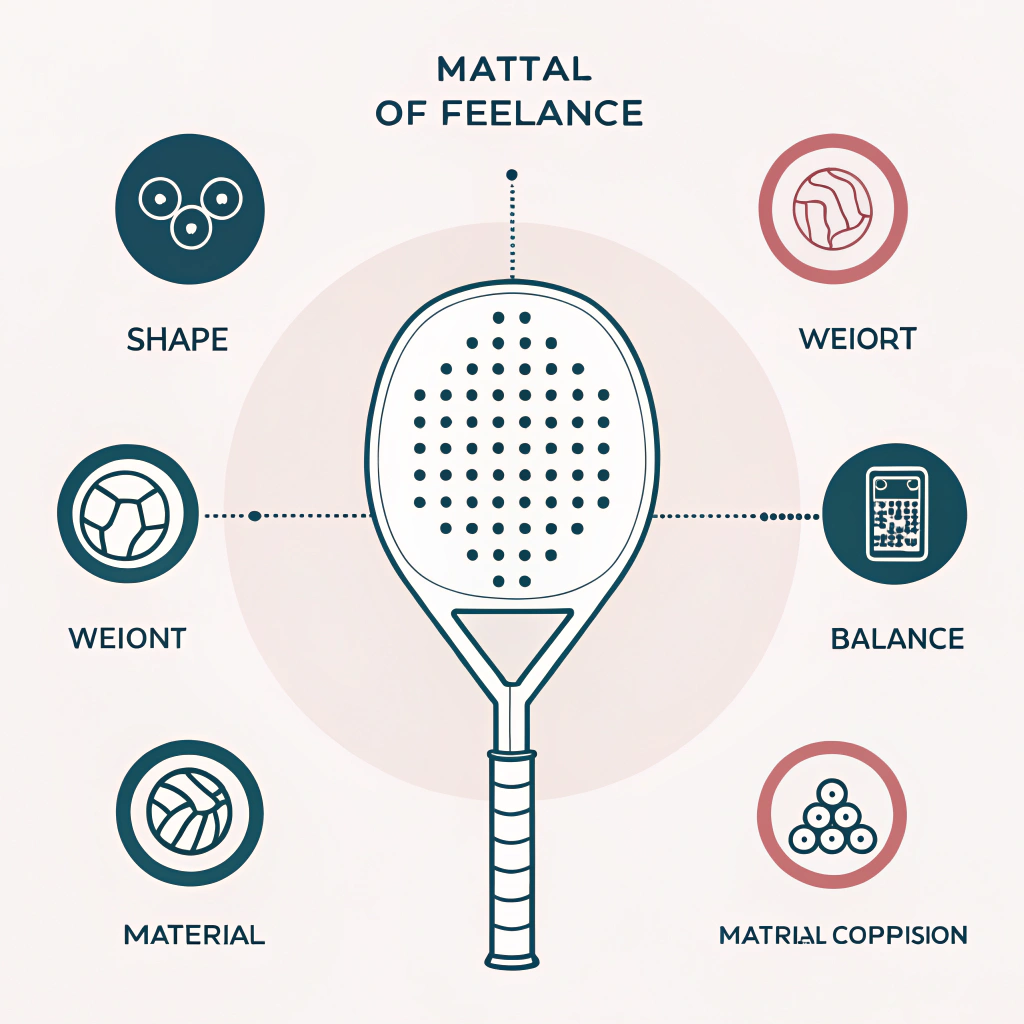

Choosing the right padel racket means balancing performance, durability, and customization to meet your business needs. In simple terms, evaluate racket shape, weight, balance, materials, design, and surface texture to ensure you get quality gear that appeals to your target market. This guide provides a complete, step-by-step approach to selecting the best padel racket in 2025.

Procurement managers and sports equipment distributors face a challenge in understanding the technical and market aspects of padel rackets. With a growing market and evolving technologies, many factors can influence the performance and appeal of a padel racket. These factors include:

• Racket Shape: Options like Diamond, Round, and Teardrop offer different benefits in terms of control and power.

