Advanced production techniques have revolutionized padel racket manufacturing by integrating automation, precision engineering, and innovative materials. These technologies ensure superior product performance, durability, and full customization options for OEM brands1. This article explains how innovation in materials and production processes is transforming the industry and why partnering with a technology-driven manufacturer like NEX Padel can drive competitive advantage.

In today’s competitive sports equipment market, especially within padel, quality and precision are paramount. The manufacturing process is undergoing a significant transformation as advanced technologies reshape every aspect from material selection to production efficiency. For procurement managers and product development leads, understanding these advancements is vital for making informed decisions when selecting a manufacturing partner.

At NEX Padel, we leverage state-of-the-art production techniques using materials like glass fiber and various grades of carbon fiber2 (3K, 12K, 18K). Our commitment to quality, speed, and customization has helped us become the go-to OEM partner for industry leaders such as Hirostar, Reebok, and Starvie.

Historically, padel racket production relied on manual processes and conventional materials. This often led to inconsistencies in quality and long lead times, which are unacceptable in a market where performance and durability define success. As the demands of professional players and competitive brands increase, traditional production methods face challenges such as:

• Inconsistent production quality

• Limited customization options

• Slow turnaround times

• Reduced durability under high-performance use

These issues create a significant risk for brand reputation. For procurement managers, partnering with a production partner who is at the forefront of technological innovation is not just an option—it’s a necessity.

Traditional manufacturing methods generally hold back modern sports equipment due to several constraints. Key issues include:

-

Material Constraints: Conventional materials lack the strength-to-weight ratio required in high-performance padel rackets. Older production techniques did not fully exploit the potential of materials like carbon fiber.

-

Manual Quality Control: Without automated systems, production variability increases, making it challenging to maintain consistent product performance. Labor-intensive quality inspections can lead to human error.

-

Limited Customization: In an era of brand differentiation, generic designs are no longer competitive. Traditional setups struggled with quick customization and adapting designs to client needs.

-

Inefficient Production Processes: Manual assembly coupled with outdated machinery hinders production speed, leading to longer lead times which can affect market responsiveness.

Understanding these barriers is key to appreciating the modern production techniques that are now available to manufacturers like NEX Padel.

Modern padel racket manufacturing is defined by a suite of advanced technologies. These techniques not only enhance quality but also provide robust customization tailored to each brand's identity. Here we outline the key technologies driving quality improvements:

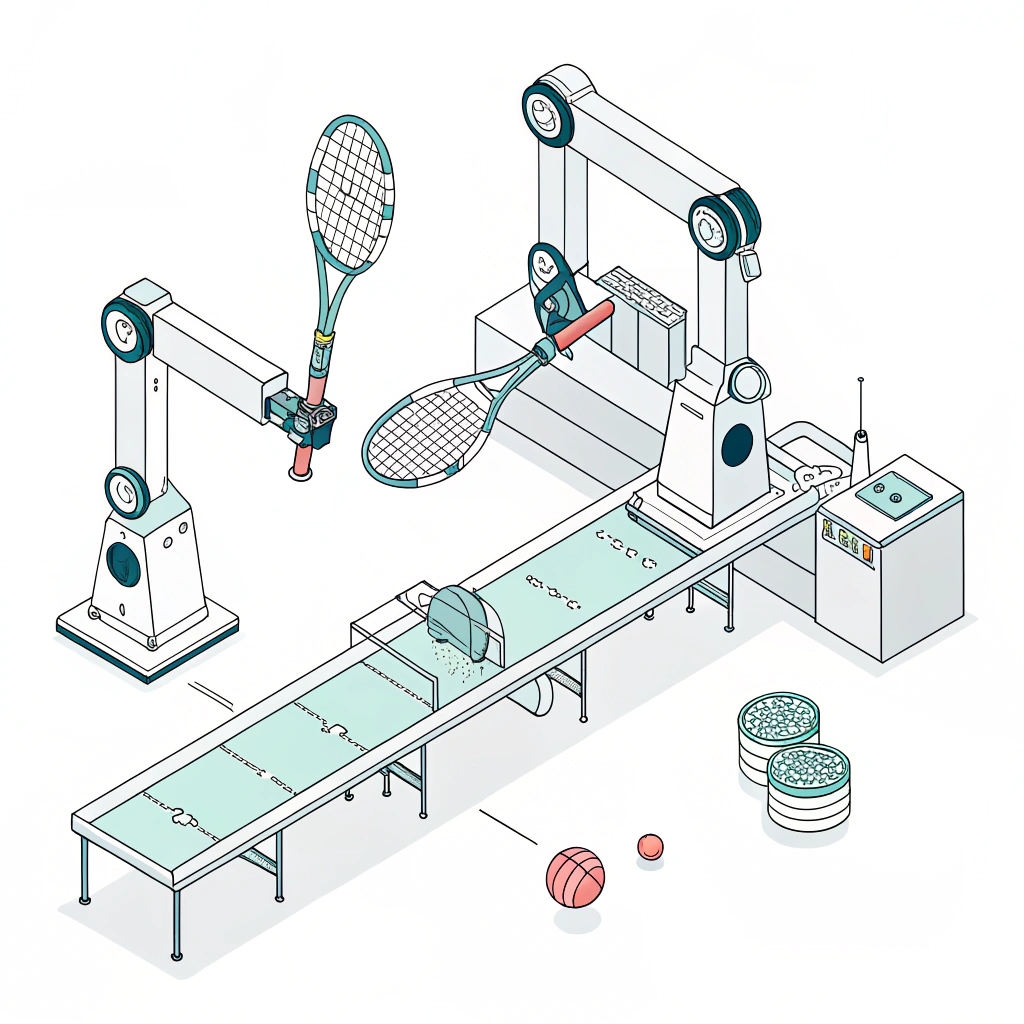

Automation has transformed padel racket manufacturing by reducing human error and increasing production speed while maintaining consistent quality. Robotics and state-of-the-art control systems now handle critical processes such as molding, assembly, and finishing.

• Benefits:

- Reduces variability

- Improves efficiency

- Enhances precision in assembly

Using different grades of carbon fiber—namely 3K, 12K, and 18K—allows manufacturers to tailor the racket’s properties based on player needs and performance requirements. Advanced composite molding techniques ensure even stress distribution and improved durability.

• Benefits:

- Customizable stiffness and flexibility

- Superior strength-to-weight ratio

- Enhanced energy transfer during play

Glass fiber continues to be a reliable material for entry-level to mid-range padel rackets. By adopting precision molding techniques, manufacturers can assure consistent quality and optimal impact resistance.

• Benefits:

- Cost-effective production

- Consistent mechanical performance

- Ideal for varying performance levels

A significant paradigm shift is the move towards individualized designs. Utilizing digital design platforms, manufacturers offer full customization—from racket shapes (Diamond, Round, Teardrop) to bespoke printing on the racket surface and even on the handle accessories.

• Benefits:

- Personalized branding possibilities

- Quick adaptation of design changes

- Enhanced market differentiation for OEM brands

The table below provides a clear overview of these technologies and their impact on padel racket production:

| Technology | Material / Component | Benefits | Application |

|---|---|---|---|

| Automated Production Lines | Various materials | Consistent quality, reduced variability | Entire production process |

| Advanced Carbon Fiber Production | 3K, 12K, 18K carbon fiber | Superior strength, durability, tailored performance | High-performance rackets |

| Precision Glass Fiber Molding | Glass fiber | Cost-effective, improved impact resistance | Entry-level to pro models |

| Digital Customization Platforms | Custom design elements | Personalized branding, rapid design changes | OEM and private label manufacturing |

Modern quality assurance hinges on the integration of automated inspection systems5 that monitor each step of the production process in real time. These systems include:

• In-line sensors and cameras: Identifying minor imperfections that might lead to product failure in later stages.

• Data analytics platforms: Analyzing production data to predict and mitigate potential quality issues.

• Automated feedback loops: Adjusting machine settings mid-production to maintain high-quality outputs.

These advancements ensure that each racket meets the rigorous standards demanded by professional athletes and competitive teams.

In today’s market, brands are not just selling a product—they are selling a story. With customizable options in every aspect of the rackets, from design to materials used, companies can differentiate their products in a crowded market. Customization includes:

• Shape personalization: With options for Diamond, Round, and Teardrop shapes, manufacturers can cater to different playing styles and ergonomic requirements.

• Logo and color printing: Customized printing on the racket face, hand grip, and handle cover provides an effective way for brands to reinforce their identity.

