Maintaining consistent quality in high-performance padel racket manufacturing is essential. In simple terms, advanced quality control methods, robust process optimization, and continuous monitoring are the keys to success. For manufacturers like NEX Padel, these strategies ensure that every racket—from Diamond to Teardrop—is produced to the highest standards, guaranteeing durability and performance at scale.

Large-scale production of padel rackets entails a myriad of challenges. The primary issue is achieving consistent quality despite high production volumes and the inherent variability in materials such as glass fiber1 and various grades of carbon fiber2 (3k, 12k, 18k). For quality control managers and operations directors, the task goes beyond simple inspection—it requires a comprehensive quality assurance system to minimize variability across batches, maintain precise manufacturing processes, and ensure that each product meets both internal standards and customer expectations.

In a dynamic production environment, factors such as variations in raw material properties, machine calibration3 discrepancies, and operator performance can contribute to batch variability. Moreover, the integration of different production methods—whether for standard models or fully customized designs—adds another layer of complexity.

Understanding the root causes of production inconsistency is vital to implementing effective quality control measures. Several factors directly affect the uniformity of padel racket manufacturing:

-

Raw Material Variability:

- Materials like carbon fiber and glass fiber can exhibit variations in structural properties that affect racket performance.

- Inconsistent material quality from suppliers may lead to slight differences in weight, stiffness, or durability.

-

Process Variability:

- The manufacturing process involves multiple steps such as molding, curing, and finishing, each with its own potential for variance.

- Machine calibration and environmental conditions (e.g., temperature and humidity) can alter the behavior of composite materials.

-

Operator and Training Issues:

- Even with automated systems, human oversight plays a significant role in quality control.

- Differences in operator expertise or training can lead to minor deviations in production standards.

-

Customization and Special Orders:

- Producing fully customized rackets with unique shapes, colors, and logos adds complexity.

- Each customization request might necessitate adjustments in the standard process, increasing the risk of inconsistency.

These factors underline why quality control must not be a one-size-fits-all approach. Instead, manufacturers should adopt tailored strategies to address variability at every stage of production.

To overcome the challenges outlined above, manufacturers can implement multiple quality control strategies. Here is a list of actionable solutions that target the root causes of production variability:

- Implement stringent incoming quality checks: Ensure that every batch of raw materials meets predefined standards before entering the production line.

- Regular supplier audits: Conduct periodic audits to verify the consistency of supplied materials. This establishes a reliable supply chain for materials such as various forms of carbon fiber.

- Develop standard operating procedures (SOPs)4: Document detailed procedures for every aspect of production, from mixing materials to finishing touches.

- Use automation where possible: Automated processes reduce human error and ensure consistency in tasks like curing and molding.

- Monitor production variables continuously: Use SPC techniques to track data from each production phase to identify trends and variances.

- Real-time data collection: Implement sensors and automated data collection systems to facilitate immediate corrective actions when deviations occur.

- Establish a calibration schedule: Regularly calibrate machines to ensure precision in processes such as resin application and composite curing.

- Perform preventive maintenance: Regular machine inspections prevent unexpected downtimes and maintain steady production quality.

- Regularly train staff: Ensure that operators are fully knowledgeable about the latest quality standards and production techniques.

- Foster a culture of continuous improvement: Encourage staff to provide feedback and suggestions that may lead to further process optimization.

| Strategy | Action Item | Expected Outcome |

|---|---|---|

| Material Specifications | Implement incoming material quality checks | Consistent raw material quality |

| Supplier Audits | Schedule regular supplier evaluations | Reliable supply chain |

| Standardized Processes | Develop and enforce SOPs | Reduced production variability |

| Automation and SPC | Install automated sensors and SPC tools | Real-time monitoring and fast corrective actions |

| Equipment Calibration & Maintenance | Set up periodic calibration schedules | Consistent machine performance |

| Staff Training | Regular training and feedback sessions | Enhance staff proficiency and process improvement |

While implementing these quality control measures is crucial, manufacturers must be aware of potential limitations:

-

Cost Implications:

Upgrading equipment, implementing automated systems, or even training programs require investments. Companies must balance these costs against the benefits of improved product consistency. -

Process Complexity:

In industries where customization is frequent, maintaining standardized processes can be challenging. It is important to develop flexible SOPs that accommodate special orders without compromising overall quality. -

Data Overload:

Collecting and monitoring real-time data can lead to information overload. It is essential to have software systems in place that analyze this data efficiently to provide actionable insights. -

Supplier Dependencies:

Even with regular audits, variability in supplier quality can still occur. Building strong relationships and having secondary suppliers as backups are recommended. -

Cultural Resistance:

Introducing new processes and technologies may encounter resistance from staff accustomed to traditional methods. Strong leadership and clear communication are essential to successfully navigating this change.

