Differentiating high-performance padel rackets requires a clear focus on manufacturing innovation1, material technology2, and customizable design3. By leveraging precise production techniques and a deep understanding of player needs, brands can stand out in a competitive padel market with unique racket shapes, cutting-edge materials, and tailored features.

In today’s saturated padel market, achieving a unique market proposition is challenging. Brand managers and business development professionals must look into core differentiators such as shape, weight, balance, and material innovations. Here, we break down actionable strategies that help differentiate your padel rackets and guide your manufacturing and branding decisions.

- Problem Description

The padel industry is growing rapidly with many established names and new entrants. Decision-makers face the challenge of distinguishing their products amid fierce competition when consumers become more discerning about performance characteristics. The common challenge is that most rackets share similar design elements, making it difficult to stand out on the basis of aesthetics and performance alone. In addition, players now demand customization in aspects such as shape, grip design, weight balance, and even surface texture.

The key questions include: How can technical adjustments enhance performance visibility? What manufacturing innovations can be integrated without bursting the budget? And, how can customization drive brand loyalty and market penetration?

- Cause Analysis

Several factors contribute to the competitive challenge in differentiating padel rackets:

- Standardization of basic design elements such as Diamond, Round, and Teardrop shapes leaves little room for differentiation without innovative modification.

- Advanced materials like various grades of carbon fiber (3k, 12k, or 18k) and fiberglass offer performance benefits, yet many manufacturers fail to highlight these differences.

- Cost constraints often limit experimentation with customization, leading to a generic product range.

- Market dynamics force manufacturers to balance cost-effectiveness with high-quality production, particularly when catering to both international brands and premium segments.

Understanding these causes is the first step towards crafting a strategic differentiation plan.

- Solution Strategy and Best Practices

To overcome these challenges, consider the following solutions that leverage both technical and branding insights:

a. Product Customization Options

Brands can diversify their product offerings by providing tailored design elements.

- Shape Customization: Offer original designs beyond standard Diamond, Round, and Teardrop shapes. Custom shapes not only cater to unique player preferences but also signal innovation.

- Color and Print Personalization: Integrate customizable printing and color options on both racket surfaces and even on accessories like the hand grip or handle cover.

- Handle Design: Customizing the handle for comfort and grip ensures players get a tailored experience, which is crucial for performance.

