A quick answer: When choosing between fiberglass1 and carbon fiber2 for padel rackets, consider that fiberglass offers enhanced flexibility and a greater spring effect for slower hits, while carbon fiber delivers superior power, durability, and precision for experienced players. This guide details key technical differences, customization options, and production insights to support your supplier decision.

The decision to use either fiberglass or carbon fiber in padel racket construction is critical. Each material offers distinct advantages that can influence performance attributes such as ball output, rigidity, flexion, and overall longevity. As a procurement manager or product development specialist, understanding these differences is essential to ensure that your final product meets quality, performance, and customer satisfaction standards.

Fiberglass is widely known for its cost-effectiveness and ability to offer excellent control. It is especially beneficial for players who rely on finesse and well-timed ball placement. In padel rackets, using fiberglass enhances the flexibility of the racket, allowing for a greater spring effect during slow, defensive hits. This characteristic leads to increased ball output when playing from the bottom of the court.

Key properties of fiberglass include:

- High elasticity for better shock absorption

- Improved ball response in slower hits due to its flexible nature

- Generally lower material cost, making it an ideal choice for mid-level performance standards

- Suitable for beginners and intermediate players seeking a reliable yet pliable racket

Carbon fiber, on the other hand, is prized for its superior strength, stiffness, and lightweight performance. This material is engineered to provide maximum performance benefits, particularly for experienced players seeking enhanced power and shot precision. With applications using 3k, 12k, or 18k carbon fiber, manufacturers can fine-tune the racket's properties to match different performance needs.

Key properties of carbon fiber include:

- High rigidity and durability, resulting in powerful shots

- Lightweight structure that enables faster swings without compromising control

- Enhanced precision and energy transfer even under high impact

- Preference among high-performance and professional players

The following table provides a comparative overview of key properties between fiberglass and carbon fiber used in padel rackets:

| Feature | Fiberglass | Carbon Fiber |

|---|---|---|

| Flexibility | High; allows greater spring effect | Low; offers superior rigidity and power |

| Weight | Generally heavier compared to carbon fiber | Lightweight, aiding faster swing speeds |

| Durability | Suitable for mid-level performance; may wear faster under high impact | High durability; maintains performance over time |

| Cost | More cost-effective | Higher cost due to advanced production process |

| Target User | Beginners to intermediate players | Experienced players seeking high performance |

| Vibration Damping | Good shock absorption | Excellent vibration damping, less flex in unexpected impacts |

Manufacturers can decide on the material based on desired performance metrics and customer profiles. For instance, a balance between cost and control favors fiberglass, while players looking for aggressive play and extended durability should consider carbon fiber.

In our production line at NEX Padel, precision is paramount. We use advanced composite manufacturing techniques to ensure that every racket meets stringent technical specifications3. These methodologies include rapid prototyping4 and rigorous quality inspections, ensuring that both fiberglass and carbon fiber components are fabricated to their full potential.

Key production aspects include:

- Material Handling: Both fiberglass and carbon fiber require specific handling processes to maintain their structural integrity. Our guided procedures ensure minimal contamination and consistent resin infusion to avoid weak spots.

- Layering Techniques: For carbon fiber, multiple layers (3k, 12k, 18k) are carefully selected and laid to optimize the balance between stiffness and shock absorption. For fiberglass, proper layering is crucial to attain its characteristic flexibility.

