Rapid turnaround in high-performance padel racket production is achievable through streamlined production processes, robust quality control, and flexible customization options. This article explains how manufacturers like NEX Padel manage urgent orders, ensuring that customers receive top-quality, custom-designed padel rackets on time without compromising performance.

When dealing with urgent orders, many sports equipment distributors face challenges such as tight deadlines, complex customization requirements, and ensuring quality standards. The need for rapid turnaround is driven by market demand fluctuations, seasonal competitions, and consumer expectations. In our experience at NEX Padel, we have honed production efficiency to support clients in scenarios where every minute counts and quality is non-negotiable.

Urgent orders in the padel equipment industry present a unique set of challenges including:

- Managing high-performance materials like carbon fiber1 (3k, 12k, and 18k) and fiberglass with precision.

- Customizing racket designs (Diamond, Round, and Teardrop shapes, or even bespoke shapes) to meet diverse client specifications.

- Integrating fast prototyping and rapid production cycles, ensuring an on-time delivery even under pressure.

- Addressing the supply chain2 intricacies from sourcing raw materials to final quality inspections.

These aspects are critical for procurement managers who need to maintain robust supply chains while ensuring that the products remain top-notch in both performance and durability.

Several factors can lead to delays when processing urgent padel racket orders:

- Material availability and quality control: Advanced materials such as carbon fiber require specific storage and handling procedures. Any disruption in supply can lead to bottlenecks in production.

- Customization complexities: Tailoring designs including shape, print, color, hand grip logos, and handle covers demands a flexible production line and reliable communication between design and manufacturing teams.

- Production workflow inefficiencies: Traditional production setups may not be designed for rapid prototyping or short-run orders, leading to increased turnaround times.

- Supply chain fluctuations: Even minor delays in raw material procurement or quality overhead during hand-offs between departments can cascade into significant lead time extensions.

Understanding these issues is the first step towards an effective solution.