b. Material and Production Techniques

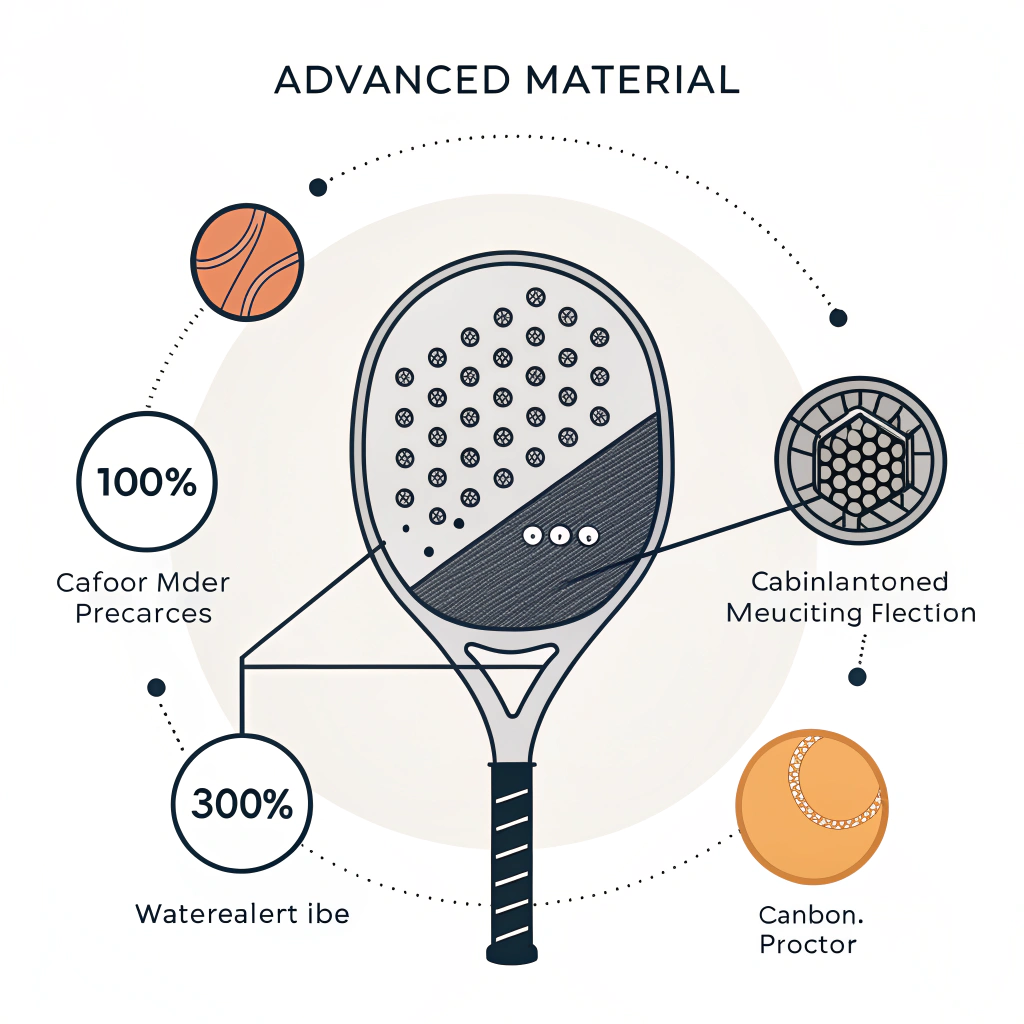

Innovative material selection is at the heart of high-performance padel rackets.

- Advanced Carbon Fiber Technologies: Employ materials such as 3k, 12k, and 18k carbon fibers to fine-tune performance attributes like rigidity, weight distribution, and durability.

- Precision Manufacturing4: Use state-of-the-art production techniques that ensure consistency and quality. Quality assurance at every step — from raw material handling to assembly — holds the key to maximizing performance benefits.

- Comparative Material Impact: Manufacturers should document how each material variant affects performance. This transparency helps marketing teams communicate the benefits to the end-user effectively.

c. Differentiation Through Design Innovation

Integrate design features that cater to both technical performance and aesthetic appeal:

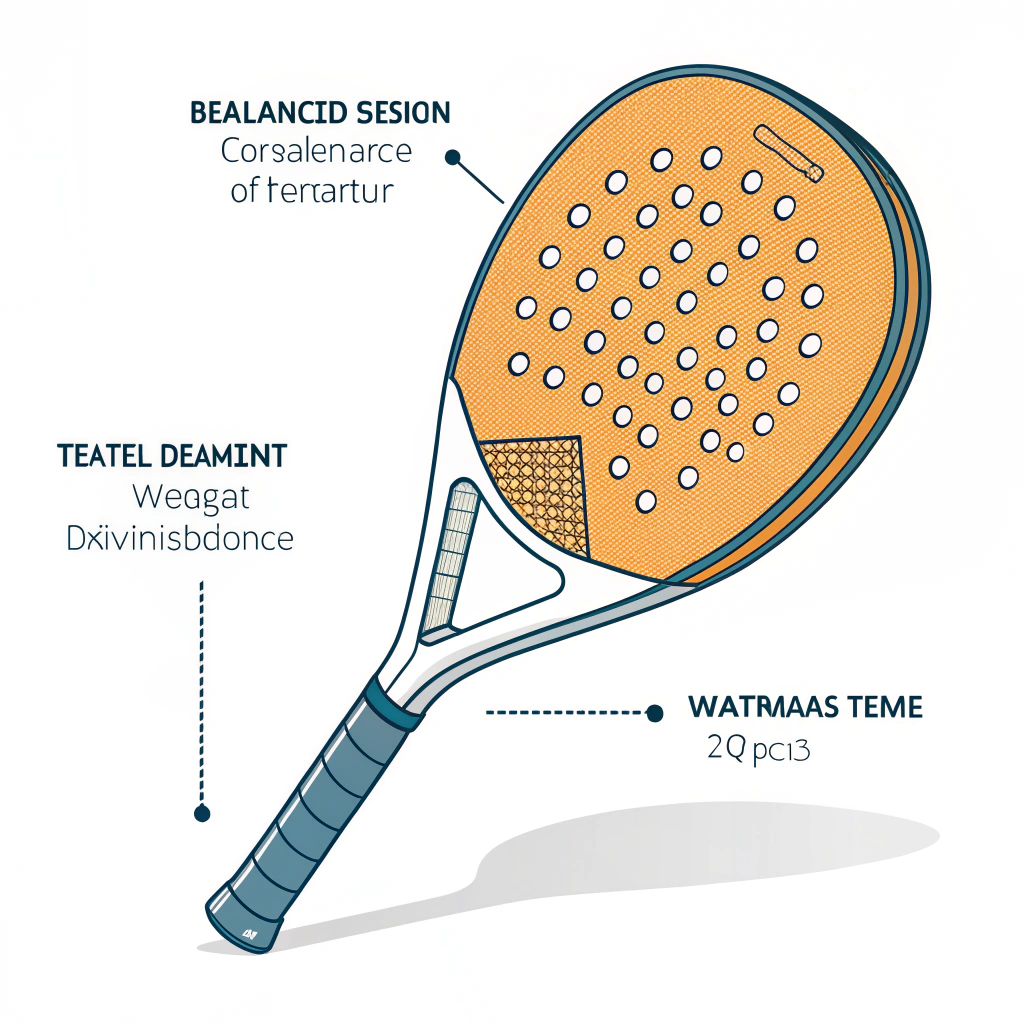

- Racket Balance: Clearly define the balance point (head-heavy, balanced, or head-light) to suit different play styles.

