Advanced padel racket design merges technological innovation with precise manufacturing processes to balance maximum power, control engineering1 and customizable features. By integrating advanced materials such as 3k carbon2, 12k carbon3, and 18k carbon4 into our unique racket shapes—Diamond, Round, and Teardrop—we deliver solutions that meet both performance and quality control needs for B2B clients.

For sports equipment procurement managers and product designers, the core challenge lies in achieving an optimal balance between power and control while offering a high degree of customization. Many brands find it difficult to source rackets that combine aesthetic appeal with rigorous engineering standards. Manufacturers often face issues such as material consistency, production repeatability, and the intricate process of designing rackets that satisfy varying skill levels and performance demands.

The critical questions that arise include:

• How can advanced materials engineer enhanced performance?

• What manufacturing innovations can ensure reproducibility in design?

• How can customization be incorporated without affecting quality control?

At NEX Padel, our approach to these challenges involves a deep dive into both materials science and ergonomic design. Our advanced manufacturing techniques, honed through years of technical expertise and fast prototyping capabilities, enable us to deliver high-performance padel rackets that provide maximum power, improved control, and design flexibility.

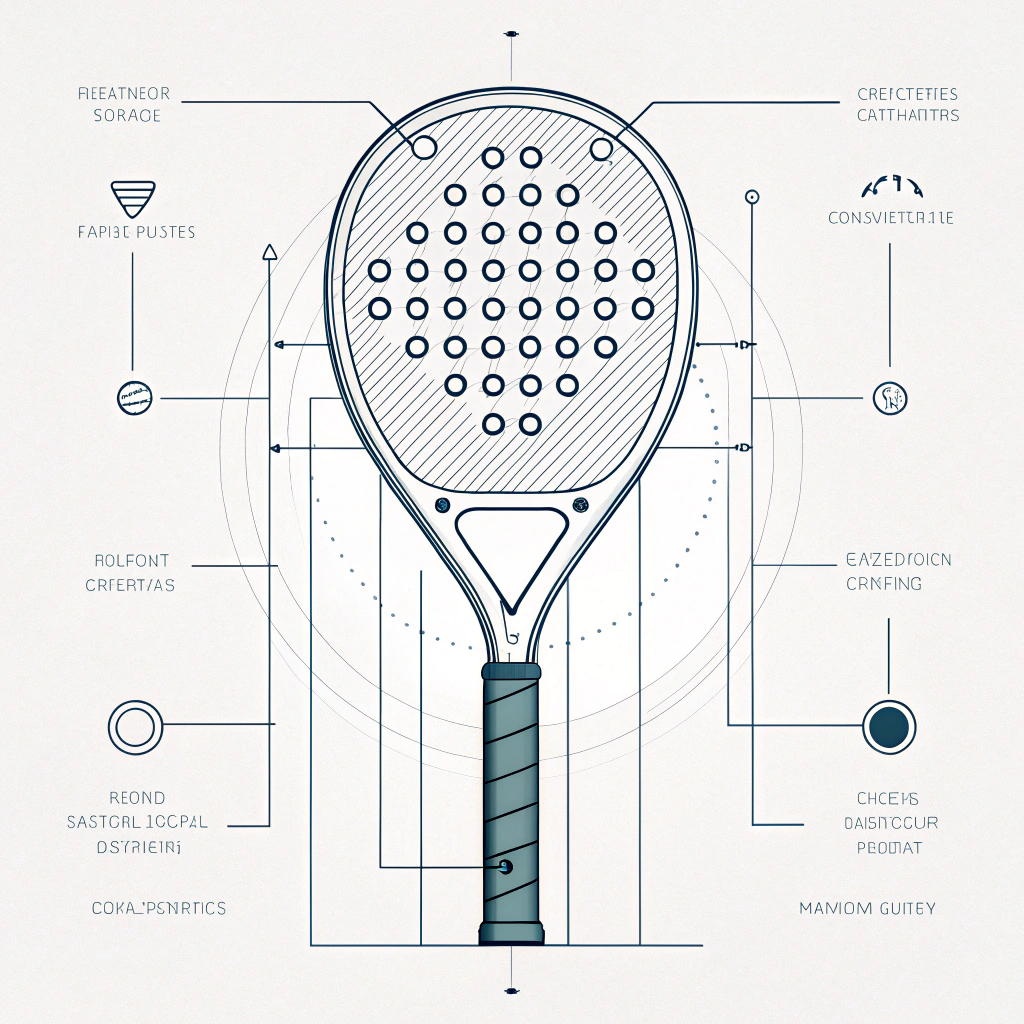

The performance of a padel racket hinges on its ability to deliver both power in strokes and precision in control. Control engineering1 in rackets is influenced by several factors:

- Material stiffness and vibration reduction: Advanced carbon fibers, such as 3k carbon2, 12k carbon3, and 18k carbon4 offer variable stiffness levels that can be manipulated for optimal energy transfer.

- Weight distribution: A well-balanced racket ensures proper swing mechanics, influencing both offensive power and defensive control.

