When selecting the ideal manufacturing partner for high-performance padel rackets, look no further than partners like NEX Padel. NEX Padel offers custom manufacturing1 with advanced production techniques2, ensuring high durability, precision, and structural innovation. This guide will help you compare core manufacturing capabilities, including materials, design options, production speed, and pricing competitiveness—empowering you to make an informed decision in your sourcing process.

In today’s competitive sporting goods market, procurement managers and business developers face the challenge of choosing a supplier that not only meets quality standards but also offers flexibility and a proven track record in custom manufacturing1. With high-performance criteria stretching from traditional fiberglass models to advanced carbon fiber3 variations (3k, 12k, 18k), understanding the key differences between manufacturing partners is critical.

At NEX Padel, our manufacturing capabilities are designed to meet the evolving needs of distributors. We specialize in three distinct padel racket designs: Diamond, Round, and Teardrop. Our custom options extend to racket shape, printing, color, and even personalized details on hand grip and handle covers. This flexibility ensures that each product resonates with your brand identity and performance requirements.

When evaluating a manufacturing partner for your padel equipment needs, consider the following factors:

-

Quality of Materials and Craftsmanship:

The choice between fiberglass and multiple grades of carbon fiber isn’t simply about cost—it’s about balancing performance and durability. Manufacturers that offer 3k, 12k, and 18k carbon fiber provide products for various performance levels, ensuring you have options tailored to your market segment. -

Custom Manufacturing Options:

Customization is key in today’s market. A supplier who can offer custom shapes, printing, and personalized components (such as logo on hand grips) not only enhances brand identity but also caters to the specific needs of sporting outlets and enthusiasts. -