• Materials: From basic glass fiber to advanced carbon fiber1 variants such as 3k, 12k, and 18k carbon filaments.

• Customization: Trends show that clients now prefer tailored designs, including custom printing, colors, and even personalized accessories like hand grips and handle covers.

• Advanced Production Techniques2: Ensuring consistency in quality, rapid prototyping, and timely delivery is crucial in today's competitive market.

Manufacturers like NEX Padel are leading the industry with high-performance, customizable padel rackets using advanced manufacturing processes in Jiaxing, Zhejiang, China. For B2B buyers, understanding these manufacturing nuances can inform better procurement decisions, securing products that not only perform well but also align with long-term strategic goals.

There are several reasons why the selection process of a padel racket is critical:

- Performance Impact: The choice of materials such as carbon fiber1 and glass fiber and design elements (shape, balance, weight distribution) directly impacts the racket's performance during play. This is important for appealing to both professional and amateur players.

- Durability and Quality Assurance: Using high-quality materials and advanced production techniques ensures that rackets maintain their performance over time, reducing costs associated with replacements and warranty claims.

- Customization Possibilities: Modern padel rackets need to cater to diverse player profiles. Offering customization in design, color, and additional features like hand grips adds value and creates differentiation in the market.

- Market Trends and Player Preferences: Understanding how different padel racket shapes (e.g., Round for beginners, Diamond for power-oriented players, and Teardrop as a versatile option) affect gameplay can help distributors stock the right mix of products.

For the B2B procurement manager looking to make informed decisions, these factors must be carefully considered alongside supplier capabilities and cost-effectiveness.

Below is a solution checklist that outlines the key areas to focus on when choosing a padel racket:

| Factor | Consideration | Impact on Performance | Customization Possibility |

|---|---|---|---|

| Racket Shape | Decide among Diamond, Round, or Teardrop | Affects sweet spot size and maneuverability | Tailored shape options available |

| Weight | Compare light vs. heavy rackets | Influences power and manoeuvrability | Custom weight balancing available |

| Balance | Equal distribution vs. head-heavy design | Determines control vs. power | Custom balance tuning offered |

| Material Composition | Glass Fiber vs. 3k/12k/18k Carbon Fiber | Affects durability and power output | Choose custom material mix |

| Surface Texture | Smooth vs. textured surfaces | Enhances spin and ball control | Custom surface finishing available |

| Handle Design | Consider handle size and length for comfort and grip | Affects control and comfort | Custom printing and color options |

This table helps clarify what attributes are most important based on your target market and play style. For manufacturers like NEX Padel, this approach has been honed using feedback from global B2B clients who require both innovation and reliability in their sports equipment.

As padel continues to grow globally, production trends and advanced manufacturing techniques are shaping the future of padel rackets. In 2025, procurement decisions are increasingly influenced by factors such as:

Modern padel rackets are produced with cutting-edge technology that ensures precision and durability. Techniques such as automated layup processes, laser cutting, and quality monitoring systems ensure that every racket meets strict performance standards. At NEX Padel, our commitment to rapid prototyping3 and streamlined production enables us to offer high-performance rackets with a quick turnaround time.

Material choice plays a critical role. While glass fiber remains a reliable, cost-effective option, advanced forms of carbon fiber1 (3k, 12k, 18k) provide superior strength and durability. The 12k and 18k carbon fibers, in particular, are favored for their enhanced stiffness and vibration dampening properties. This not only improves the racket’s performance but also its lifespan, a key selling point for distributors.

Customization and OEM manufacturing4

Customization has become a significant market differentiator. Businesses and clubs are interested in personalizing their gear to reflect brand identity or match customer preferences. Complete OEM manufacturing services, including custom shapes (tailoring Diamond, Round, or Teardrop designs), personalized printing, and adjustable accessories, ensure that every order aligns with the customer’s requirements. This flexibility is critical in B2B relationships, where decision-makers expect products that set them apart in their competitive landscape.

