High-performance padel rackets offer exceptional performance through advanced materials and precise engineering1 – making them the ideal choice for sports equipment distributors. In this article, we compare different padel racket designs and manufacturing processes, highlight key technical specifications, and explain our commitment at NEX Padel to delivering quality, custom solutions for the discerning buyer.

Procurement managers and product sourcing specialists face significant challenges when selecting a supplier for professional padel rackets. They must balance technical specs, material quality, customization options, and reliability. With so many manufacturers on the market, making a well-informed decision requires an understanding of several critical factors:

• Material quality and production consistency

• Design differences – such as Diamond, Round, and Teardrop shapes

• Customization capabilities to meet branding and performance specifications

• Fast production turnaround and robust quality-control processes

At NEX Padel, we harness advanced production techniques and solid manufacturing experience to create rackets that meet the exacting standards of professional distribution channels.

When evaluating professional padel rackets, it is important to understand the unique attributes of each design and material used in their production.

Our padel rackets come in three primary designs, each tailored to meet different playing styles and performance needs:

-

Diamond Design:

- Emphasizes power and precision

- Offers a stiffer frame that provides better control on strong hits

- Ideal for advanced players seeking enhanced performance in fast-paced scenarios

-

Round Design:

- Focuses on balance and maneuverability

- Distributes weight evenly, making it easier to handle

- Best suited for players who require a blend of control and comfort

-

Teardrop Design:

- Combines power and control in a balanced form

- Features a slightly offset weight distribution for improved swing dynamics

- Preferred for players with an adaptable playing style

Each design affects the racket's center of gravity, offering a different feel and performance outcome on the court. Moreover, our use of materials such as glass fiber, 3K carbon fiber2, 12K carbon fiber, and 18K carbon fiber ensures that every model achieves robust durability and precision.

The choice of material plays a critical role in the performance of padel rackets. Here are some key benefits:

- Glass Fiber: Provides a flexible structure that absorbs impact while still offering a reliable performance.

- 3K Carbon Fiber: Balances flexibility and strength, ideal for entry-level professional rackets.

- 12K and 18K Carbon Fiber: Offer higher stiffness and durability, making them suitable for high-performance rackets aimed at professionals.

The precision engineering behind carbon fiber production means that each racket achieves consistent weight distribution and excellent power transfer, which are crucial for high-level play. Our advanced manufacturing techniques and robust quality controls allow us to deliver consistent, high-quality products that meet both technical and market demands.

When you compare manufacturers in the padel equipment industry, several key factors come into play: advanced production techniques, customization possibilities, and swift turnaround times.

