High-performance padel rackets are made using advanced composite materials1 and precision engineering processes2 that ensure unmatched durability, performance, and customization. At NEX Padel, our manufacturing process combines state-of-the-art production techniques with rigorous quality control, ensuring that every racket meets the highest industry standards.

For many procurement managers and product developers, understanding how padel rackets are manufactured is key to making informed decisions on sourcing high-quality sports equipment. This article unravels our comprehensive production process at NEX Padel, highlighting critical steps, materials, and quality control measures that set our products apart in the competitive market.

Our approach intertwines advanced industrial production techniques with custom design capabilities. We use a range of high-grade materials—from glass fiber to various grades of carbon fiber3 (3K, 12K, and 18K)—to cater to different performance and pricing thresholds. This detailed insight into our manufacturing process helps you assess our technical expertise and commitment to quality.

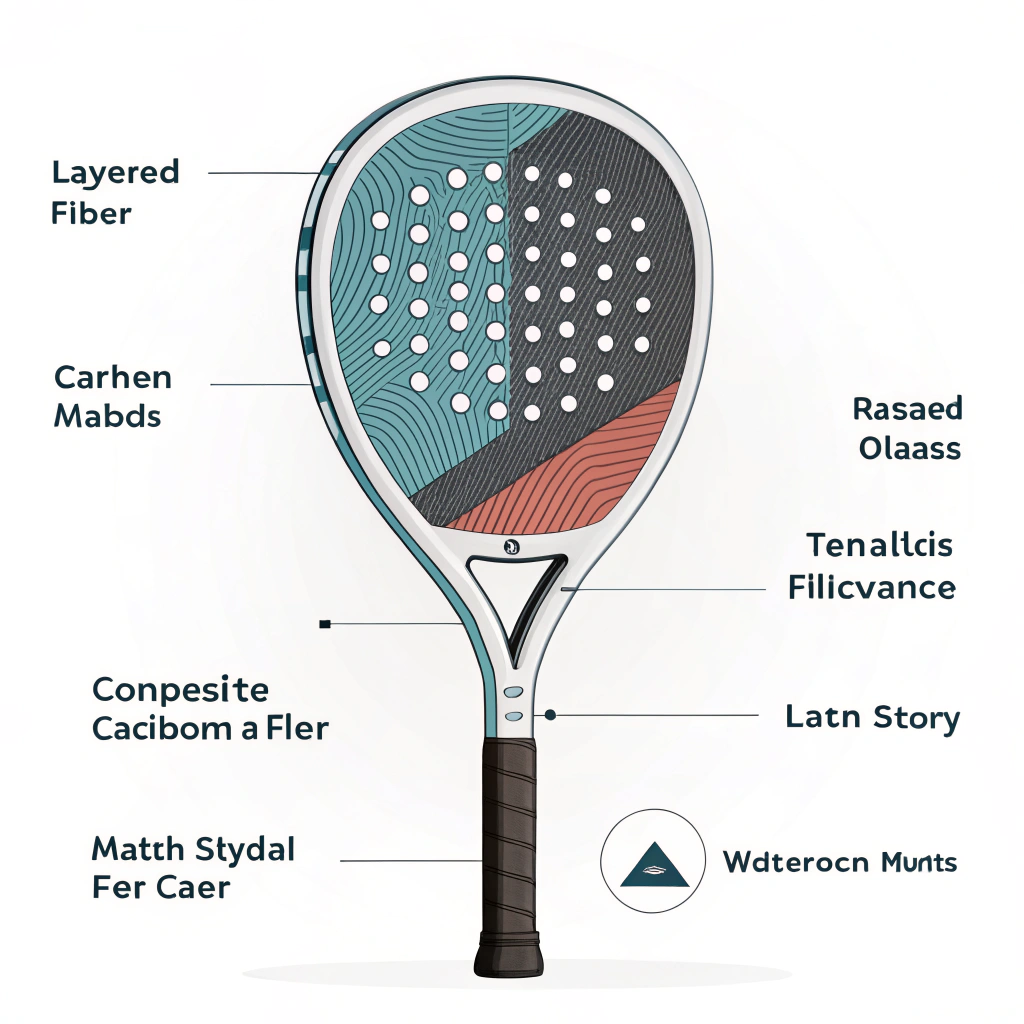

The selection of raw materials is the foundation of every high-performance padel racket. At NEX Padel, we meticulously choose materials based on their strength, weight, and durability:

- Glass Fiber: Known for its excellent impact resistance and flexibility, it is typically used in combinations where a balance between strength and cost is required.

