Advanced padel racket production hinges on advanced materials and precise manufacturing techniques that directly improve player performance, durability, and overall satisfaction. In this article, we explain how choices—from fiberglass1 to various types of carbon fiber2 (3k, 12k, 18k)—and racket design profiles (Diamond, Round, Teardrop) play a crucial role in shaping play experience, thus providing a competitive edge to businesses selecting or partnering with manufacturers such as NEX Padel.

In today’s dynamic sports equipment industry, procurement managers and business development leads must navigate a complex landscape where technology, material science, and design converge. When it comes to padel rackets, understanding the technical nuances is essential for making informed purchasing decisions. Here, we break down the problem, identify key factors influencing performance, and present clear solutions that illustrate how advanced production techniques enhance product quality.

Challenge Overview

The primary challenge for sports equipment procurement is ensuring that each padel racket combines power, control, and durability. The market is saturated with various technological claims and material innovations. For a business focused on distributing high-performance rackets, it can be overwhelming to compare differences in materials and production methods. Key issues include:

• Inconsistent manufacturing quality

• Varying technological claims about materials (fiberglass vs. carbon fibers)

• Trade-offs between control, power, and durability

• Lack of transparency in customization options

The procurement manager must thus evaluate these aspects to guarantee that adopted equipment meets the rigorous demands of players while maximizing operational efficiency.

Cause Analysis

Several factors contribute to these challenges:

• Material Properties: Selecting between fiberglass, 3k carbon, 12k carbon, and 18k carbon involves understanding stiffness, weight, and flexibility. Each material offers distinct advantages, and differences are often subtle yet impactful.

• Production Techniques: Advancements in molding, precision engineering3 technologies, including automated layup4 and pressurization methods, lead to more consistent and reliable product performance.

• Design Polishing: The shapes of rackets—whether a Diamond for power, a Round for control, or a Teardrop for a balanced profile—affect playability.

• Customization Imperatives: Today’s market demands personalized options ranging from racket shape to printing logos on grips and handle coverings.

Through detailed material science and process optimization, manufacturers can overcome these challenges and produce rackets that fulfill both technological efficiency and performance requirements.

Solution Framework

Below is a solution framework that details how advanced production techniques and materials can address the challenges in padel racket manufacturing:

-

Material Selection

Manufacturers start by choosing the right blend of fiberglass and carbon fiber. Each choice directly influences the racket’s characteristics:- Fiberglass: Offers flexibility with a lower manufacturing cost. Ideal for beginners and intermediate players.

- 3k Carbon: Provides a balance between stiffness and weight, suitable for players needing moderate power and control.