At NEX Padel, we have refined our production processes through continuous quality improvement and by incorporating advanced techniques tailored to the unique challenges of padel racket manufacturing. Here’s a brief look at our journey:

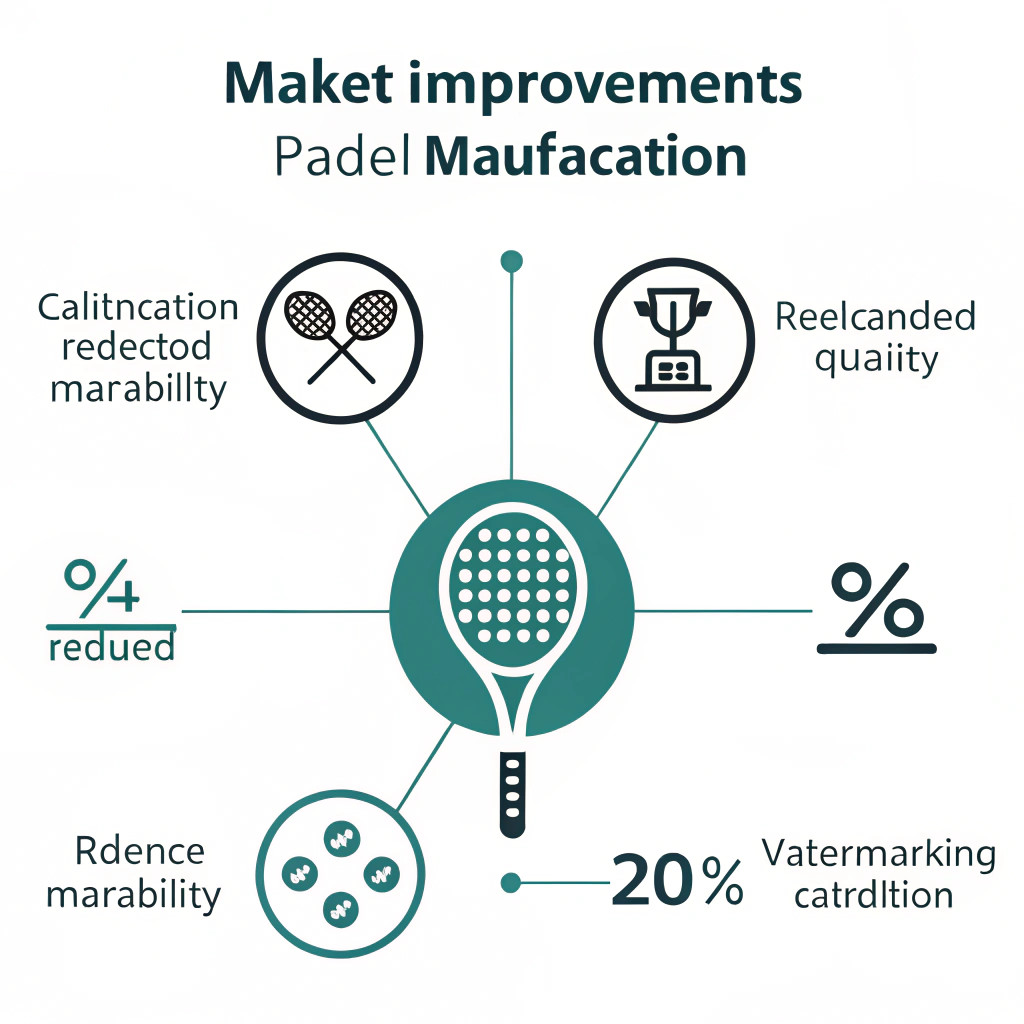

When facing variability in raw material quality, our team initiated a comprehensive supplier audit program. This involved setting up standardized evaluation metrics and partnering closely with suppliers to ensure transparency in material production. Over time, these measures led to a noticeable decrease in batch variability and improved overall consistency.

