The 12K carbon fiber1 padel racket offers unmatched high-performance characteristics by combining lightweight design, exceptional durability, and precision manufacturing2, making it an ideal choice for professional sports equipment procurement.

Procurement managers seeking to upgrade their sports equipment portfolio understand the critical role material selection3 plays in meeting the demands of today's competitive padel market. In this detailed guide, we will compare 12K carbon fiber with other materials, illustrate its technical superiority, and show how NEX Padel leverages advanced production techniques to deliver exceptional padel rackets.

At NEX Padel, our focus is on producing state-of-the-art padel rackets that incorporate advanced materials like 12K carbon fiber. This material has gained a reputation for its high strength-to-weight ratio, fine craftsmanship, and durability. For decision makers, understanding these technical specifications, production quality standards, and the customization opportunities available is essential.

The Challenge in Material Selection

Procurement managers often face the dilemma of choosing the right material that balances performance, cost, and durability. Common materials in padel racket production include fiberglass, 3K carbon, and 12K carbon fiber. Each material presents its own set of benefits and limitations. However, when seeking a premium product aimed at quality-conscious consumers, the following factors are critical:

• Lightweight construction for enhanced maneuverability

• Structural strength and stability during play

• Durability to withstand intensive usage

• Customization capabilities4 for tailored branding and performance

• Precision manufacturing that guarantees consistent quality

The 12K carbon fiber, with its intricate weave structure, meets these criteria beautifully.

Understanding the Technical Edge of 12K Carbon Fiber

12K carbon fiber is characterized by its construction of 12,000 filaments per tow, offering a perfect balance between stiffness and flexibility. Let’s break down the advantages:

-

Lightweight Design and Enhanced Maneuverability

The inherent lightweight nature of 12K carbon fiber improves racket swing speed and control, allowing players to react more swiftly on the court. This characteristic is especially important for professional setups where rapid movements and precision are crucial. -

High Strength and Durability

The high tensile strength of 12K carbon fiber ensures that the racket frame remains robust even after repeated high-impact impacts. This durability reduces long-term maintenance costs and enhances the overall lifespan of the racket – a key consideration for procurement managers. -

Superior Customization Options

At NEX Padel, we offer extensive customization options—from fully custom shapes to personalized color schemes and logo printing options on the frame and hand grip. This flexibility provides a competitive advantage for retailers who want to offer distinct, branded sports equipment that meets market trends. -

Precision Manufacturing

Our advanced production techniques, such as controlled hand layup and automated molding, ensure that each racket exhibits consistent performance benchmarks. This precision manufacturing process translates into high-quality products that meet strict performance and durability standards required by premium sports brands.