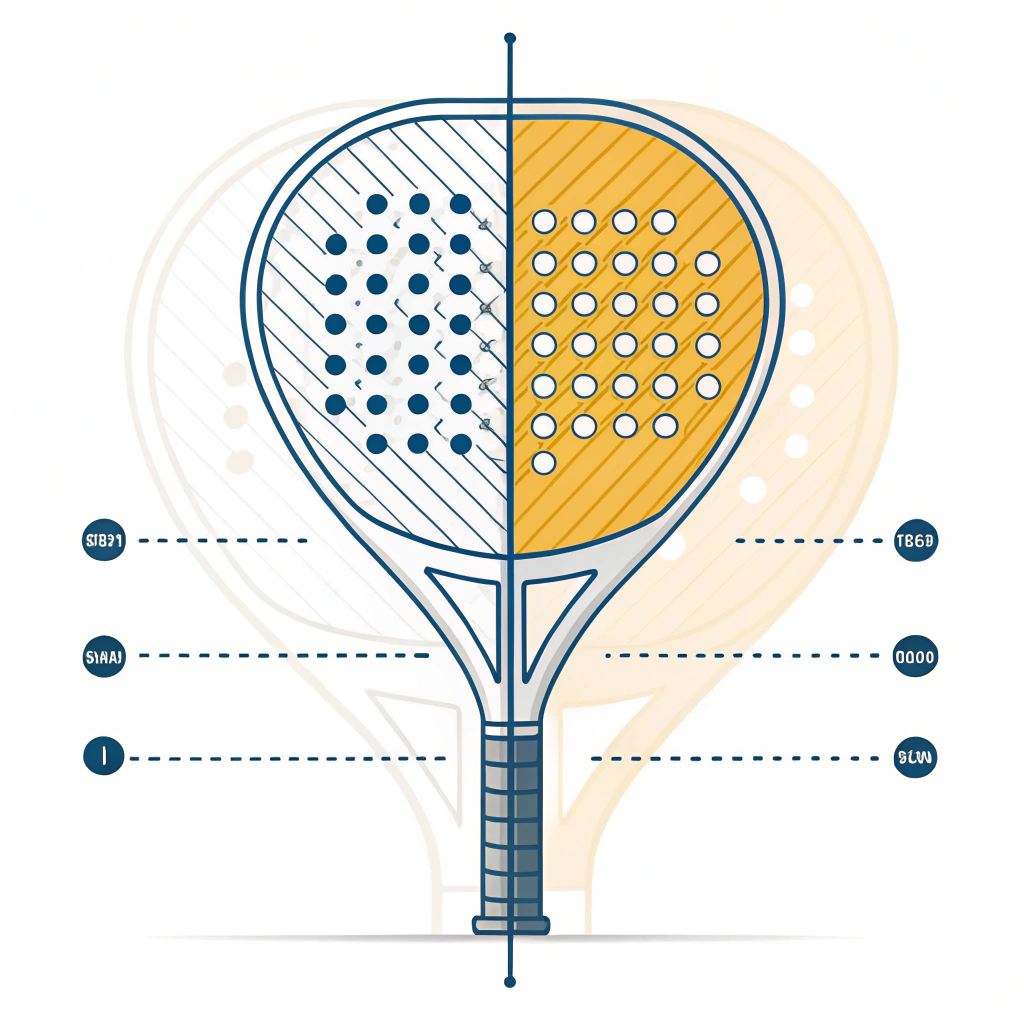

- Customization: We offer complete customization options, including three core shapes—Diamond, Round, and Teardrop—to meet diverse player preferences. Additionally, customization extends to hand grip designs and handle cover logos.

Customization and OEM manufacturing5

Our capacity to provide full OEM manufacturing lies at the heart of our services. We not only supply high-performance rackets but also cater to various branding requirements:

- Shape Customization: Clients can choose from our standard shapes or request fully customized designs tailored to ergonomic and aesthetic demands.

- Graphic and Finish Options: Beyond the racket’s feel, customization extends to printing and color selections on the racket's surface, hand grips, and handle covers.

- Material Mix: There is flexibility in design choices regarding the mix of fiberglass and carbon fiber components in the racket frame. This flexibility allows a balanced approach to performance, merging control with power.