In parallel, we invested in automated SPC systems that monitored key production parameters such as resin viscosity and curing time. The visual representation of this data was crucial for quickly identifying trends. For instance, data analysis revealed that even minor temperature variations in our curing ovens could affect the final product. Addressing this required tightening environmental controls and recalibrating equipment.

We also conducted regular training sessions focusing on detailed aspects of quality control. This cross-functional training ensured that both floor managers and machine operators understood the importance of adhering to standardized procedures. The result was a more engaged workforce that played an active part in quality improvement initiatives.

Below is a simplified table that compares key performance metrics before and after implementing the new quality control measures:

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Batch Variability (Standard Deviation) | High | Significantly Reduced |

| Material Rejection Rate | Approximately 8% | Less than 2% |

| Production Downtime | Frequent due to recalibrations | Minimal with scheduled maintenance |

| Overall Product Consistency | Variable | Consistently high |

This structured approach allowed us not only to enhance the consistency of our padel rackets but also to significantly cut down on waste, reduce production delays, and improve customer satisfaction. The improvements have been particularly noticeable in our flagship products offered to renowned brands such as Hirostar, Reebok, and Starvie.

In conclusion, ensuring production consistency in padel racket manufacturing requires an integrated approach that encompasses precise quality control techniques, rigorous process standardization, and advanced monitoring systems. The challenges of variability in materials, equipment issues, and the complexities associated with customization can be managed effectively by following these actionable steps:

- Establish strict material specifications and conduct regular supplier audits.

- Standardize manufacturing processes through documented SOPs and automation.

- Utilize Statistical Process Control (SPC)5 to continuously monitor production variables.

- Schedule regular equipment calibration and preventive maintenance.

- Invest in training programs and foster a culture of continuous improvement.

For quality control managers and operations directors, investing in these strategies will result in higher product consistency, reduced variability, and stronger supplier relationships—ultimately contributing to lower costs and improved customer satisfaction.

It is recommended that industry leaders consider these quality assurance measures as part of a broader production optimization strategy. By doing so, manufacturers can better navigate the complexities of large-scale production while ensuring every padel racket meets the quality standards expected by industry-leading brands.

Below is a brief action plan that summarizes the key steps:

| What to Do | How to Do It | Benefit |

|---|---|---|

| Material Verification | Implement rigorous incoming checks | Ensures raw material consistency |

| Supplier Management | Perform regular audits and build partnerships | Reduces risk of material variability |

| Process Standardization | Develop SOPs and integrate automation | Minimizes human error and process deviations |

| Data Monitoring | Adopt SPC and real-time monitoring systems | Quick detection of variances for immediate fixes |

| Maintenance and Training | Schedule regular calibrations and provide training | Sustains production quality over time |

We encourage manufacturers in the padel sports equipment industry to review and integrate these practices into their quality assurance protocols. The investment in robust quality control not only secures the consistency of every product but also builds trust with your clients, ensuring competitive advantage in a demanding market.

Q1: How do manufacturers maintain consistency in high-volume padel racket production?

A1: Manufacturers maintain consistency through standardized manufacturing processes, rigorous incoming material quality checks, regular equipment calibration, and the use of Statistical Process Control (SPC) to monitor and correct deviations in real time.

Q2: What role does automation play in quality control for padel racket manufacturing?

A2: Automation plays a crucial role by reducing human error, ensuring precise control over production variables, and allowing for real-time data collection which supports timely corrective actions and consistent product quality.

Q3: How can training and process standardization improve production consistency?

A3: Regular training ensures that operators understand and adhere to detailed Standard Operating Procedures (SOPs), fostering a culture of continuous improvement. This standardization minimizes variability and leads to more consistent product outputs.

-

glass fiber: Click to learn about the properties, applications, and manufacturing benefits of using glass fiber in composite materials. ↩

-

carbon fiber: Click to explore the different grades (3k, 12k, 18k) of carbon fiber and their impact on product performance and durability. ↩

-

calibration: Click to delve into the importance of regular calibration for machinery to maintain precision and prevent production discrepancies. ↩

-

standard operating procedures (SOPs): Click to read how well-documented SOPs ensure process consistency and compliance in industrial production. ↩

-

Statistical Process Control (SPC): Click to understand how SPC tools help monitor and control manufacturing processes for consistent quality. ↩ ↩2