- Weight Distribution: Offer variants that address either power or maneuverability, dictated by the specific needs of different player segments.

- Surface Texture: Experimentation with surface textures can enhance spin and control, providing players extra performance benefits.

d. Competitive Comparison and Decision-Making

It is helpful to deploy a side-by-side comparison when pitching your product differentiators to potential business partners or buyers.

Below is a simplified comparison table to illustrate how focusing on these features can create differentiation:

| Feature | Diamond Design | Round Design | Teardrop Design |

|---|---|---|---|

| Shape Attributes | Optimized for power shots | Enhanced control | Balanced performance |

| Weight Distribution | Generally head-heavy | Even distribution | Variable depending on customization |

| Ideal For | Advanced players seeking impact | Intermediate players focusing on accuracy | Players seeking versatility |

| Customization Options | Can integrate high-end materials and texture variations | Emphasis on color and grip customization | Perfect blend of the two approaches |

By clearly understanding and documenting these differences, your marketing messages can align with specific player needs while emphasizing the unique values your production process brings.

e. Operational Considerations and Best Practices for Implementation

- Lean Manufacturing & Rapid Prototyping5: Prioritize a responsive production process. Rapid prototyping and swift sampling mean that modifications based on market feedback can be implemented quickly, keeping your offerings relevant.

- Cost vs. Benefit Analysis: While premium materials may raise production costs, the enhanced performance and brand reputation can justify this investment. This strategy also differentiates your product from those that are merely expensive without added performance benefits.

- Collaboration with Industry Leaders: Working with renowned partners like Hirostar, Reebok, or Starvie not only strengthens market credibility but offers insights into industry best practices.

- Clear Marketing Communications: Once the technical advantages are in place, educate the consumer about these benefits through detailed product descriptions, performance data, and customer testimonials.

- Case Example: Leveraging Innovation for Differentiation

Imagine a scenario where your company rolls out a line of padel rackets featuring advanced 18k carbon fiber frames. The design team creates a unique teardrop shape that offers a balanced blend of power and control. The marketing campaign highlights that the handbags and handle grips are fully customizable with a choice of colors and logos tailored for the buyer’s corporate identity.

Key success metrics include:

- Increased product differentiation leading to higher brand recognition.

- A significant uptick in repeat orders from sports equipment stores.

- Positive feedback regarding the enhanced player performance with measurable improvements in racket durability.

This case demonstrates that integrating technical production innovations with robust customization can create a new standard within the padel sector.

- Summary and Call to Action

Differentiating your padel rackets in today’s competitive market is not merely about supercharging performance but about creating a holistic product experience. By focusing on multiple dimensions such as shape customization, advanced material technology, and effective quality assurance, brands can provide a tailored solution that meets both performance and aesthetic needs.

We invite brand managers and business development professionals to re-examine their current product lineup and consider integrating these solutions. Leverage rapid prototyping, premium materials, and unique design features to capture the attention of discerning padel enthusiasts worldwide. It is time to turn these technical advantages into your brand’s unique selling propositions and lead the padel industry into a new era of innovation and customer satisfaction.

People Also Ask

Q: How to differentiate between padel rackets?

A: Differentiation can be achieved by focusing on key features such as shape, weight, balance, handle size, and materials. For instance, unique shapes like Diamond, Round, and Teardrop can be tailored to enhance power, control, and versatility. Detailed customization of surface texture and grip also helps in meeting individual play styles.

Q: Do expensive padel rackets make a difference?

A: While higher-priced padel rackets often incorporate premium materials and advanced design features, they may not be ideal for beginners or intermediate players due to smaller sweet spots and increased stiffness. It is essential to match the racket’s specifications with the intended playing level and style.

Q: Which brand makes the best padel rackets?

A: Multiple brands excel in the padel market. For example, Head is known for its control and power, while Wilson is recognized for its precision and innovation. The best brand often depends on the player's or retailer’s specific requirements in terms of performance, aesthetics, and customization options.

-

manufacturing innovation: Click to learn how advancements in production techniques and process improvements drive efficiency and competitive advantage in manufacturing. ↩ ↩

-

material technology: Click to gain insights on how the latest materials and their properties can enhance product performance and durability in high-performance equipment. ↩ ↩

-

customizable design: Click to explore strategies and benefits of tailoring product design to meet specific customer demands and differentiate in competitive markets. ↩ ↩

-

Precision Manufacturing: Click to understand the importance of precision in production processes to ensure consistent quality and performance in finished products. ↩ ↩

-

Rapid Prototyping: Click to learn about methods to quickly iterate product designs and reduce time-to-market while aligning with customer feedback. ↩ ↩