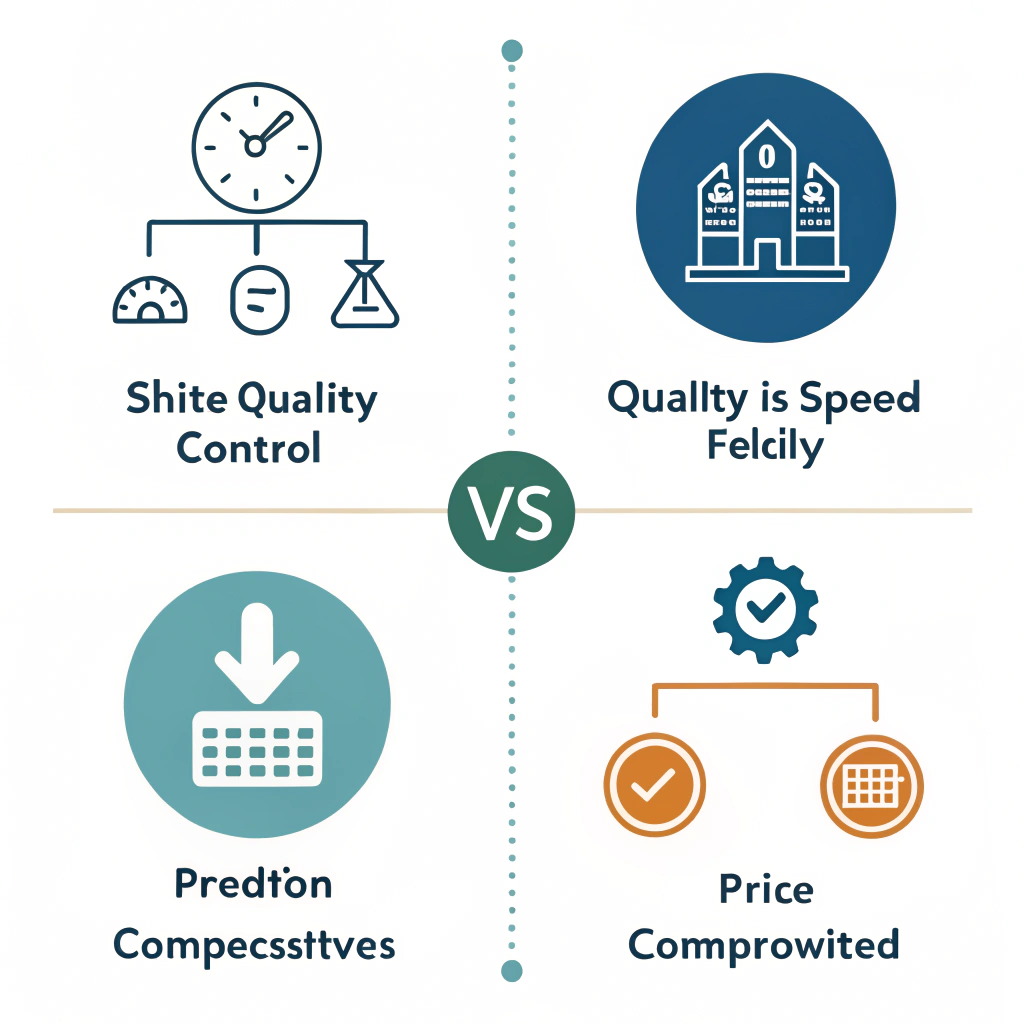

Production Efficiency and Lead Times4:

Fast sampling and on-time delivery are critical to keep up with market demands. A reliable partner that practices advanced production techniques and maintains rigorous quality control5 can significantly reduce your time-to-market while ensuring consistent product quality. -

Pricing Competitiveness:

Quality should never come at a prohibitive cost. Competitive pricing—coupled with high-quality output—can give your distribution business a strong edge. Case studies from successful partnerships with globally recognized brands underscore the competitive advantage that transparent pricing structures bring. -

Proven Track Record and Partnerships:

Suppliers with a history of catering to well-known brands (e.g., Hirostar, Reebok, Starvie) demonstrate their ability to maintain high standards over time. Long-term business relationships are often built on trust, consistency, and a shared commitment to high performance.

To simplify the decision process, here is a detailed comparison table covering essential aspects:

| Feature | NEX Padel Capabilities | Other Manufacturers (General) |

|---|---|---|

| Material Variety | Fiberglass, 3k, 12k, 18k Carbon Fiber | Limited to standard fiberglass or basic carbon options |

| Design Flexibility | Customizable shapes (Diamond, Round, Teardrop) and printing | Standard designs with minimal custom options |

| Production Speed | Fast sampling and on-time delivery | Inconsistent lead times and slower sampling processes |

| Quality Control | Advanced production techniques with rigorous QC | Variable quality control standards |

| Pricing Competitiveness | Transparent, competitive pricing model | Higher or less competitive pricing |

| Customization Options | Comprehensive: racket forms, hand grip, handle caps, logos | Limited or costly customization options |

| Industry Partnerships | Trusted by brands such as Hirostar, Reebok, Starvie | Lesser-known or untested in prominent partnerships |

This table emphasizes how a supplier like NEX Padel stands apart by offering a wide range of material choices, robust quality control, and an array of customization solutions—all while delivering on time and within budget.

When you are in the process of sourcing a padel racket manufacturing partner, consider these practical insights:

-

Evaluate Your Market Needs: Are your customers looking for high-end performance equipment? If so, prioritize suppliers that offer advanced carbon fiber options and proven durability through rigorous quality control.

-

Assess Customization Capabilities: If your brand strategy includes niche designs or specific branding elements (like custom logos on the racket or grip details), choose a partner that demonstrates flexibility in offering bespoke solutions.

-

Consider Supply Chain Reliability: In the sporting goods industry, consistency is critical. Ensure that your supplier can maintain a steady production flow, with quick turnarounds for new samples and reliable on-time delivery.

-

Balance Cost and Value: While the cheapest option might seem attractive, remember that higher initial investments can lead to better product longevity and reduced returns. Analyzing the overall value proposition is essential.