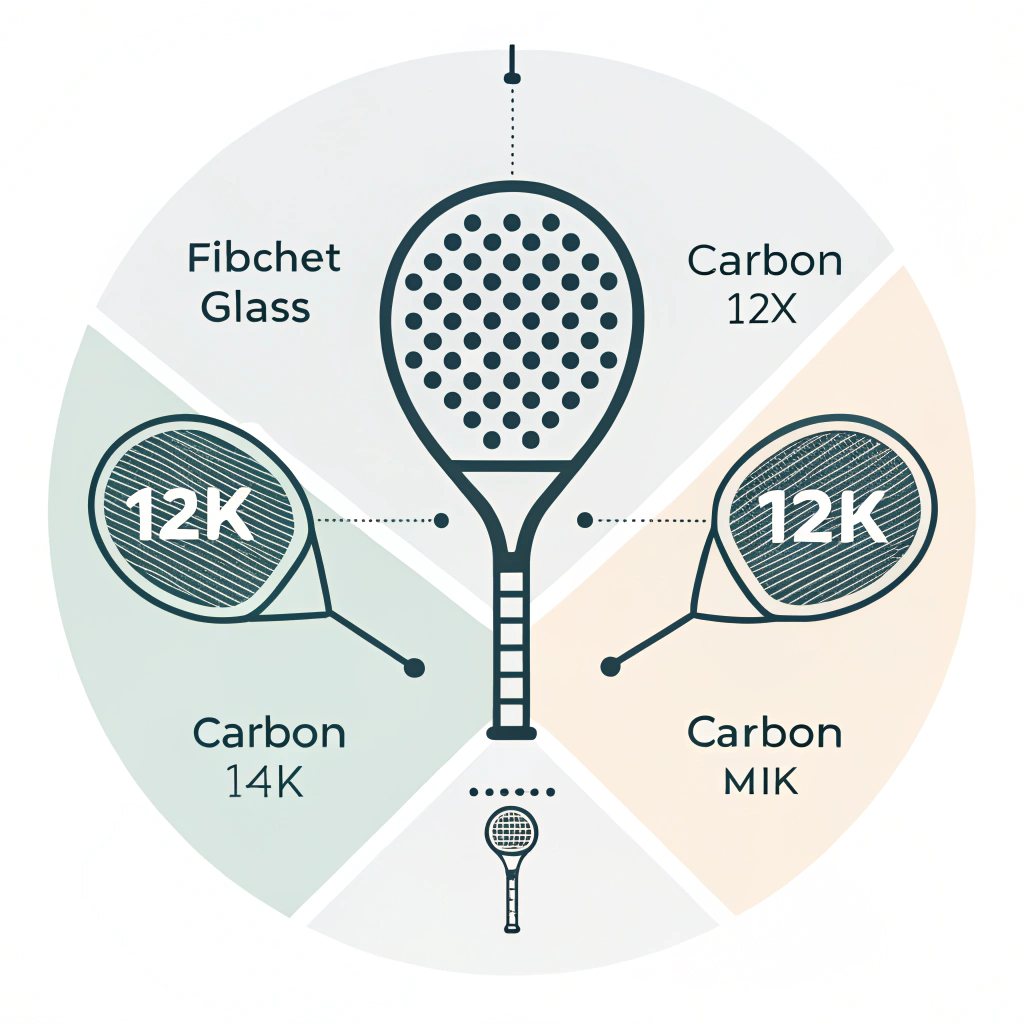

- 12k Carbon: Enhances durability and power, often appealing to advanced players.

- 18k Carbon: Maximizes performance with superior stiffness and heat resistance, tailored for professionals and high-level competition.

-

Production Process Advancements

Utilizing precision engineering3 technologies, including automated layup4 and pressurization methods, ensures uniform quality across production batches. This step also integrates rigorous testing—such as material stress tests and balance assessments—to maintain consistency. -

Design Profiles and Customization

Racket shapes (Diamond, Round, and Teardrop) have been meticulously engineered to cater to different play styles. Customization capabilities extend to logo printing and personalized handle accessories (e.g., hand grips, handle covers), offering an excellent brand differentiation. -

Quality Control and Certification

A reliable production line employs systematic quality control measures to enforce strict standards. Certifications and performance endorsements from known sports teams or brand partners (Hirostar, Reebok, Starvie) underscore product integrity.

Below is a table summarizing material properties and suitable player profiles:

| Material | Stiffness & Weight | Ideal For | Key Benefits |

|---|---|---|---|

| Fiberglass | Lower stiffness, lighter | Beginners, casual play | Cost-effective, flexible |

| 3k Carbon | Moderate stiffness | Intermediate players | Balanced power and control |

| 12k Carbon | High stiffness | Advanced players | Enhanced durability & power |

| 18k Carbon | Very high stiffness | Professional performance | Superior precision & performance |

Case Study: NEX Padel Production Excellence

At NEX Padel, we have refined our rackets through continuous innovation and rigorous testing. For instance, our integration of 18k carbon fiber in Diamond-shaped rackets has significantly reduced vibration upon impact, leading to improved ball control and reduced player fatigue. A series of controlled player trials demonstrated that rackets with this material construction endured extreme stress while maintaining optimal shape and performance consistency.

Additionally, our flexible customization options extend to a broader range of accessories. Our hand grips and handle covers can be branded with custom logos, providing retailers with a unique selling proposition that resonates with end consumers. Such detailed customization is not only a technical achievement but also a strong marketing differentiator in a crowded marketplace.

Practical Implementation Guide

To implement these advanced production techniques effectively, businesses should consider the following steps:

Step 1: Material Analysis

Begin with a clear understanding of the various materials available. Use lab tests and consultation with material experts to quantify each material’s contribution to stiffness, durability, and weight distribution. Drawing insights from scientific data helps in aligning product specifications with player needs.

Step 2: Process Validation

Analyze each stage of your production process. Invest in technologies that automate and precisely control the fabrication process. For example, using computer-aided design (CAD)5 in conjunction with automated layup systems minimizes human error and material inconsistencies. It is advisable to incorporate periodic audits and testing phases that simulate intense playing conditions.

Step 3: Customize to Market Demand

Explore market segmentation to determine which designs and customization features will yield the highest market traction. Rackets designed with a focus on advanced players may favor the incorporation of 18k carbon, while those for recreational play might leverage fiberglass for cost efficiency. Custom logo options on grips and handle covers further reinforce brand identity and market appeal.