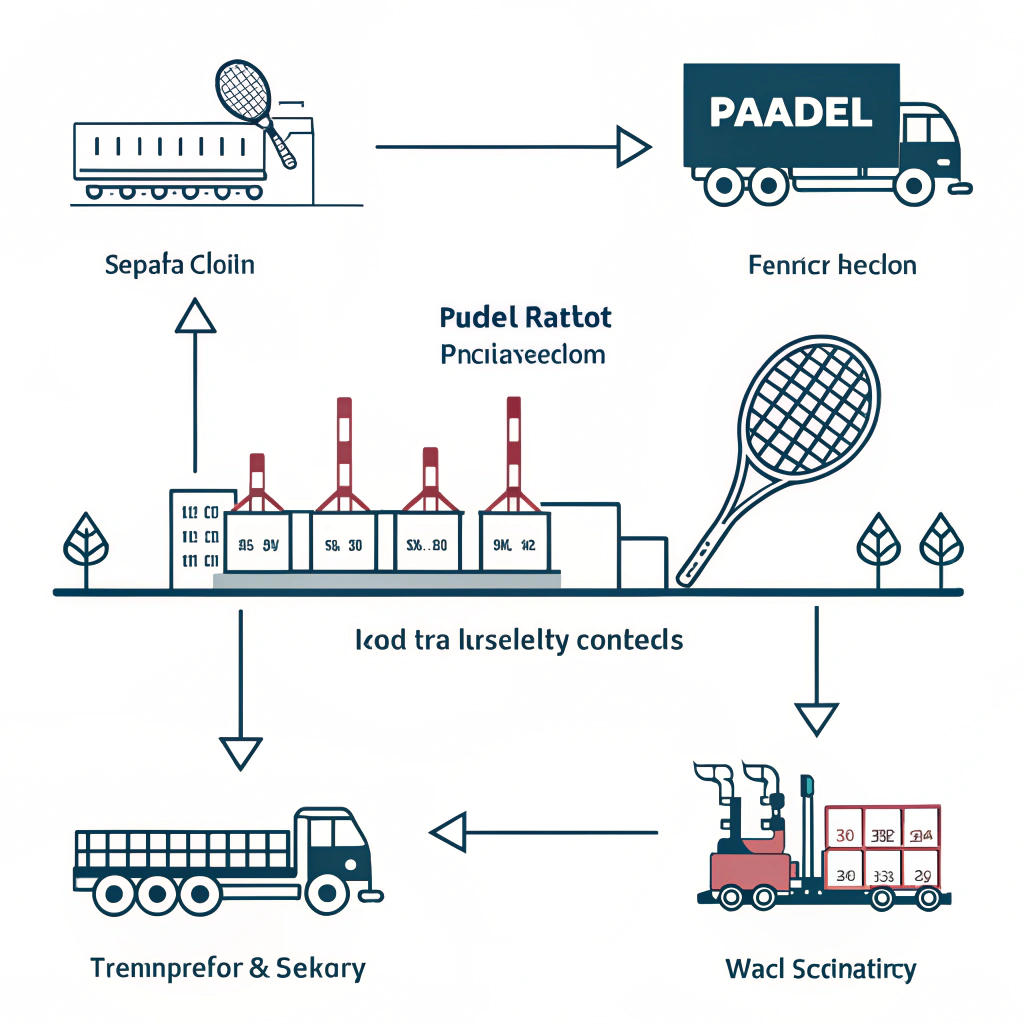

OEM partners such as Hirostar, Reebok, and Starvie have benefited from our precise manufacturing, ensuring consistency, and timely delivery. Our streamlined supply chain and rapid prototyping help keep production efficient and adaptable to market demands.

The choice of material will directly affect how the racket performs on the court:

- Fiberglass Rackets: Due to their enhanced flexion, these rackets are particularly suitable for defensive play. In scenarios where soft hits are predominant, the spring effect provided by fiberglass translates to superior ball response, giving strategic advantages during prolonged rallies.

- Carbon Fiber Rackets: Designed for aggressive play, the stiffness of carbon fiber rackets allows for pronounced energy transfer. This material minimizes excessive bending, enabling powerful and accurate strokes that are crucial during fast-paced exchanges.

Players often encounter varying degrees of vibration during matches. Carbon fiber's rigid structure effectively minimizes unwanted vibrations, thus protecting the player’s arm from fatigue. In contrast, fiberglass’s inherent flexibility can absorb shock, which may aid in reducing overall strain during extensive play sessions. Each material’s impact resistance further emphasizes critical decisions based on expected game dynamics and player needs.

Durability remains a pivotal factor in material selection. Carbon fiber is engineered for long-term resilience, maintaining performance even under repetitive high-stress conditions. While fiberglass offers excellent initial performance, its durability may be compromised when repeatedly subjected to high impacts, resulting in potential performance degradation over time. The decision will thus vary depending on whether the end-client prioritizes initial cost savings or long-term performance durability.

