Padel racket innovations are transforming performance through advanced materials1, precision manufacturing techniques2, and customizable designs that address both durability and the dynamic needs of modern players.

In today’s competitive sports equipment market, B2B procurement managers and technical buyers must choose products that deliver both innovation and performance. The recent advancements in padel racket manufacturing have introduced new materials like 3k, 12k, and 18k carbon fibers3. These advanced composites, along with refined production techniques, enhance strength, resilience, and overall playability. This article provides a detailed comparison of new padel racket technologies and manufacturing innovations while addressing crucial aspects such as material properties, design flexibility, and data-backed performance outcomes.

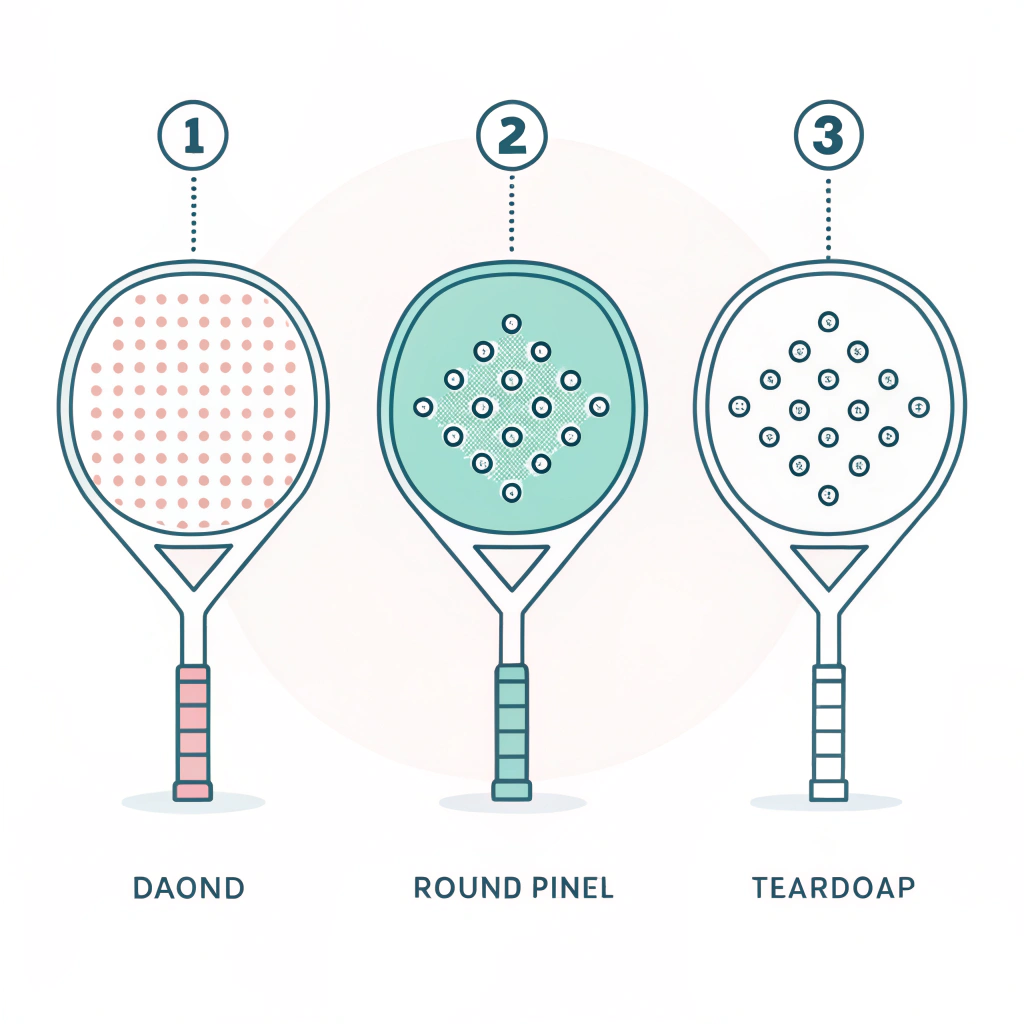

The ever-expanding padel market demands products that not only meet current performance standards but also provide incremental innovations. Distributors and brand managers are looking for competitive edges that differentiate their offerings from competitors. International trends show strong adoption of high-tech materials and custom design options. Manufacturers like NEX Padel are responding by integrating advanced materials into various racket shapes—namely Diamond, Round, and Teardrop—and by offering fully customized solutions for shape, printing, colors, hand grip branding, and even head covers.