- Carbon Fiber (3K, 12K, and 18K): Each grade of carbon fiber serves a specific purpose:

- 3K Carbon Fiber offers a good balance of weight and strength, ideal for players seeking moderate performance.

- 12K Carbon Fiber provides higher stiffness and enhanced control, fitting for advanced players.

- 18K Carbon Fiber is used for high-performance rackets, delivering superior power and precision.

The use of these materials ensures that our rackets are not only lightweight and durable but also highly responsive on the court.

The production process begins with careful preparation of the raw materials. Our engineers ensure the fibers are cut and treated correctly before being layered. Multiple layers of glass fiber or carbon fiber are applied according to meticulously defined specifications. Each layer is positioned to optimize the racket’s strength and balance.

During the layering process, controlled environmental conditions are maintained to prevent any resin curing issues that might impact the final product quality.

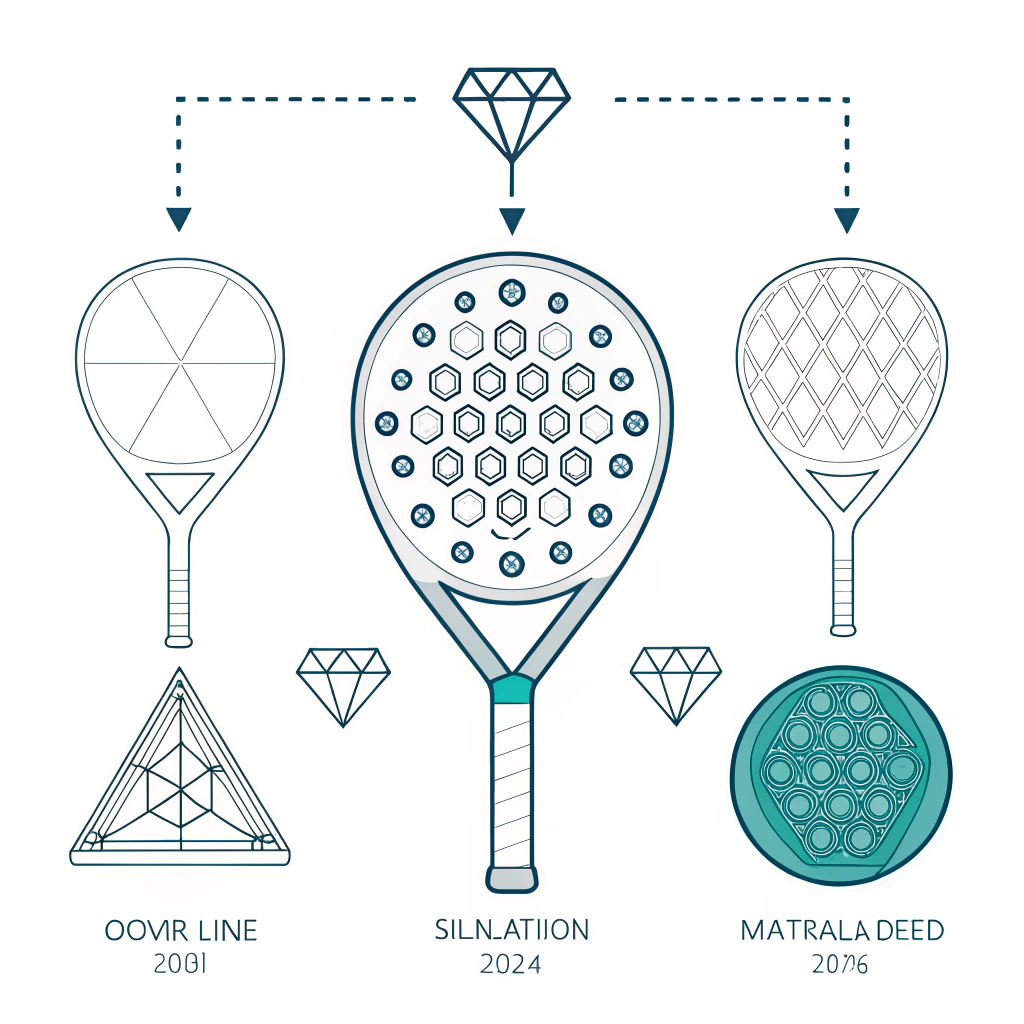

Once the layers are in place, the semi-finished racket is transferred to high-pressure molds. These molds are designed with precision to achieve the Diamond, Round, or Teardrop shapes—three distinct designs that cater to various playing styles. The molding process is pivotal because:

- It shapes the racket to the exact dimensions.

- It ensures the layers bond seamlessly during the curing cycle.

- Presses and molds are used to impart the final appearance and consistent quality.

A high degree of automation in our molding process minimizes human error while improving production time. Fast prototyping4 techniques mean that design iterations can be quickly tested and finalized, ensuring that we remain agile in a competitive market.

After molding, the rackets undergo meticulous finishing:

- Handle Assembly: The handle is attached with a special focus on ergonomics and grip performance. We offer full customization in terms of hand grips and handle covers, including the addition of custom logos.

- Printing and Decoration: Custom printing technology allows vendors to imprint designs, brand logos, or even player-specific graphics. This not only enhances the aesthetic appeal but also reinforces brand identity.

- Quality Enhancements: Each racket is thoroughly inspected and tuned to meet strict quality standards. Testing includes balance assessment, vibration reduction analysis, and stress tests.

