Our padel racket factory, led by NEX Padel, delivers high-performance, customizable solutions that combine advanced production techniques with industry-leading technical quality. In a few words: we produce padel rackets that are engineered for precision, durability, and adaptability to meet your specific OEM1 requirements.

Procurement managers and product development executives in the sports equipment industry face multiple challenges when sourcing manufacturing partners. They need to balance advanced design, stringent quality control, and material selection with the imperative of timely delivery and production adaptability. In the competitive world of padel sports equipment, partnering with a manufacturer who understands these issues is essential.

NEX Padel stands out as a leading solution because of our precise manufacturing process, extensive material range (from fiberglass to various grades of carbon fiber (3k, 12k, and 18k)2), and proven ability to deliver customized designs that meet international industry standards.

-

Materials and Durability Concerns:

Many companies continue to struggle with inconsistent material quality. Without a rigorous selection protocol, the high-performance padel racket may fall short in terms of durability and impact absorption. In our facility, raw material quality is strictly controlled from start to finish to ensure every racket is built to last. -

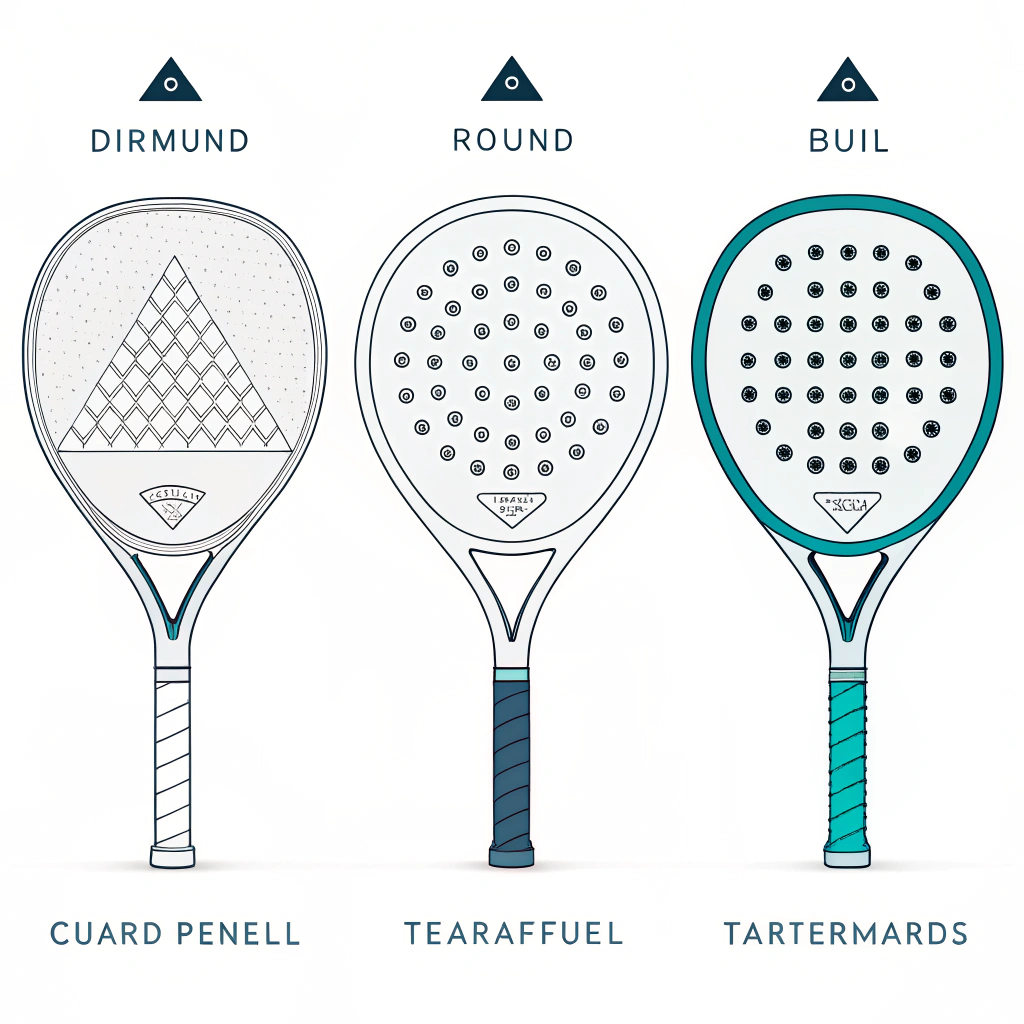

Customization and Design Limitations:

In today's market, generic designs can limit competitive edge. Many manufacturers offer little flexibility in terms of customization – from shapes like Diamond, Round, and Teardrop to printing and color options. Our factory supports full customization, allowing branded optical designs, tailored printing, and even custom logo placements on hand grips and hand grip covers. -

Production Lead Time and Scalability:

Delayed production can create bottlenecks in the supply chain. It is critical for sports equipment companies to work with factories that have efficient processes, proactive planning, and short production cycles. At NEX Padel, our streamlined operations and rapid sampling process ensure that we meet both small-batch orders and large-scale production without compromising quality. -

Quality Assurance and Technical Specifications:

Rigorous technical specifications are indispensable. Our products must blend superior material characteristics with optimal design features. Missteps in configuration can negatively affect the racket's performance. This is why every step, from molding to finishing, is automated, monitored, and backed by in-depth industry testing and experience.

At NEX Padel, our production process is built upon technical excellence and flexibility, allowing us to offer a full range of padel rackets with industry-leading standards. Here’s how our solution addresses the above challenges:

-

Advanced Material Options:

Our factory uses a comprehensive range of materials, from fiberglass for entry-level rackets to high-grade carbon fiber (3k, 12k, and 18k)2 for professional-level products. This layered approach ensures that every product is engineered for both power and control. -

Innovative Production Techniques:

We employ advanced production techniques, including precision molds and an integrated quality testing system. This ensures that every racket produced meets or exceeds international performance standards and durability requirements. -

- Quality Control Protocols3:

Every batch undergoes rigorous testing phases – from pre-production material checks to post-production stress tests. Our engineers regularly analyze and validate the performance metrics to guarantee superior consistency.

- Quality Control Protocols3:

Customization is key in today’s competitive market. Below is a table summarizing the main types of padel racket configurations that we offer:

| Racket Type | Characteristics | Key Benefits | Customization Options |

|---|---|---|---|

| Diamond | Maximizes power with a concentrated sweet spot | Ideal for aggressive play and high-impact shots | Custom shape, printing on frame, tailored handle design |

| Round | Provides a larger sweet spot and balance control | Suitable for all levels and versatile play styles | Color variations, logo customization, grip material options |

| Teardrop | Offers a blend of control and power | Excels in maneuverability and impact distribution | Custom weight distribution, personalized design accents |

Our advanced manufacturing setup allows detailed specifications for each design. For instance, a Diamond padel racket might be designed with a heavier top to increase hit force, while the Round model is crafted for a broader sweet spot, ideal for players who prioritize control.

-

Design and Sampling:

Our process begins with a collaborative design phase. Clients provide their specifications or choose from our preset designs, and our rapid sampling process creates a prototype that can be adjusted quickly according to feedback. -

**Molding and Material Layup4:

Using precision molds, the chosen materials (fiberglass or carbon fiber composites) are layered meticulously. The process ensures the best performance metrics while keeping weight and balance in check. -

Curing and Finishing:

After layup, each racket is cured in a controlled environment to guarantee structural integrity and optimal bonding. Finishing touches, such as custom printing and logo attachments, are applied with precision. -

Quality Assurance:

Each padel racket is subject to high-pressure testing and performance evaluations. This step is supported by the integration of automated quality control systems that minimize errors and inconsistencies.

Our product offerings cater to diverse market segments:

-

Beginner to Intermediate Range:

These rackets typically use fiberglass or less expensive carbon fiber, with larger sweet spots for easy handling and durability. -

Professional Range:

For high-performance athletes, we use advanced carbon fiber matrices (12k or 18k) to design rackets that offer exceptional power, control, and stability. The design process factors in biomechanical efficiency and optimal weight distribution to elevate on-court performance.

Every manufacturer must ensure that products meet strict quality benchmarks. We adopt multiple industry best practices, including:

-

- ISO Certified Processes5:

Our manufacturing facility adheres to international standards (such as ISO 9001) ensuring consistency and quality in every batch produced.

