A leading manufacturer of high-performance padel rackets, NEX Padel combines advanced production techniques with flexible customization options to meet the dynamic needs of global procurement professionals seeking reliable, innovative, and cost-effective sports equipment solutions.

Procurement managers face broad challenges when sourcing padel rackets. On one hand, they must evaluate production quality, meet customization demands, and secure reliable delivery timelines. On the other, global manufacturers offer diverse production technologies, material options, and competitive pricing. In this increasingly competitive field, choosing the right partner is essential to maintain a solid inventory and achieve market advantages.

Today's consumers demand superior performance, premium materials, and a personalized touch when it comes to sports equipment. At NEX Padel, we stand out with our capabilities: from using the most advanced materials such as 3k, 12k, and 18k carbon fiber1 to offering bespoke designs like Diamond, Round, and Teardrop shapes. Our track record with renowned brands like Hirostar, Reebok, and Starvie proves that our production techniques meet the highest quality standards.

When evaluating global padel racket manufacturers, key factors demand attention. Below are the core differentiators that help procurement specialists make informed decisions:

-

Quality Control & Precision:

- Use of advanced materials such as glass fiber2 and varying grades of carbon fiber.

- Rigorous quality control processes testing every stage of production.

- Precision in design ensuring high durability and performance.

-

Customization Capabilities:

- Multiple shape options (Diamond, Round, Teardrop) based on player preference.

- Custom printing, color choices, and logo placement on hand grips and handle covers.

- Options for bespoke design elements tailored to unique market needs.

-

Production Techniques & Lead Times:

- Fast prototyping (rapid prototyping3 (rapid sampling)) and efficient production cycles.

- State-of-the-art manufacturing processes that guarantee consistency.

- Reliable delivery schedules that support large-scale B2B orders.

-

Cost Competitiveness & Supply Chain Reliability:

- Balancing premium quality with competitive pricing.

- Streamlined supply chain management4 ensuring timely shipments.

- Long-term contracts with flexible order sizes to accommodate market fluctuations.

Choosing the right partner involves a side-by-side comparison of several crucial aspects. Below is a summary table that highlights the key attributes:

| Feature | NEX Padel | Competitor A | Competitor B |

|---|---|---|---|

| Material Options | Glass fiber to 18k carbon fiber | Limited to standard carbon fiber | Standard composite materials |

| Customization | Fully customizable shapes & prints | Limited customization | Basic logo embroidery |

| Production Speed | Rapid prototyping & timely deliveries | Moderate lead times | Extended production cycles |

| Quality Control | Rigorous multi-stage inspections | Good quality control | Variable quality consistency |

| Reputation & Partnerships | Trusted by top brands (Hirostar, Reebok) | Emerging market players | Established, but with fewer innovations |

This table underscores the competitive advantage that NEX Padel offers by balancing advanced production techniques with robust customization capabilities and reliable supply chain management.