Recent market studies indicate that while more expensive rackets are often assumed to be superior, they may not necessarily suit every player. For beginners and intermediate players, rackets with larger sweet spots and balanced weight distribution provide better playability. Successful case studies show that sports equipment distributors who offer a well-rounded product portfolio, catering to various player levels, enjoy higher customer retention and satisfaction.

A practical example includes our partnership with major brands like Hirostar, Reebok, and Starvie. These companies trust our manufacturing process because of our emphasis on quality materials, precision engineering, and the ability to quickly adapt to evolving market demands.

With the technical and market factors clear, here is a practical guide for procurement managers:

Review your current lineup and match it against market needs:

- Who is your target player? Beginners, intermediates, or advanced players?

- What do your competitors offer, and how does that compare to potential new products?

- Is there a current gap in the market that could be filled with a specialized racket?

When vetting suppliers like NEX Padel, consider:

- Production lead times and the ability to handle custom orders.

- Consistency in product quality, specifically related to material composition and performance standards.

- Support for customization, including OEM services and additional accessories options.

Before finalizing supplier agreements:

- Request sample products and arrange a trial period with professional players or in-house experts.

- Use objective performance metrics to evaluate how the racket performs in various play conditions.

- Collect and analyze feedback to ensure the product meets both industry standards and customer expectations.

Choose a supplier who offers:

- Scalability: The ability to grow with your business requirements.

- Continuous innovation: Keeping abreast of technological advancements and market trends.

- Flexible customization: Options to adapt to changing market demands and personalization needs.

A strategic partnership should allow you not just ordinary transactions, but a collaborative approach to future product developments. With continuous dialogue, updates on trends, and shared market data, your supply chain becomes a competitive advantage.

In summary, selecting the right padel racket involves a thorough understanding of both technical specifications and market trends. The key steps include:

- Analyzing the critical factors such as racket shape, weight, balance, material, and customization options.

- Leveraging advanced production techniques and material innovations to secure a performance edge.

- Engaging in thorough supplier evaluation, testing, and validation to ensure quality and market fit.

- Building long-term partnerships that allow for scalability and continuous innovation.

For distributors and procurement managers, using this guide as a framework can simplify the decision-making process. By making well-informed choices, you position your business to capture greater market share and meet the evolving needs of padel players worldwide. Prioritize partnerships with manufacturers who demonstrate reliability, technical excellence, and a commitment to innovation—qualities we proudly uphold at NEX Padel.

Ready to choose the best padel rackets for your business? Start by reviewing your current stock, contacting reliable suppliers, and engaging with players for feedback. Adapt these practices to ensure your product portfolio continues to resonate with customers.

Q: How to decide what padel racket to buy?

A: To decide on a padel racket, first consider the shape (Diamond, Round, or Teardrop), weight, balancing attributes, handle size, materials, and surface texture. These factors together influence the racket's performance and durability, and matching them with the player's style can ensure the best fit.

Q: What shape padel rackets are for me?

A: For beginners and intermediate players, a round racket is often ideal due to its large sweet spot and balanced weight. This design minimizes the need for precise striking and offers easier maneuverability, making it a great choice for many players.

Q: Do expensive padel rackets make a difference?

A: While more expensive rackets can offer advanced materials and design features, they are not necessarily better for beginners or intermediate players. Expensive rackets typically have smaller sweet spots and may be stiffer, which can affect maneuverability and ease of use.

-

Carbon fiber: Click to understand the properties, advantages, and variants (such as 3k, 12k, and 18k) of carbon fiber, a vital material for enhancing performance and durability in sports equipment. ↩ ↩ ↩2 ↩3

-

Advanced Production Techniques: Click to explore detailed insights on how cutting-edge manufacturing methods improve product consistency, performance, and scalability in competitive markets. ↩ ↩

-

Rapid prototyping: Click to learn about rapid prototyping techniques that reduce product development time and costs while enhancing innovation and quality control. ↩ ↩

-

OEM manufacturing: Click to read more about how Original Equipment Manufacturer services enable businesses to customize products efficiently, ensuring brand consistency and streamlined production workflows. ↩ ↩