Approach: Utilize rapid prototyping5 and fast sampling to experiment with different designs, ensuring that your production line can quickly adapt to market feedback.

-

Emphasize Customization: In today’s market, custom designs can set your products apart. Offer personalized graphic printing, adjustable grip options, and bespoke color schemes to appeal to a broader consumer base.

-

Integrate Data and Analytics: Make production decisions based on robust data. Analyze performance metrics and historical trends to identify which design innovations yield the most significant benefits.

-

Cross-Industry Collaboration: Leverage insights from other sports equipment manufacturing sectors that have successfully utilized high-performance materials and custom designs. This can also open new avenues for innovation and efficiency.

Below is a summary table of key strategic recommendations:

| Strategy | Key Actions | Expected Benefit |

|---|---|---|

| Material Innovation | Research advanced carbon fiber and alternatives | Enhanced performance and production quality |

| Flexible Production | Implement rapid prototyping | Faster response to market changes |

| Customization | Offer product personalization | Increased market differentiation |

| Data-Driven Decision Making | Use analytics for design optimization | Informed production investments |

| Cross-Industry Collaboration | Learn from other sectors’ innovations | Broader perspectives and innovation |

These strategies are designed to help procurement specialists and product development managers align their production capabilities with evolving market trends. By understanding where the industry has been, decision-makers can better predict where it is heading and position their businesses for future success.

The evolution of padel racket design is a compelling story of innovation driven by material advancements and changing consumer demands. From the early use of fiberglass to the modern integration of various grades of carbon fiber, each development phase has brought the sport closer to achieving optimal performance and durability. The diversification into Diamond, Round, and Teardrop shapes illustrates the industry's commitment to catering to diverse playing styles and technical requirements.

For B2B buyers and product development managers, these historical insights are not merely academic; they serve as actionable intelligence that can help justify investment in new technologies and production techniques. Embracing customization and data-driven decision making can further enhance product differentiation, ensuring that companies remain competitive in a rapidly evolving market.

By integrating lessons learned from the past with current technological innovations, manufacturers can ensure that their future product lines are both cutting edge and responsive to the demands of modern players. This comprehensive approach not only enhances the overall quality of the product but also solidifies the brand's reputation as a leader in performance and innovation.

Continuous research, flexibility in production, and strategic collaborations remain key to navigating future trends. As the padel industry continues to grow and evolve, informed procurement strategies will play a pivotal role in shaping the next generation of high-performance sports equipment.

People Also Ask

Q1: How has padel racket design evolved over the years?

A1: Padel racket design has evolved from simple fiberglass constructions to high-performance models featuring advanced carbon fiber materials. Innovations in shape—such as Diamond, Round, and Teardrop—have been introduced to enhance power, control, and vibration dampening, reflecting both player feedback and technological progress.

Q2: What are the primary materials used in padel rackets and their benefits?

A2: Key materials include fiberglass for its light weight and cost-effectiveness, and various grades of carbon fiber (3K, 12K, 18K) which provide enhanced stiffness, durability, and vibration reduction. These materials allow for customized designs that meet different performance needs.

Q3: What are the key differences between Diamond, Round, and Teardrop racket designs?

A3: Diamond rackets are designed for power with an angular form, Round rackets offer excellent balance and control, while Teardrop designs blend power with ease of handling. Each shape targets different player preferences, influencing performance and handling characteristics.

-

carbon fiber: Click to learn how carbon fiber innovations improve product performance through enhanced stiffness, vibration dampening, and durability in sports equipment manufacturing. ↩ ↩

-

fiberglass: Click to explore the benefits of fiberglass in sports products, including cost-effectiveness, light weight, and its role in early equipment production. ↩ ↩

-

data-driven design techniques: Click to understand how integrating data analytics into design processes can optimize production and improve product performance. ↩ ↩

-

customization: Click to discover how product personalization and adaptive manufacturing strategies can boost brand identity and meet specific market demands. ↩ ↩

-

rapid prototyping: Click to learn about rapid prototyping methods that help businesses quickly test, iterate, and refine product designs to stay competitive. ↩ ↩