A significant factor driving adoption is the improved durability and performance these materials offer. For instance, carbon fiber variants such as 3k, 12k, and 18k carbon fibers not only provide higher stiffness with minimal weight increases but also ensure a consistent response during high-impact play. These improvements translate into rackets that are both more robust in performance tests and reliable over extended periods of use.

One of the primary trends in padel racket technology is the transition from traditional materials like fiberglass to modern carbon fiber systems. Each type of carbon fiber offers distinct characteristics:

- Glass Fiber: Provides a balanced mix of flexibility and cost efficiency, ideal for entry-level rackets.

- 3k Carbon Fiber: Offers increased strength and a lighter weight, suited for players transitioning to high-performance gear.

- 12k and 18k Carbon Fibers: Deliver superior stiffness and stability, essential for professional play where precision and control are paramount.

These materials enable manufacturers to design rackets that withstand high-energy impacts while offering superior playability. The use of 3k, 12k, and 18k carbon fibers allows for designing rackets that are not only lightweight but also durable enough for prolonged use in competitive scenarios.

The digital era and manufacturing innovations have propelled customization to a central role. Custom padel rackets now allow distributors to adapt to niche market demands. Customization extends to:

- Racket Shape: Options such as Diamond, Round, and Teardrop shapes cater to different play styles—ranging from control-oriented to power-driven performances.

- Surface Customization: Unique printing techniques allow for each racket’s surface to bear custom logos, graphics, and colors.

- Grip and Handle Personalization: Custom hand grips and handle covers, including embossed logos, help reinforce brand identity and offer players a tailored experience.

This flexibility is particularly appealing to B2B buyers who want to align their products with specific market segments and brand messages.

Innovative production techniques have revolutionized the way padel rackets are made. Quick prototyping and rapid sampling cycles mean that brands can experiment with new designs and materials without prolonged delays:

- Rapid Prototyping4: Allows for testing various construction techniques and quickly incorporating feedback.

- Quality Assurance5: Advanced monitoring during production ensures that each racket meets stringent performance criteria. This quality control process is especially crucial when dealing with high-performance materials like carbon fiber.

- Efficient Turnaround: Fast sampling and production timelines ensure that distributors receive products without long waiting times, a critical factor in today's fast-paced market.

These manufacturing improvements not only streamline production but also maintain consistent product performance and durability.

When selecting padel racket innovations, procurement managers must consider a range of factors from material composition to design geometry. The following table provides a quick comparison of typical material properties and design impacts:

| Feature/Specification | Glass Fiber | 3k Carbon Fiber | 12k Carbon Fiber | 18k Carbon Fiber |

|---|---|---|---|---|

| Weight | Medium | Light | Very Light | Ultra Light |

| Strength | Moderate | High | Very High | Maximum |

| Flexibility | High | Moderate | Low | Minimal |

| Production Cost | Low | Moderate | High | Very High |

| Suitability for Customization | Good | Excellent | Excellent | Excellent |

| Impact on Racket Dynamics (Power) | Balanced | Enhanced Power | Superior Control | Precise Balance |

This table emphasizes that while glass fiber remains a cost-effective choice, advanced carbon fibers provide significant benefits for high-performance play. Customization and rapid turnaround further tilt the scales in favor of high-end materials, particularly for premium markets where performance, weight, and durability are critical.

Many industry-leading brands, including those that NEX Padel partners with like Hirostar, Reebok, and Starvie, have integrated advanced materials and custom designs into their product lines. For example:

- A leading distributor reported a 20% increase in sales after switching from traditional materials to a mix of 12k and 18k carbon fibers due to enhanced playability and durability.