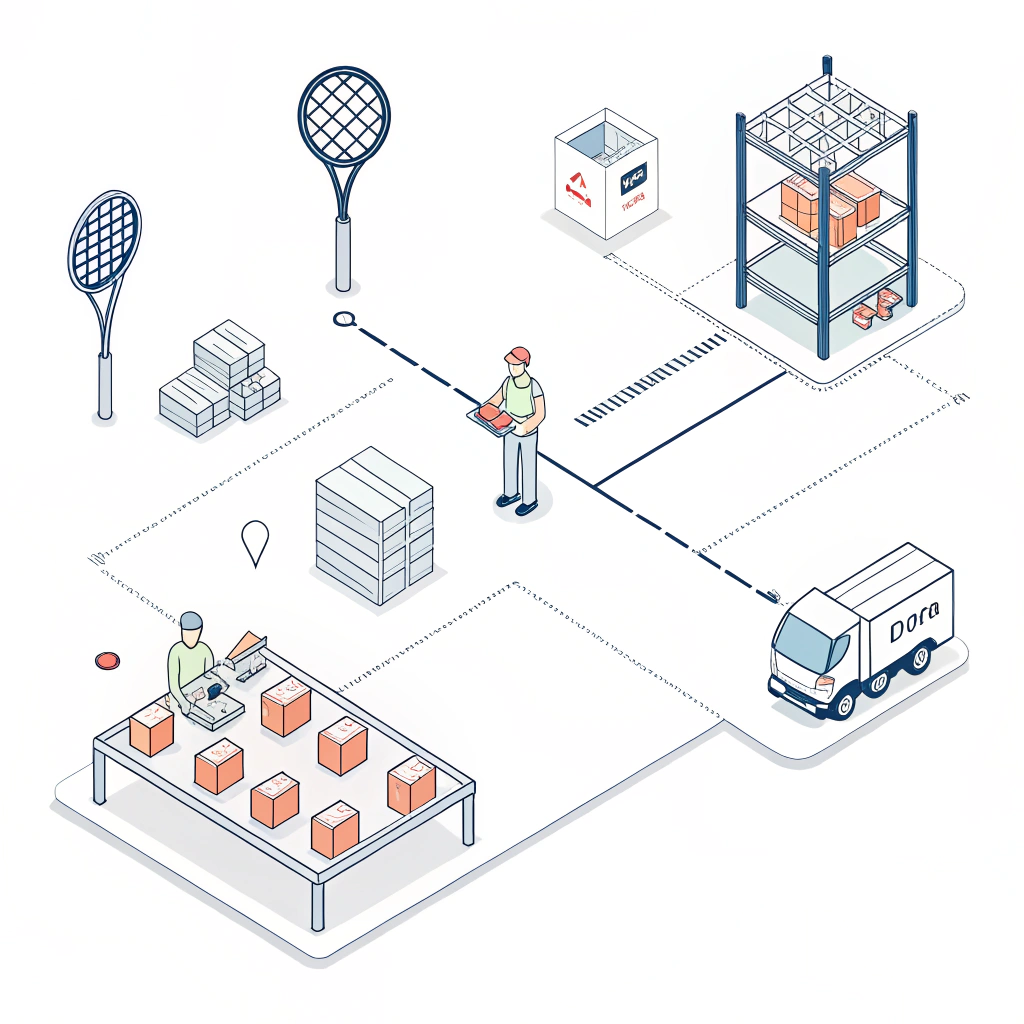

Our approach to managing urgent orders is rooted in structured and efficient production processes. Here we outline a clear, step-by-step solution to these challenges:

- Pre-stocked Critical Materials: Keeping an inventory of essential materials such as different grades of carbon fiber ensures that production isn't held up by ordering delays.

- Multiple Supplier Relationships: Establishing relationships with trusted suppliers minimizes risks if one supplier faces disruptions.

- **Rapid Prototyping3: Implementing quick prototype cycles allows us to verify designs and make necessary modifications swiftly.

- **Bespoke Manufacturing Lines4: Our production lines are designed to handle both standard and custom designs without significant downtime.

- Integrated Quality Control: Continuous monitoring and in-line quality control ensure that every racket meets high-performance specifications before it leaves the factory.

- Real-time Order Tracking: Utilizing advanced ERP systems5 enables transparent and real-time tracking of each order through production.

- Custom Support Teams: Our specialized teams ensure that any client requests for customization or design changes are addressed promptly.

- Feedback Loops: Collecting client feedback helps refine our process, ensuring that repetitive issues are resolved, and innovations are effectively implemented.

- Performance Metrics: We monitor lead times, production efficiency, and quality control metrics to continuously optimize our manufacturing and logistics processes.

| Production Stage | Challenge | NEX Padel Solution |

|---|---|---|

| Material Procurement | Supply chain delays | Pre-stocked materials and multiple suppliers |

| Customization | Complex design modifications | Flexible design and rapid prototyping systems |

| Quality Control | Inconsistent product quality | Integrated in-line quality control checkpoints |

| Order Processing | Communication bottlenecks | Real-time ERP tracking systems |

| Turnaround Time | Production inefficiencies | Dedicated production lines for urgent orders |

The table above summarizes our approach to handling urgent orders, emphasizing how each stage of production is optimized to meet strict deadlines while maintaining the quality and performance expected from high-end padel equipment.

While the outlined solutions are effective, there are several factors that procurement managers should consider before finalizing a supply partner:

- Customization Limits: Some designs may require extended prototyping phases, particularly for bespoke shapes or novel materials. It is critical to set realistic timelines if extensive modifications are necessary.

- Scaling Production: Rapid production may sometimes lead to oversight if quality control methods are not robustly maintained. Partners must balance speed with quality.

- Cost Factors: Accelerated production and dedicated resources can entail higher initial costs. However, the long-term benefits include sustained customer satisfaction and market competitiveness.

- Regulatory Compliance: High-performance sports equipment must comply with various safety and performance standards. Ensure that your partner has robust certification processes in place.

