Rapidly launching innovative padel products is crucial for startup success. By partnering with an experienced OEM1 like NEX Padel, you gain access to high-performance, customizable padel rackets that meet industry standards while accelerating your time to market.

For startup founders, product managers, and business development leads, entering the competitive padel market means overcoming several hurdles. The demand for high-quality, customized equipment is ever-growing, and meeting these demands involves not only impeccable design but also robust manufacturing processes, quality assurance2 and rapid prototyping3.

Many startups struggle with:

• Managing time-to-market pressures

• Keeping up with industry standards in materials and performance

• Balancing customization options with scalability

• Ensuring consistent quality under strict performance requirements

When selecting an OEM partner, it is essential to address these pain points. NEX Padel’s full-service manufacturing capabilities are specifically designed to support startups and emerging brands in rapid product development while ensuring top-quality performance standards.

Several factors contribute to the pain points experienced by startups in the sporting goods sector:

-

Complex Material Requirements:

The production of high-performance padel rackets involves advanced materials such as fiberglass and various grades of carbon fiber4 (3K, 12K, 18K). Each material has unique properties, and managing these technical nuances is challenging without expert oversight. -

Speed vs. Customization:

Balancing rapid prototyping with extensive customization is a delicate act. Startups need short turnaround times to capitalize on market opportunities, yet they also require tailored solutions to differentiate their products. -

Quality Assurance and Production Consistency:

Maintaining consistent quality, meeting performance benchmarks, and adhering to global industry standards often requires state-of-the-art production techniques and rigorous quality control. These are not trivial concerns when working with new technologies or scaling up production. -

Technological Integration:

Implementing automated production processes and advanced manufacturing technologies5 is essential yet difficult. An OEM partner must have the right mix of modern machinery and skilled labor to ensure that customized orders meet both aesthetic and performance criteria.