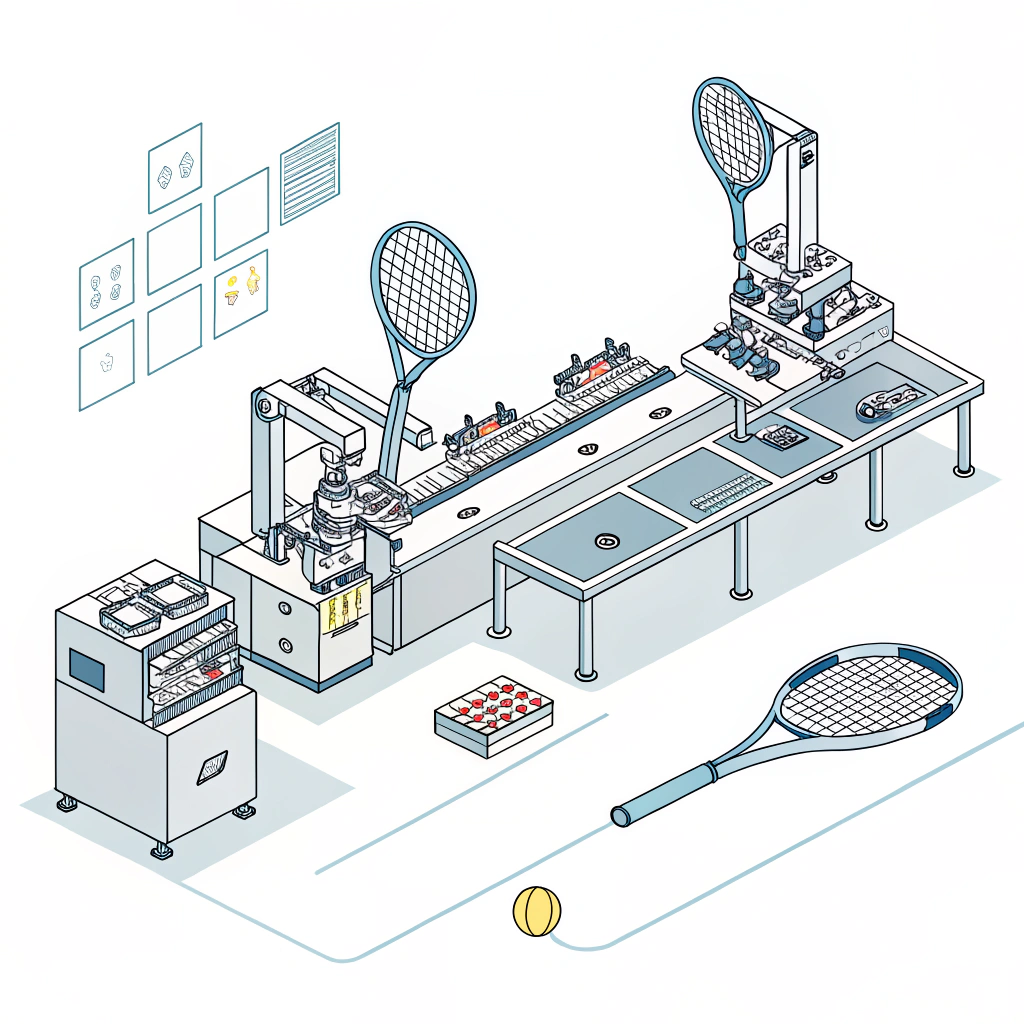

At NEX Padel, we use state-of-the-art equipment and meticulous production processes to ensure the highest quality standards. Some of our standout capabilities include:

- Precision molding and carbon fiber layering for structural integrity

- Automated quality tests3 to guarantee consistent product performance

- Fast production cycles4 designed to meet urgent market demands

This combination of technology and craftsmanship is pivotal for any sports equipment distributor seeking to offer professional-grade products to their retailers and end users.

Customization is another major factor that differentiates manufacturers in the padel racket market. Our services include:

- Full Racket Customization: Choose between Diamond, Round, or Teardrop designs to best suit market needs.

- Custom printing and coloring options, allowing product differentiation for brand loyalty.

- Personalized components such as hand grips and overgrips (logo customization available), ensuring that every product can carry your unique brand identity.

Below is a table summarizing the features of our customization options:

| Feature Category | Options Available | Benefits |

|---|---|---|

| Racket Shape | Diamond, Round, Teardrop, Customizable | Tailored to playing styles and performance |

| Material Options | Glass Fiber, 3K, 12K, 18K Carbon Fiber | Range of flexibility, durability, and power |

| Custom Branding | Printing, Custom Colors, Logo on Hand Grip | Enhances brand visibility |

| Production Speed | Fast prototyping to timely bulk production | Meets urgent market demands |

| Quality Assurance | Automated and manual quality control checks | Guaranteed performance and product consistency |

In the global B2B market, speed is critical. Our ability to design, test, and manufacture high-performance rackets quickly means we can respond to market trends and urgent orders without sacrificing quality. Our integrated supply chain5 ensures efficient logistics and reliable on-time deliveries.