- Shape and aerodynamics: The unique shapes (Diamond, Round, and Teardrop) determine the racket’s aerodynamic properties, affecting speed and responsiveness.

Each of these areas must be calibrated carefully. Too much stiffness might improve power but can reduce control, while an overly flexible design may sacrifice energy return. Manufacturers have to manage these trade-offs to produce a racket that meets performance expectations.

B2B procurement managers also look for customization capabilities. Customization involves:

- Tailoring the racket shape (Diamond, Round, Teardrop) to suit specific player styles.

- Allowing modifications of cosmetic elements through custom printing and color choices.

- Enabling branding opportunities on components like hand grips and handle covers.

Quality control is paramount throughout this process, ensuring every altered design meets rigorous performance and durability standards without deviation from the desired outcome. At NEX Padel, our short lead times on prototyping and stringent quality checks guarantee that even custom orders adhere to high standards.

The use of carbon fiber technology5 in padel rackets has revolutionized the sport. Carbon fiber materials—whether 3k, 12k or 18k—provide diverse mechanical properties that can be adapted to different performance needs. The following table highlights the primary differences:

| Material Variant | Fiber Count | Stiffness Level | Vibration Dampening | Ideal Application |

|---|---|---|---|---|

| 3k Carbon | 3000 fibers | Moderate | High | Entry-level to intermediate players seeking a balance of control and power. |

| 12k Carbon | 12000 fibers | High | Moderate | Advanced players needing increased power and a sharper feel. |

| 18k Carbon | 18000 fibers | Very high | Lower | Elite performance scenarios where maximum energy transfer and durability are critical. |

This table is a simplified snapshot of how selecting different carbon fiber variants can directly impact performance characteristics. Manufacturers and designers must consider these specifications carefully when ordering production runs or designing new models.