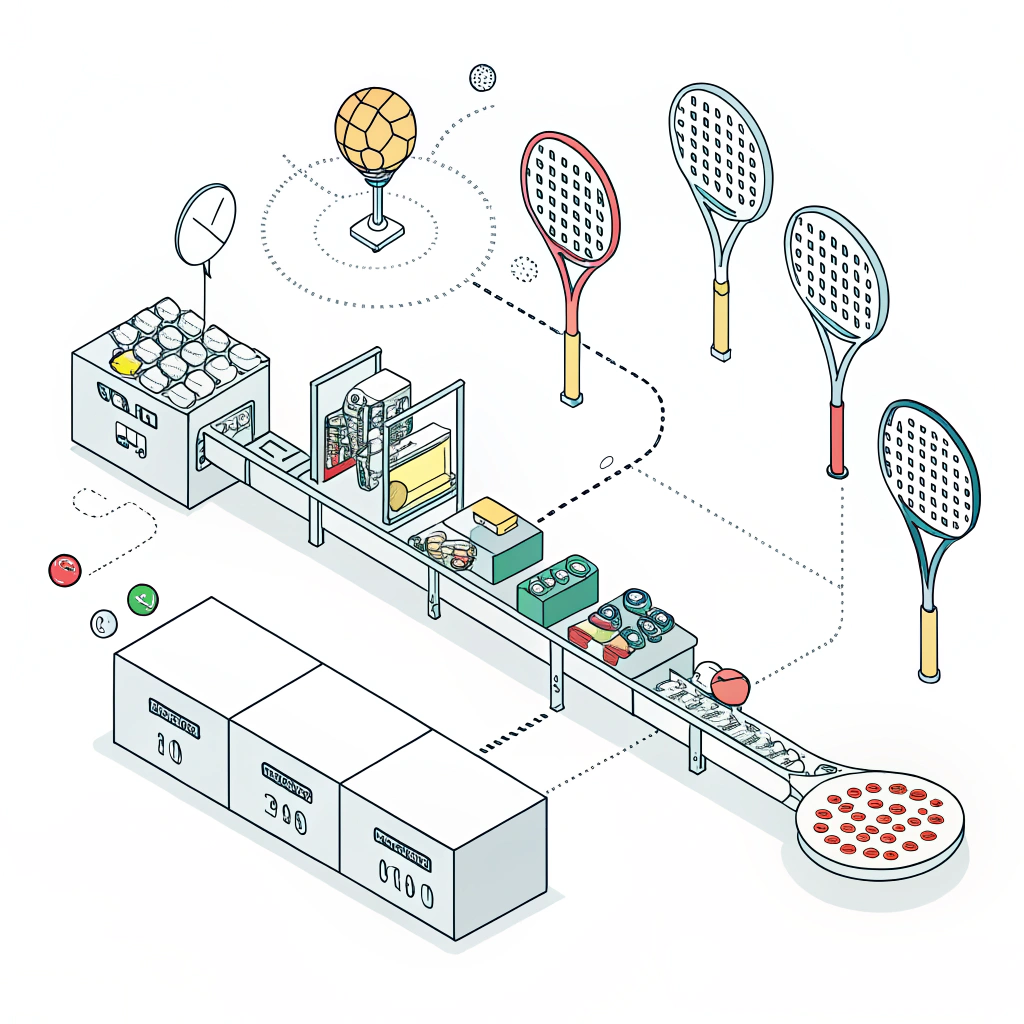

By addressing these challenges, NEX Padel offers a proven solution that accelerates product development while maintaining the highest quality standards. We break down our approach into key phases:

NEX Padel leverages advanced production techniques to significantly reduce sample and production lead times. Our rapid prototyping process enables startups to test, iterate, and finalize designs quickly. With fast approval cycles and immediate feedback, you can enter the market with the most innovative designs ahead of competitors.

