A quick answer: Selecting the right padel racket involves balancing the performance characteristics—such as control, power, carbon fiber grade1, and customization options2—with your manufacturing and supply chain3 requirements. In this article, we discuss how B2B procurement managers can evaluate technical specifications, compare carbon fiber grades, and leverage customization to achieve high-performance padel equipment that meets brand and market demands.

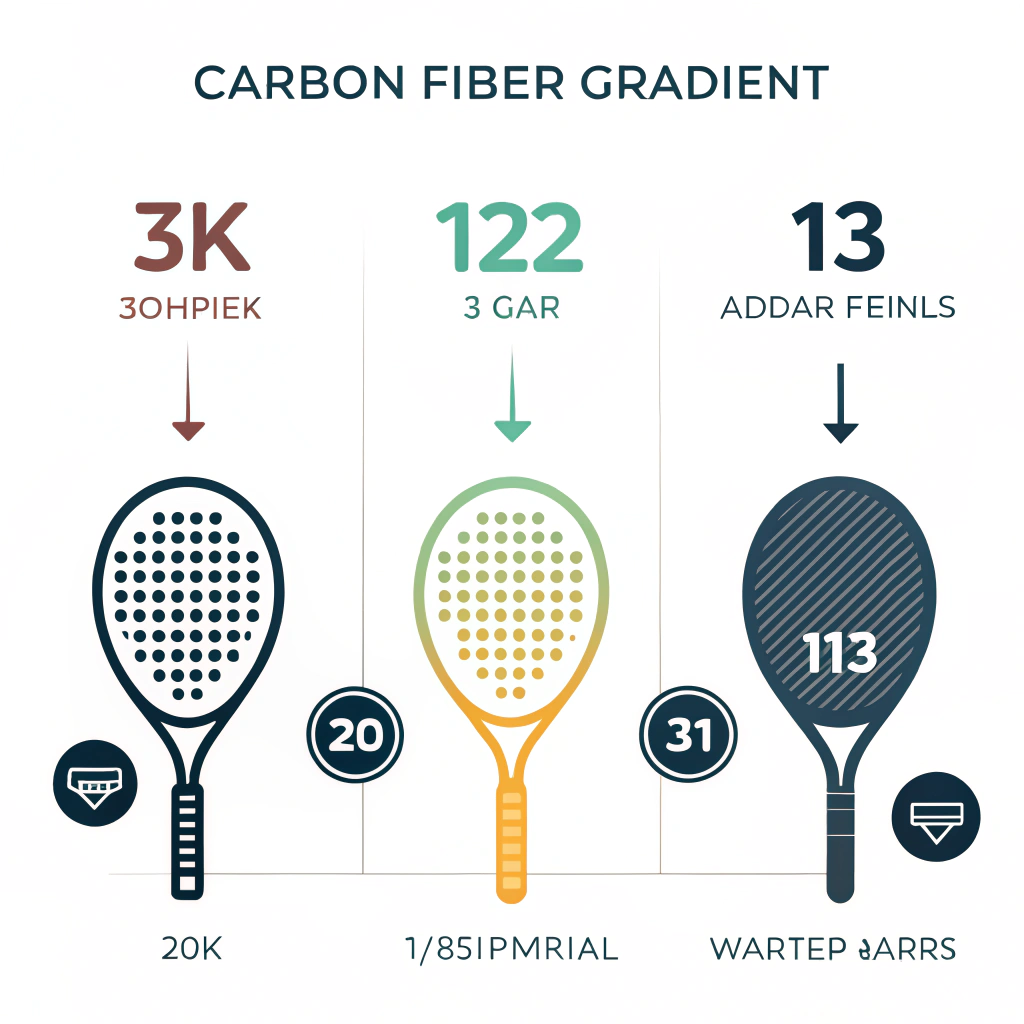

In today’s competitive sports equipment market, padel rackets are no longer one-size-fits-all products. B2B buyers must evaluate technical performance data, production precision, and material durability before making a decision. With materials like 3K, 12K, and 18K carbon fiber available, understanding their characteristics is crucial.

Manufacturers like NEX Padel emphasize not only the quality of raw materials but also the precision engineering and reliability in production. High-performance rackets aim to offer optimal control, power, and durability for players at all levels.

-

Carbon Fiber Grade

Carbon fiber is predominantly used in high-performance padel rackets because it enhances strength and durability while reducing weight. The different gradations—3K, 12K, and 18K—are not merely numbers. They indicate the filament count in the weave:- 3K Carbon Fiber: Known for its hardness and is typically used where stiffness and strength are key.

- 12K Carbon Fiber: Offers a balance between flexibility and strength, often used to create a racket that caters to both power and control.

- 18K Carbon Fiber: The denser filament composition tends to increase hardness and resilience, making it an ideal choice for players who need a robust, long-lasting racket.

-

Racket Shape and Design

High-performance rackets come in several designs—Diamond, Round, and Teardrop—each suiting different play styles.- Diamond: Typically optimized for power and aggressive play.

- Round: Focuses on control and maneuverability for precise ball placement.

- Teardrop: Offers a compromise between power and control, making it versatile for all-around performance.

-

Customization Options2

For B2B procurement teams, customization is a significant advantage. Being able to tailor prints, colors, hand grips, and even the shape can differentiate your product line. At NEX Padel, we support full customization so that each racket can be tweaked to meet the unique needs of your brand and regional preferences. -

Manufacturing Techniques and Quality Assurance

Advanced production processes ensure that each racket is crafted with precision. Techniques such as pre-preg layup4 and hand-finishing lead to consistent quality and durability. Additionally, strict quality control processes guarantee that products meet international standards and performance requirements.