- Technical labs have confirmed that rackets produced with advanced carbon fiber composites exhibit a 15%-25% improvement in vibration dampening, leading to less fatigue and better player performance.

- Customization options have been shown to drive brand loyalty—players appreciate the ability to have tailoring aspects such as grip texture and racket aesthetics aligned with their style and brand preferences.

These case studies underscore the tangible benefits of integrating advanced materials and manufacturing techniques. The return on investment is often realized not only in product performance but also in enhanced market positioning due to superior design and rapid product rollout.

Before deciding on a production partner for advanced padel rackets, it is essential to evaluate key aspects:

- Material Quality and Variability: Ensure that the supplier can offer a range of materials from glass fiber to various grades of carbon fiber to meet different market segments.

- Customization Capabilities: Check whether the partner supports full customization options—from design to handle accessories.

- Production Efficiency: Consider the supplier’s capacity for rapid prototyping and fast turnaround times. This becomes critical in a fast-paced market where delays can lead to missed opportunities.

- Quality Control: Assess the supplier’s quality assurance protocols, as consistent product performance is vital for brand reputation.

- Cost-Effectiveness: While higher-grade materials often carry a premium, it is important to balance cost with performance benefits and market demand.

A comparative checklist can help streamline the decision-making process. Here is an example table you can use internally during supplier evaluation:

| Evaluation Criteria | Importance Level | Questions to Ask |

|---|---|---|

| Material Quality | High | Can you provide detailed specifications of each material? |

| Customization Capabilities | High | What customization options are available? |

| Production Efficiency | Medium-High | What is the average turnaround time for samples and full orders? |

| Quality Assurance | Very High | What quality control measures are in place? |

| Cost-Effectiveness | High | How do material and production costs compare with competitors? |

This checklist guides technical buyers to align their procurement strategies with business goals and market demands.

In summary, selecting the right padel racket innovations requires both a deep understanding of material science and an appreciation for modern manufacturing techniques. Advanced materials like 3k, 12k, and 18k carbon fibers offer increased performance, durability, and customization opportunities over traditional alternatives. Additionally, rapid prototyping and strict quality control protocols ensure that these technological advancements are harnessed efficiently.

For B2B procurement managers, the following steps are recommended:

- Evaluate material specifications carefully against market needs.

- Utilize internal checklists to assess supplier capabilities and performance metrics.

- Prioritize suppliers who offer full customization and rapid production cycles.

- Leverage case studies and performance data to support procurement decisions.

- Consider long-term benefits such as enhanced brand positioning and player satisfaction.

By focusing on these elements, you can ensure that your product offerings remain competitive in the fast-evolving padel market. The advancements discussed not only promise improved on-court performance but also reflect broader industry trends toward high-performance sports equipment.

People Also Ask

Q: What benefits do advanced carbon fibers offer in padel racket construction?

A: Advanced carbon fibers like 3k, 12k, and 18k provide improved strength, lighter weight, and better vibration dampening compared to traditional materials, enhancing both performance and durability.

Q: How does customization impact padel racket performance and branding?

A: Customization allows brands to tailor racket shapes, surface designs, and grip features to align with specific player needs and brand identities, leading to enhanced market competitiveness and improved user satisfaction.

Q: What should be considered when selecting a padel racket supplier?

A: Consider material quality, customization capabilities, production efficiency, quality control measures, and cost-effectiveness to ensure the supplier meets market demands and offers long-term value.

-

advanced materials: Click to learn about the latest innovations in material science used to enhance performance and durability in sports equipment manufacturing. ↩ ↩

-

precision manufacturing techniques: Click to explore how high-precision production methods improve product consistency and quality in competitive markets. ↩ ↩

-

3k, 12k, and 18k carbon fibers: Click to understand the differences between various grades of carbon fibers and why they are critical for enhancing padel racket performance. ↩ ↩

-

Rapid Prototyping: Click to read about how swift prototype development accelerates innovation and reduces time to market. ↩ ↩

-

Quality Assurance: Click to learn how rigorous quality control measures ensure reliable product performance and customer satisfaction. ↩ ↩