The evolution of padel racket face materials has rapidly shifted from fiberglass to sophisticated carbon fiber variants like 3k, 12k, and 18k carbon, offering significant performance, durability, and customization benefits for manufacturers and OEM specialists1.

Over the past decades, the padel racket industry has experienced a transformation driven by changing player needs, technological advancements, and competitive market pressures. Early padel rackets heavily relied on fiberglass due to its affordability and ease of production. However, as player demands evolved, manufacturers increasingly turned to high-performance carbon fiber variants. In this article, we explore the design evolution, technical advances, and practical considerations that have shaped the modern padel racket face materials and discuss how these developments influence today’s OEM decisions.

Initially, padel rackets were crafted primarily with fiberglass—a material that provided a good balance between cost efficiency and acceptable performance for beginners. Fiberglass allowed manufacturers to introduce padel to a wider audience, making the sport more accessible. However, as competitive play increased, the need for rackets that offered better power, control, and durability became apparent.

The advent of carbon fiber technology2 marked a turning point in racket evolution. The transition from fiberglass to carbon fiber was not abrupt but rather a gradual process influenced by continuous research and development. Manufacturers experimented with different carbon fiber weaves, such as 3k, 12k, and 18k, to tailor the rackets' stiffness, flexibility, and overall performance properties.

The technical improvements in carbon fiber production allowed for:

- Enhanced stiffness-to-weight ratios, leading to lighter rackets with improved impact resistance.

- Increased vibration dampening, which reduces stress on the player's arm.

- Superior durability under repetitive high-stress impacts common in padel play.

These material advancements align well with industry demands, where the ultimate goal is to balance performance, durability, and customization capabilities.

Understanding the technical properties of each material type is crucial for sourcing managers and technical experts. Below is an analysis of the three primary materials used in modern padel racket manufacturing:

Fiberglass remains relevant primarily in entry-level rackets. Its key features include:

- Lower production costs, making it economically favorable.

- Adequate flexibility, which appeals to beginners needing a lenient touch.

- Relatively heavier compared to advanced carbon fiber composites.

- Limited customization in terms of weight distribution and stiffness control.

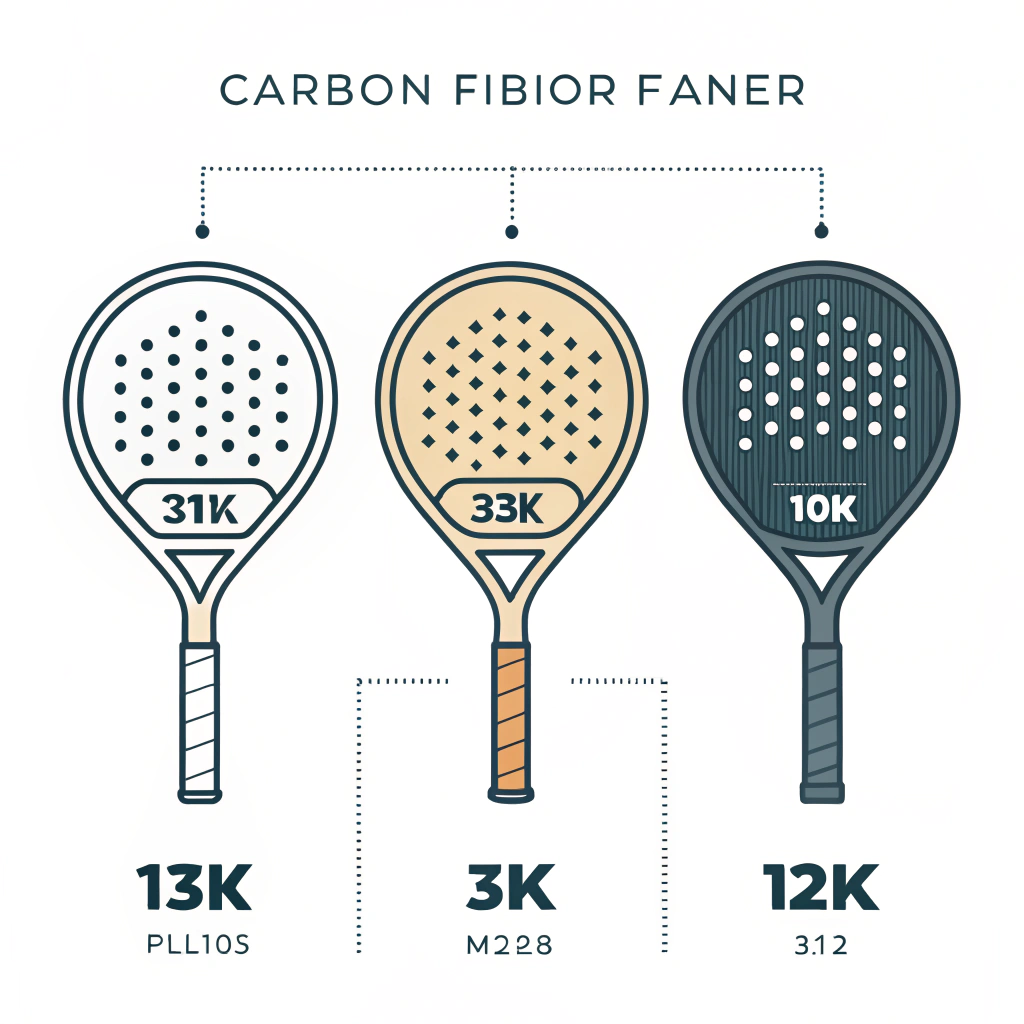

As performance requirements grew, manufacturers adopted various forms of carbon fiber. Each type offers distinct benefits and trade-offs:

-

3k Carbon Fiber

This type is woven from smaller bundles, resulting in a lighter, more flexible structure. It is often used in intermediate-level rackets for its balanced performance.- Advantages: Enhanced maneuverability and vibration dampening; slightly lower cost compared to higher denier types.

- Considerations: May offer less stiffness under extreme conditions.

-

12k Carbon Fiber

With wider fiber bundles, 12k carbon increases stiffness and durability. This material is preferred for rackets designed to deliver higher power and precision.- Advantages: Improved strength and responsiveness during play; ideal for players who favor an aggressive style.

- Considerations: The cost is higher due to more complex manufacturing; may result in a slightly heavier racket if not properly engineered.

-

18k Carbon Fiber

Representing the pinnacle of high-performance materials in padel rackets, 18k carbon fiber offers maximum stiffness without sacrificing weight.- Advantages: Best suited for high-impact conditions and offers excellent energy transfer upon ball contact; provides long-term durability even with intense usage.

- Considerations: Production complexity can lead to increased costs and manufacturing lead times.

A comprehensive comparison of these materials is outlined in the table below:

| Material Type | Cost Efficiency | Weight | Stiffness | Vibration Dampening | Durability | Customization Potential |

|---|---|---|---|---|---|---|

| Fiberglass | High | Heavier | Low | Moderate | Moderate | Low |

| 3k Carbon Fiber | Moderate | Light | Moderate | High | High | High |

| 12k Carbon Fiber | Lower | Moderate | High | High | Very High | Very High |

| 18k Carbon Fiber | Lowest | Light | Highest | Excellent | Highest | Maximum |

The constant push for improvement has driven technology and production methods to fine-tune material compositions. Manufacturers like NEX Padel leverage these advancements by offering customizable solutions with options to integrate various carbon fiber types, ensuring that every padel racket meets the desired performance specifications and brand identity.

The evolution of padel racket materials goes hand in hand with improved manufacturing processes. Modern production facilities implement advanced molding techniques, precision layering, and automated quality controls to maintain consistency across batches. At NEX Padel, for instance, we use state-of-the-art production machinery that ensures exact deposition of carbon fiber layers to achieve the desired stiffness and durability.

- Resin Infusion Technology3:

This process ensures even distribution of resin throughout the carbon fiber layers. It improves the bond between layers, resulting in enhanced strength and consistency. - Prepreg Molding4:

Pre-impregnated materials (prepregs) offer controlled resin content and fiber orientation, critical for achieving high-performance targets in 12k and 18k carbon fiber rackets. - Customization Options:

We provide OEM clients the flexibility to customize not only the shape (Diamond, Round, or Teardrop) but also to alter material compositions and integrate customer-specific branding directly into the design. Features such as custom printing, tailored color schemes, and personalized grip enhancements (hand grip and handle cap with logos) are available. These customizations allow brands to maintain a unique market identity while delivering performance-tailored solutions.

For sourcing and production managers evaluating new suppliers, it is important to consider:

- Material Consistency:

Ensuring the raw materials meet industry standards consistently is vital for maintaining product performance. - Lead Time and Sampling:

Fast sampling and timely delivery are trade keywords in this competitive industry. NEX Padel has a proven track record where our quick prototyping capabilities significantly reduce time-to-market. - Cost versus Value Analysis:

Although high-denier carbon fibers such as 12k and 18k come at a premium, these costs are offset by lower production errors, longer durability, and improved customer satisfaction.

Adopting advanced materials and innovative techniques is a strategic move that optimizes both performance characteristics and production efficiency. Manufacturers can leverage these insights to develop rackets that cater to various market segments—from beginners to top-tier competitive players.

Transitioning from fiberglass to advanced carbon fiber materials is not without its challenges. Several factors need to be addressed by technical sourcing experts and OEM specialists when considering a shift:

- Knowledge Requirement:

The design and fabrication of carbon fiber components demand high technical expertise. Designers must understand the interplay of fiber orientation, layering techniques, and resin compatibility. - Production Adaptation:

Upgrading manufacturing plants to process carbon fiber, especially higher-grade forms like 18k, involves significant capital and training investments.

- Quality Assurance Protocols:

Implementing rigorous quality control measures is necessary to ensure that every racket produced meets stringent performance standards. Automated control systems can help minimize human error. - Batch Testing:

Use of statistical process controls and regular batch testing ensures durability and performance metrics are consistently achieved.