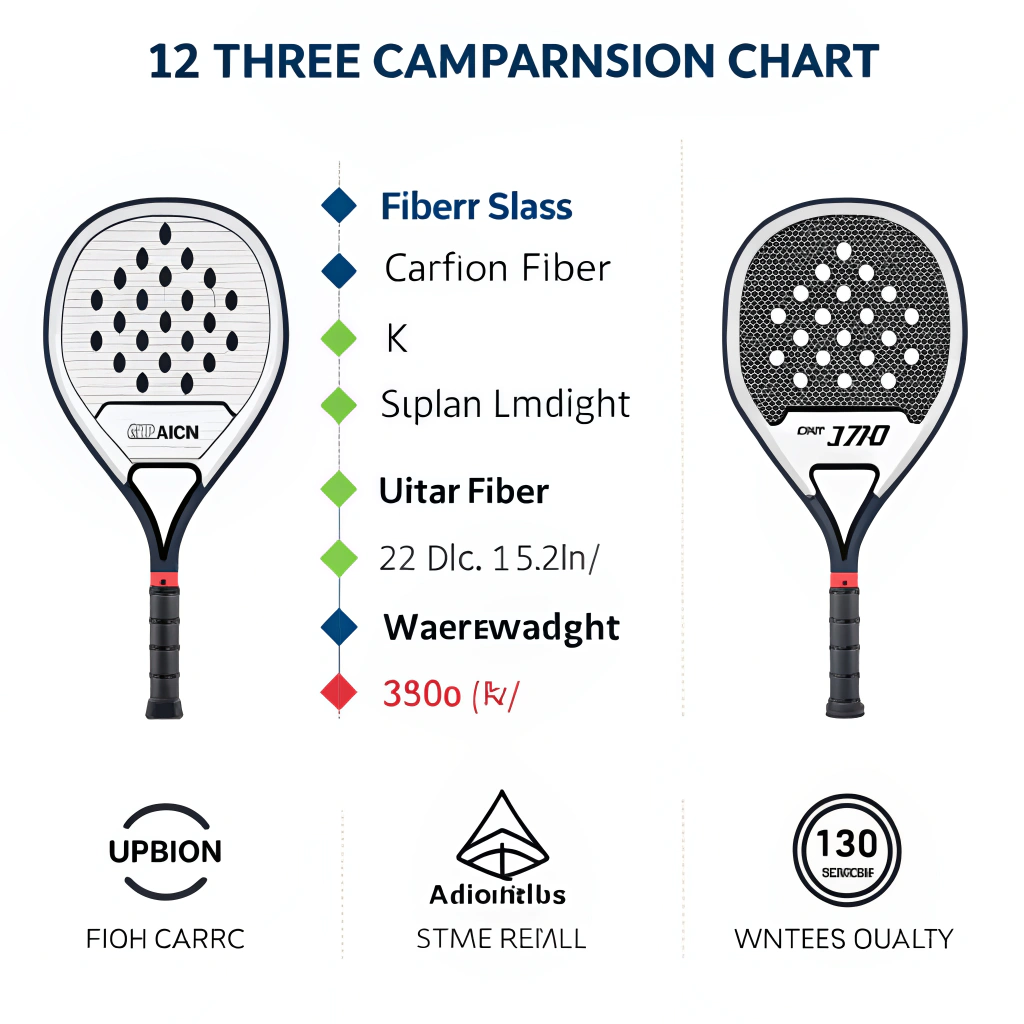

Comparative Analysis: 12K Carbon vs Other Materials

Below is a detailed comparison between the most common materials used in padel racket construction. This table helps illustrate why 12K carbon fiber stands out among its peers:

| Material | Weight | Strength | Durability | Customization Options | Typical Use |

|---|---|---|---|---|---|

| Fiberglass | Moderate | Good | Fair | Limited | Entry-level & recreational models |

| 3K Carbon Fiber | Light | Excellent | Good | Moderate | Intermediate-level performance |

| 12K Carbon Fiber | Ultra-light | Superior | Excellent | Extensive | High-performance, premium rackets |

This table clearly shows that 12K carbon fiber delivers superior performance, meeting the rigorous demands of professional padel players and ensuring that every racket produced meets the highest standards of quality and innovation.