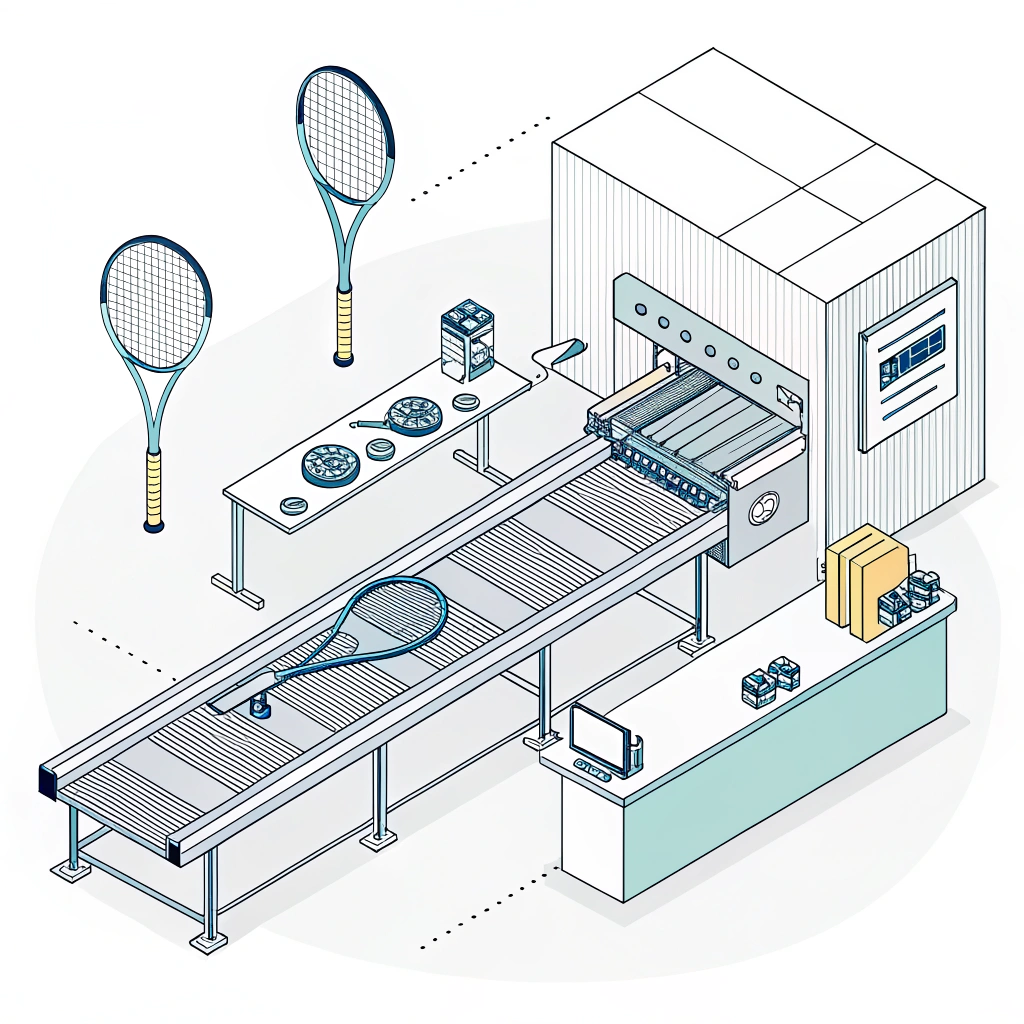

At NEX Padel, our production process combines technology and artisan craftsmanship to produce high-performance padel rackets. The process begins with precise design using Computer-Aided Design (CAD)5 tools and advanced simulation technology to ensure aerodynamics and impact resistance. Manufacturing then proceeds with careful selection of materials—using varying grades of carbon fiber—to match specific performance needs.

-

Material Selection:

We offer options ranging from glass fiber2 to high-grade 3k, 12k, and 18k carbon fiber. These materials provide a balance between stiffness, flexibility, and vibration damping, catering to a range of player skill levels and preferences. -

Customization Integration:

Beyond the basic design, our production line allows for extensive customization. Clients can choose the racket's shape—Diamond, Round, or Teardrop—and incorporate bespoke color schemes and printing. Customized hand grips and handle logos further enhance brand identity, ensuring that every product meets unique market demands. -

Quality Assurance:

Our rigorous quality assurance stages include both automated testing and manual inspections. Each racket undergoes performance testing to verify its structural integrity, ensuring the product not only meets international standards but exceeds industry expectations. -

Rapid Prototyping & Sampling:

Fast sample production allows clients to evaluate prototypes before committing to full-scale orders. This agile manufacturing process minimizes risk and optimizes production schedules for bulk orders, making us an attractive partner for large chains and distributors.

Through these processes, NEX Padel ensures that every padel racket delivers top-tier reliability and performance, which is essential for maintaining competitive advantage in the global sports equipment market.

Customization is central to tomorrow’s market strategy. Modern procurement managers seek partners who can adapt to consumer trends and regional preferences. Our extensive customization options make NEX Padel an ideal partner.

-

Shape Variability:

- Diamond: Offers stability and power, suitable for aggressive players.

- Round: Provides a balanced feel and softer touch for enhanced control.

- Teardrop: Merges benefits of both shapes for a versatile play experience.

-

Visual Identity:

- Clients can specify color schemes that align with their brand image.

- Custom printing allows for personalized logos on the racket surface.

- Options extend to hand grip logos and finishes on handle covers, ensuring the product is unique to each client.

-

Technical Enhancements:

- Incorporation of specific materials to adjust racket weight and stiffness.

- Custom adjustments in string tension and balance points to optimize player performance.

For retailers and distributors, these customization options offer the necessary flexibility to capture diverse market segments and tailor products to local tastes, thereby enhancing market relevance and customer satisfaction.