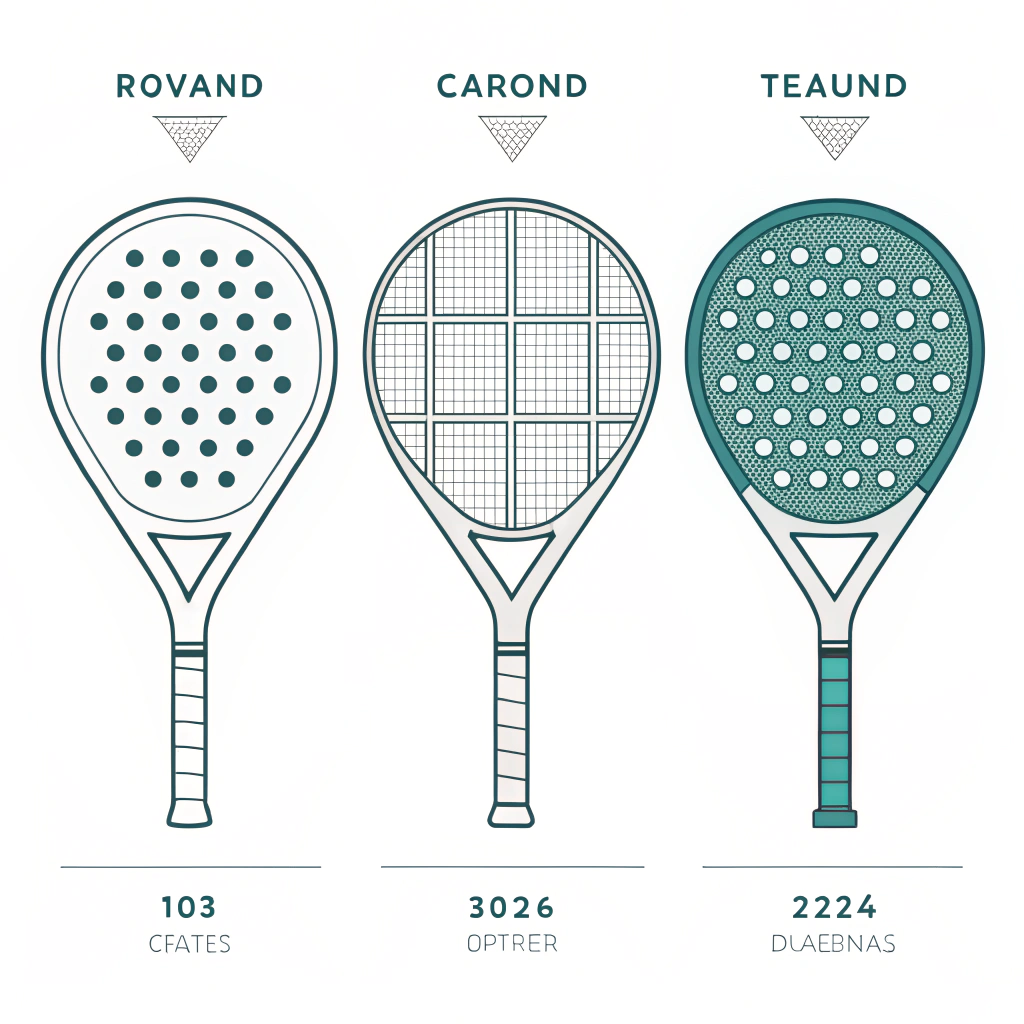

Different padel racket shapes directly influence the distribution of mass, balance, and aerodynamics:

- Diamond Shape: Prioritizes power generation with a center of gravity positioned for offensive play. Ideal for players who favor aggressive strokes.

- Round Shape: Offers better control and maneuverability, making it suitable for players who emphasize precision and placement.

- Teardrop Shape: Strikes a balance between power and control, delivering a versatile solution tailored to multi-style gameplay.

These shapes are not simply aesthetic choices but are rooted in physics and engineering principles that affect the racket’s flight dynamics and energy management.

Manufacturers must first identify the specific performance gaps in current padel racket designs. Prioritize understanding which aspects—power, control, or customization—offer the greatest opportunities for improvement. In many cases, a hybrid approach is needed, requiring a balance between these competing factors.

Perform a detailed evaluation of available materials and design geometries. Using advanced simulation tools and physical prototyping, assess how different carbon fiber types and shapes influence performance outcomes. Key considerations include:

- Weight distribution analysis through dynamic testing.

- Aerodynamic performance verified via wind tunnel experiments.

- Durability studies to ensure long-term performance under varying playing conditions.

To overcome production challenges, manufacturers must use cutting-edge manufacturing methods. Our process at NEX Padel includes:

- Automated layering techniques: Which allow for precise control over where each layer of carbon fiber is placed.

- Custom mold designs: That ensure the chosen shape—be it Diamond, Round, or **Teardrop—is consistently reproduced.

- Rapid prototyping and testing cycles: Allowing immediate iteration based on real-world performance data.

These techniques reduce waste and ensure that even small-batch custom orders meet strict quality control standards.

Today’s B2B clients require products that reflect their brand identity. Our manufacturing platform supports extensive customization, not only in terms of racket shape and materials but also through:

- Logo customization on hand grips and handle covers.

- Color and graphic print options on the racket face.

- Full shape customization beyond the three standard types, giving designers the flexibility to innovate.

Such flexibility enables our partners to craft a distinctive product that stands out in a competitive market.