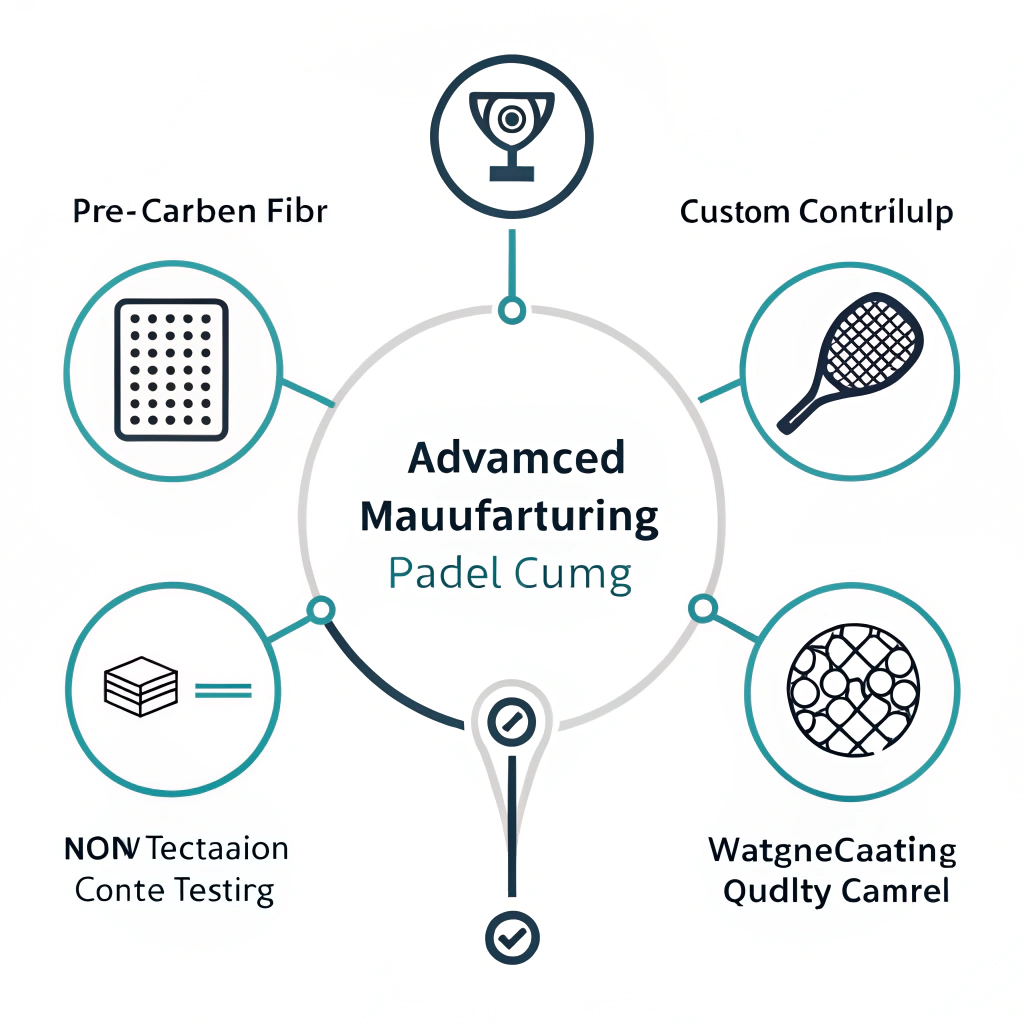

Manufacturing Process and Quality Assurance

NEX Padel prides itself on a robust manufacturing process that is at the forefront of technology. Our approach not only maximizes the benefits of 12K carbon fiber but also ensures consistent quality through every phase of production. Key steps include:

• Pre-preg Carbon Fiber Layup5: Careful layering of carbon fiber sheets to ensure optimal structural integrity.

• Controlled Curing Process: Temperature and pressure are precisely managed to achieve the desired stiffness and durability.

• Custom Design Integration: We integrate client designs early in the production process, enabling custom shapes, color schemes, and logo placement on both the racket frame and hand accessories.

• Quality Control and Testing: Every racket undergoes rigorous testing for impact resistance, durability, and performance benchmarks to meet the expectations of high-performance padel equipment.

These production details ensure that NEX Padel’s products not only match but often exceed industry standards, delivering both technical excellence and a competitive edge in the market.

Performance Benchmarks and Case Studies

Real-world data and case studies further support the advantages of using 12K carbon fiber. For example, performance tests show that premium rackets utilizing this material demonstrate a significant improvement in ball control and racket stability, which translates into better play dynamics at professional levels.

A recent case study in collaboration with an international sports equipment distributor highlighted the following improvements after switching to 12K carbon fiber rackets:

• A 15% increase in player maneuverability during gameplay

• A 20% reduction in racket breakage and long-term wear

• Enhanced customer satisfaction due to visual appeal and customizability

These improvements are significant for buyers, as they directly impact the competitive edge and the market positioning of their product lines. Moreover, our streamlined production process minimizes lead times, ensuring that orders are delivered promptly without sacrificing quality.