Understanding these limitations can help experts better assess a potential supplier’s capabilities against your business requirements.

At NEX Padel, we recently collaborated with a noted sports equipment distributor facing an imminent sporting event. They required a large volume of customized padel rackets with unique color schemes and branding on very tight deadlines. Here’s how we responded:

-

Initial Consultation and Rapid Design Verification:

Within 24 hours, our design team worked with the distributor to finalize the customization requirements—covering the shape, logo placement, and material selection (carbon fiber variants including 3k and 12k). -

Fast-Tracked Prototyping and Quality Checks:

Leveraging our rapid prototyping techniques, we produced a sample batch within 48 hours. Intensive quality checks were performed during production to ensure each racket met industry standards. -

Efficient Production and Logistics Coordination:

Our production line was reconfigured to prioritize the urgent order, reducing the usual production cycle by 30% without compromising quality. An integrated ERP system allowed all stakeholders to track the progress in real time. -

On-Time Delivery and Client Satisfaction:

The distributor received the complete order ahead of the event, enabling them to meet consumer demand while reinforcing their reputation for prompt delivery and high-quality products.

This case study exemplifies how combining robust technological integrations with flexible production processes results in efficient order fulfillment even under demanding circumstances.

The experience of managing urgent padel racket orders highlights several essential insights for procurement managers:

- Embrace Flexibility: The ability to quickly adapt production processes to meet customized requirements is a distinct competitive advantage—look for partners who offer bespoke manufacturing solutions.

- Integrate Technology: Utilize comprehensive tracking and ERP systems to maintain transparency and ensure every production stage aligns with deadlines.

- Prioritize Quality Control: Invest in robust quality assurance processes that run concurrently with production to avoid last-minute issues.

- Collaborative Communication: Clear and consistent communication between suppliers and buyers is vital for anticipating and mitigating potential delays.

By partnering with a manufacturer that integrates these practices, companies can efficiently manage urgent padel racket orders while upholding the high standards expected in competitive sports equipment markets.

In conclusion, NEX Padel’s combination of advanced production techniques, flexible customization options, and rigorous quality control processes demonstrates our ability to support urgent orders reliably. For distributors operating on tight deadlines, partnering with an experienced manufacturer like NEX Padel ensures that production efficiency and product performance are never compromised. Engage with us today to experience a new level of operational excellence in padel racket manufacturing.

Q: What processes ensure rapid turnaround in padel racket manufacturing?

A: Rapid turnaround is achieved through pre-stocking vital materials, rapid prototyping, customized production lines, real-time ERP tracking, and integrated quality control measures.

Q: How does NEX Padel guarantee quality control and customization?

A: NEX Padel maintains quality control with in-line inspections during production and flexible manufacturing processes. Our dedicated team works closely with clients to ensure all customization, such as bespoke shapes, colors, and logos, meets specific requirements while adhering to high-performance standards.

Q: What are the key factors in efficient production management for urgent padel orders?

A: Efficient production management involves strategic inventory management, robust communication channels, data-driven process improvements, and automated tracking systems. These factors help reduce lead times and ensure reliable order fulfillment even under tight deadlines.

-

carbon fiber: Click to learn more about carbon fiber, its types, and how its properties contribute to enhanced performance in high-end sports equipment production. ↩ ↩

-

supply chain: Click to explore an in-depth analysis of supply chain management strategies, addressing complexities from raw material procurement to delivery logistics. ↩ ↩

-

Rapid Prototyping: Click to review the benefits and methodologies of rapid prototyping, including how it accelerates design verification and production modifications. ↩ ↩

-

Bespoke Manufacturing Lines: Click to understand bespoke manufacturing, its customization capabilities, and how tailored production lines meet unique client demands. ↩ ↩

-

ERP systems: Click to delve into ERP systems, examining how integrated software solutions streamline order tracking, communication, and overall production management in complex operations. ↩ ↩