Quality control is integrated at every stage—from material sourcing to final assembly. Our inspectors conduct detailed checks to ensure:

- Dimensional accuracy of the racket

- Bonding integrity between layers

- Consistency in material properties

A well-organized supply chain ensures that the finished rackets are packaged and delivered on time. Fast prototyping and rapid turnaround mean that any custom order can be fulfilled with speed and precision.

To help you understand the differences among the various carbon fiber types we use, the following table presents a comparative overview:

| Fiber Type | Weight | Stiffness | Ideal For | Key Benefit |

|---|---|---|---|---|

| 3K Carbon Fiber | Light to Moderate | Moderate | Entry-level to intermediate players | Balanced performance and cost effectiveness |

| 12K Carbon Fiber | Moderate to Light | Higher | Advanced players | Enhanced control and power |

| 18K Carbon Fiber | Ultra-light | Highest | Professional and premium segment | Maximum precision and superiority |

This table illustrates how each grade meets different requirements, allowing you to select the right product based on your players’ or customers' needs.

Quality control is not merely a step in the production; it is a continuous process that starts with raw material selection and extends to final packaging:

- Automated Inspections: Modern imaging tools and sensors are used to inspect the integrity of each layered structure.

- Hands-on Testing: Our quality experts regularly perform manual checks to ensure that every shift in production maintains the consistency of our high standards.

- Continuous Improvement: Feedback from partners like Hirostar, Reebok, and Starvie helps us refine our process continuously.

This robust quality control measure underpins our reputation for delivering reliable and durable high-performance padel rackets.

Given the technical requirements and precise engineering needed in padel racket manufacturing, NEX Padel stands out due to:

- Advanced Production Techniques: Utilizing high-tech molds, automated layering, and fast prototyping allows us to maintain high consistency and meet delivery deadlines even for custom orders.

- Customization Flexibility: From racket shape to custom prints, grips, and even handle covers, our offerings are highly customizable, supporting full branding and player-specific adjustments.