- Educating Procurement Managers:

B2B purchasers must be educated on the long-term value benefits of advanced materials. Although upfront costs may be higher, the overall lifespan and performance improvements justify the investment. - Cost-Benefit Analysis:

It is essential to compare the life-cycle costs, including replacements and performance reliability. Detailed case studies can support decision-making processes.

- Balancing Standardization with Customization:

While higher material grades allow for extensive customization, maintaining production efficiency for multiple product lines can be challenging. A modular design approach can help balance these needs.

Manufacturers who successfully overcome these challenges provide a strong value proposition to OEM clients by delivering products that not only enhance gameplay performance but also extend the life span of the rackets, reducing overall maintenance and replacement costs.

At NEX Padel, our journey reflects the broader evolution in padel racket manufacturing. By adopting advanced carbon fiber technologies, we have achieved significant improvements in both our product lineup and our production efficiency.

- Rapid Prototyping5:

We offer fast sampling capabilities, allowing OEM clients to test various configurations (Diamond, Round, Teardrop) with different material compositions such as 3k, 12k, and 18k carbon fibers. - Customization at Scale:

NEX Padel stands out by offering extensive customization options. This includes custom printing, color matching, and logo integration on not just the racket but also complementary parts like the hand grip and handle cap. - Advanced Production Techniques:

Our facilities use automated resin infusion and prepreg molding processes. This results in optimal material consistency and performance across large production volumes. - Cost-Effective Innovation:

Despite the higher cost of advanced materials, our efficient production workflows ensure competitive pricing for our customers. We balance cost with enhanced performance values, which is crucial for building trust with OEM partners.

This case study demonstrates that by investing in advanced materials and production capabilities, companies can achieve a significant market edge. The information provided herein equips purchasing managers with the critical insights needed to evaluate production methodologies, technical merits, and long-term benefits.

The evolution from fiberglass to advanced carbon fiber in padel racket face materials highlights the importance of ongoing innovation in sports equipment manufacturing. Key takeaways include:

- A clear understanding of material properties is essential. Fiberglass remains an entry-level solution, while 3k, 12k, and 18k carbon fibers offer progressively higher performance at increased costs.

- Modern manufacturing techniques ensure material consistency, which is critical for OEM decisions. Processes such as resin infusion and prepreg molding guarantee superior product quality.

- Overcoming production and technical challenges requires investment in both technology and expertise. However, the long-term benefits in performance and durability make these investments worthwhile.

- Customization and rapid prototyping are critical components in meeting the diverse needs of today's market. They allow companies like NEX Padel to efficiently produce high-performance, branded products for various market segments.

For procurement and sourcing experts, the recommendation is clear: evaluate your supplier’s material sourcing, production processes, and customization capabilities. Ensure that these align with your end-user expectations and product positioning. Engaging with a manufacturer who understands these nuances will not only secure high-quality padel rackets but also support innovation in your product portfolio.

By continuously following industry advancements and incorporating new technologies, OEM partners can stay ahead of market trends. This proactive approach leads to products that deliver enhanced performance and long-term customer satisfaction.

Q1: How have tennis rackets evolved over time?

A1: Tennis rackets have evolved significantly, with changes not only in frame materials but also in string technology. Early wooden rackets have given way to composite materials that enhance power and control. Modern designs focus on lighter frames, improved durability, and optimized string tension, providing a balance between performance and playability.

Q2: What material are padel rackets made of?

A2: Padel rackets are typically made from either fiberglass or advanced carbon fiber. Fiberglass is common in beginner rackets because of its cost-effectiveness, while carbon fiber—especially in forms like 3k, 12k, and 18k—is used in higher-performance models to provide greater power, durability, and precise control.

Q3: What is the new technology in padel?

A3: Recent innovations in padel include the integration of advanced materials and smart court technologies. Modern rackets benefit from enhanced carbon fiber production techniques that improve strength and reduce weight. Additionally, concepts like the Next-Gen Smart Padel Court are emerging, which integrate sensor-driven technology to provide real-time analytics during play.

-

OEM specialists: Click to read about the role of Original Equipment Manufacturer specialists in optimizing production, supply chain integration, and quality assurance for B2B applications. ↩ ↩

-

Carbon fiber technology: Click to learn more about how carbon fiber technology advances improve product performance through enhanced material properties and innovative manufacturing processes. ↩ ↩

-

Resin Infusion Technology: Click to explore the resin infusion process, its benefits in ensuring even resin distribution, and how it contributes to stronger, more consistent composite materials. ↩ ↩

-

Prepreg Molding: Click to read about prepreg molding techniques, including how pre-impregnated materials offer controlled resin content and precise fiber orientation in high-performance manufacturing. ↩ ↩

-

Rapid Prototyping: Click to understand the advantages of rapid prototyping in reducing lead times, optimizing design iterations, and accelerating time-to-market in a competitive manufacturing environment. ↩ ↩