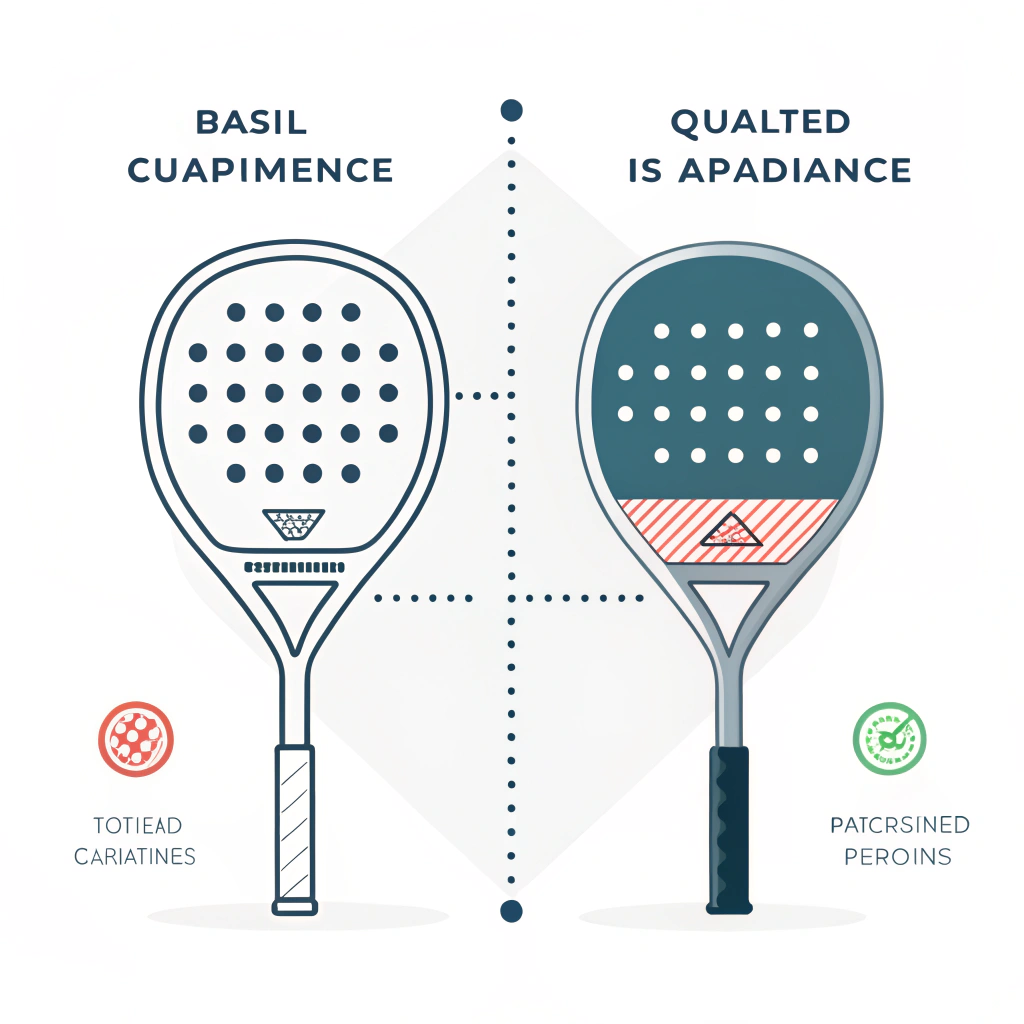

Our padel rackets are constructed using a variety of premium materials—from fiberglass to multiple grades of carbon fiber (3K, 12K, 18K). This ensures that we can match or exceed industry performance standards with each product batch. With a full range of customization options, including racket shapes (Diamond, Round, and Teardrop), custom prints, and color options, you can tailor each racket to your specific market needs.

Our comprehensive quality control protocols are integral to our production process. NEX Padel strictly monitors each stage of production, ensuring that every padel racket meets rigorous performance and durability standards. By prioritizing quality assurance, we minimize defects and ensure every product delivered is reliable and safe for competitors.

Using a blend of modern automation and skilled craftsmanship, we achieve high production consistency. Our production lines are designed to handle both large-scale orders and highly customized, low-volume batches with the same attention to detail. This versatility is key for startups that may shift from limited releases to mass production as demand grows.

To illustrate why NEX Padel stands out as the preferred OEM partner, consider the following table outlining key performance parameters:

| Feature | Traditional OEM | NEX Padel Advantage |

|---|---|---|

| Material Options | Limited to standard materials | Extensive range: Fiberglass, 3K/12K/18K Carbon Fiber |

| Customization | Basic customization available | Fully customizable: Shapes, prints, colors, grips, and logo placement |

| Prototyping Speed | Longer lead times | Rapid prototyping with fast turnaround |

| Quality Assurance | Variable standards | Rigorous quality control at every stage |

| Production Scalability | Less flexible, high minimum orders | Scalable production with low to high order quantities |

| Industry Partnerships | Limited brand collaborations | Trusted by industry leaders like Hirostar, Reebok, and Starvie |

This table highlights how NEX Padel provides a comprehensive, flexible, and high-quality approach that directly addresses startup challenges in product differentiation and market entry.

A closer look at market trends reveals several key factors making custom OEM partnerships indispensable for padel startups:

• Rising Demand for Customization:

As consumers increasingly seek unique and personalized sports equipment, customization is no longer a luxury—it’s a market necessity. High-performance padel rackets tailored to specific play styles or market aesthetics drive customer loyalty and brand differentiation.

• Technological Advancements in Manufacturing:

The padel industry is evolving quickly, with new materials and innovative production techniques emerging. OEM partners who invest in technology can offer products that deliver superior performance and longer durability.

• Competitive Market Entry:

Research shows that startups utilizing rapid prototyping and customization tend to achieve faster market penetration. An agile production partner reduces time-to-market, ensuring that early products can be fine-tuned through real-world feedback.

These trends underscore the importance of working with a partner who not only understands advanced production techniques but also possesses the flexibility to cater to evolving market demands.

For startups considering an OEM partner, here are some practical tips to ensure a successful collaboration:

-

Clearly Define Your Requirements:

List out the specific design, materials, and performance benchmarks you need. This could include shape, weight, grip design, and customization details like logo placements or color specifications. -

Evaluate Manufacturer Capabilities:

Investigate potential partners’ technological capabilities and production processes. Ask for case studies, production timelines, and quality control measures. -

Prioritize Communication and Feedback:

Establish a clear line of communication for feedback during the prototyping phase. A collaborative approach ensures that your design vision is realized and any issues are resolved swiftly. -

Leverage Data and Analytics:

Utilize market data to inform production decisions. For example, incorporate user feedback and performance statistics in your design iteration process to enhance product competitiveness. -

Plan for Scalability:

Consider both your current and future production needs. Working with an OEM that can scale production helps ensure a seamless transition from startup to growth phase.