• Component personalization: Customizing attachments and comfort components such as hand grips ensures a personalized touch that appeals to end-users.

The ability to customize not only boosts product aesthetics but also plays a significant role in performance enhancement—by tailoring the product to the specific needs of athletes.

NEX Padel’s production techniques have proven highly successful with several leading brands. For instance, our collaboration with top sports brands demonstrates how integrating automated processes and advanced materials can yield rackets that perform consistently under competitive conditions. A few key takeaways include:

• Reduced production lead times through automation streamlined our supply chain, ensuring on-time delivery.

• Enhanced performance capabilities by optimizing the type of carbon fiber used based on specific game demands.

• Increased customer satisfaction due to full customization options that align with their brand ethos.

These successes highlight how technology-driven quality improvements not only meet but exceed market expectations.

Recent surveys from high-performance sports equipment markets indicate that manufacturers employing state-of-the-art production techniques see a marked reduction in product returns and quality complaints. Data analytics has shown:

• A decrease of up to 25% in production defects.

• An increase in operational efficiency by 30%.

• Higher client satisfaction and repeat business due to the reliability and performance consistency of products.

These numbers underline the tangible benefits of investing in advanced manufacturing technology.

For procurement managers and product development leads evaluating new manufacturing partners, consider the following action steps:

- Assess the technology integration in production facilities. Automation and digital customization are key indicators of a capable partner.

- Request evidence-based case studies and performance data to verify the technological capability and quality improvements.

- Understand the range of material options, particularly the use of advanced carbon fiber grades and precision glass fiber for product differentiation.

- Evaluate the scalability of production processes. Ensure the producer can handle both high-volume orders and custom, small-batch productions.

- Prioritize partners who offer end-to-end solutions from design customization to rigorous quality control, ensuring that each product meets market and performance standards.

By following these recommendations, decision-makers can confidently choose a partner that aligns with their brand's need for quality, innovation, and speed.

Advancements in padel racket manufacturing have ushered in a new era of product quality and customization. The integration of automated production lines, advanced carbon fiber technologies, precision molding techniques, and digital customization platforms has transformed the way high-performance rackets are produced. These innovations not only solve traditional manufacturing challenges but also offer significant advantages in performance, durability, and brand differentiation.

For brands seeking a competitive edge in the padel market, partnering with a technologically advanced manufacturer like NEX Padel can be the key to unlocking superior product performance and operational efficiency. By emphasizing quality, customizing products to meet market demands, and leveraging cutting-edge production methods, we help our partners stay ahead in an increasingly competitive industry.

Your next step should be to evaluate your current manufacturing partners, compare technological capabilities, and consider the benefits of aligning with a production leader committed to excellence. With robust technology-driven strategies, the future of padel racket manufacturing is bright, and joining this wave of innovation could be the deciding factor in redefining your brand’s success.

-

What advanced technologies are used in padel racket manufacturing?

Advanced technologies include automated production lines, high-precision carbon fiber molding (using 3K, 12K, and 18K variants), precision glass fiber molding, and digital customization platforms that enable personalized designs and rapid prototyping. -

How does automation enhance padel racket quality?

Automation reduces human error by incorporating in-line sensors, robotics, and real-time data analytics, ensuring consistent quality and efficiency throughout the production process, which results in highly durable and uniformly manufactured products. -

How can OEM manufacturers benefit from partnering with advanced production facilities?

OEM manufacturers benefit from reduced lead times, improved quality control, and full customization options that meet diverse market demands, ultimately supporting brand differentiation and higher product performance in competitive environments.

-

OEM brands: Click to read more about the role and benefits of Original Equipment Manufacturer (OEM) partnerships in modern production strategies. ^Return ↩

-

Carbon fiber: Click to learn about the properties, grading (3K, 12K, 18K), and advanced applications of carbon fiber in high-performance manufacturing. ^Return ↩

-

Automated Production Lines: Click to explore how automation in production lines increases efficiency and consistency, reducing human error in manufacturing processes. ^Return ↩

-

Digital Customization Platforms: Click to understand how digital platforms enable personalized product design and rapid adaptation to market demands, boosting brand differentiation. ^Return ↩

-

Automated inspection systems: Click to discover how incorporating automated inspection systems into production can enhance quality control and reduce defect rates. ^Return ↩