Based on technical performance and customization requirements, consider the following:

-

For Players Seeking Flexibility and Cost-Effectiveness:

- Fiberglass is recommended due to its affordability and flexibility. It is ideal for suppliers targeting entry- and mid-level performance markets.

-

For High-Performance and Professional Use:

- Carbon fiber proves to be the optimal choice. Its lightweight and rigid properties offer enhanced power and precision necessary for advanced play. When budget allows, integrating high filament counts like 12k or 18k can further boost racket performance.

-

For OEMs Needing Customization:

- Leverage our advanced production techniques at NEX Padel to mix materials if desired. This approach enables the fine-tuning of performance attributes, balancing flexibility with rigidity, thus appealing to a broader range of skill levels.

| Requirement | Recommended Material | Justification |

|---|---|---|

| Cost Efficiency | Fiberglass | Lower material cost with superb control for beginners |

| Enhanced Power and Precision | Carbon Fiber | Superior stiffness and lightweight design |

| Customization and Branding | Both (with tailored mix) | Ability to balance performance based on target market |

| Longevity and Durability | Carbon Fiber | Resists wear and maintains performance under stress |

| Shock Absorption | Fiberglass | Higher flexibility provides better shock absorption |

Our advanced manufacturing process enhances supply chain efficiency. With rapid prototyping and rigorous quality control measures across our facilities in Jiaxing, Zhejiang, China, we ensure that our padel rackets leave the factory with impeccable performance metrics. Our production expertise enables us to meet tight deadlines while accommodating full customization—export quality is our standard.

Additional benefits for our OEM partners include:

- Timely production and delivery from our streamlined supply chain network.

- Flexibility in order quantities and customization options tailored to market trends.

- Support from an experienced R&D team to align product features with the latest industry trends.

Our commitment is to provide high-performance padel rackets that cater to both immediate and long-term business needs. With detailed technical specifications and a blend of materials tailored to diverse playing styles, we help you make an informed procurement decision that supports market success.

In summary, selecting the right material for your padel racket involves considering not only the immediate performance attributes of fiberglass and carbon fiber but also overall production efficiency, customization potential, and long-term durability. While fiberglass offers excellent control and cost-effectiveness ideal for defensive play, carbon fiber provides the rigidity and power favored by experienced players.

At NEX Padel, our deep understanding of composite materials and advanced OEM manufacturing processes enables us to deliver products that meet exacting performance standards and customization needs. We invite you to explore these options further by engaging with our technical and sales teams, ensuring that your next production run consistently meets your quality expectations and end-user demands.

By aligning your procurement strategy with the right material choice, you can enhance product performance, reduce overall costs, and boost customer satisfaction—paving the way for market leadership in the competitive world of padel sports goods.

Q: Which is better carbon fiber or fibreglass padel racket?

A: A padel racket constructed entirely from fiberglass typically provides greater ball output in slower hits due to its enhanced flexion and spring effect. In contrast, a carbon fiber racket offers maximum performance with superior power and precision due to its lightweight, stiff design.

Q: What is the best material for a padel racket?

A: The best material depends on the player’s skill level, playing style, and budget. Fiberglass is ideal for players needing more control at an affordable cost, while carbon fiber is best for enhancing power and durability, especially among experienced players.

Q: Are carbon fiber rackets good?

A: Yes, carbon fiber rackets are excellent for experienced players seeking maximum performance. Their lightweight, rigid structure allows for faster swings and powerful, precise shots, making them a preferred choice when looking for top-tier performance and durability.

-

Fiberglass: Click to learn more about this composite material known for its flexibility, cost-effectiveness, and applications in various sporting goods manufacturing. ↩

-

Carbon Fiber: Click to explore how carbon fiber is engineered for strength, stiffness, and lightweight performance, making it ideal for high-performance products. ↩

-

Technical Specifications: Click for an overview of key product parameters and standards that ensure performance and quality in manufacturing. ↩

-

Rapid Prototyping: Click to understand this innovative process that accelerates product development cycles and enhances design validation. ↩

-

OEM Manufacturing: Click to delve into the process of Original Equipment Manufacturer production, which enables customized product branding and streamlined production techniques. ↩