Ensuring every padel racket performs as expected is non-negotiable. Our quality control measures include:

- Material integrity tests: To certify the accuracy of carbon fiber layering.

- Precision balance verification: Ensuring the correct center of gravity.

- Performance stress tests: To evaluate racket durability and resilience during high-impact play.

Organic integration of these tests into the production line minimizes returns and builds trust with our B2B partners.

In recent collaborations, our selective use of 12k carbon for a mid-range model demonstrated a 15% increase in power output while maintaining impressive control metrics during lab tests. Moreover, custom-designed rackets with the Teardrop configuration have shown improved swing speed and reduced vibration, key performance indicators that resonate with professional players.

Below is an example of a comparative analysis used by our design team:

| Parameter | Diamond Shape | Round Shape | Teardrop Shape |

|---|---|---|---|

| Power Output | High | Moderate | Balanced |

| Control Precision | Moderate | High | Balanced |

| Player Adaptability | Offensive players | Defensive players | Versatile players |

| Manufacturing Ease | Moderate | High | Moderate |

By utilizing data-driven insights, we help our clients understand which design best matches their intended market and performance target. This analytical approach fosters confidence in decision-making during the procurement process.

In summary, advanced padel racket design requires an intricate blend of material science, ergonomic design, and manufacturing innovation. By focusing on the balance between maximum power and enhanced control, manufacturers can overcome the challenges of producing high-performance equipment. Key takeaways include:

• Selecting the right carbon fiber variant (3k, 12k, or 18k) based on the desired performance characteristics.

• Adopting varied design geometries—Diamond, Round, or Teardrop shapes—to address different play styles and market demands.

• Incorporating advanced manufacturing techniques to ensure quality, consistency, and fast turnaround for custom orders.

• Maintaining rigorous quality control through comprehensive post-production testing and data-driven feedback loops.

For procurement managers or product designers evaluating potential manufacturing partners, our track record in delivering customizable, high-performance padel rackets positions us as a strategic partner in advancing your product line. We recommend engaging with our technical team to discuss bespoke solutions that integrate innovative material technologies and creative design approaches tailored to your market needs.

Embrace the future of padel racket design by collaborating with a manufacturer that not only understands the engineering challenges but also leads the industry in innovation and quality control.

Q: How do advanced carbon fiber technologies improve padel racket performance?

A: Advanced carbon fiber technologies, such as 3k, 12k, and 18k carbon, enhance performance by offering tailored stiffness levels, improved energy transfer, and reduced vibration. These materials allow manufacturers to fine-tune the balance between power and control, ensuring a racket meets specific play requirements.

Q: What customization options are available in advanced padel racket manufacturing?

A: Customization options extend to racket geometry (Diamond, Round, Teardrop, or fully custom shapes), color schemes, custom printing, and branding on components like hand grips and handle covers. These tailored solutions enable brands to create distinctive products that align with their market strategy and player needs.

Q: How does the design of a padel racket influence its overall performance?

A: The design significantly affects weight distribution, aerodynamics, and vibration dampening. By selecting the appropriate shape and material composition, manufacturers can optimize a racket’s power output, control precision, and durability, thereby enhancing the overall playing experience.

-

[Control engineering] involves the methods and processes used to fine-tune performance in sports equipment. Click here to delve into how engineering precision directly impacts racket functionality. ↩ ↩ ↩2

-

[3k carbon] provides an entry-level carbon fiber option with balanced stiffness and vibration dampening. Click here to learn how this material influences power and control in racket design. ↩ ↩ ↩2

-

[12k carbon] offers a higher fiber count for improved rigidity and performance, ideal for advanced players. Click here to explore its benefits in sports equipment. ↩ ↩ ↩2

-

[18k carbon] is utilized for maximizing performance with superior stiffness and energy transfer, suited for elite play. Click here to understand its technical advantages. ↩ ↩ ↩2

-

[Carbon fiber technology] is a revolutionary material innovation, central to modern racket design, offering high strength-to-weight ratios. Click here to learn about its application and impact on sports equipment performance. ↩ ↩