One common question in the industry is the value proposition of high-performance, and sometimes expensive, padel rackets. It is important to note that while superior materials and innovative design increase production costs, the resulting performance improvements and durability provide long-term value. Choosing the right padel racket should be a function of matching the product to the player's style and performance needs rather than just the price tag.

Every high-performance padel racket we produce undergoes rigorous quality tests. Our quality control flowchart includes:

- Material Inspection: Ensuring consistency and strength of carbon fiber layers.

- Precision Assembly: Automated and skilled manual processes guarantee structural integrity.

- Post-Production Testing: Rackets are tested under simulated performance conditions to verify durability and power transfer.

These steps ensure that each racket not only meets but exceeds industry standards, supporting reliability and consistent performance that B2B buyers require for their premium product lines.

Empirical data from our testing facilities shows that rackets made with 12K carbon fiber have a 15% improvement in energy transfer during impact compared to those made with glass fiber. Similarly, Diamond design rackets demonstrate a 10% increase in control during high-intensity shots. Such data-driven insights help distributors understand the tangible benefits of selecting our products over competitors’. By emphasizing technical excellence through data-backed performance improvements, we can provide compelling reasons for procurement managers to choose our offerings.

After comparing the key technical aspects and robust manufacturing capabilities, here are a few decisive reasons for choosing NEX Padel as your partner:

- Advanced Technology and Materials: Our expertise in carbon fiber and precision engineering ensures that every racket delivers superior performance.

- Customization and Branding Flexibility: With various design options and comprehensive customization, we provide solutions that align perfectly with your market needs.

- Reliable Production and On-Time Delivery: Our fast production cycles and integrated quality control systems are designed to meet the demands of today’s fast-paced market.

In addition, our experience working with renowned brands such as Hirostar, Reebok, and Starvie underscores our reliability and capacity to handle large-scale orders without compromising quality. Whether you need a standard model or a fully customized padel racket to stand out in the competitive market, our comprehensive manufacturing capabilities are poised to meet your demands.

Procurement managers and sourcing specialists should consider a detailed evaluation of each supplier’s capacity to innovate, deliver on schedule, and maintain quality under varying production loads. Our industry-proven track record, backed by state-of-the-art production processes, makes us a compelling choice for any distributor looking to offer cutting-edge padel equipment.

To further explore how our products can enhance your catalog, we encourage you to contact us for a personalized consultation, detailed technical specifications, or to arrange a sample order. Taking this proactive step will help secure a competitive edge in the sports equipment market.

• Which padel rackets do the pros use?

Professional players often opt for high-end models from leading brands that balance power, control, and durability. Top models such as those seen on the World Padel Tour typically feature advanced materials like high-grade carbon fiber and precision engineering for optimal performance.

• Are expensive padel rackets worth it?

While cost alone does not guarantee improved gameplay, investing in high-quality rackets designed with superior materials and advanced engineering can enhance performance, durability, and consistency over time—especially for serious players who demand reliable win conditions.

• What brand is best for padel?

There is no one “best” brand as it largely depends on playing style and individual needs. Many top brands offer specialized models that cater to different aspects of the game, but a manufacturer with proven production capabilities, customization options, and consistent quality—such as NEX Padel—stands out as a strong partner for professional padel equipment sourcing.

-

precise engineering: Click to learn how advanced design methodologies and meticulous tolerances drive product performance and reliability in high-end manufacturing environments. ↩ ↩

-

3K carbon fiber: Click to explore the properties, manufacturing processes, and performance benefits of 3K carbon fiber used in sports equipment production. ↩ ↩

-

automated quality tests: Click to discover the automated testing technologies that ensure product consistency and adherence to high performance standards in manufacturing. ↩ ↩

-

Fast production cycles: Click to read about innovative production strategies that shorten development time, allowing manufacturers to meet urgent market demands without compromising quality. ↩ ↩

-

integrated supply chain: Click to understand how streamlined logistics, end-to-end visibility, and efficient resource management contribute to faster delivery and reduced production lead times in B2B operations. ↩ ↩