When evaluating padel racket manufacturers, consider the following strategic aspects:

-

Reliability and Lead Times:

Consistent delivery is as critical as product quality. NEX Padel’s efficient production cycle and transparent supply chain reduce bottlenecks and ensure timely shipments, critical for managing seasonal sales and promotions. -

Scalability of Production:

Assess whether the manufacturer can scale production volumes in response to demand fluctuations. NEX Padel supports both small batch prototyping and large-scale production runs, making them a flexible partner for long-term growth. -

Cost vs. Quality Balance:

While competitive pricing is important, it must not compromise quality. Investing in high-quality, customizable padel rackets leads to improved customer satisfaction and lower return rates. This balance is a cornerstone of our business philosophy at NEX Padel. -

After-Sales Support and Communication:

A transparent communication channel with post-production support adds value to the partnership. Clear documentation, timely responses, and dedicated customer service help build trust and streamline the procurement process. -

Industry Reputation and Partnerships:

Consider manufacturers with established partnerships and a robust reputation. NEX Padel’s collaborations with global brands like Hirostar, Reebok, and Starvie underscore our commitment to excellence and market-leading performance.

Integrating these strategic considerations into your decision-making process will ensure you select a manufacturing partner that not only meets technical requirements but also aligns with your broader business strategies.

For procurement managers and product sourcing specialists looking for a global manufacturing partner that offers both high performance and extensive customization, the following recommendations summarize our approach at NEX Padel:

-

Assess Production Quality:

Scrutinize every component of the production process. Evaluate material integrity, finishing quality, and performance testing protocols. -

Leverage Customization:

Utilize manufacturers who offer a broad range of customization options. This flexibility allows you to cater to diverse market segments and stay ahead of consumer trends. -

Prioritize Supply Chain Reliability:

Choose partners with proven track records in timely delivery and robust quality control to mitigate risks associated with production delays. -

Embrace Technological Innovation:

Seek manufacturers that invest in advanced production techniques and rapid prototyping. This ensures that your products remain innovative and competitive. -

Build Long-Term Partnerships:

Establish relationships with manufacturers who share your vision for quality and efficiency. Long-term collaborations often lead to better pricing, superior quality, and more responsive customer support.

In conclusion, the competitive landscape of padel racket manufacturing requires a well-rounded evaluation of quality, customization, and reliability. By aligning with a partner like NEX Padel, which combines advanced production techniques with flexible customization, procurement managers can secure a strategic advantage. Our commitment to excellence, backed by proven industry relationships and innovative manufacturing processes, makes us a reliable choice for meeting the evolving needs of the sports equipment market.

As you refine your procurement strategy, consider these key points alongside our detailed comparisons and industry insights. We invite you to further discuss your unique requirements with our team, ensuring that every padel racket not only elevates your product portfolio but also resonates with your target market.

Who manufactures padel rackets?

Many global manufacturers produce padel rackets, including established brands and emerging players. Prominent examples include companies from Spain, Scandinavia, and other regions. It is important to choose a manufacturer that offers advanced production techniques and a commitment to quality, much like NEX Padel.

What are the top 5 padel racket brands in the world?

Top padel racket brands often cited include Adidas, Bullpadel, Nox, Head, and Babolat. These brands are known for their superior performance, innovative design, and reliability, making them popular among both recreational and competitive players.

Which padel rackets are made in Spain?

Several high-end padel rackets originated in Spain, where craftsmanship and quality are highly valued. For instance, certain models from brands like Varlion are designed and handmade in Spain, ensuring that they offer the highest quality and adhere to strict EU production standards.

-

carbon fiber: Click to explore an in-depth explanation of carbon fiber properties, its grading (3k, 12k, 18k), and how it impacts product performance and durability in high-performance sporting equipment. ↩ ↩

-

glass fiber: Click to learn about glass fiber, its manufacturing benefits, and why it is used alongside carbon fiber to achieve optimal balance between stiffness and flexibility in sports equipment. ↩ ↩ ↩2

-

rapid prototyping: Click to read about the rapid prototyping process, its role in reducing time-to-market, and how it allows for quick iterations and validation of design concepts in production. ↩ ↩

-

supply chain management: Click to understand the fundamentals of supply chain management, including strategies to streamline operations, ensure timely deliveries, and manage risks effectively in a global procurement context. ↩ ↩

-

Computer-Aided Design (CAD): Click to discover how CAD tools enhance precision in product design, enabling robust simulation and prototyping that are crucial in modern manufacturing. ↩ ↩