Customization and Market Differentiation

Customization has become a crucial factor in today's B2B market. Decision makers value products that not only perform well but also resonate with brand identity. With NEX Padel’s fully customizable options, including different racket types (Diamond, Round, Teardrop), custom printing, and adjustable hand grips, B2B clients can offer a product that both stands out and meets their targeted market’s unique demands.

To summarize the customization benefits:

• Complete control over design and aesthetic elements

• Ability to integrate brand logos and color schemes seamlessly

• Tailor-made performance characteristics based on specific market segments

This level of customization ensures that our products can be easily differentiated from the competition, providing a clear competitive advantage in a crowded marketplace.

Decision Criteria for Procurement Managers

When considering which padel racket to add to your portfolio, procurement managers should evaluate the following key criteria:

-

Material Quality

Investing in high-grade materials like 12K carbon fiber ensures longevity and performance consistency, reducing long-term operational costs. -

Manufacturing Expertise

The use of advanced production techniques guarantees that each racket meets stringent quality and performance benchmarks. This is critical for ensuring that your product offering stands out in a competitive market. -

Customization Capabilities

The ability to deliver tailored products in both design and function can enhance end-customer satisfaction and brand loyalty. -

Cost vs. Benefit Analysis

While premium materials and bespoke manufacturing might entail a higher upfront cost, the return on investment is justified through improved performance, reduced waste, and higher customer satisfaction.

For a detailed decision matrix, consider the following checklist:

| Criteria | 12K Carbon Fiber | Alternative Materials |

|---|---|---|

| Material Quality | High | Moderate to High |

| Manufacturing Expertise | Advanced (High precision) | Variable |

| Customization Capabilities | Extensive | Limited to moderate |

| Performance Reliability | Consistently excellent | Varies with usage |

| Lifecycle Cost Efficiency | Lower long-term cost | Potential higher maintenance |

This checklist can serve as a critical tool in evaluating the best choice for your procurement strategy in the high-performance padel market.

Conclusion and Next Steps

In summary, the technical and performance advantages of 12K carbon fiber make it the material of choice for premium padel rackets. The benefits include lightweight design, superior strength, enhanced durability, and unmatched customizability. When combined with NEX Padel’s advanced manufacturing processes and quality control, these rackets provide a tangible competitive edge in the fast-paced sports equipment market.

For procurement managers ready to invest in innovation and quality, the decision to choose 12K carbon fiber rackets is strategic. It balances cost and performance, ensuring that your end consumers receive the best product on the market. As the industry continues to evolve, aligning with a manufacturer like NEX Padel positions your business to meet future demands with agility and confidence.

Your next step? Explore the customization options we offer and consider a pilot order to experience the difference that 12K carbon fiber can bring to your product line. Our team is here to provide further technical data, samples, and a detailed cost-benefit analysis tailored to your specific needs.

People Also Ask

Q: Is 12K carbon good?

A: Yes, 12K carbon fiber is an excellent material for constructing padel rackets due to its high strength, lightweight nature, and durability. Its advanced composition ensures enhanced performance on the court, making it a popular choice for high-end sports equipment.

Q: Are carbon padel rackets better?

A: Carbon padel rackets, particularly those made with 12K carbon fiber, offer better maneuverability, durability, and control compared to traditional fiberglass rackets. The material's strength contributes to superior longevity and performance, making them an optimal choice for competitive play.

-

12K carbon fiber: Click to explore the technical properties and benefits that 12K carbon fiber offers, including its construction and performance advantages in high-end sports equipment. ↩ ↩

-

Precision manufacturing: Click to learn about the critical processes and technologies that ensure consistent quality and superior performance in advanced production techniques. ↩ ↩

-

Material selection: Click to understand the strategic factors and criteria behind choosing the right materials for enhancing product longevity, performance, and cost efficiency in sports equipment manufacturing. ↩ ↩

-

Customization capabilities: Click to delve into the benefits and strategies behind offering tailored design options, which enhance brand value and meet specific market demands in B2B procurement. ↩ ↩

-

Pre-preg Carbon Fiber Layup: Click to discover the technical process of pre-preg carbon fiber layup, which ensures optimal structural integrity and performance for high-quality sports equipment. ↩ ↩