-

Request Case Studies or References: Ask prospective suppliers for case studies or references from established brands. This provides practical insights and builds confidence in their production capabilities and service reliability.

These steps can help ensure that your final decision is based on a thorough assessment of quality, performance, and long-term reliability.

At NEX Padel, our manufacturing process is designed to meet the rigorous demands of the padel racket market. We begin with precision material selection, using advanced production techniques2 to combine various carbon fiber grades and fiberglass. Each product undergoes multiple rounds of quality checks, ensuring that every racket meets strict performance standards required by professional and amateur sports alike.

Additionally, our design team works closely with clients to translate custom branding into tangible design elements. This collaborative approach ensures that every product not only meets technical specifications but also resonates aesthetically with end consumers.

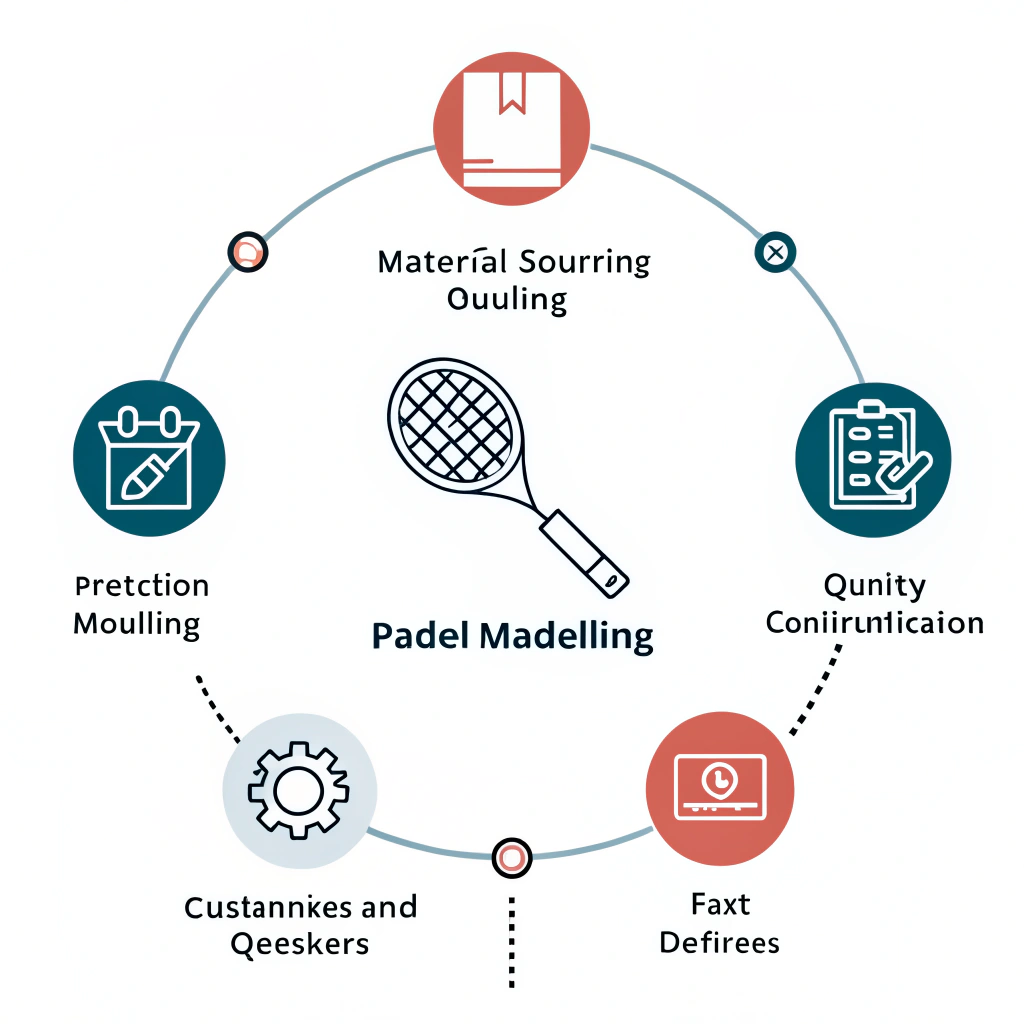

Here are the key steps in our process:

-

Material Sourcing and Preparation:

We source high-grade fibers and resins that provide the optimal balance of strength and flexibility. This includes the choice between fiberglass for cost efficiency and carbon fiber grades (3k, 12k, 18k) for enhanced performance. -

Precision Molding and Assembly:

Using state-of-the-art molding techniques, we form the distinctive shapes of padel rackets — be it Diamond, Round, or Teardrop designs. Our machines are calibrated to maintain consistency and reduce waste. -

Customization & Quality Assurance:

Throughout production, custom printing, color matching, and personalized logo integration take place. Our quality assurance team ensures that each racket passes through several rigorous tests aimed at validating durability and performance under various conditions. -

Fast Sampling and On-Time Delivery:

With an emphasis on speed and efficiency, our sampling process allows clients to preview and approve designs quickly. Our production timeline is transparent, ensuring on-time delivery while maintaining the highest quality standards. -

After-Sales and Partnership Support:

We view every order as the start of a long-term partnership. Our after-sales team provides ongoing support, helping adapt to market changes and tweaking production as needed to meet emerging trends.

Choosing the right padel racket supplier is more than just comparing prices or available materials. It is about forging a partnership with a manufacturer who understands the nuances of high-performance sports equipment. At NEX Padel, our commitment to quality, flexibility in design, and efficient supply chain management means that you can confidently choose us as your strategic manufacturing partner.

Action recommendations:

- Review the Comparison Table: Compare the detailed capabilities of your current suppliers with what NEX Padel offers.

- Conduct a Pilot Order: Test our fast sampling and delivery process with a smaller batch to evaluate quality and custom options.

- Engage in a Consultation: Discuss your specific market needs and design preferences with our team to tailor a partnership that grows with your business.

- Request Case Studies: Ask for references from existing partnerships with well-known brands to understand our production reliability and quality control.

By focusing on these areas, you’ll ensure that your procurement decisions are backed by proof of performance and strong supplier accountability. This detailed approach supports your goal of finding a long-term, reliable, and innovative manufacturing partner in the competitive padel equipment market.

People Also Ask

Q: Who makes the best padel rackets?

A: Top performance padel rackets are produced by reputable manufacturers such as Adidas, Bullpadel, Nox, Head, and Babolat. These brands are known for their high quality, innovative design, and reliability, catering to both professional and recreational players.

Q: Do expensive padel rackets make a difference?

A: Expensive padel rackets typically offer enhanced performance, improved comfort, and greater durability, making them worthwhile for regular players who require top-tier equipment. For beginners or casual players, entry-level rackets may suffice until a transition is needed.

Q: What is the premium padel brand?

A: Among premium options, Volt Padel is recognized for its distinctive design and high-quality equipment. However, the best choice often depends on your specific performance requirements and customization needs.

-

custom manufacturing: Click to learn how tailored production processes can meet unique business requirements and increase competitive advantage in specialized markets. ↩ ↩ ↩2

-

advanced production techniques: Click to understand the innovative manufacturing methods that enhance product durability, precision, and overall performance in high-demand industries. ↩ ↩ ↩2

-

carbon fiber: Click to explore the properties and benefits of various carbon fiber grades (3k, 12k, 18k) and how they contribute to product strength and performance. ↩ ↩

-

Lead Times: Click to read about the importance of managing production schedules and delivery timelines for optimal supply chain efficiency and customer satisfaction. ↩ ↩

-

quality control: Click to delve into strategies for ensuring consistent product quality and reliability through rigorous testing and quality assurance processes. ↩ ↩