Quick Answer: High-quality EVA foam1 in padel rackets is crucial for optimizing player feel, offering a balanced impact absorption, enhancing control, and ensuring durability, all of which are key factors for a competitive edge in the sport.

In the competitive world of padel equipment, the material quality in each component directly affects the overall performance of the racket. Among these materials, EVA foam plays a central role in determining the racket's feel, impact absorption, and durability. This article provides a detailed analysis of how different qualities of EVA foam impact padel racket performance, with actionable insights for procurement managers seeking to optimize product offerings and enhance player experience.

EVA (ethylene vinyl acetate2) is a polymer known for its excellent shock absorption and resilience. In padel rackets, EVA foam is integrated into the core to cushion impacts and provide a firm yet responsive feel when striking the ball. Its performance characteristics vary with its density and composition, which in turn influences the racket's balance of power, control, and vibration dampening.

- Impact Absorption: EVA foam is engineered to absorb high-impact forces during play. A higher-quality EVA foam is capable of dispersing energy more efficiently, providing a smoother hit and reducing the risk of injury.

- Player Feel: The firmness and elasticity of the EVA foam directly affect the tactile feedback players experience. A harder foam offers enhanced control, while a slightly softer foam may provide greater comfort, particularly for extended play.

- Durability: The longevity of a padel racket depends significantly on the integrity of its inner core. High-quality EVA foam resists compression and deformation over time, thereby maintaining the racket’s performance across prolonged usage.

Procurement managers often encounter several challenges when evaluating EVA foam quality for padel rackets. The decision process involves balancing performance with cost, understanding the technical specifications, and ensuring consistency in manufacturing. Below are the common challenges:

- Material Integrity: Lower-grade EVA foam might lose its structure faster, leading to decreased playability.

- Density Variability3: Variations in foam density can result in unpredictable performance characteristics, such as altering the racket's weight distribution.

- Manufacturing Precision4: Achieving consistent quality requires advanced production techniques, especially when working with custom shapes and meticulous detailing as demanded by modern padel players.

- Supplier Reliability: In a global market, sourcing materials that consistently meet high-performance criteria is essential. Manufacturers like NEX Padel excel by delivering tailor-made solutions through quality-controlled processes.

Understanding the technical attributes of EVA foam can help procurement managers make informed decisions. The following table summarizes the key performance indicators associated with different foam qualities used in padel rackets:

| Attribute | Lower-Grade EVA Foam | Higher-Grade EVA Foam | Effect on Performance |

|---|---|---|---|

| Density | Low to Medium | High | Higher density improves control and durability |

| Resilience | Tends to wear quickly | Excellent shock absorption and recovery | Provides consistent playability |

| Elasticity | Softer feel, less rebound | Balanced firmness and elasticity | Enhanced responsiveness and comfort |

| Manufacturing Consistency | Variable quality across batches | High production precision | Reduced risk of deformation and performance variability |

The technical specifications of EVA foam play a pivotal role in determining comfort, impact absorption, and racket speed. These factors are particularly critical for mid-level and professional players who demand high precision and reliability during gameplay.

At NEX Padel, our production process leverages advanced techniques to ensure that every padel racket meets stringent quality standards. Here are key manufacturing considerations regarding EVA foam integration:

Our quality control process includes rigorous testing of foam density, elasticity, and long-term resilience. Consistent production methods ensure that every paddle meets the design specifications, minimizing variations that can affect performance.

NEX Padel offers a variety of customization options:

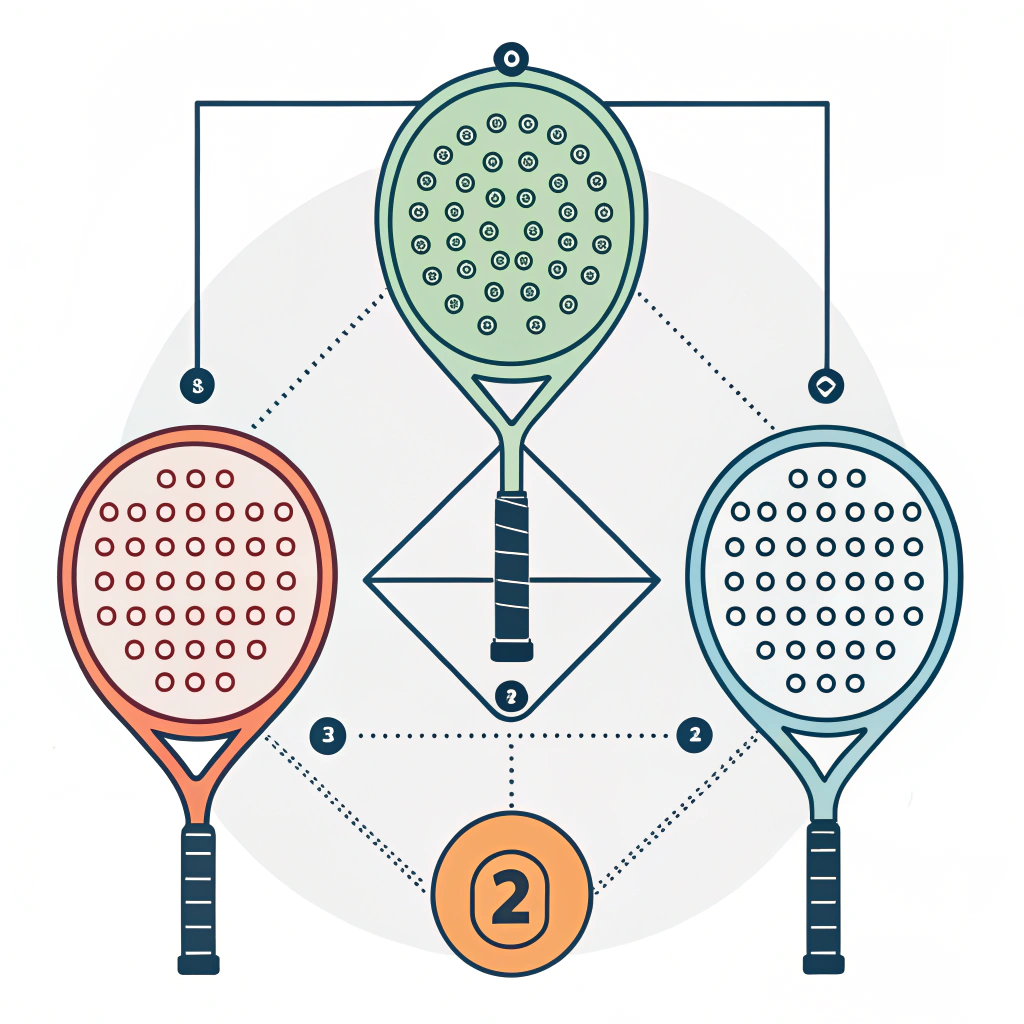

- Racket Shapes: Options include Diamond, Round, and Teardrop shapes. The choice of shape, when paired with the right EVA foam density, can tailor a racket’s performance to suit different playing styles.

- Material Customization: Depending on the desired player feel, EVA foam formulations can be modified to increase hardness or softness. This provides an opportunity to target market segments ranging from beginners to advanced players.

- Custom Printing & Color: Beyond performance, aesthetic customization such as printing logos on both the racket and hand grips allows brands to maintain a distinct market presence.

While superior EVA foam enhances control and durability, it also influences production costs. Our approach focuses on striking a balance that satisfies both top-tier performance and competitive pricing.

A table summarizing customization options is presented below:

| Customization Element | Options Available | Key Benefit |

|---|---|---|

| Racket Shape | Diamond, Round, Teardrop | Optimizes play style (e.g., control vs. power) |

| EVA Foam Density | Different grades from lower to higher quality | Tailors impact absorption and resilience |

| Aesthetic Customization | Custom colors and logos, hand grip design options | Enhances brand identity and market appeal |

For procurement managers evaluating padel racket materials, particularly EVA foam, consider the following best practices:

-

Assess Performance Needs: Evaluate whether the intended market segment leans towards control, power, or a balance of both. For instance, a harder EVA foam generally offers better control, which is ideal for defensive players, whereas a slightly softer foam might be preferable for beginners.

-

Compare Technical Specifications: When choosing between suppliers, review the density, elasticity, and long-term durability of the EVA foam. Detailed comparison tables can aid in understanding these critical differences.

-

Monitor Product Testing and Quality Assurance: Always request evidence of quality control processes, including standardized testing results. A robust quality assurance program is indicative of a reliable supplier.

-

Consider Flexibility for Customization: Suppliers that offer a wide range of customization options can cater to niche markets. Understanding your end customer’s requirements will guide the selection of product features such as foam density and racket shape.

-

Evaluate Supplier Experience: Long-standing manufacturers like NEX Padel that produce for renowned brands demonstrate proven expertise in managing quality and meeting market standards.

-

Take Advantage of Expert Consultation: Engage with technical experts to discuss how specific materials like EVA foam can influence the end product. This dialogue can lead to improved product development and a competitive market advantage.

A leading padel brand partnered with NEX Padel to re-engineer its racket design by integrating higher-grade EVA foam. The project involved:

- Detailed testing of various foam densities.

- Iterative adjustments in the manufacturing process to maintain consistency.

- A focus on balancing control, durability, and user comfort.

The re-engineered rackets saw a remarkable improvement in performance metrics such as reduced vibration and enhanced ball control. Feedback from players highlighted a noticeably improved hitting experience, leading to increased sales and brand loyalty. This case confirms that investing in premium EVA foam, coupled with advanced production techniques, delivers tangible benefits in the competitive padel market.

What is the best shape for a padel racket?

The best shape depends on player preference. For beginners or defensive players seeking control and precision, a round shape is recommended. In contrast, all-round players looking for a balance between power and control might opt for a teardrop shape.

What is the best material for a padel racquet?

Material selection varies by player level and comfort requirements. Generally, beginners may prefer fiberglass for its light weight and comfortable feel, while advanced players might opt for carbon fiber due to its superior performance and durability.

What is EVA in padel?

EVA, or ethylene vinyl acetate, is a core material used in padel rackets. It provides a firmer feel when hitting the ball compared to softer foam cores, offering enhanced control through its superior impact absorption and vibration dampening properties.

-

EVA foam: Reading this article will provide insights into the role of EVA foam in padel racket design, including its impact on player feel, shock absorption, and overall durability, which are critical for optimizing product performance. ↩

-

ethylene vinyl acetate: This external resource explains the chemical composition and properties of ethylene vinyl acetate, helping procurement teams understand its benefits in shock absorption and resilience in sporting goods. ↩

-

Density Variability: Learn more about how variations in foam density can affect product performance and the importance of maintaining consistent material properties in manufacturing. ↩

-

Manufacturing Precision: Discover advanced production techniques and quality control measures that ensure consistent manufacturing precision, reducing performance variability and enhancing product reliability. ↩