Step 4: Collaborate with Established Partners

Engaging with established brands and industry thought leaders can provide additional validation. For instance, partnerships with companies like Reebok or Starvie can serve as endorsements of production quality and product performance. Their input can also offer critical feedback on design improvements.

Step 5: Monitor Post-Sales Performance

Feedback loops from distributors and end users allow continuous improvement of the manufacturing process. Tracking data such as racket lifespan, customer satisfaction, and return rates can shine a light on any areas needing enhancements. In doing so, companies can swiftly tackle any deviation from desired performance standards.

Below is a checklist summarizing the key steps:

| Step | Action Item | Outcome Expected |

|---|---|---|

| Material Analysis | Laboratory testing, expert consultation | Optimal material selection |

| Process Validation | Automation, periodic audits, CAD integration | Consistent manufacturing quality |

| Market Customization | Analyzing market trends, offering design/personality features | Differentiated product lineup |

| Partner Collaboration | Strategic alliances with established brands | Enhanced credibility and market trust |

| Post-Sales Performance Check | Customer feedback loops and data tracking | Continuous product improvement |

Considerations and Limitations

While advanced materials and production techniques provide multiple benefits, it is important to consider several limitations:

• Cost Considerations: Higher-grade materials such as 18k carbon may lead to increased production costs. Balancing cost efficiency with performance is critical, especially when targeting price-sensitive market segments.

• Production Complexity: Advanced production techniques require specialized equipment and highly skilled operators. This may call for increased training investments.

• Market Segmentation: Not every consumer segment requires the highest performance specification. Tailoring product lines to distinct market segments is essential to ensure both profitability and customer satisfaction.

• Customization Trade-offs: While offering bespoke options enhances buyer appeal, it can lead to longer production lead times and additional logistical challenges.

By understanding these limitations, businesses can better plan their procurement strategies and work closely with manufacturers who invest in cutting-edge production capabilities.

Conclusion and Action Recommendations

To summarize, advanced padel racket production, driven by a blend of innovative materials and precision manufacturing techniques, directly translates into improved playing performance and customer satisfaction. With detailed material comparisons, rigorous process validations, and customizable designs, modern manufacturers like NEX Padel are well-equipped to meet the evolving demands of the market.

Key takeaways include:

• Selecting the right material (fiberglass, 3k, 12k, 18k carbon) is crucial for achieving desired performance characteristics.

• Rigorous process validation and precision manufacturing reduce inconsistencies and elevate overall product quality.

• Customization not only enhances brand appeal but also tailors performance to specific player needs.

• A holistic approach, incorporating partner collaborations and post-sales feedback, ensures continuous improvement.

For procurement managers and business leaders in padel retail/distribution, aligning with manufacturers who utilize such advanced production techniques is essential for staying competitive and delivering superior products. Consider initiating detailed quality assessments and factory audits while exploring strategic partnerships with trusted brands. This will ensure that every racket delivered to your customers stands as a testament to technological innovation and performance excellence.

People Also Ask

• How do advanced production techniques improve padel racket performance?

Advanced production techniques enhance padel racket performance by ensuring consistent quality, reducing vibration, and optimizing balance—leading to better control, power, and durability on the court.

• What are the differences between fiberglass, 3k, 12k, and 18k carbon materials in padel rackets?

Each material differs in stiffness, weight, and durability. Fiberglass is generally more flexible and cost-effective, while 3k, 12k, and 18k carbon fibers provide increasing levels of stiffness and performance, with 18k carbon offering the highest precision and strength.

• How does customization impact the player experience in padel rackets?

Customization allows players to choose racket shapes, handle grips, and design finishes that best match their playing style. This personalized approach not only enhances comfort and performance but also reinforces brand identity and consumer satisfaction.

-

fiberglass: Click to read an in-depth analysis of fiberglass properties and its role in enhancing product flexibility and cost-efficiency in sports equipment manufacturing. ↩ ↩

-

carbon fiber: Click to explore comprehensive insights on carbon fiber, including its various types (3k, 12k, 18k) and how they contribute to racket performance and durability. ↩ ↩

-

precision engineering: Click to understand how precision engineering technologies optimize product quality and minimize manufacturing inconsistencies in high-performance equipment. ↩ ↩ ↩2

-

automated layup: Click to learn about automated layup systems, their role in ensuring uniform material distribution, and their impact on production efficiency. ↩ ↩ ↩2

-

computer-aided design (CAD): Click to delve into the benefits of CAD in advanced manufacturing, including enhanced design accuracy and streamlined production processes. ↩ ↩