A summarized checklist to guide your OEM partnership selection:

| Step | Action Item | Why It Matters |

|---|---|---|

| Define Requirements | Document specific design and performance needs | Provides clarity and aligns expectations |

| Research Capabilities | Evaluate technology, experience, and production quality | Ensures partner can meet both quality and volume needs |

| Communication Strategy | Set up regular meetings and clear feedback channels | Facilitates timely updates and rapid problem-solving |

| Data-Driven Decisions | Use market insights to guide customization and production choices | Maximizes your product’s market competitiveness |

| Plan for Future Growth | Assess potential for scaling production | Supports long-term business success |

NEX Padel’s experience and technical expertise position us as the ideal partner for startups wishing to enter or expand in the padel market. Here are several compelling factors that differentiate us:

• Comprehensive Customization:

Offering everything from diverse materials to fully tailored designs—including racket shapes such as Diamond, Round, and Teardrop—NEX Padel empowers you to create a truly unique product line. Additional options like custom hand grips and handle covers with logo printing further enhance brand identity.

• Proven Industry Partnerships:

Our collaborations with renowned brands like Hirostar, Reebok, and Starvie are a testament to our product performance, reliability, and consistent quality. These partnerships underscore our repute and capability in executing high-performance manufacturing at scale.

• Optimized Production Flow:

By integrating advanced manufacturing technologies with traditional craftsmanship, we ensure that every product not only meets rigorous industry standards but also achieves an optimal balance of speed and customization. This hybrid approach enables us to efficiently address the diverse needs of startups without compromising quality.

• Responsive and Collaborative Service:

Our team understands the dynamic nature of startup environments. We closely work with clients to adapt production strategies in real-time, ensuring that customizations or design changes are seamlessly integrated with minimal delays.

In conclusion, choosing an OEM partner like NEX Padel significantly reduces the time to market while providing customizable, high-performance padel rackets that stand out in a competitive sporting goods market. Our comprehensive approach addresses common startup challenges through rapid prototyping, high-quality materials, rigorous quality control, and scalable production solutions.

If you are a startup founder, product manager, or business development lead looking to accelerate your product development, now is the time to leverage partnerships with experienced manufacturers. Explore how NEX Padel can bring your innovative padel equipment designs to life with speed, reliability, and unmatched customization.

Contact us today to discuss your product needs and start your journey toward market leadership.

Q1: What are the advantages of choosing a custom OEM partner for padel rackets?

A1: Custom OEM partners provide rapid prototyping, extensive customization options, and rigorous quality assurance. This translates to faster time-to-market, products that stand out in performance and design, and a scalable production process.

Q2: How does NEX Padel ensure the quality of its padel rackets?

A2: NEX Padel uses advanced production techniques along with stringent quality control protocols. Every stage of manufacturing is monitored to meet industry standards, ensuring each racket delivers consistency, durability, and high performance.

Q3: What customization options are available with NEX Padel’s OEM services?

A3: NEX Padel offers a wide range of customizations, including selection of materials (fiberglass, 3K/12K/18K carbon fiber), multiple shapes (Diamond, Round, Teardrop), custom printing, colors, hand grips, and handle covers with logo placement.

-

OEM: Click to learn more about Original Equipment Manufacturers, their role in production, and how partnering with experienced OEMs can streamline product development. ↩

-

Quality assurance: Click to read about quality assurance practices that ensure products meet industry standards and provide consistent performance. ↩

-

Rapid prototyping: Click to explore rapid prototyping techniques that enable faster iterations and quicker market entry. ↩

-

Carbon fiber: Click to understand the properties of carbon fiber, its various grades, and why it’s crucial for high-performance sporting goods. ↩

-

Advanced manufacturing technologies: Click to discover the latest automation and production technologies that enhance manufacturing efficiency and product quality. ↩