Carbon fiber is the backbone of modern padel rackets. Its composition directly affects the racket’s stiffness, weight distribution, and durability. Below is a detailed table comparing the specifications and applications of different carbon fiber grades used in racket manufacturing:

| Carbon Fiber Grade | Description | Hardness Level | Best For |

|---|---|---|---|

| 3K Carbon Fiber | Lower filament count; stiffer and more rigid | High | Aggressive power hits and enhanced stability |

| 12K Carbon Fiber | Medium filament count; balanced flexibility and strength | Moderate | Versatile performance combining control and power |

| 18K Carbon Fiber | Higher filament count; denser and more resilient | Highest | High durability and excellent resilience for professional-grade equipment |

Understanding these specifications is key to aligning the mechanical properties of a padel racket with performance expectations.

When evaluating padel rackets for procurement, consider the following points:

- Precision Engineering5: The manufacturing process should ensure precise molding and consistent material distribution, minimizing weak points in the racket.

- Material Testing: Implementing thorough testing procedures helps in maintaining high-quality performance during extended use. Rigorous quality assurance checks make sure that each batch meets performance and durability benchmarks.

- Supply Chain Reliability: Fast prototyping and timely deliveries are essential in a competitive market. NEX Padel prides itself on its agile production capabilities, ensuring that sports retailers never face inventory shortages.

By combining technical performance with reliable supply and advanced customization, manufacturers can offer a product that satisfies both the retailer’s and the end-user’s needs.

Customization is more than just a marketing approach; it is a competitive edge in the B2B sports equipment landscape. Here’s how customization plays a role in decision-making:

- Brand Alignment: Customizing racket designs to match your brand’s identity helps maintain consistency across your product offerings. The ability to print logos, adjust color schemes, and tailor shapes (Diamond, Round, Teardrop) can significantly enhance brand value.

- Performance Segmentation: Different players require different features. Offering customization allows retailers to target niche segments—those who prioritize speed, control, or power. These options allow you to cater to regional market trends and player preferences.

- Marketing Leverage: Highlighting the fact that your padel rackets are fully customizable can build trust with your end clients. By aligning technical sophistication with personalization, you provide a unique selling proposition that differentiates your products in a crowded market.

NEX Padel’s in-house customization capabilities cover everything from the racket’s frame to the hand grip. This flexibility ensures that our partners can meet evolving market trends and customer specifications with ease.

Let’s look at a real-world scenario to illustrate the benefits of modern manufacturing and customization:

A leading European sports distributor approached NEX Padel with a challenge. They needed a padel racket that could offer the following:

- Outstanding durability for professional players.

- A balance between power and control tailored to diverse game styles.

- A customized design that matched their brand identity.

NEX Padel responded by proposing a solution using a mix of 12K and 18K carbon fibers to balance resilience, flexibility, and weight distribution. Adjustments to the racket’s shape, opting for the Teardrop design, allowed for a versatile performance profile. The added value of customizable prints and hand grip logos catered perfectly to the brand’s design requirements.

The result was a high-performance, highly customizable product that not only met but exceeded the distributor’s expectations, thereby strengthening their market position and leading to repeat orders.

When selecting the right padel racket for your portfolio, it is crucial to consider the interplay between material technology, design, and customization. Here are the key takeaways:

- Understand Carbon Fiber Dynamics: Evaluate the differences between 3K, 12K, and 18K carbon fibers to align with your product’s performance goals.

- Focus on Customization: Tailor the padel racket’s design—including shape, color, and logo placement—to meet market demands and differentiate your brand.

- Prioritize Quality Assurance: Ensure that your manufacturing partner uses advanced techniques and strict quality control processes to provide reliable, high-performance products.

- Analyze Supply Chain Reliability: In dynamic B2B markets, quick prototyping and timely delivery are vital for maintaining competitive advantage.

We recommend procurement managers consider these factors when evaluating potential racket suppliers. A well-informed decision by balancing technical specifications with real-world manufacturing capabilities can lead to a successful product launch and sustained market growth. By choosing a trusted partner like NEX Padel, you are investing in quality, precision, and innovation that resonates with today's performance-focused consumers.

How to choose the right padel racket for you?

Choosing the right padel racket depends on finding a balance between control, power, and durability. A control racket suits players who prioritize precision, while a power racket is ideal for aggressive play. A balanced option provides versatility for all playing styles. Consider technical aspects such as carbon fiber grade, design shape, and customization options to match the performance needs of your target market.

Which is better 3K or 12K carbon?

The decision between 3K and 12K carbon depends on the desired performance characteristics. Generally, 3K carbon fiber is harder and offers greater stiffness, making it a good choice for aggressive power play. In contrast, 12K carbon fiber provides a balance between flexibility and strength, creating a racket that can deliver both control and power effectively.

Is 12K or 18K carbon harder?

When comparing 12K and 18K carbon fibers, 18K carbon is typically harder and more resilient due to its denser filament composition. This makes it an excellent choice for applications demanding high durability and strength, such as professional sports equipment where performance consistency is paramount.

-

carbon fiber grade: Click to learn about the different classifications of carbon fiber used in high-performance sports equipment and how each grade affects strength, weight, and durability. ↩

-

customization options: Click to explore how customization can provide a competitive edge in product differentiation by aligning unique design features with brand identity. ↩ ↩2

-

supply chain: Click to understand the importance of supply chain management for ensuring a reliable production process and timely delivery in B2B procurement. ↩

-

pre-preg layup: Click to delve into the technical process of pre-preg layup used in composite manufacturing, ensuring consistent material performance and structural integrity. ↩

-

Precision Engineering: Click to discover how precision engineering optimizes design and manufacturing processes to achieve high-quality, durable sports equipment. ↩