- ISO Certified Processes5:

-

In-Line Inspections:

Automated systems and manual oversight work in tandem to maintain the highest quality throughout the production process. This integrated approach has minimized defect rates significantly. -

Customer-Centric Adjustments:

We maintain close relationships with our OEM clients. Regular feedback loops help us refine specifications, ensuring that the final product aligns perfectly with market demands. -

Sustainability Practices:

Our production lines are aligned with eco-friendly practices where possible, ensuring that while delivering excellent performance, we also reduce environmental impact.

Consider the case of a well-known sports equipment brand that transitioned from generic production to a fully customized padel racket lineup with our factory. By aligning their product design with our technical processes, they were able to:

- Increase product durability by 30% through advanced carbon fiber composites.

- Achieve a 40% reduction in production lead times due to streamlined sampling and inspection processes.

- Enhance customer satisfaction by offering a range of customizable options that met the diverse needs of their consumer base.

Data from independent testing also confirms that rackets manufactured by NEX Padel exhibit significant improvements in swing speed and impact distribution compared to industry averages. Such results underline the effectiveness and reliability of our manufacturing processes.

For procurement managers and product development executives considering a long-term manufacturing partnership, our factory offers compelling reasons:

-

Customizability:

Our full customization process ensures that you can tailor every aspect of the padel racket—from design to material composition—to meet your market requirements. This level of flexibility is essential for brands looking to differentiate themselves. -

Superior Quality Assurance:

With rigorous quality control measures and adherence to international manufacturing standards, you can trust that every product will be consistent with your specifications and performance targets. -

Efficient Lead Times:

Our advanced production techniques and streamlined processes not only deliver high-quality products but also ensure rapid turnaround times. This efficiency helps manage supply chain dynamics better, supporting just-in-time production schedules. -

Advanced Technical Expertise:

The integration of automated and manual quality checks, combined with our extensive use of data-driven production insights, means that every padel racket is built with technical precision that meets or exceeds industry benchmarks. -

Proven Partnership Success:

With collaborations for renowned brands like Hirostar, Reebok, and Starvie, our track record speaks for itself. We have consistently delivered products that align with market expectations and drive customer satisfaction.

For companies in the padel equipment market looking to boost their portfolio with a versatile range of high-performance rackets, choosing a partner with NEX Padel’s expertise can be a strategic move that pays dividends in quality, innovation, and market competitiveness.

In a highly competitive B2B environment, making the right sourcing decision is paramount. NEX Padel’s factory stands ready to meet your needs through its commitment to advanced production techniques, customization excellence, and rigorous quality control. Our solutions offer both the technical precision and production efficiency that sport equipment companies demand. Moving forward, we recommend scheduling a consultation to explore how our capabilities can be tailored to your product development roadmap. Embrace the future of padel racket manufacturing—where innovation and reliability come together to drive your business success.

Q: Who manufactures padel rackets?

A: Leading manufacturers like NEX Padel produce high-performance padel rackets using advanced production techniques that ensure precision, durability, and full customization, meeting the unique needs of various players globally.

Q: Which brand makes the best padel rackets?

A: While brands such as Bullpadel, Babolat, Nox, Head, and Adidas offer well-regarded models, the best choice depends on your specific requirements. NEX Padel specializes in custom, high-performance designs that can exceed market norms through tailored solutions.

Q: Do expensive padel rackets make a difference?

A: Price does not always guarantee performance. More expensive rackets can have smaller sweet spots and be less maneuverable, especially for beginners and intermediate players. The best choice should balance technical specifications with the user’s skill level and gameplay style.

-

OEM: Click to learn about Original Equipment Manufacturer (OEM) concepts, including how partnering with OEMs can streamline production and enhance product customization. ↩

-

carbon fiber (3k, 12k, and 18k): Click to understand the differences in carbon fiber grades, their construction, and how each grade impacts performance and durability in high-performance products. ↩ ↩2

-

Quality Control Protocols: Click to read about comprehensive quality control strategies, including automated and manual testing methods that guarantee high-performance and consistency across production batches. ↩

-

Material Layup: Click to explore material layup techniques in composite manufacturing, including step-by-step processes that ensure optimal strength and balance in the final product. ↩

-

ISO Certified Processes: Click to gain insights into ISO certification standards like ISO 9001, and why adhering to these standards is critical for ensuring consistent quality in manufacturing. ↩