- Rigorous Quality Assurance: With a dedicated quality control team and strict adherence to international quality standards, every product is a testament to our commitment to excellence.

- Industry Collaboration: Our role as an OEM5 for globally recognized brands reflects our technical prowess and strong standing in the market. By aligning with industry leaders, we continuously evolve our manufacturing strategies based on real market demands and technological advancements.

Through these efforts, we forge strong relationships with our partners, ensuring our products not only meet but exceed industry expectations.

For procurement managers and product developers evaluating potential suppliers, consider the following points when assessing a padel racket manufacturer:

- Material Quality: Understand the types of fibers used. The difference between 3K, 12K, and 18K carbon fiber can have significant impact on performance and cost.

- Production Process: Look for manufacturers who have streamlined processes, including automated molding and precision layering techniques, ensuring high-quality outputs.

- Customization Capabilities: Ensure that the supplier can provide tailored solutions, from custom printing to ergonomic handle designs, to ideal match your brand’s identity.

- Quality Control: Inquire about quality testing procedures and certifications. A robust quality assurance system translates to fewer defects and longer product life cycles.

- Delivery Timelines: Fast prototyping and quick turnaround should be a priority. This helps maintain your supply chain’s efficiency even when dealing with custom orders.

- Partnership Background: A history of collaborating with industry leaders often indicates a level of reliability and technical sophistication that is crucial in rigorous sports equipment markets.

By focusing on these aspects, procurement professionals can make an informed decision when partnering with a padel racket manufacturer. NEX Padel’s commitment to precision engineering, combined with our flexible production capabilities, positions us as a trusted partner in delivering high-quality, customized equipment that meets market demands.

The production of high-performance padel rackets is a complex yet precisely controlled process that begins with the careful selection of materials and extends through to advanced molding, finishing, and quality control. At NEX Padel, we have perfected our manufacturing process to deliver products that balance innovation, customization, and quality. With state-of-the-art production techniques, rigorous quality checks, and a commitment to continuous improvement, we provide a reliable solution to meet the diverse needs of sports equipment distributors.

For B2B procurement managers and product developers, understanding this process not only helps in evaluating suppliers but also in ensuring that your end customers receive a product that can perform under competitive conditions. When looking to enhance your product lineup with technologically advanced and customizable padel rackets, consider the offerings of NEX Padel—a partner committed to excellence in every stage of production.

Q: How are padel rackets made?

A: High-performance padel rackets are typically crafted by layering advanced fibers such as glass fiber and various grades of carbon fiber. After the layers are applied, the racket is molded using press and precise molds to achieve the desired shape and size. Final finishing includes attaching the handle and adding custom decorations such as logos and prints.

Q: Why is padel suddenly so popular?

A: Padel has grown in popularity because it offers an accessible sport that is easy on the body, reducing high-impact injuries while still challenging players competitively. Its smaller court, lower ball speed, and social nature make it appealing for both casual and competitive athletes.

Q: What is padel called in the USA?

A: In the USA, padel is often referred to as Platform Tennis or paddle tennis. The sport evolved as a winter alternative and is played on raised courts surrounded by screens, distinguishing it from other racquet sports.

-

Advanced composite materials: Click to read more about the innovative material blends that combine fibers and resins to create lightweight, durable products and why they are essential for high-performance sports equipment. ↩ ↩

-

Precision engineering processes: Click to explore detailed insights into the meticulous manufacturing steps that ensure each product meets exacting standards in dimensions and performance. ↩ ↩

-

Carbon fiber: Click to understand the differences between 3K, 12K, and 18K carbon fiber grades, including their properties, applications, and benefits in producing superior sports equipment. ↩ ↩

-

Fast prototyping: Click to learn how rapid prototyping techniques accelerate the design process, allowing for quicker iterations and a more agile response to market demands. ↩ ↩

-

OEM: Click to read about Original Equipment Manufacturing, its role in today's supply chains, and how partnering with OEMs can offer strategic advantages in product development and scalability. ↩ ↩